Patents

Literature

85results about How to "Reduce residual material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

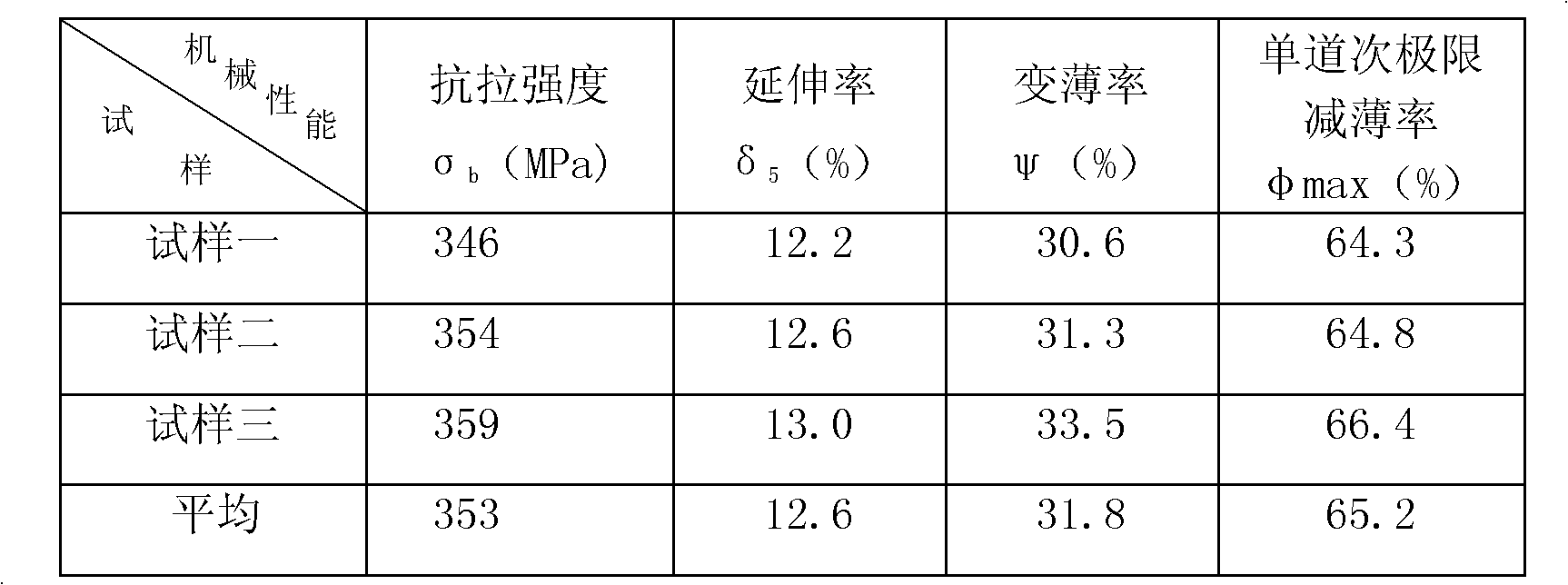

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

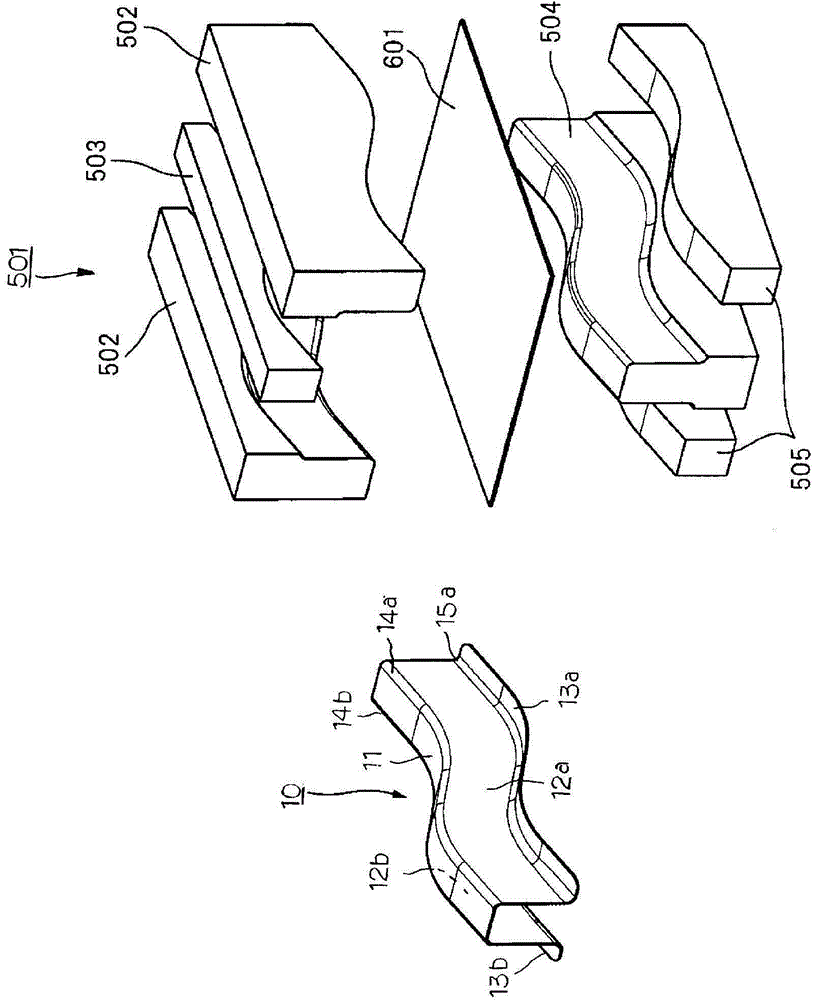

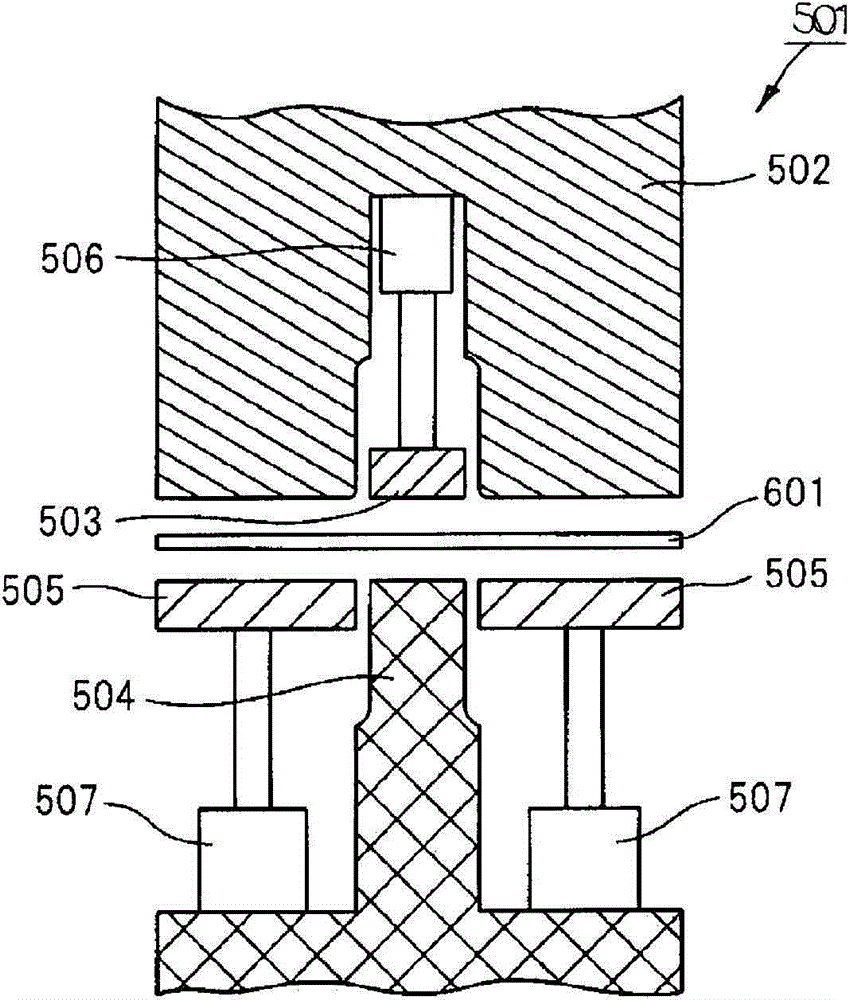

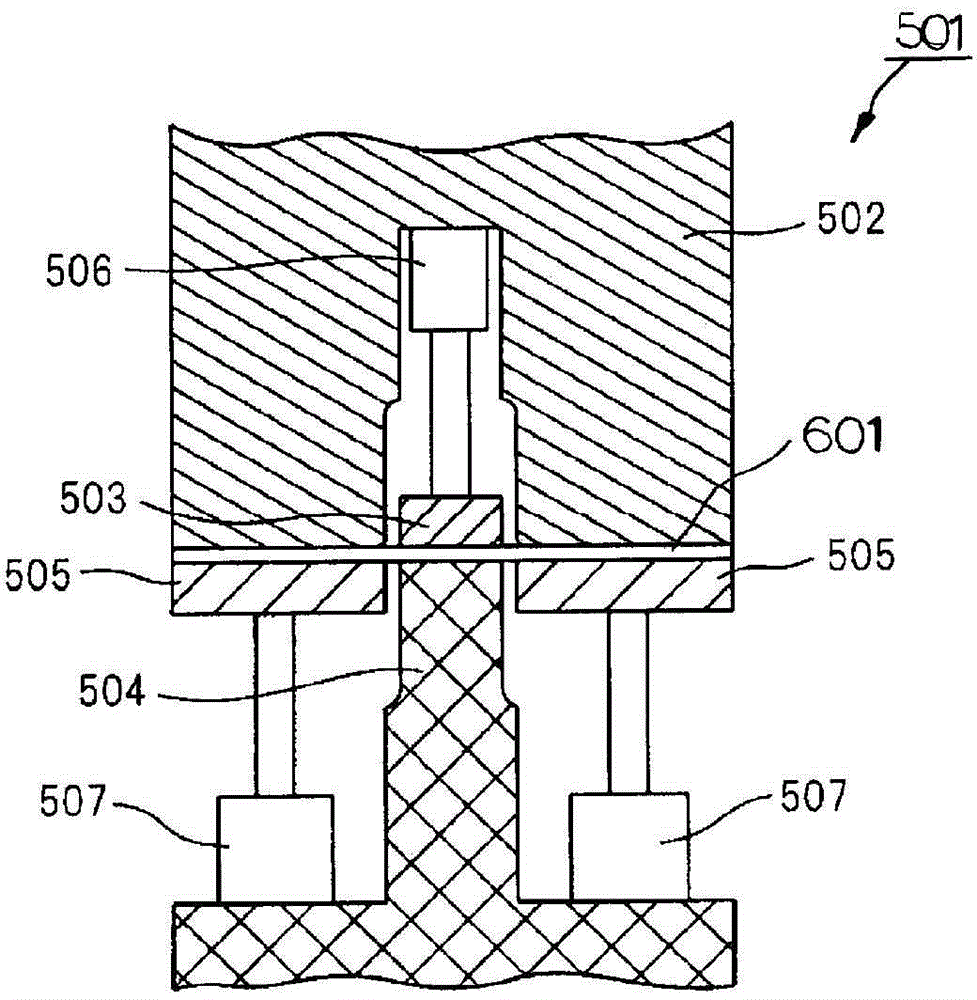

Method for producing curved article and skeleton structure member for automobile body shell

ActiveCN104582870AAvoid wrinklesIncrease profitSuperstructure subunitsThin material handlingEngineeringMechanical engineering

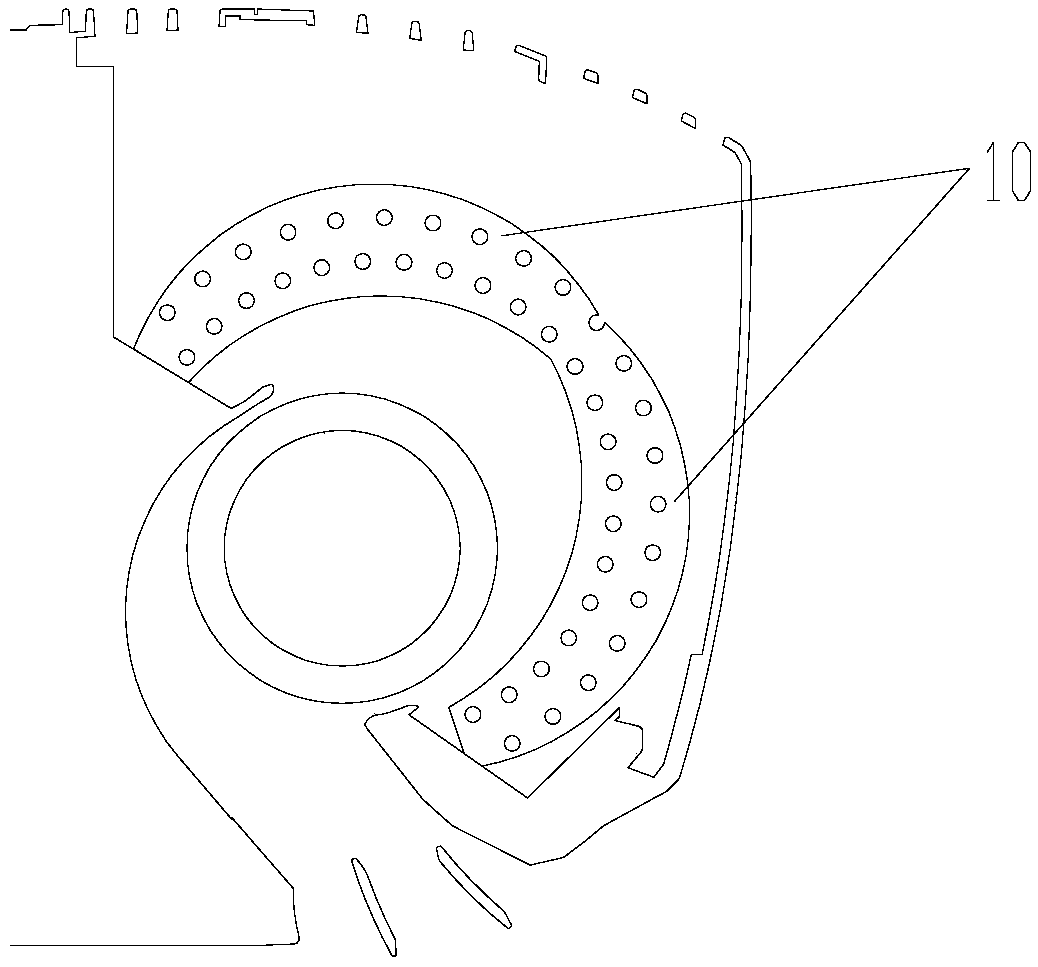

The present invention produces a curved article (10) having a hat-shaped cross section by means of press molding without generating cracks or wrinkles. When producing by means of press molding a curved article (10) having a roughly hat-shaped cross section comprising a top plate (11), vertical walls (12a, 12b) extending in parallel to each other along the ridge line (14a, 14b) of the top plate, and outward-facing flanges (13a, 13b) joined to the tips of the vertical walls, a starting material metal plate (601) is sandwiched and bound by a die (502) and a blank holder (505) and press molded while the starting material metal plate (601) is sandwiched and bound by a pad (503) and a punch (504).

Owner:NIPPON STEEL CORP

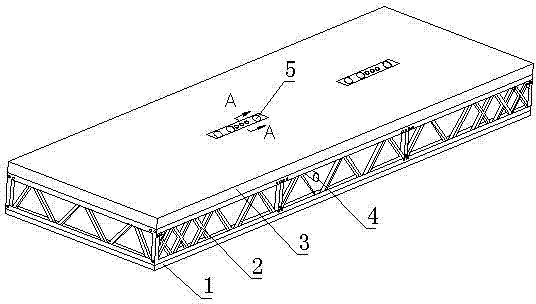

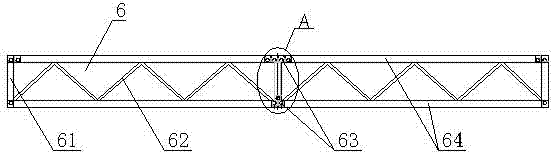

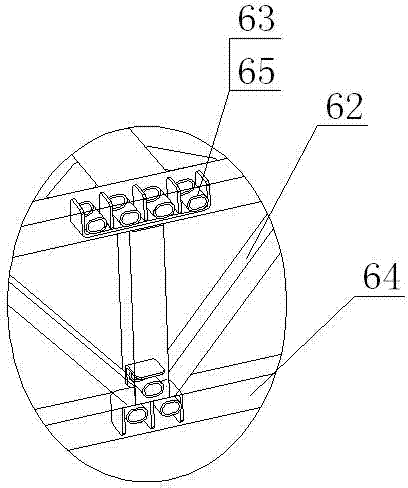

Floor system

ActiveCN103498523AQuality improvementImprove interchangeabilityFloorsFlooring insulationsFloor slabBuilding construction

The invention relates to the technical field of the building technology, in particular to a floor system. The floor system is formed by rectangular frames composed of steel beams. The floor system has the advantages of being reliable in quality, standard in production, high in construction speed, less in rubbish in a construction site and capable of being combined at will and saving materials.

Owner:张跃

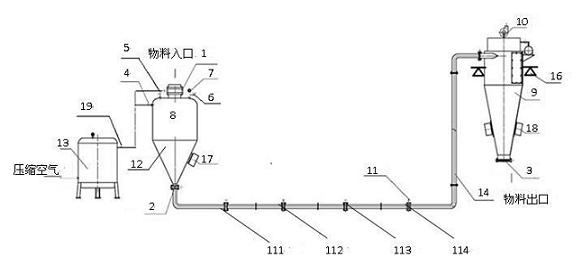

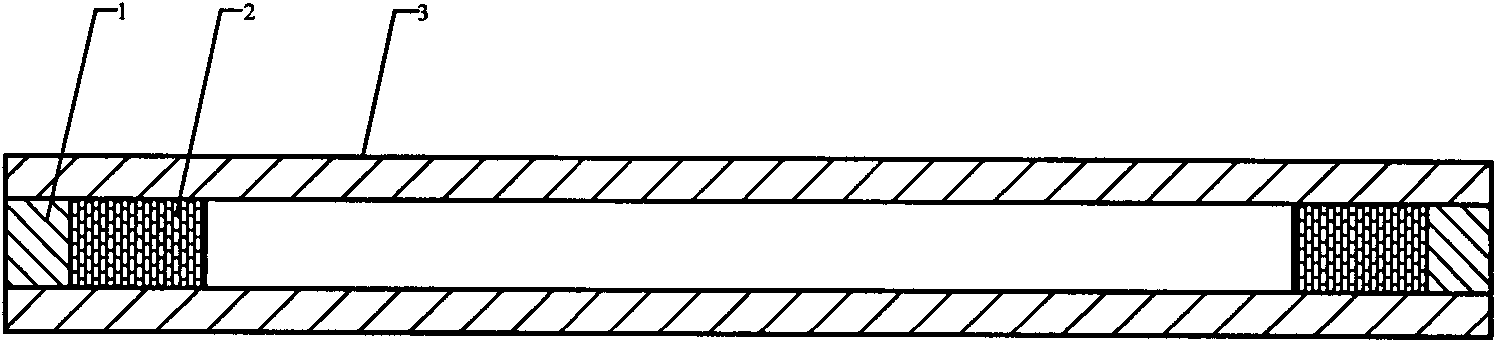

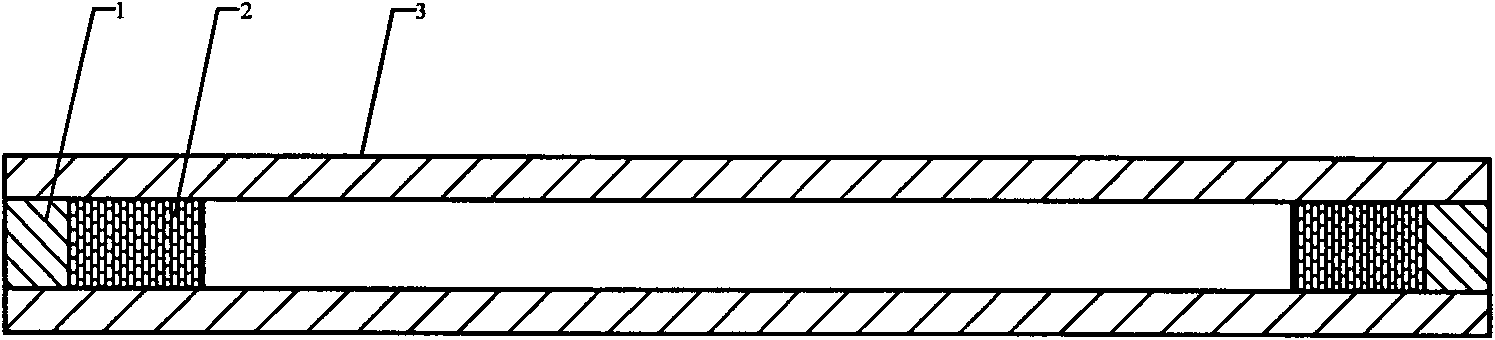

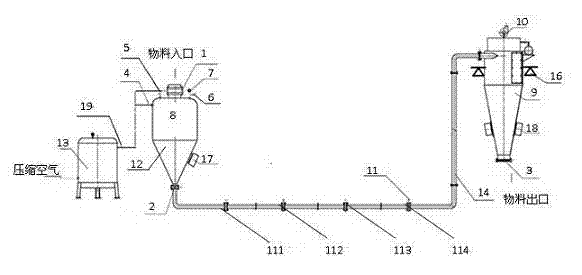

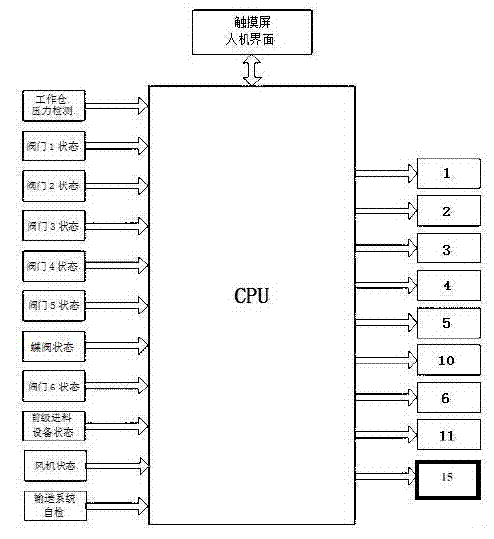

Horizontal long-distance superfine powder pneumatic conveying device

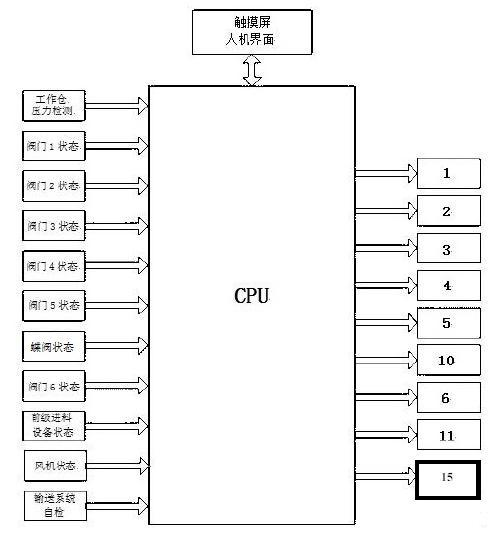

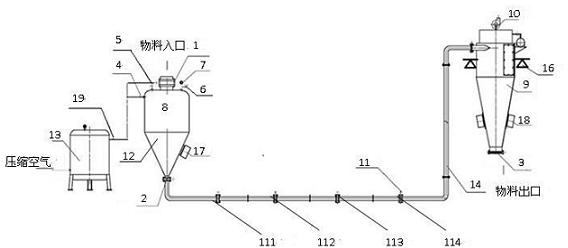

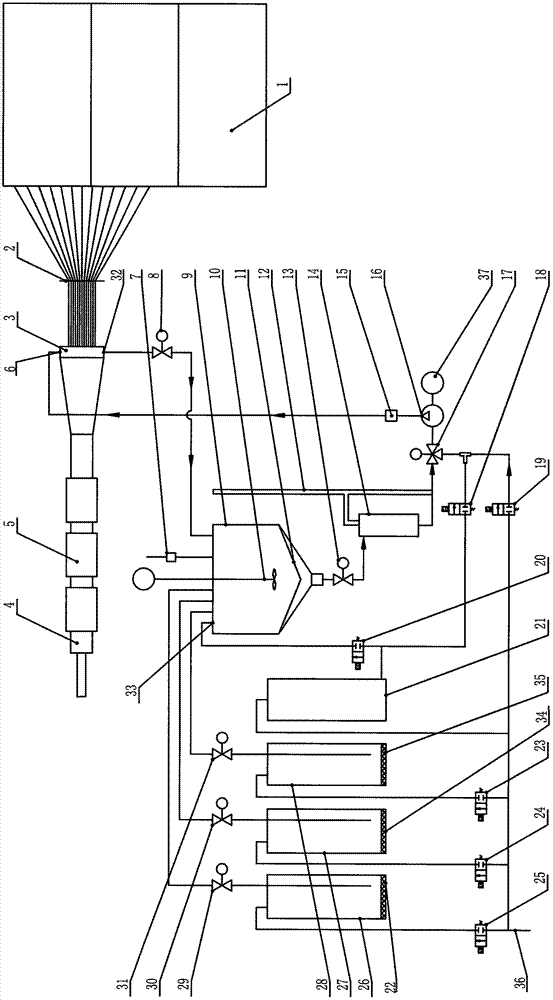

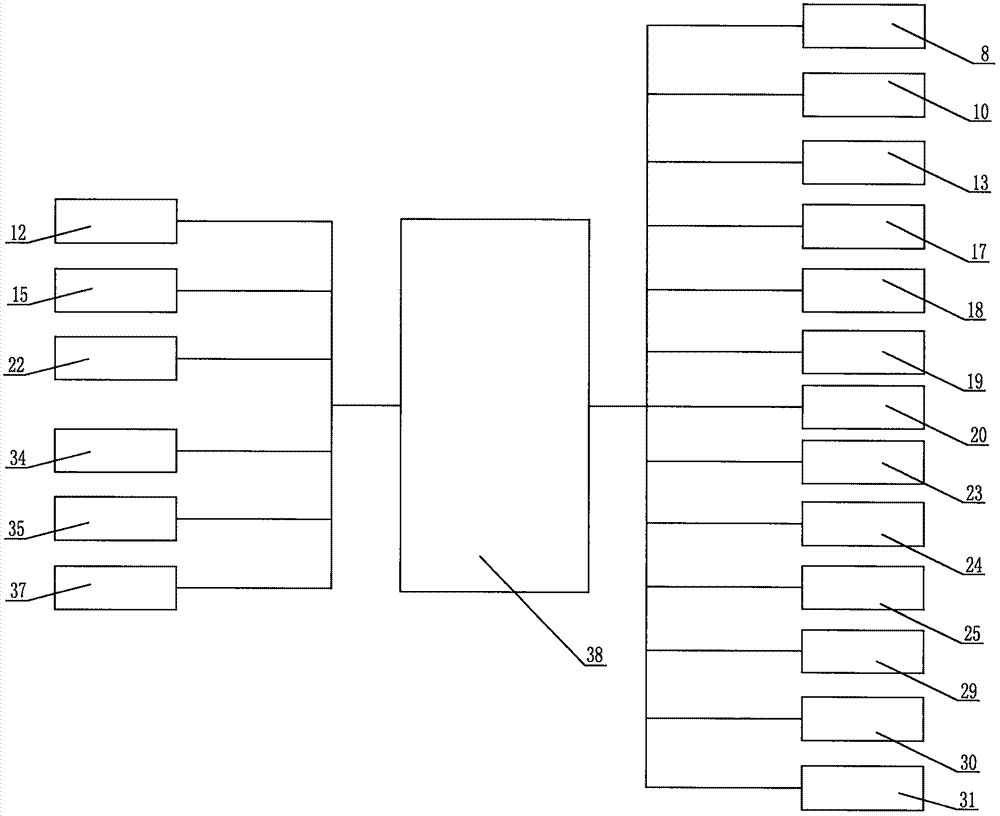

The invention relates to a horizontal long-distance superfine powder pneumatic conveying device which is connected with previous-level feeding equipment and used for long-distance conveying of superfine power and toxic or corrosive materials. The horizontal long-distance superfine powder pneumatic conveying device comprises an air source machine, a working cabin, a material conveying pipe and a controller with a CPU (central processing unit), wherein the air source machine consists of an air storage tank, an air compressor and a fan, a material inlet is communicated with the working cabin andcontrolled by a first valve, one end of the material conveying pipe is communicated with the working cabin and controlled by a second control valve, the other end of the material conveying pipe is communicated with a separator, n segmental control valves are uniformly distributed on a horizontal section of the material conveying pipe, an air pipe with three branches is arranged on the air storagetank and is respectively communicated with the working cabin and a rotary sweeping and conveying device, the working cabin is communicated with the air storage tank and is controlled by a fourth valve, the rotary sweeping and conveying device is communicated with the air storage tank and controlled by a fifth valve, material is fed into the separator and discharged from a material outlet and the material outlet is controlled by a third valve. The horizontal long-distance superfine powder pneumatic conveying device is in a segmental suction type pneumatic conveying mode, the material is pressed segment by segment, and the conveying loss of the material is less than 20g.

Owner:SHANGHAI TIANYI GAODE ELECTROMECHANICAL

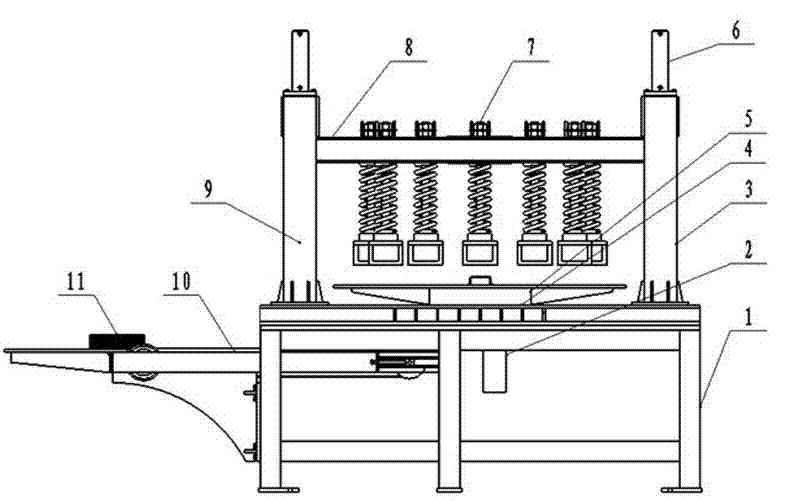

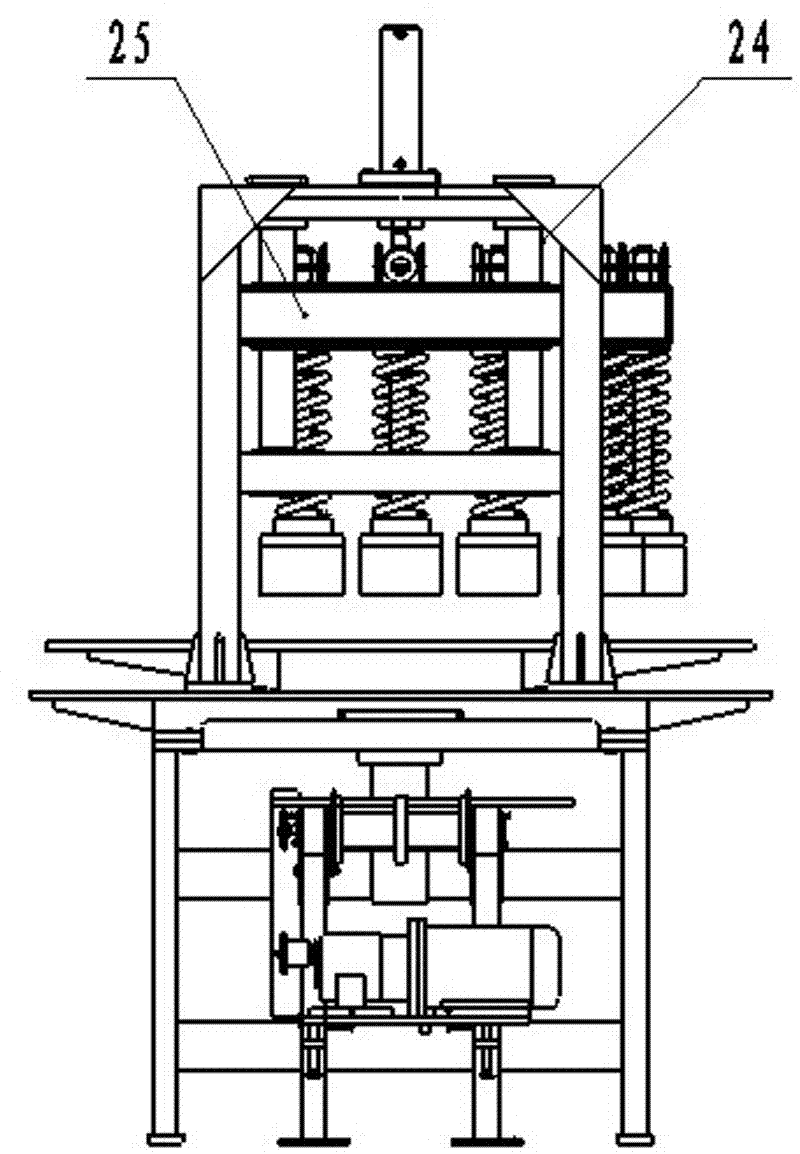

Hydraulic rotary koji pressing machine and pressing method thereof

InactiveCN102206564AUniform qualityQuality improvementAlcoholic beverage preparationEngineeringMechanical engineering

The invention relates to a hydraulic rotary koji pressing machine and a pressing method thereof. The hydraulic rotary koji pressing machine comprises a hydraulic motor, a frame, a rotary assembly, a pressure assembly and a runout table for starter materials. The hydraulic motor drives the rotary assembly into rotation, a hydrocylinder provides impetus for a pressuring hammer assembly to perform vertical reciprocating motion. The pressuring hammer crushes the koji material in a koji mould box located on a turntable, and the koji material is then output by the runout table for koji material. After prepressing and multiple crushing of the koji material, water and powder within the koji material have been mixed uniformly. The generated koji piece has appropriate tightness, so that the phenomena of tight koji piece surface, loose center and poor slurry extraction are completely avoided. The hydraulic rotary the koji pressing machine provided in the invention is characterized by simple structure, convenient operation, low energy consumption and high efficiency, thus being suitable for brewing and koji making.

Owner:TAIYUAN UNIV OF TECH

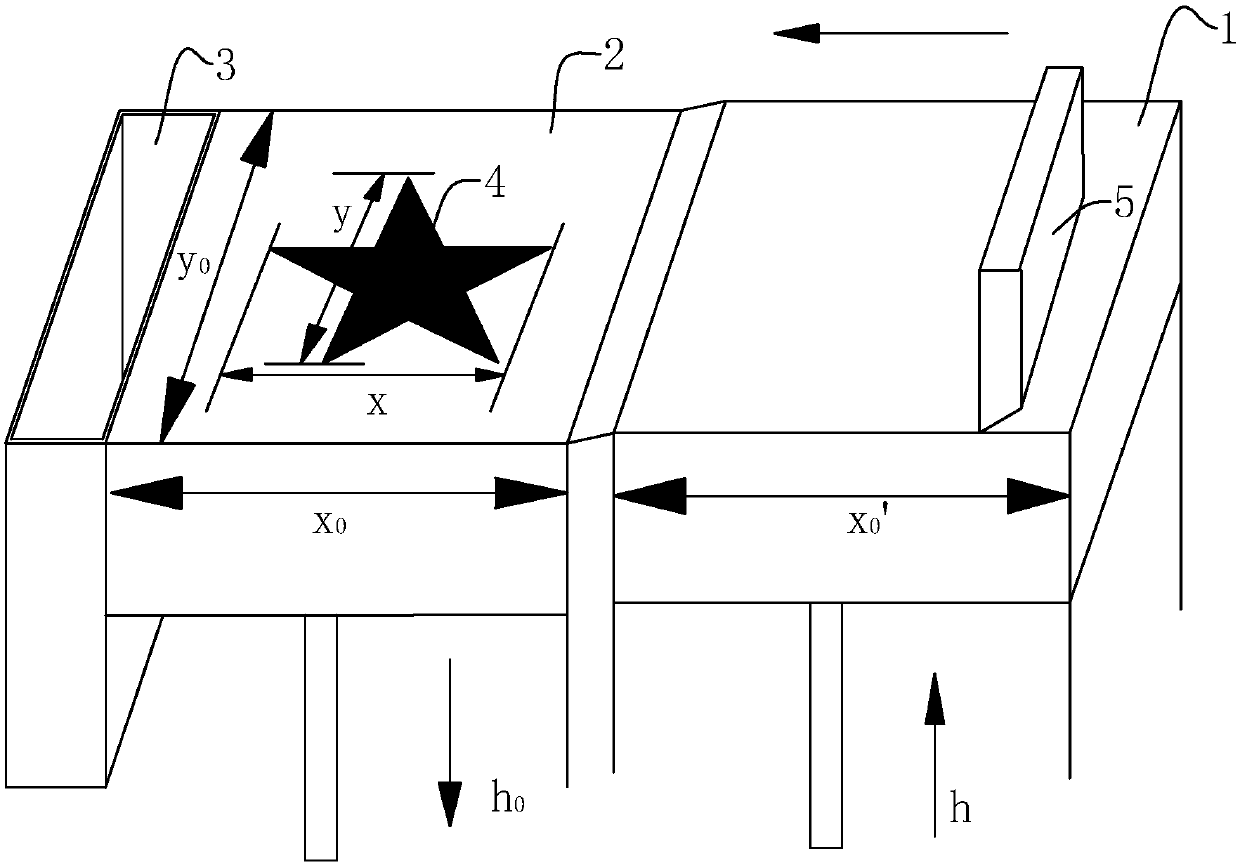

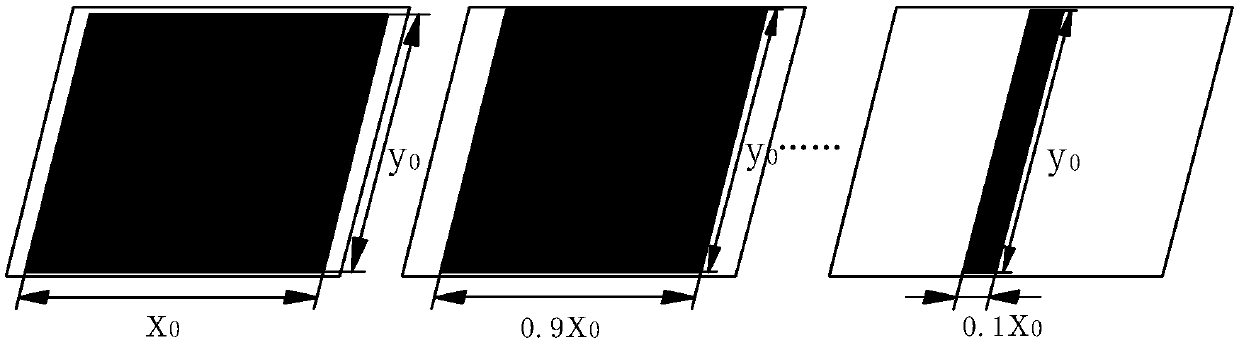

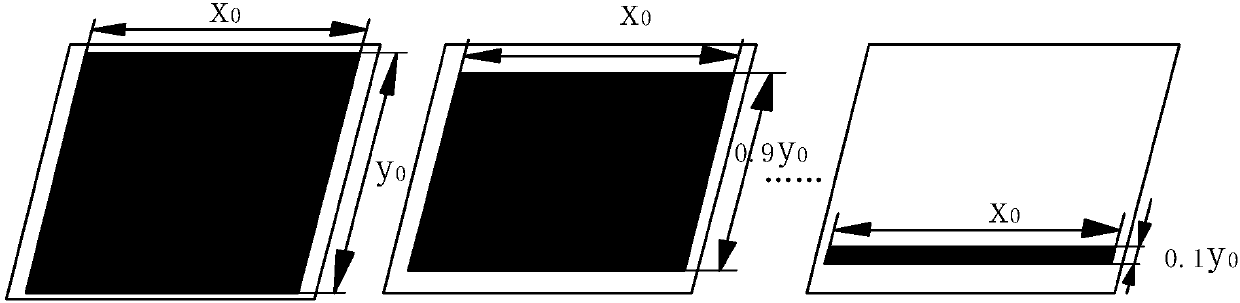

Method for automatically adjusting powder supplying amount of metal 3D printing machine

ActiveCN107774994AReduced powder supply balanceAvoid molding failureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLayer thickness

The invention discloses a formula for automatically adjusting the powder supplying height of a metal 3D printing machine. The formula includes the following steps that S1, the size parameters x0 and y0 of a forming cylinder and the size parameter x0' of a powder supplying cylinder are input; S2, the values of x and y are obtained and input according to the contour of a current printing layer; S3,the layer thickness h0 of the current printing layer is obtained; S4, the powder supplying height is changed in real time according to the formula (please see the formula in the specifications); and S5, when the S1, the S2, the S3 and the S4 are conducted for the fifteenth time, the coefficient A is multiplied before the current powder supplying height calculating formula according to the waste material amount in a waste material collecting box, the value ranges from 0.9 to 1.5, and the powder supplying height is increased or reduced according to the waste material amount. The powder supplyingheight of the current printing layer can be dynamically adjusted in real time according to the part section area, the part placing position, the powder batch, the powder density changes in the forming cylinder and the powder supplying cylinder and changes of operators and other factors, and therefore the size of waste materials can be minimized on the premise that powder is fully spread on the current printing layer.

Owner:BEIJING E PLUS 3D TECH CO LTD

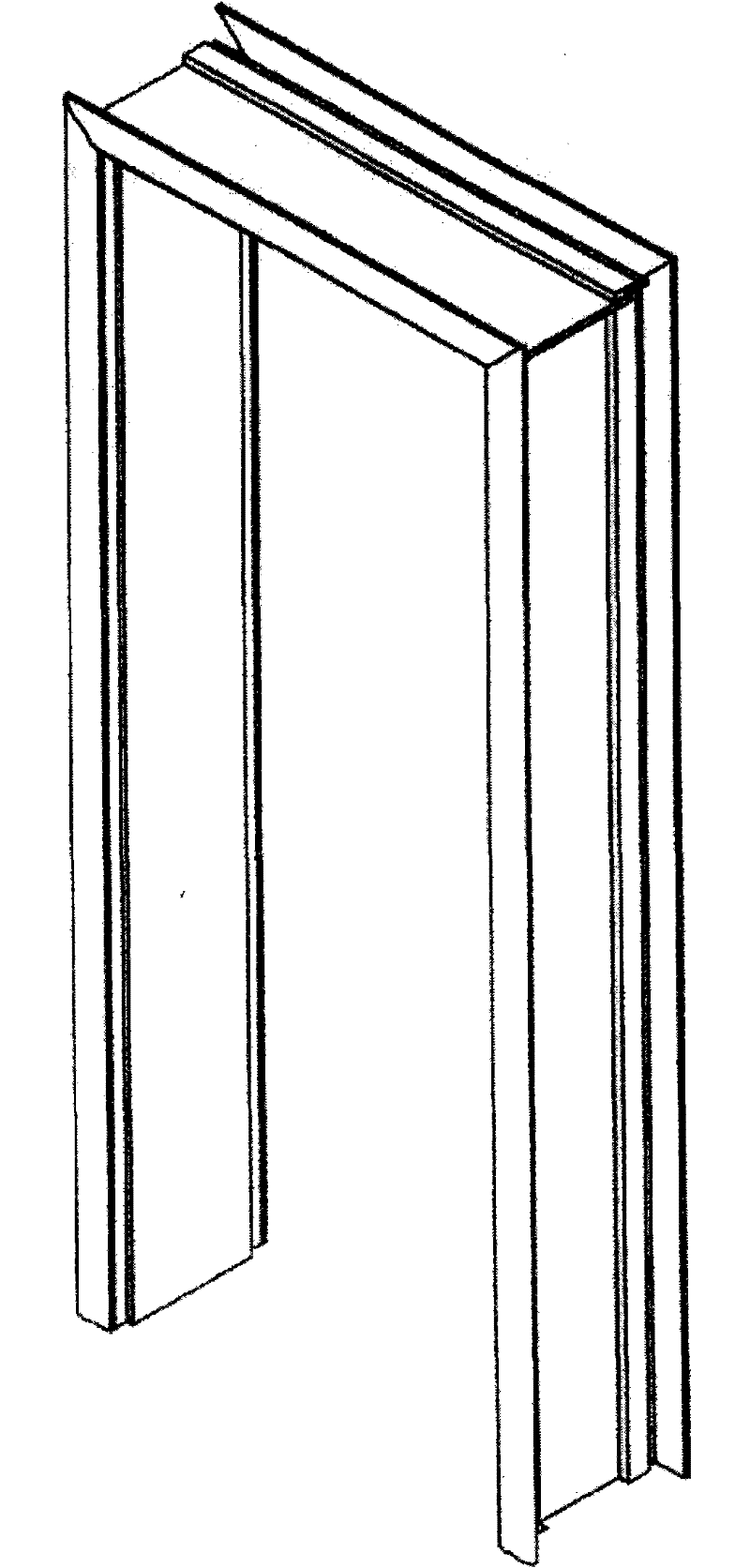

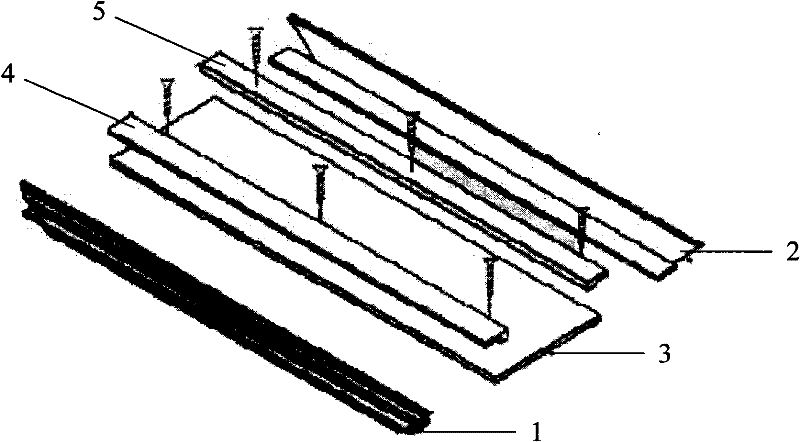

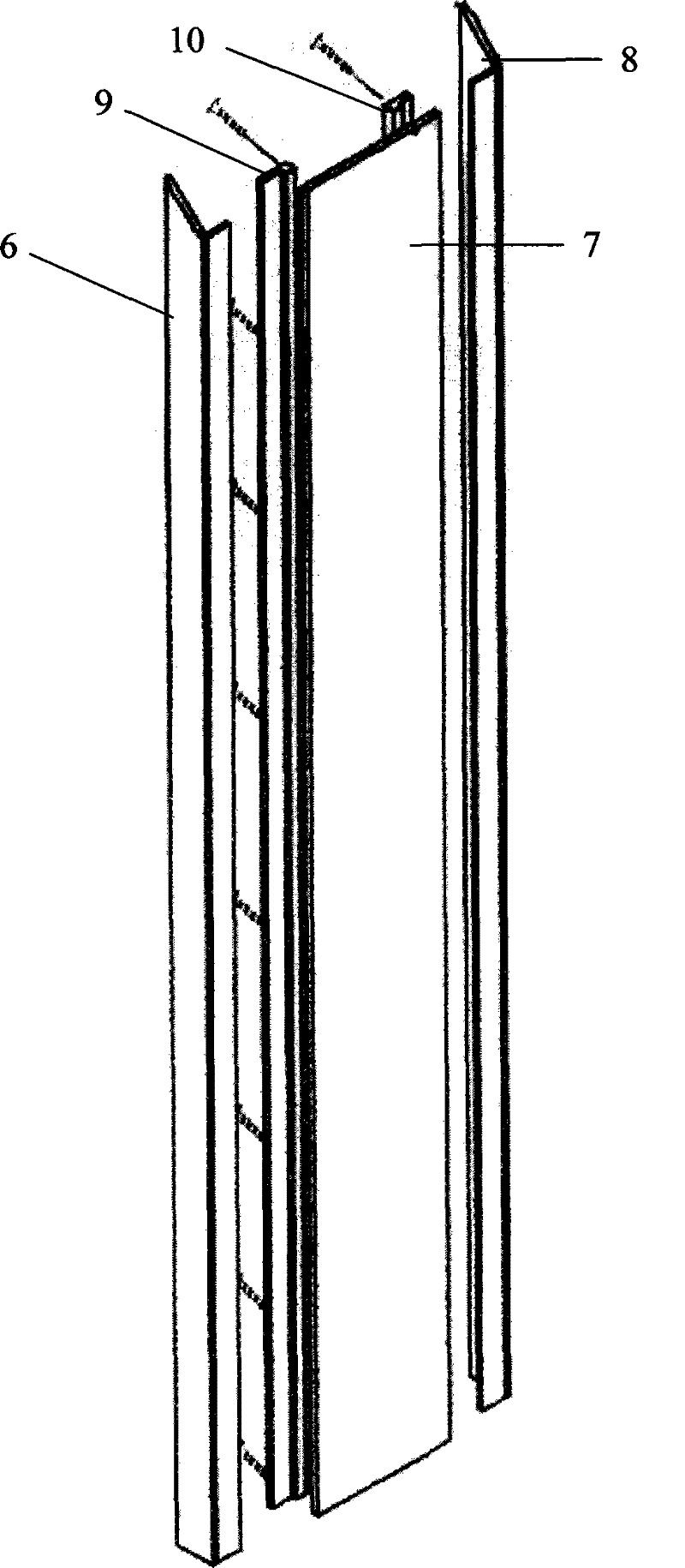

Novel convenient split door and window set and manufacturing method thereof

InactiveCN101748955AReduce residual materialIncrease profitWindow/door framesWood working apparatusEngineeringMechanical engineering

Owner:徐州华克木业有限公司

Production method of integrated car carpet

ActiveCN103386912AReduce weightMeet the requirements of lightweight designVehicle arrangementsLamination ancillary operationsThermoplasticCompression molding

The invention discloses a production method of an integrated car carpet. The production method comprises the steps of laying of shock pad raw materials, drying of the shock pad raw materials, compression molding, laying of a surface carpet and a semi-finished product of shock pad below the carpet, drying of the surface carpet, fit molding, water cutting and the like. The integrated car carpet produced by the method disclosed by the invention meets the requirements of performance index, such as vibration reducing, environment protecting and lightening; the weight of the integrated car carpet is greatly reduced, and the requirement of the whole car lightening is met; the cost of raw materials is reduced due to the selection of thermoplastic felt and a PET and EVA compounded surface carpet, so that the selectivity is high; in the process of material processing, a hot air box is adopted for heating, a mold is adopted for compression molding, a water jet scalpel is adopted for cutting, the technology is stable, the safety and the accuracy of the operation are ensured, and the working efficiency is improved; excess materials of the product are less; no semi-finished products are stacked in the process, and the manufacturing cost is reduced; and no harmful substance is generated in the whole production process of the product.

Owner:WUXI GISSING AUTO PARTS CO LTD

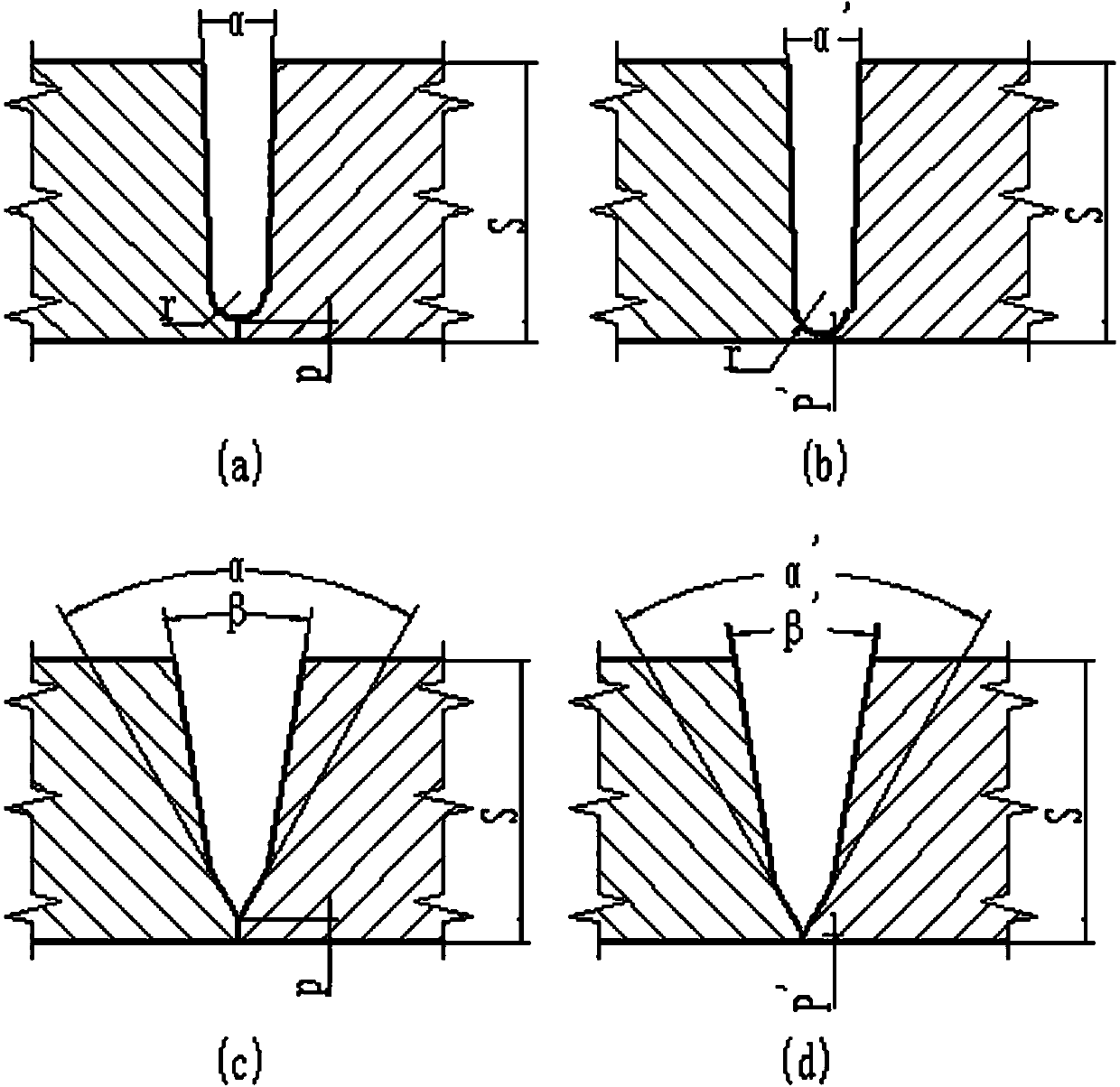

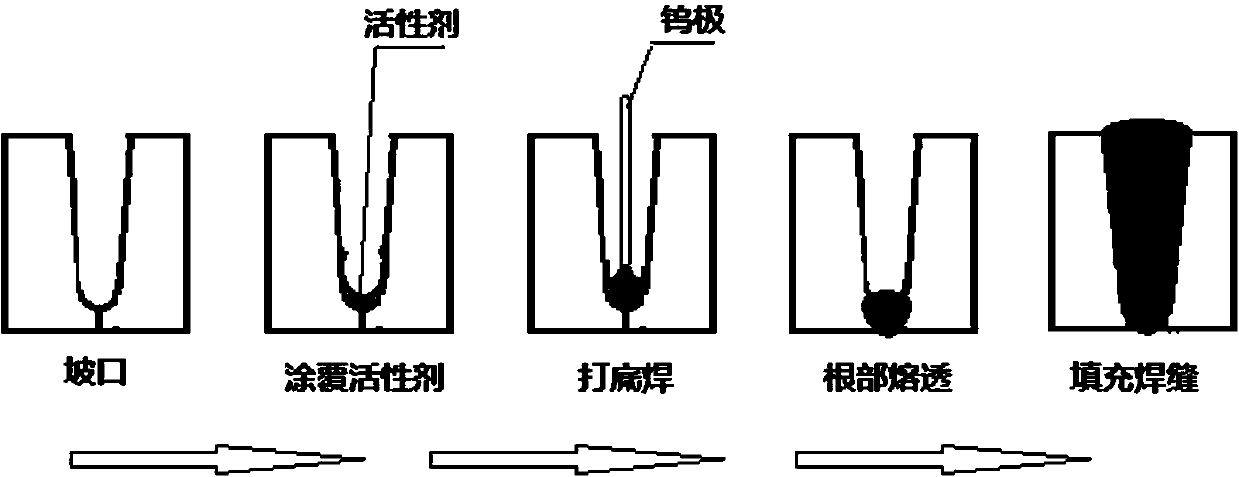

Method for improving welding efficiency of narrow-gap argon tungsten-arc welding

InactiveCN104043894AReduced processing performanceReduce residual materialArc welding apparatusWorkpiece edge portionsWeld seamMelt depth

The invention discloses a method for improving the welding efficiency of narrow-gap argon tungsten-arc welding. The method includes the steps of (1) machining a narrow-gap notch with a truncated edge 6 mm to 12 mm in thickness on base metal, (2) coating the root of the notch with active welding flux, (3) carrying out notch root welding with the A-TIG welding technology, and (4) filling the narrow-gap notch, and completing narrow-gap welding. By means of the method, due to the adoption of the design of the narrow-gap notch with the truncated edge 6 mm to 12 mm in thickness, the processing amount and waste materials of the notch are reduced, the base metal is saved, the filling amount of welded joint metal is reduced, and a welding wire is saved; first welding on the root is carried out through the high fusion depth of the A-TIG technology, it is guaranteed that the root and the two sides of the notch are completely melted, and therefore the welding efficiency and the welding quality are effectively improved; notch filling and notch surface covering are carried out with the welding technology, such as the MIG / MAG, with the high efficiency and the slightly-poor quality, narrow-gap combination welding is achieved, and the method can be applied to the condition with the high requirement for the welding efficiency.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Energy-saving and environment-friendly screw extruder

The invention discloses an energy-saving and environment-friendly screw extruder, relates to an extruder and aims to solve the technical problems that the extruder in the prior art is easy to block materials and waste the materials. The energy-saving and environment-friendly screw extruder is characterized by comprising an extruder body and a hopper arranged on the extruder body; at least two receiving plates are rotatably arranged in the hopper, the receiving plates are located at the lower part of a material inlet of the hopper, material conveying spaces for conveying the materials are keptbetween the receiving plates and the inner side wall of the hopper, the adjacent receiving plates are arranged in an up-down mode, the adjacent material conveying spaces are arranged in a staggered mode, and a power assembly is arranged on the hopper; when the materials need to be fed in, the materials are poured into the hopper and fall on the receiving plates, the power assembly drives the receiving plates to rotate, therefore, the speed of feeding the materials into the extruder body is controlled, and the materials may get into the extruder body smoothly; and thus, materials are reduced, which are all piled up at the hopper bottom, causing remaining materials; and extravagant materials are reduced, and the energy-saving and environment-friendly screw extruder is energy-saving and environment-friendly.

Owner:南京盛驰橡塑机械制造有限公司

Heat treatment process for hollow drill collar

ActiveCN101942550AEasy to processShorten heating timeFurnace typesHeat treatment process controlProduction scheduleQuenching

The invention discloses a heat treatment process for a hollow drill collar and belongs to the technical field of production of tubes special for petroleum. The heat treatment process comprises the steps of machining an inner bore on a workpiece, and then quenching and tempering, and is characterized in that: rock wool is filled in the inner bore before the inner bore is quenched, and then a port is blocked by fire clay. In the heat treatment process for the drill collar, drilling after heat treatment changes into drilling before heat treatment, so that original machining twice changes into molding at one time, and machining procedure of the drill collar is simplified; meanwhile, the rigidity of the workpiece before the workpiece is tempered is much lower than that of the workpiece after the workpiece is tempered, therefore the difficulty of drilling is reduced greatly, the times of cutter hitting and working loss are reduced. By using the heat treatment process, the forged workpiece changes into a round rod shape from a step axle shape; and machining difficulty and raw material consumption are reduced. In addition, the solid heat treated workpiece changes into the hollow heat treated workpiece, the heating time and cooling time of quenching and tempering the drill collar are shortened greatly, and the production schedule is accelerated, so that the whole production cycle of the drill collar is shortened greatly.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

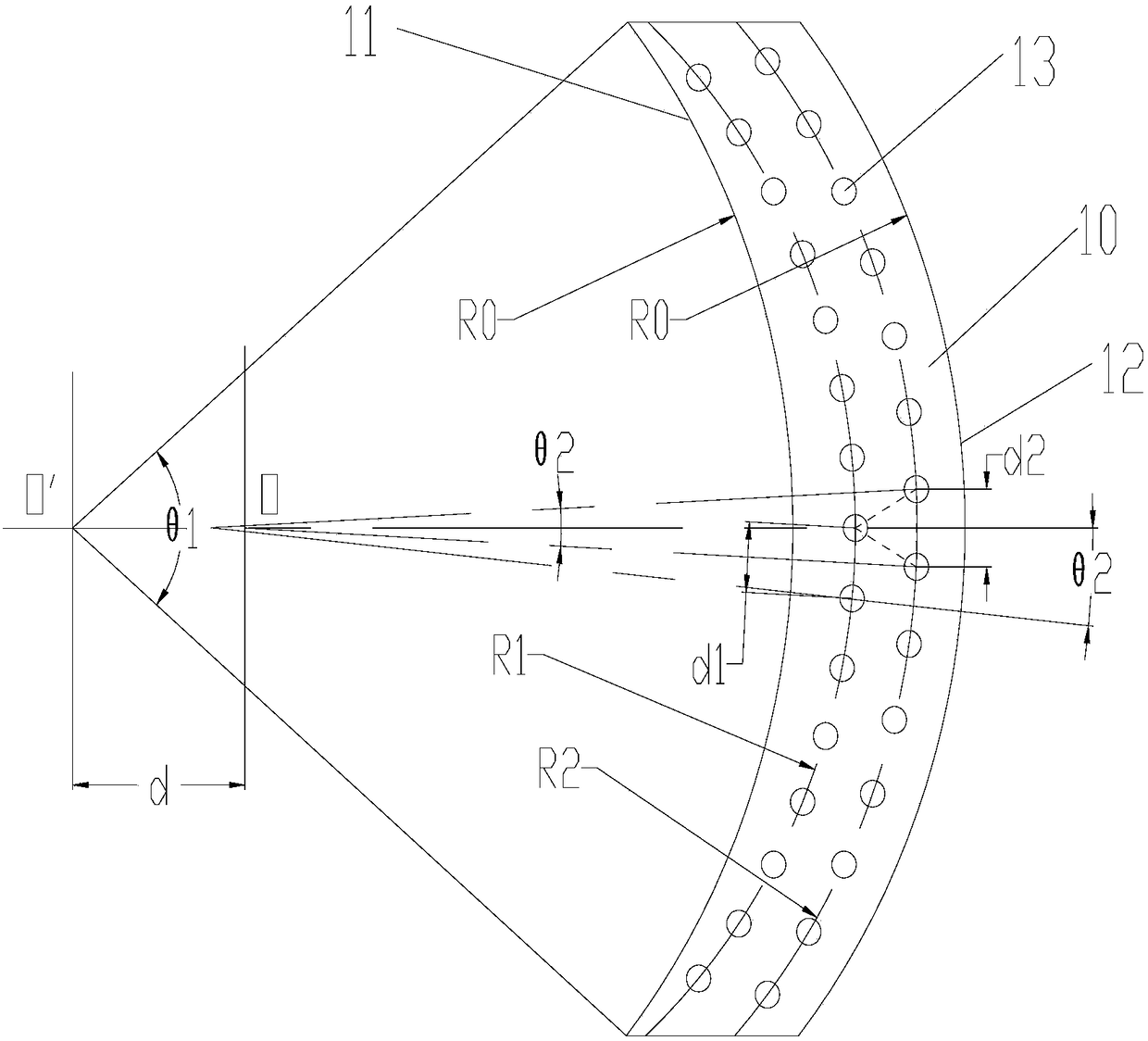

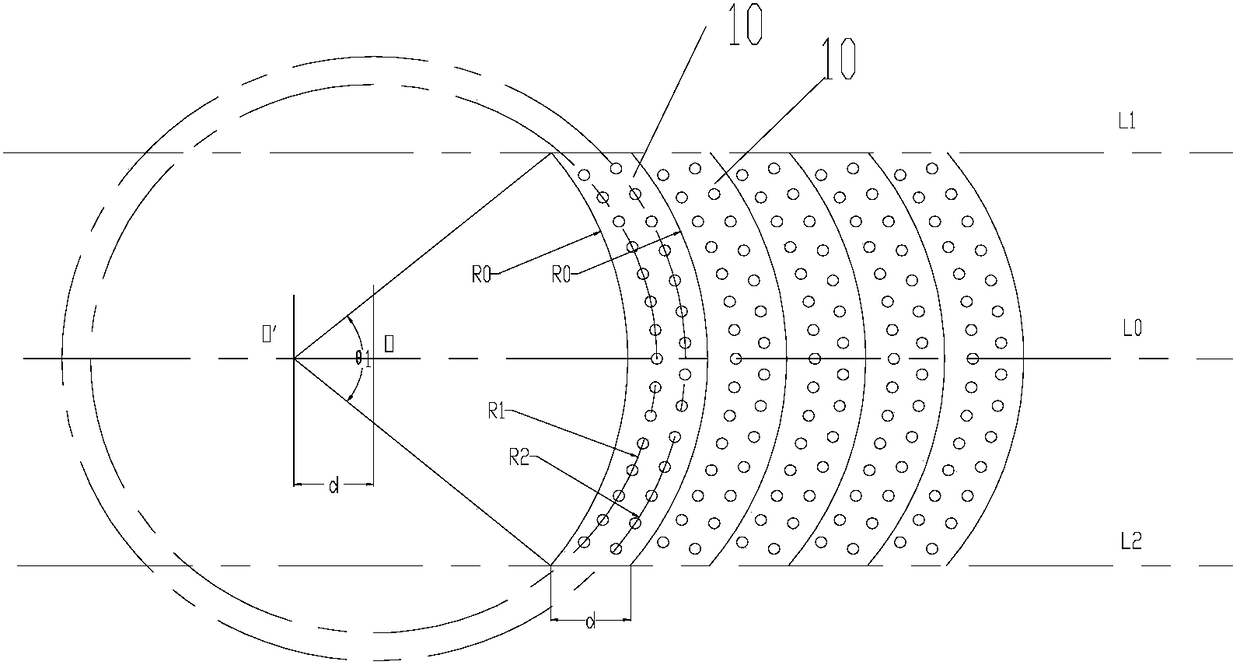

Fin, heat exchanger and air conditioner

ActiveCN108458621AReduce residual materialReduce manufacturing costSpace heating and ventilation detailsTubular elementsEngineeringPlate heat exchanger

The invention provides a fin, a heat exchanger and an air conditioner. The fin is in an arc shape and comprises an inner arc edge and an outer arc edge. The circle center corresponding to the inner arc edge is O', and the circle center corresponding to the outer arc edge is O. The fin is arranged symmetrically about the straight liner of O' and O. The radius of the inner arc edge is equal to the radius of the outer arc edge. The central angle corresponding to the inner arc edge and the central angle corresponding to the outer arc edge are theta 1, wherein theta 1 is less than or equal to 180 degrees. Compared with previous rectangular fins, through the arc-shaped fin, the phenomenon that rewinding is liable to occur to the rectangular fins due to bending can be avoided, ventilation and heat exchange of the heat exchanger are facilitated, in addition, the space of the heat exchanger can be utilized conveniently, the problem that water is liable to accumulate at outer corners of bent positions is solved, the situation that water is blown due to the fact that accumulated water drops in an air duct of the air condition can be avoided as much as possible, and the product quality is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Production method of car engine compartment cover assembly

ActiveCN103331581AReduced assembly weightMeet the requirements of lightweight designMiniaturizationPerformance index

The invention relates to a production method of a car engine compartment cover assembly. An engine compartment cover inner plate finished product can be obtained through the steps such as measuring and cutting of sheet stock, pavement of raw materials, hot pressing forming, mold stripping of a semifinished product, cooling stereotyping and blank processing, and an engine compartment cover outer plate finished product is obtained through the steps such as measuring and cutting of sheet stock, pavement of raw materials, hot pressing forming, mold stripping of a semifinished product, cooling stereotyping and blank processing; and a car engine compartment cover assembly finished product is obtained by assembling and splicing the engine compartment cover inner plate and outer plate. The engine compartment cover assembly produced through the method has the advantages that performance indexes such as sound insulation, environmental protection and miniaturization can meet the requirement that no accumulation of semifinished products in the entire production process, and the manufacturing cost is saved; and the entire production process of the product is free from producing harmful substances.

Owner:WUXI GISSING AUTO PARTS CO LTD

Method for producing light automobile acoustic carpet

InactiveCN104192041AReduce weightLow costVehicle arrangementsLaminationEnvironmental resistanceSurface layer

The invention relates to a method for producing a light automobile acoustic carpet, and belongs to the technical field of automobile part production. The light automobile acoustic carpet is obtained through paving, adsorption forming and water jet cutter cutting of an acoustic shock pad surface layer below the carpet, paving, temperature drying and pressing forming of an acoustic shock pad base material below the carpet, and paving, temperature drying, attaching forming and water jet cutter cutting of a surface carpet and a semi-finished acoustic shock pad below the carpet. The light automobile acoustic carpet produced through the method meets the index requirements of performance such as shock absorption, environmental friendliness and lightness; the weight of the automobile acoustic carpet is greatly reduced, and the requirement for the whole automobile light design is met.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Glue injection machine for unsaturated polyester resin glass fiber reinforced plastic production and process

ActiveCN107263889ANot volatileNo pollution in the processHollow article cleaningCleaning using liquidsYarnGlass fiber

The invention belongs to a glue injection machine for unsaturated polyester resin glass fiber reinforced plastic production and a process. The machine comprises a yarn frame, the tail end of the yarn frame is sequentially connected with a pre-forming device, a glue injection box and a mold, a heating board is arranged on the outer surface of the mold, a glue injection inlet is formed in the top of the glue injection box, the glue injection inlet is connected with a glue production device, an excess material outlet is formed in the bottom of the glue injection box, and is connected with a stirring tank in the glue production device, and the glue production device comprises the stirring tank; an excess material flow back opening, a resin inlet, a padding inlet, a curing agent inlet and a compression air inlet are formed in the top of the stirring tank, a stirrer and a filter net are arranged in the stirring tank, a glue outlet is formed in the bottom of the stirring tank, and the excess material flow back opening is connected with the excess material outlet of the glue injection box through a first pneumatic two-way valve. The glue injection machine has the beneficial effects that the structure is simple, design is reasonable, operation is convenient, the phenomena that traditional opening gum dipping hurts human body health, and the environment is polluted are avoided, the excess materials can be effectively recycled, and the product quality is improved.

Owner:河南鑫景龙智能机器人装备有限公司

Plastic particle mixing cooler

PendingCN106003456ALiquidityGood for mixingElectrostatic separationWoven fabricElectrostatic precipitator

The invention discloses a plastic particle mixing cooler and relates to the field of plastic processing. The plastic particle mixing cooler comprises a material storage barrel, a material return barrel and a feeding pipe, wherein a discharge pipe and a material return pipe are arranged at the lower end of the material storage barrel, the discharge pipe and the material return pipe are respectively provided with a discharge valve I and a discharge valve II, the material return pipe communicates with the material return barrel, and a feeding hole is formed in the material return barrel; the material storage barrel comprises a barrel body made from non-woven fabric and a support frame for tensioning the barrel body, a dust collection barrel is arranged outside the material storage barrel, an electrostatic precipitator is arranged between the material storage barrel and the dust collection barrel, and vent holes are formed in the lower end of the dust collection barrel; and the feeding pipe comprises a main pipe and a branch pipe communicating with the main pipe, one end of the main pipe communicates with the upper end of the material storage barrel, the other end of the main pipe is connected with an air blower, and the branch pipe communicates with the material return barrel. According to the invention, due to arrangement of the electrostatic precipitator and change of the mounting position of the air blower, discharged ash is greatly reduced, and the circulating mixing effect is improved.

Owner:重庆敏驰塑胶有限公司

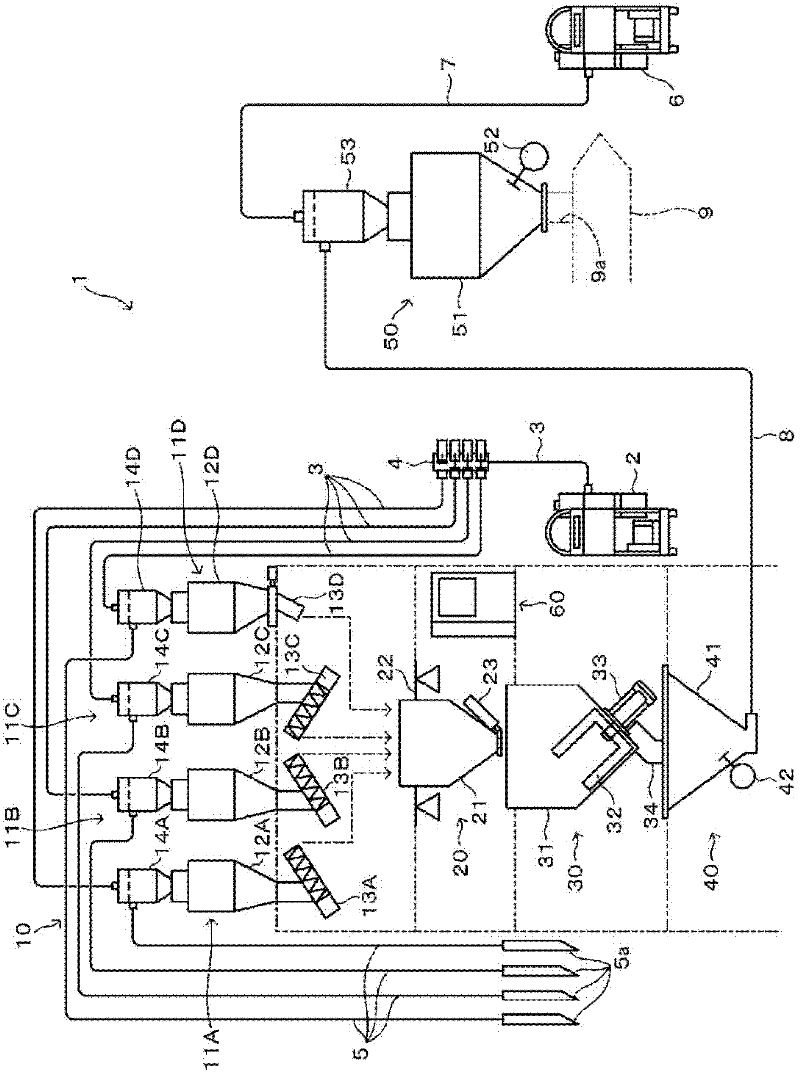

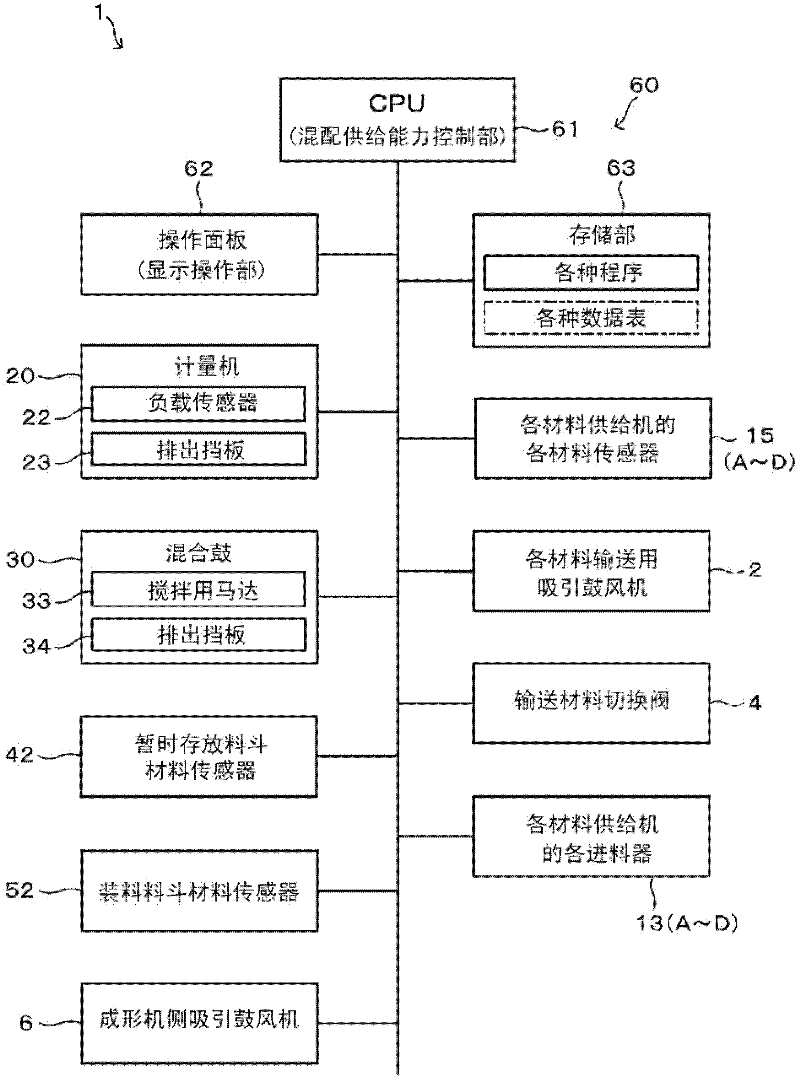

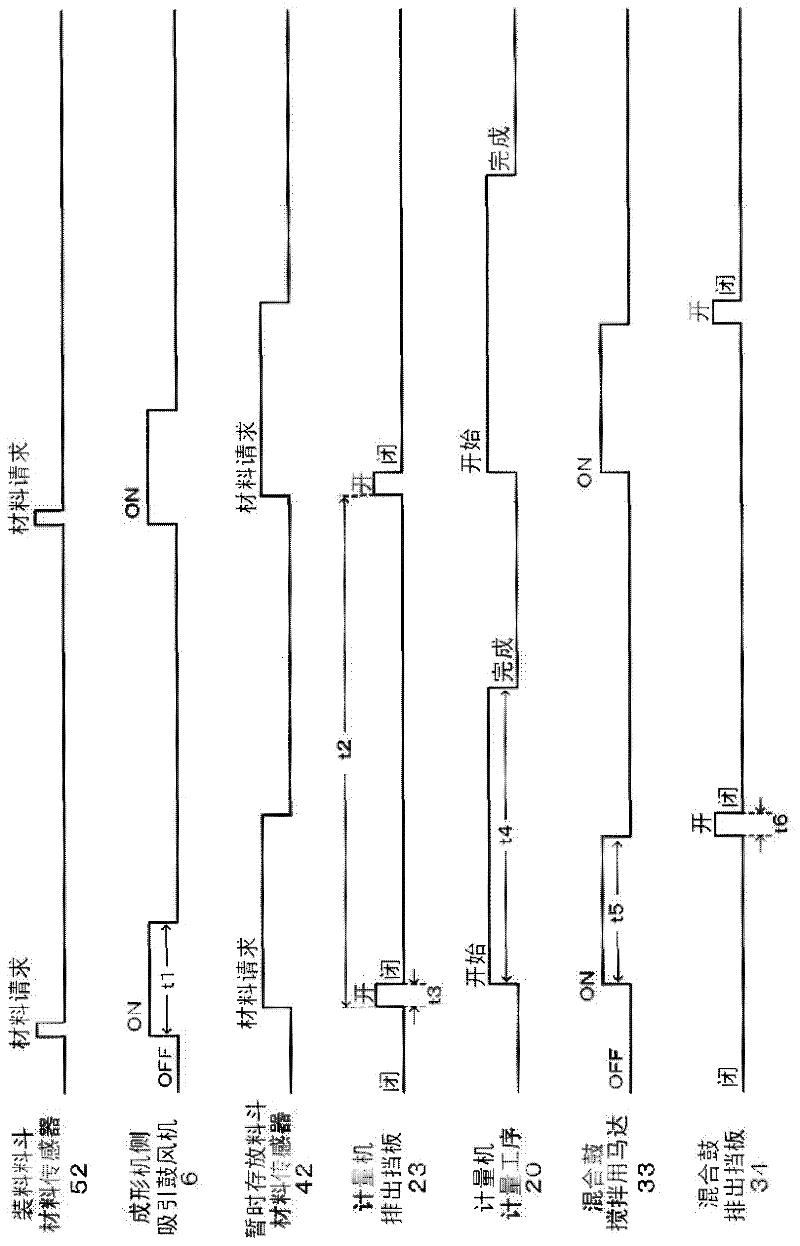

Material blending/supplying device and method

Disclosed is a material blending / supplying device (1) that weighs the respective particulate materials supplied by a plurality of material suppliers (10A, 10B, 10C, 10D) by means of a weighing mechanism (20) so that the materials have a predetermined mass ratio, and then blends the materials with a blending means (30) and supplies the blended materials to a molding mechanism (9). The material blending / supplying device is provided with: a processing capacity detection means (61) for detecting the processing capacity of the molding mechanism in terms of the material processed per unit of time; a blend supply capacity detection means (61) for detecting the blend supply capacity in terms of the amount of blended material that can be supplied to the molding mechanism per unit of time; and a blend supply capacity control means (61), for comparing the processing capacity and the blend supply capacity based on a predetermined programme, and updating the blending / supplying process so as to reduce the blend supply capacity when the blend supply capacity exceeds the processing capacity and the blend supply capacity can be reduced to a predetermined level.

Owner:MATSUI MFG

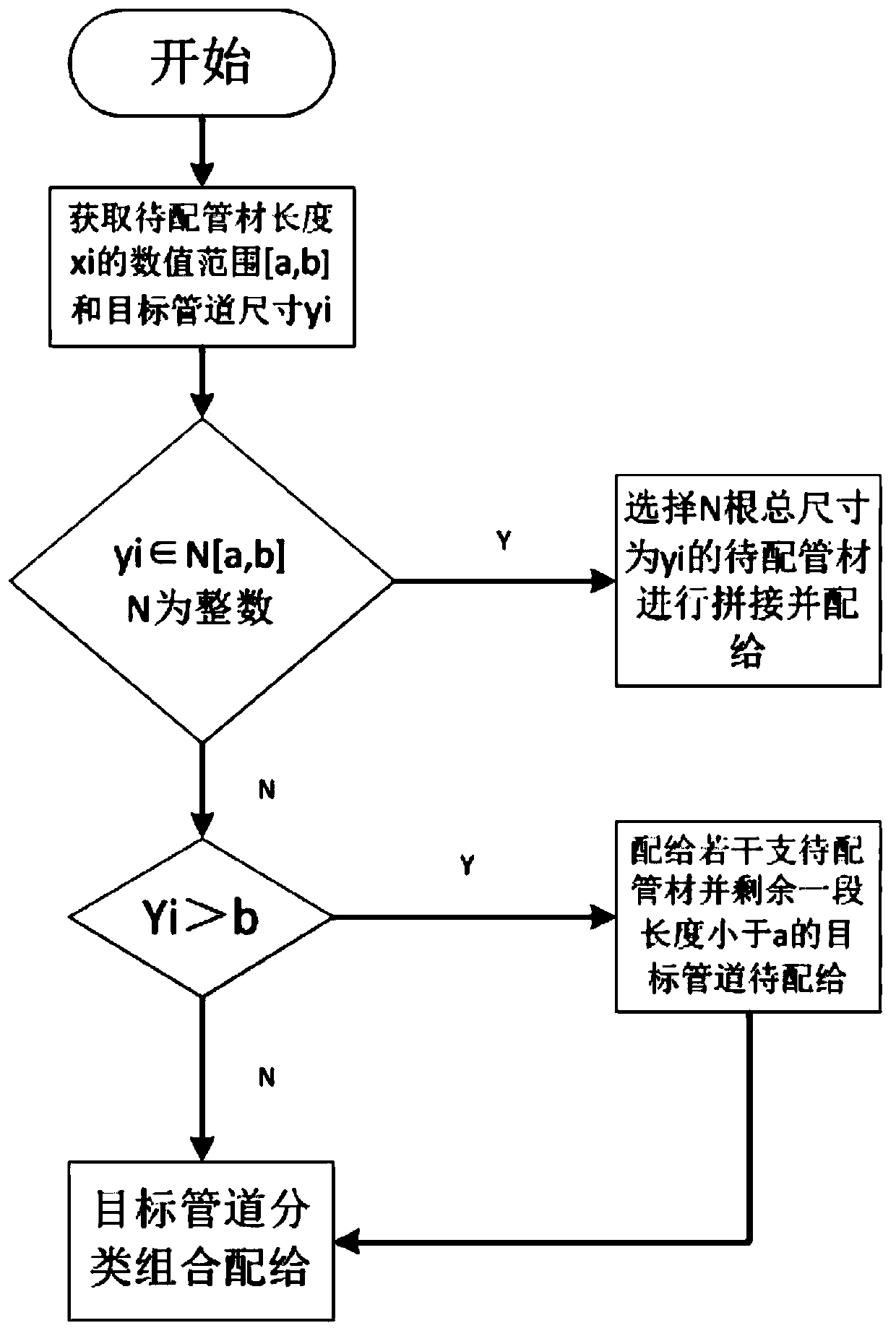

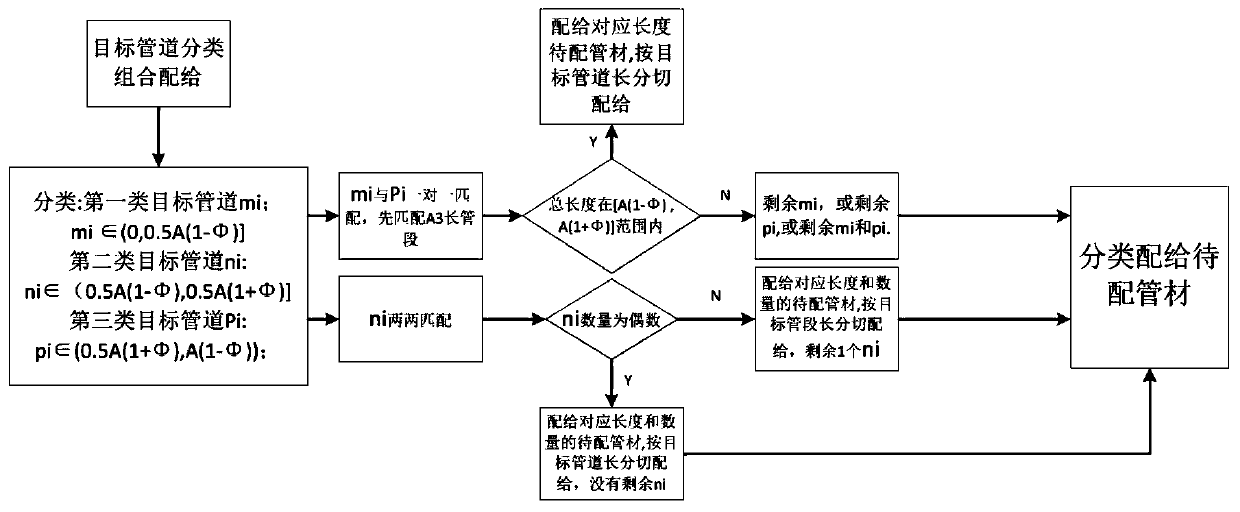

Optimization method for pipe discharging

ActiveCN110516834AReduce the number of cutsIncrease profitForecastingCharacter and pattern recognitionLower limitEngineering

The invention provides an optimization method for pipe discharging. The method comprises the steps of obtaining a length range of a to-be-matched pipe and a target pipeline, wherein the length of thetarget pipeline is integral multiples of the length of a to-be-matched pipe; taking the to-be-matched pipes with the corresponding number and length to be matched, wherein the size is greater than theupper limit of the to-be-matched pipe length and the length of the target pipeline is not within the range of integral multiples of the length of the to-be-matched pipe; taking the to-be-distributedpipes with the corresponding number and length to be distributed, and remaining a target pipe with the length smaller than the lower limit of the to-be-distributed pipes. In this way, the pipes distributed to the target pipe are all the whole pipes. The number of spliced pipes and the cutting frequency of the pipes are reduced. Losses are reduced. The utilization rate of the pipes is increased. All the target pipelines smaller than the lower limit of the length of the to-be-matched pipes are classified and combined. The target pipelines with the total length reaching integral multiple of the length of the to-be-matched pipes after combination are cut and matched according to the corresponding number and length. Useless pipe excess materials are reduced. The utilization efficiency of the pipes is improved, and the pipe discharging mode is optimized.

Owner:HUADIAN HEAVY IND CO LTD

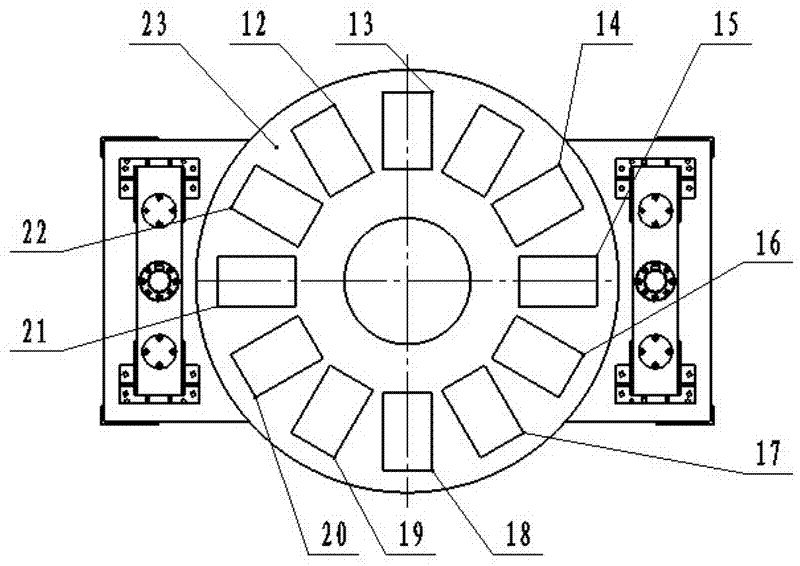

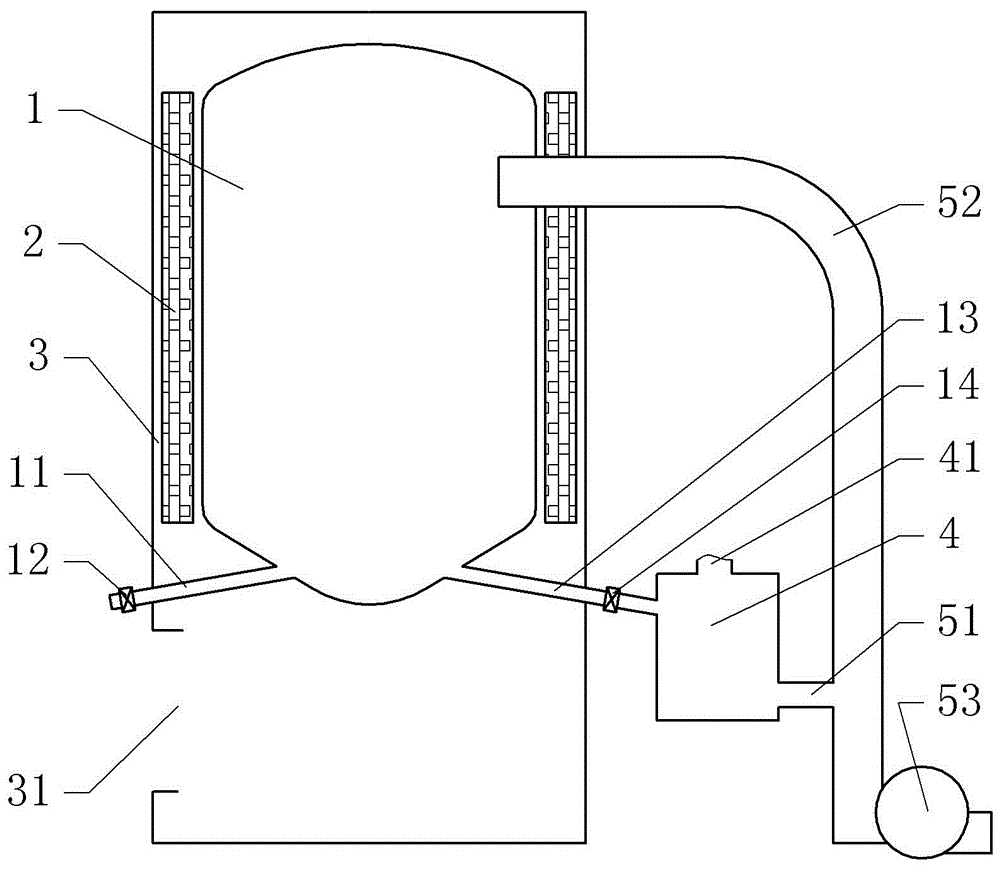

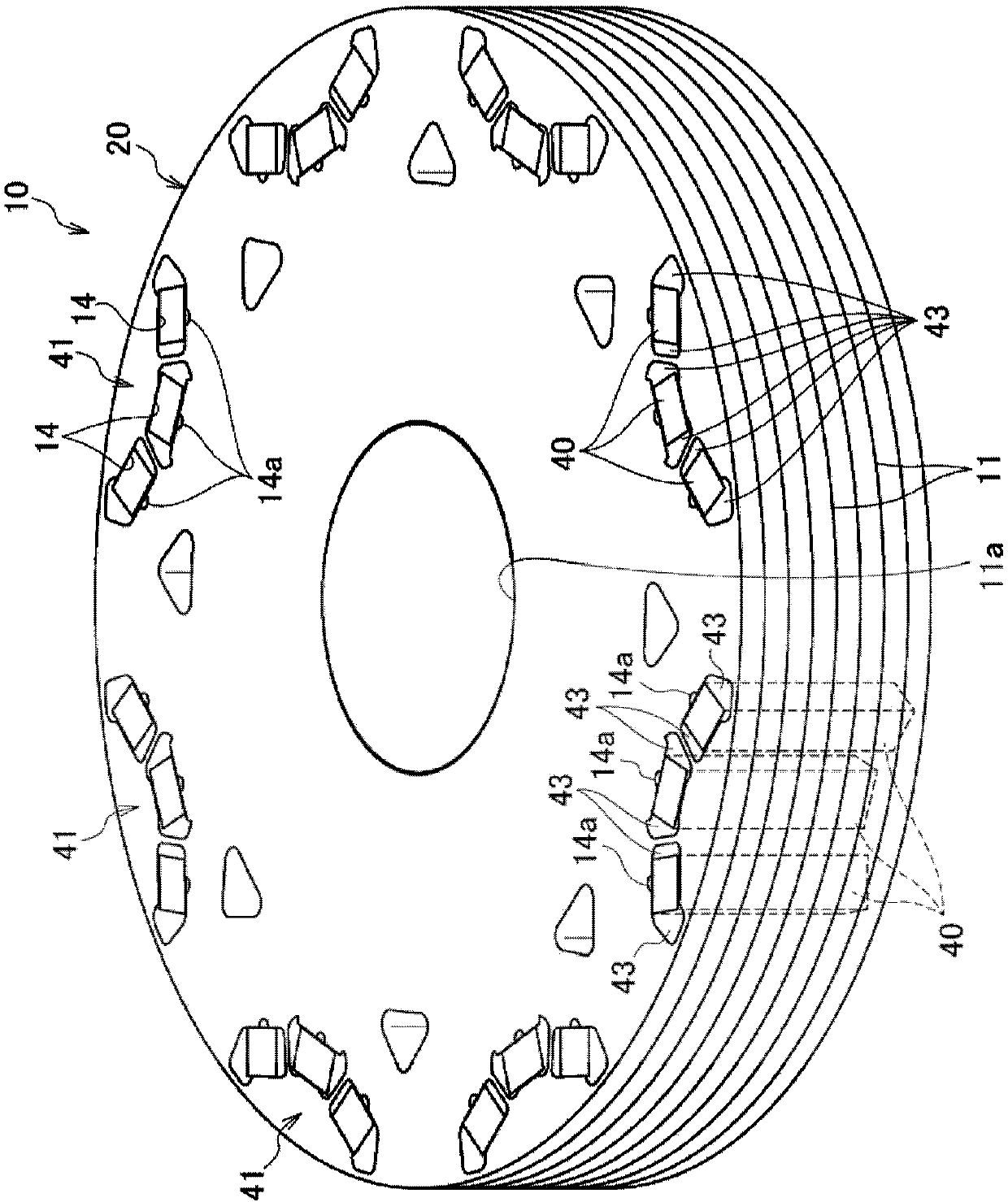

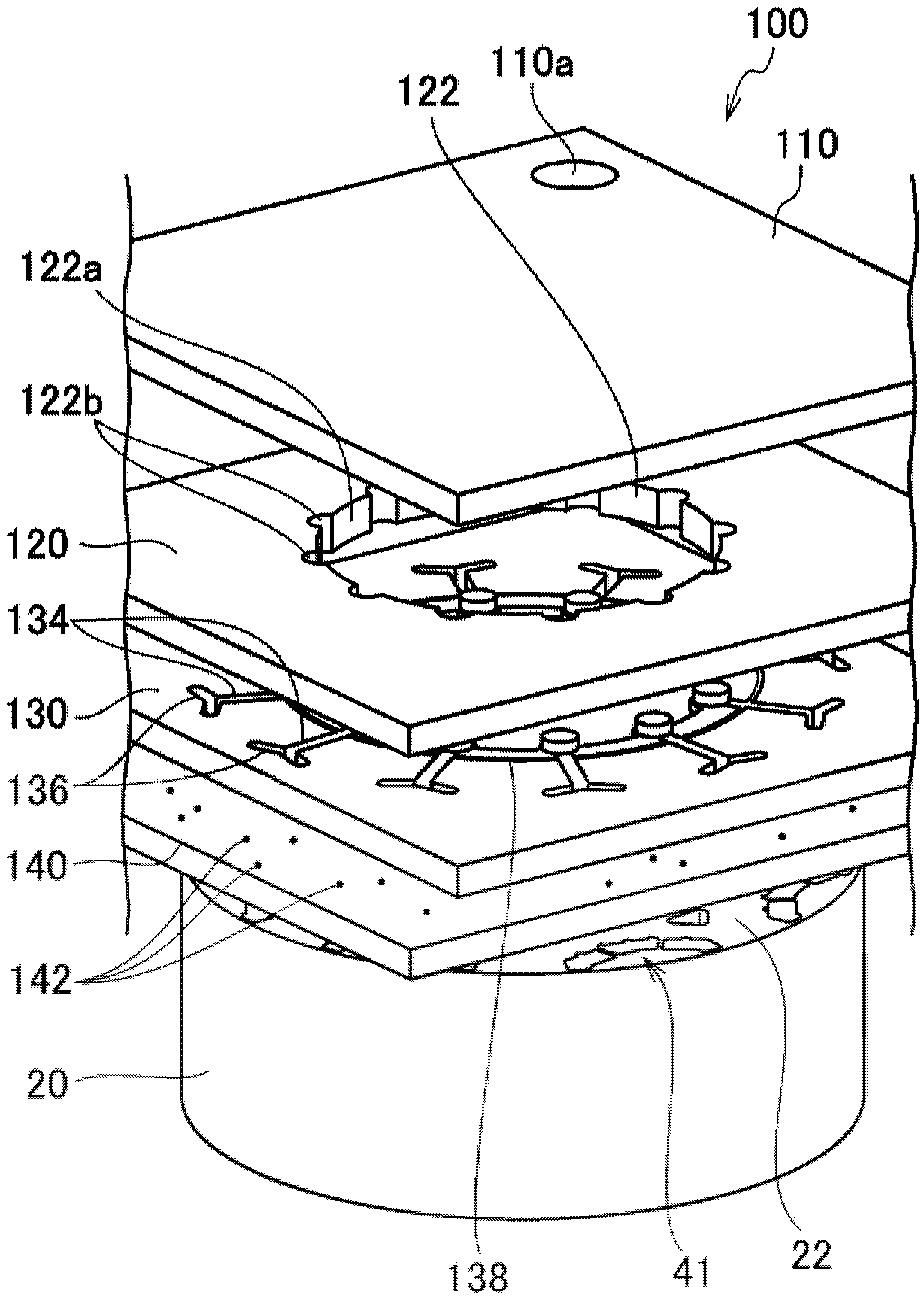

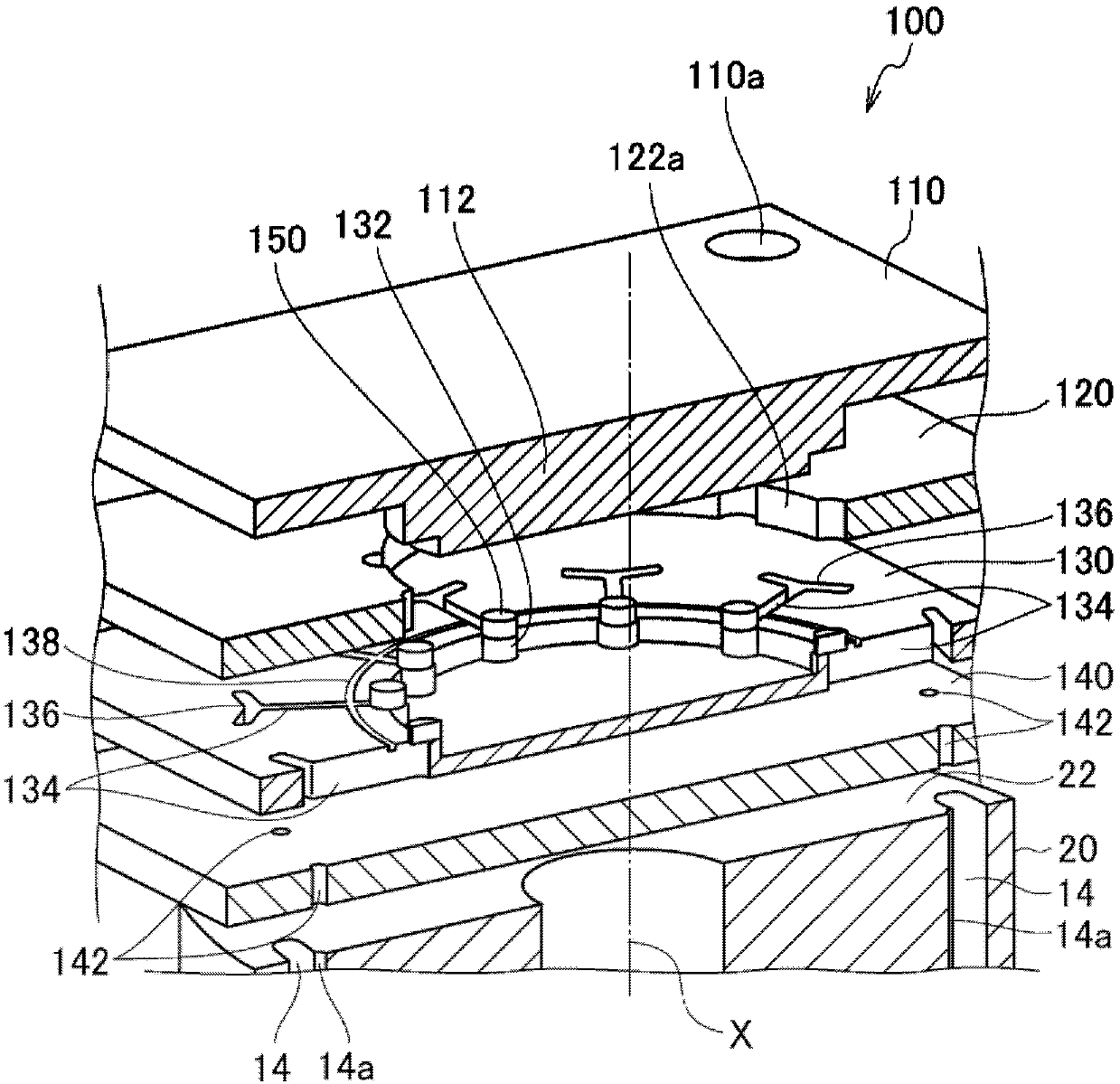

Rotor manufacturing method

InactiveCN107919771AReduce residual materialLow set injection pressureMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringPlunger

The invention provides a rotor manufacturing method capable of reducing the amount of cull which is a residual cured product of resin. In the rotor manufacturing method, a plurality of resin tablets (150) are disposed to be annularly spaced from each other in resin tablet disposing step (S230), and resin (150a) is filled between a magnet insertion hole (14) and a permanent magnet (40) in resin filling step (S240) when the plurality of resin tablets (150) are pressed by one plunger (112). Therefore, it is possible to reduce the amount of cull which is a residual cured product of a resin material.

Owner:HONDA MOTOR CO LTD

Production method of acoustic shock absorption pad under automobile carpet

InactiveCN105856783AReduce weightMeet the requirements of lightweight designLamination ancillary operationsLaminationThermoplasticAcoustic shock

The invention relates to a production method of an acoustic damping pad under an automobile carpet, belonging to the technical field of automobile parts production. It includes: laying the skin, drying and softening the skin, forming the skin by adsorption, laying the base material, heating the base material, pressing and forming, and cutting with a water jet. The acoustic damping pad under the carpet of the automobile produced by the method of the present invention meets the performance index requirements such as sound insulation, shock absorption, environmental protection and light weight; the weight of the acoustic damping pad under the carpet is greatly reduced, and the requirements for the lightweight design of the whole vehicle are met ;The use of thermoplastic felt reduces the cost of raw materials and is more selective; in the process of material processing, the use of hot air box heating, mold cooling and shaping, and water jet cutting, the process is stable, ensuring the safety and accuracy of the operation, and at the same time improving Operational efficiency; less product residue; saving manufacturing costs; no harmful substances are produced in the entire production process of the product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

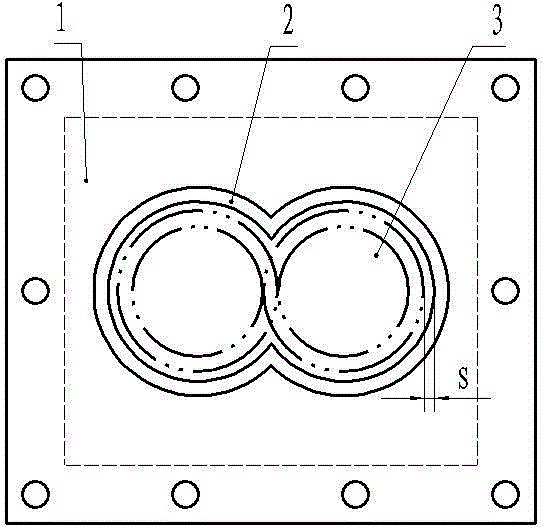

Extrusion device of plastic extruder

InactiveCN104647723AImprove product qualityReduce residual materialManufacturing technologyWhole body

The invention discloses an extrusion device of a plastic extruder and relates to the technical field of manufacturing of the plastic extruder. The extrusion device comprises a barrel body which is internally provided with a barrel sleeve, and two screw rods which are arranged in the barrel sleeve and are mutually engaged, wherein the barrel sleeve is provided with two arc-shaped barrels with connected side walls; the two arc-shaped barrels are connected to form a whole body; and the gap between the inner walls of the arc-shaped barrels and the outer circle generatrixes of the two screw rods is 0.2mm-0.25mm. Compared with the prior art, the machining position precision and size precision of inner cavities of the arc-shaped barrels can be controlled better so that the mounting gap between the inner walls of the arc-shaped barrels and the two screw rods is ensured, furthermore, materials can be forwards extruded very well by using the two mutually-engaged screw rods; and the residual material remained on the inner wall of the barrel sleeve also can be reduced so that the product quality of produced modified plastic is improved.

Owner:LIUZHOU HAIDA NEW MATERIAL TECH

Horizontal long-distance superfine powder pneumatic conveying device

The invention relates to a horizontal long-distance superfine powder pneumatic conveying device which is connected with previous-level feeding equipment and used for long-distance conveying of superfine power and toxic or corrosive materials. The horizontal long-distance superfine powder pneumatic conveying device comprises an air source machine, a working cabin, a material conveying pipe and a controller with a CPU (central processing unit), wherein the air source machine consists of an air storage tank, an air compressor and a fan, a material inlet is communicated with the working cabin andcontrolled by a first valve, one end of the material conveying pipe is communicated with the working cabin and controlled by a second control valve, the other end of the material conveying pipe is communicated with a separator, n segmental control valves are uniformly distributed on a horizontal section of the material conveying pipe, an air pipe with three branches is arranged on the air storagetank and is respectively communicated with the working cabin and a rotary sweeping and conveying device, the working cabin is communicated with the air storage tank and is controlled by a fourth valve, the rotary sweeping and conveying device is communicated with the air storage tank and controlled by a fifth valve, material is fed into the separator and discharged from a material outlet and the material outlet is controlled by a third valve. The horizontal long-distance superfine powder pneumatic conveying device is in a segmental suction type pneumatic conveying mode, the material is pressed segment by segment, and the conveying loss of the material is less than 20g.

Owner:SHANGHAI TIANYI GAODE ELECTROMECHANICAL

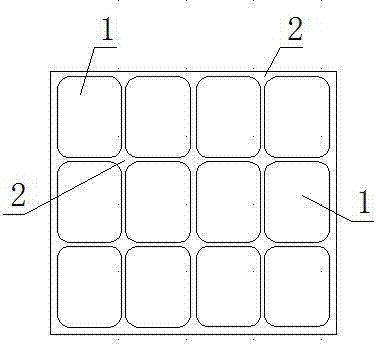

Microphone polar plate assembly and method for machining polar plate unit by using same

InactiveCN102970644AReduce the fixed partReduce parasitic capacitanceElectrostatic transducersParasitic capacitanceEngineering

The invention discloses a microphone polar plate assembly. The microphone polar plate assembly comprises more than two polar plate units, wherein the polar plate units are square and are closely arranged in upward-downward and left-right directions. According to the microphone polar plate assembly, fixing parts for fixing the polar plate units are reduced, and remainders are reduced; meanwhile, the polar plate assembly is cut into single polar plate units by using a cutting tool, so that the operation is simple; and when the polar plate units are matched with diaphragms, the polar plate units are not matched with the diaphragms 3 in a complete overlap manner, so that the parasitic capacitance between the polar plate units and the diaphragms can be reduced.

Owner:GOERTEK INC

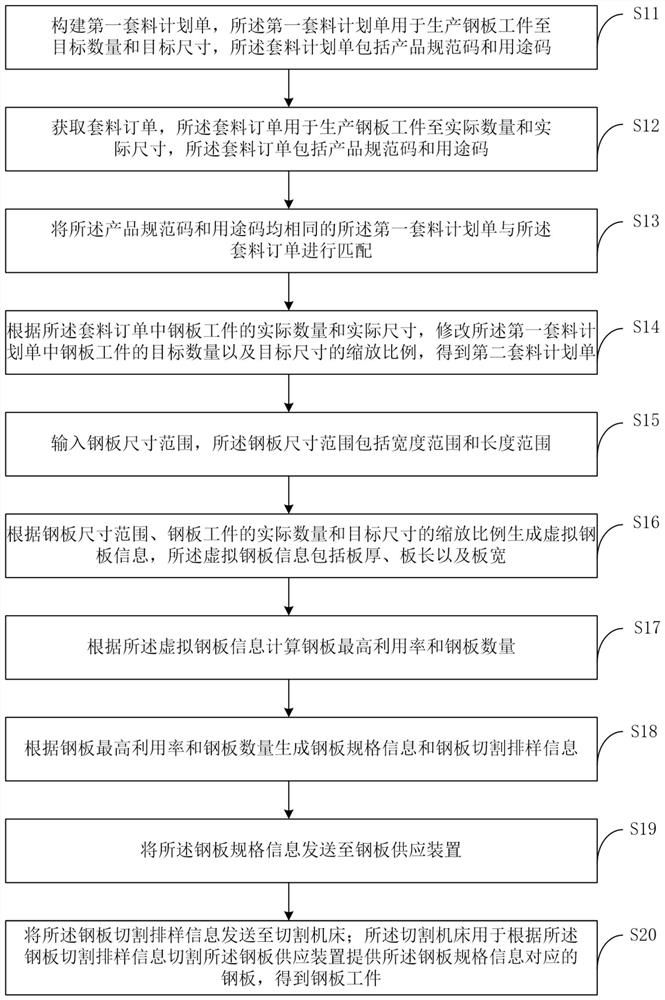

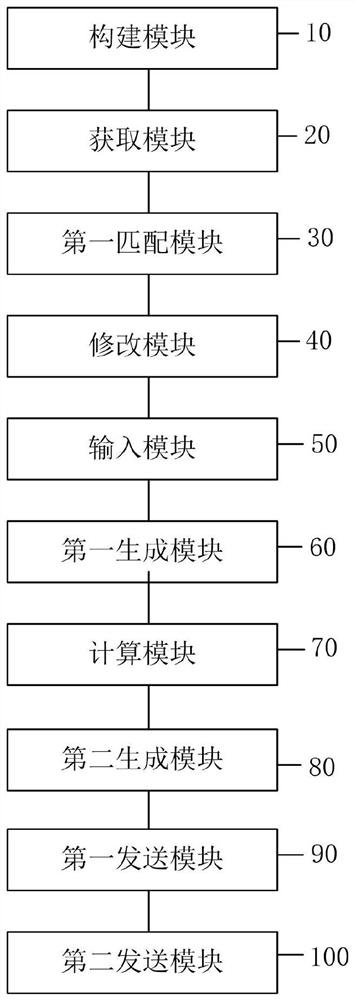

Steel plate workpiece machining method and system

PendingCN112990751AReduce residual materialIncrease profitResourcesOther databases queryingSteel platesStructural engineering

The invention provides a steel plate workpiece machining method and system. The method comprises the following steps: constructing a first nesting plan list; obtaining a nesting order; matching the first nesting plan list with the nesting order; modifying the target number of the steel plate workpieces in the first nesting plan list and the scaling of the target size according to the nesting order; inputting a steel plate size range; generating virtual steel plate information according to the steel plate size range, the actual number of the steel plate workpieces and the scaling of the target size; calculating the steel plate maximum utilization rate and the steel plate number according to the virtual steel plate information; and generating steel plate specification information and steel plate cutting layout information according to the steel plate maximum utilization rate and the steel plate number. A cutting machine tool is used for cutting steel plates provided by a steel plate supply device. By the adoption of the scheme, the size and number of actually-needed steel plates can be calculated according to the trepanning order, the steel plates are purchased according to the actually-needed steel plate size and number, the machining time of steel plate workpieces is saved, excess materials of the steel plates after trepanning are reduced, and the steel plate utilization rate is increased.

Owner:JIANGSU JINHENG INFORMATION TECHNOLOGY CO LTD

Production method for low-weight automotive carpet lower acoustic shock pad

InactiveCN105905016AReduce weightLow costVehicle arrangementsSynthetic resin layered productsThermoplasticCooking & baking

The invention relates to a production method for a low-weight automotive carpet lower acoustic shock pad and belongs to the technical field of automobile part production. The method includes the surface layer laying step, the surface layer baking, warming and softening step, the surface layer adsorption forming step, the surface layer water jet cutter cutting step, the base material laying step, the base material baking and warming step, the compression forming step and the water jet cutter cutting step. The low-weight automotive carpet lower acoustic shock pad produced through the method meets the requirements for the performance indexes such as sound insulation, shock absorption, environmental protection and low weight; the weight of the carpet lower acoustic shock pad is greatly reduced, and the requirement for low weight design of a whole automobile is met; thermoplastic felt is selected, so that the cost of a raw material is reduced, and selectivity is higher; EVA is additionally arranged on part of the surface layer of the felt, so that the product has the beneficial effect of being low in weight, and meanwhile the cost of the material is reduced; in the material processing process, hot air box heating, die cooling and shaping and water jet cutter cutting are adopted, the technology is stable, the safety and accuracy of operation are guaranteed, and meanwhile the operation efficiency is improved; the redundant material of the product is small; the manufacturing cost is saved; and no harmful substances are generated in the whole production process of the product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Large-line discharging method

InactiveCN107578144AEfficient use ofIncrease profitResourcesManufacturing computing systemsDatabase analysisProcess design

The invention provides a large-line discharging method. According to the method, a high-efficiency discharging algorithm is adopted and the optimal utilization of the large-line material discharging technology and cables is realized. Therefore, the amount of residual materials is ensured to be minimum. The remote transmission and control of the technical data of the process design and data betweenlarge-line automatic blanking equipment are realized by utilizing the database analysis and sharing technology. Therefore, the utilization rate and the production efficiency of raw materials are improved, and the cost is saved.

Owner:CRRC QINGDAO SIFANG CO LTD

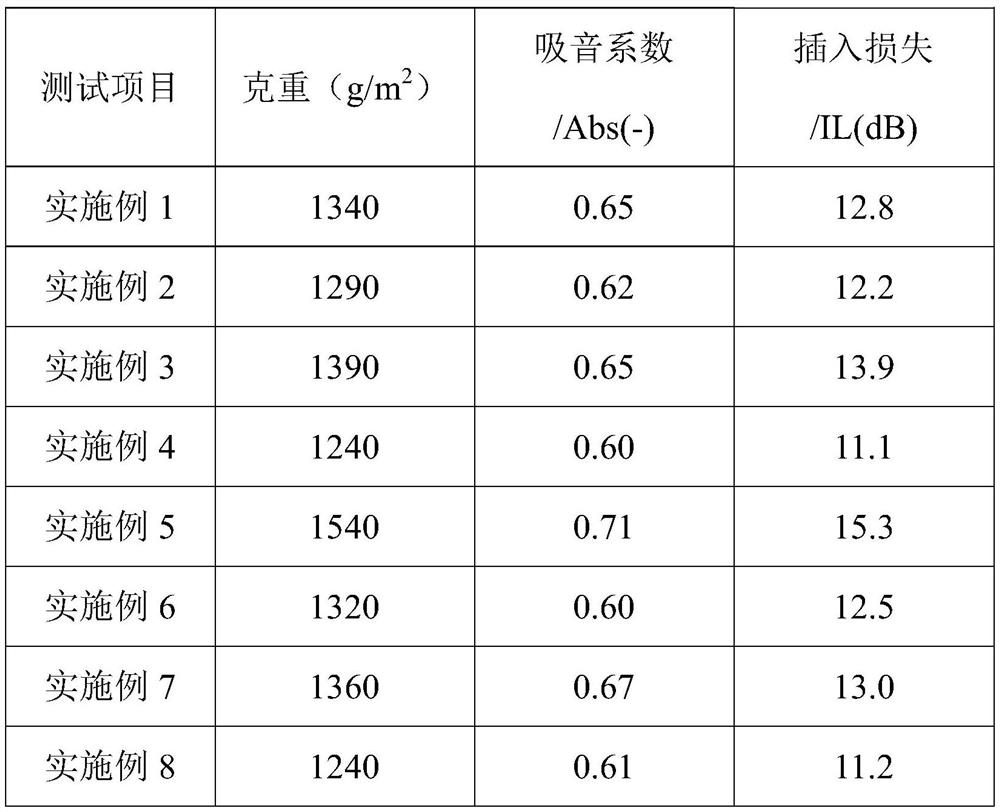

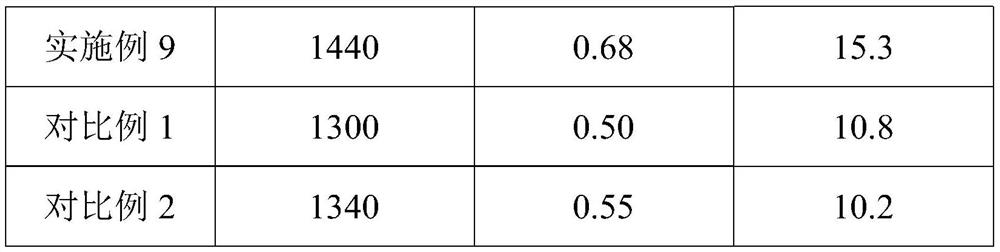

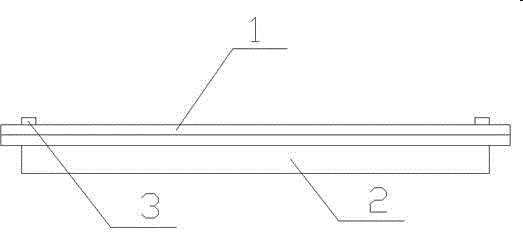

High-sound-insulation carpet as well as preparation method and application thereof

InactiveCN111844993ALose weightLow costVehicle arrangementsLamination ancillary operationsAcousticsMechanical engineering

The invention provides a high-sound-insulation carpet as well as a preparation method and application thereof. The high-sound-insulation carpet comprises a surface carpet layer, a heavy coating and athermoplastic respun cotton layer which are sequentially stacked. On the basis of reducing the gram weight and the cost of the carpet, the sound absorption and sound insulation performance of the carpet with high sound insulation performance can still be effectively improved.

Owner:WUXI GISSING AUTO PARTS CO LTD

Novel limiting frame for mounting precipitating-preventing rainwater strainer and construction method of novel limiting frame

InactiveCN106436875AReasonable structural designEasy to installSewerage structuresArchitectural engineeringAsphalt pavement

The invention discloses a novel limiting frame for mounting a precipitating-preventing rainwater strainer and a construction method of the novel limiting frame. The novel limiting frame comprises a panel and a frame body, wherein the frame body is fixed below the panel, the panel and the frame body are rectangular, and the size of the frame body is smaller than that of the panel. During construction, the limiting frame is coated with diesel oil, so that the pitch adhesion during asphalt pavement can be avoided, therefore, the waste of the asphalt material can be reduced, the cost can be saved, the construction efficiency can be improved, the waste of labor force can be reduced, and the mounting quality of the precipitating-preventing rainwater strainer is improved.

Owner:JINAN URBAN CONSTR GRP

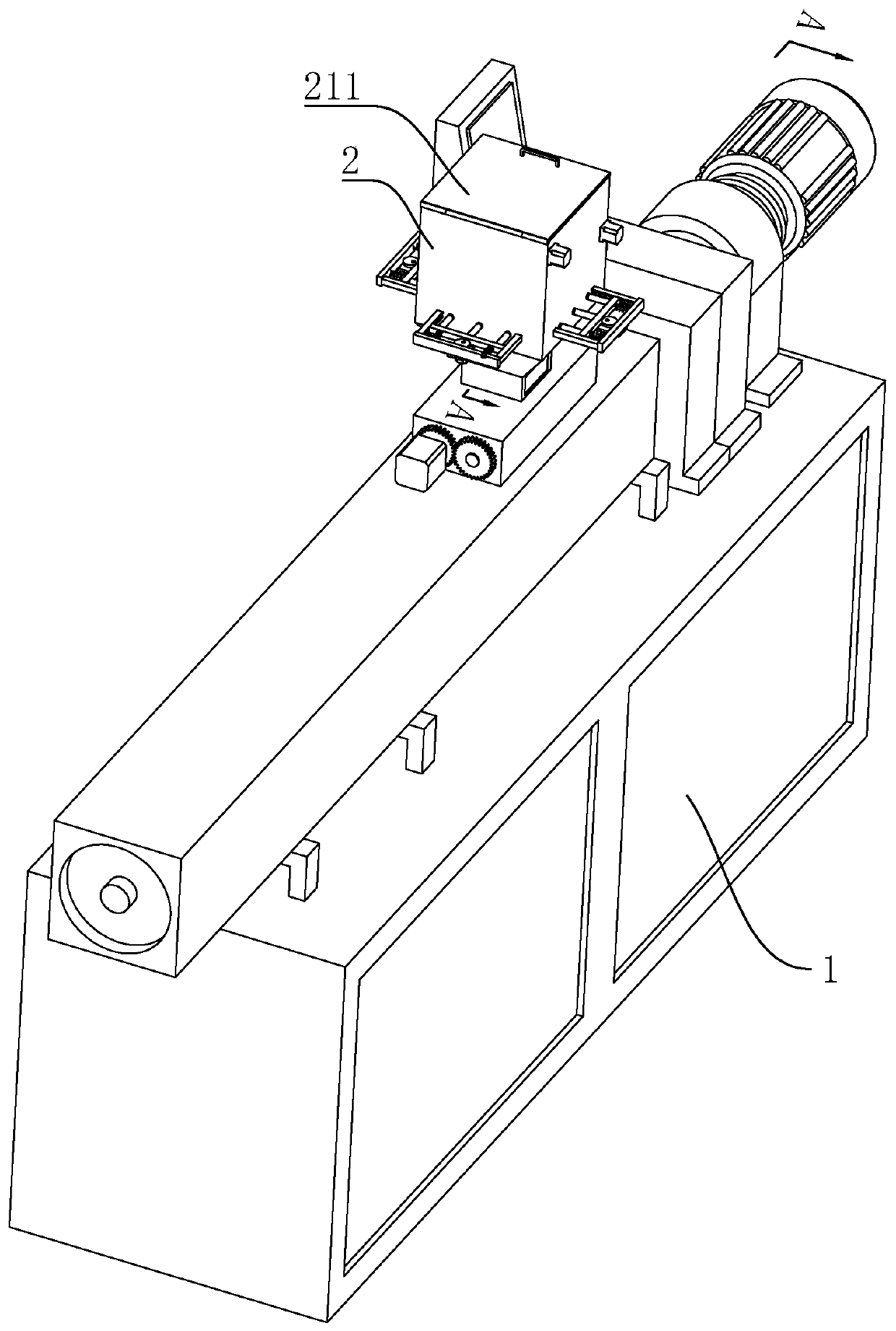

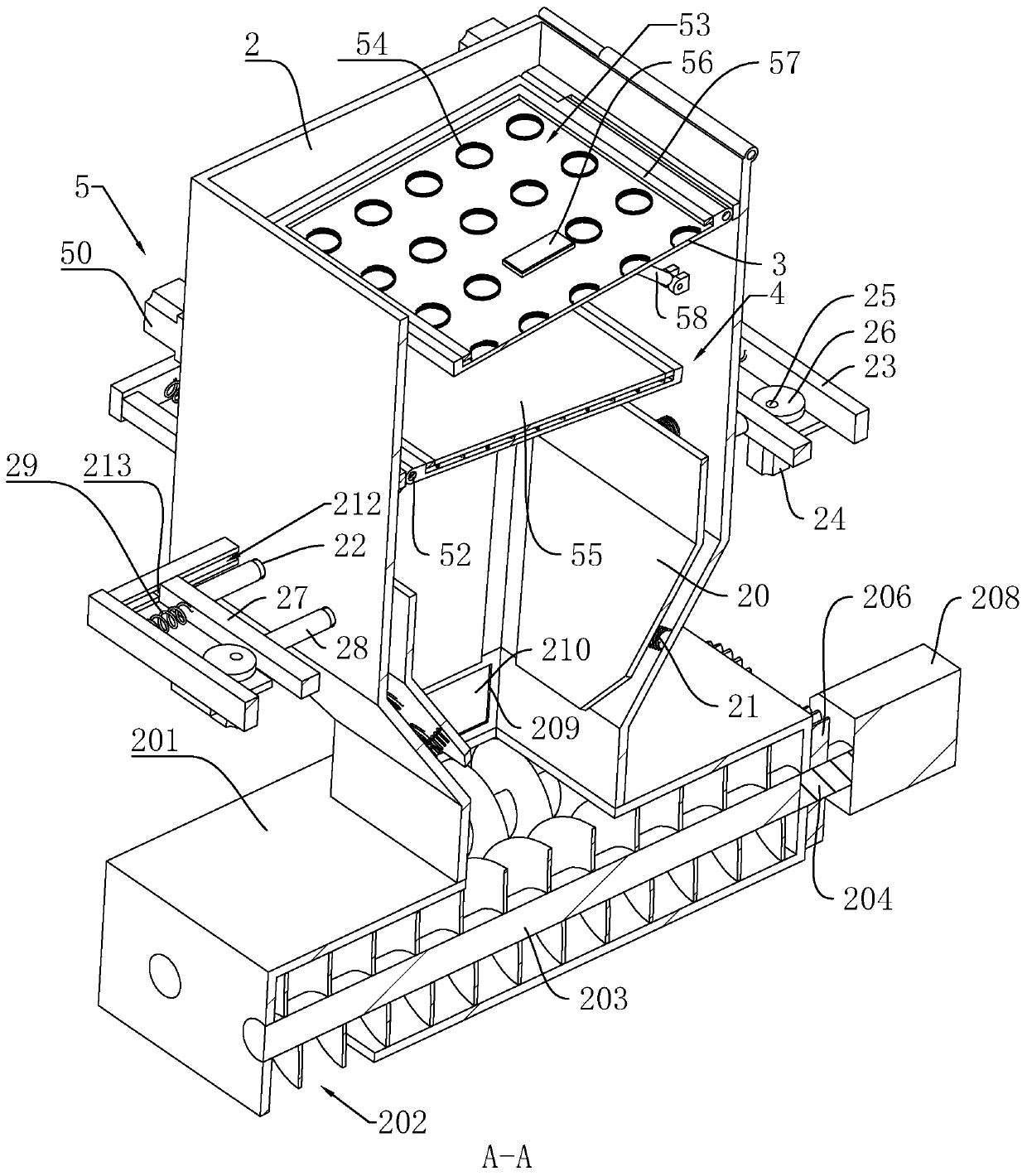

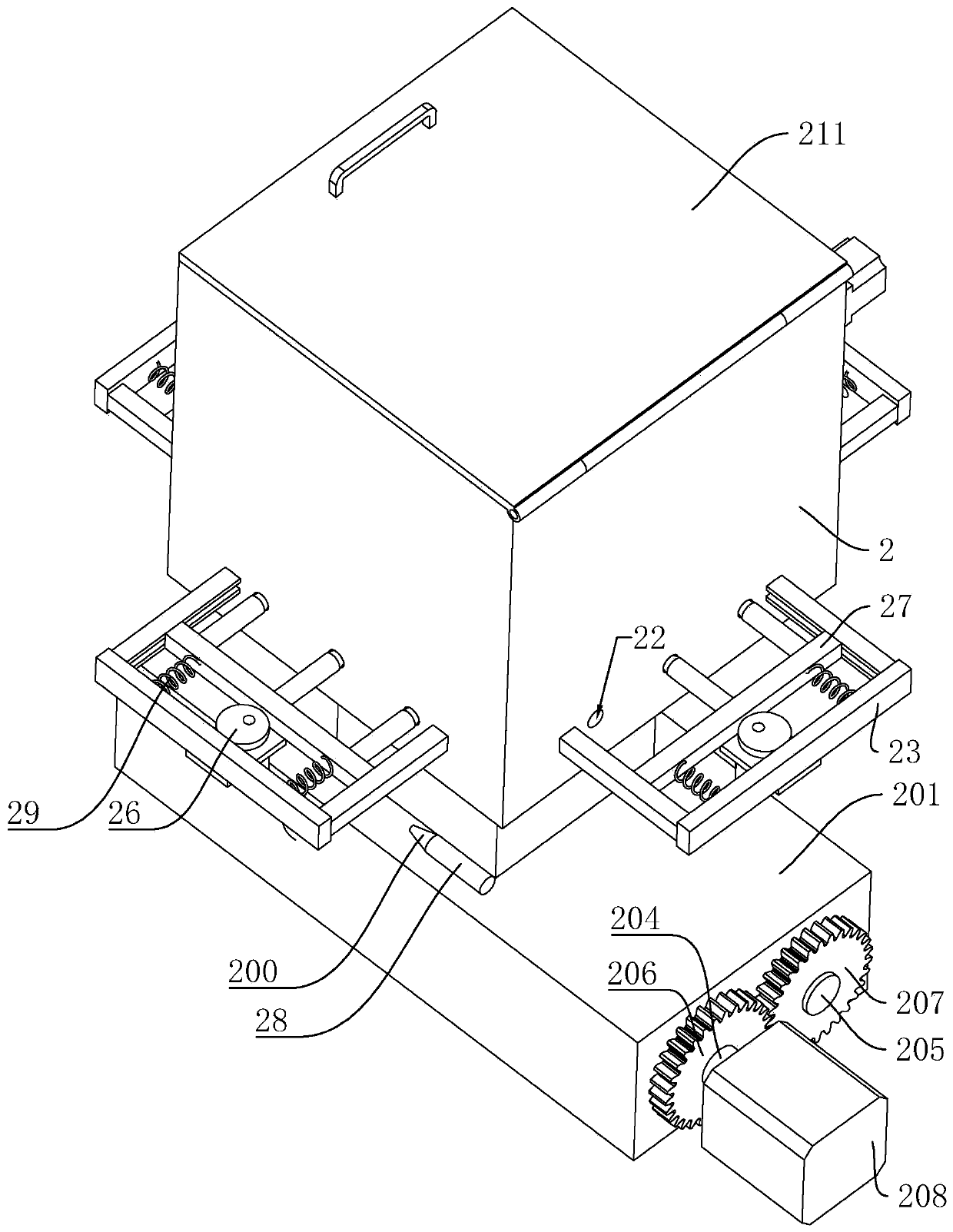

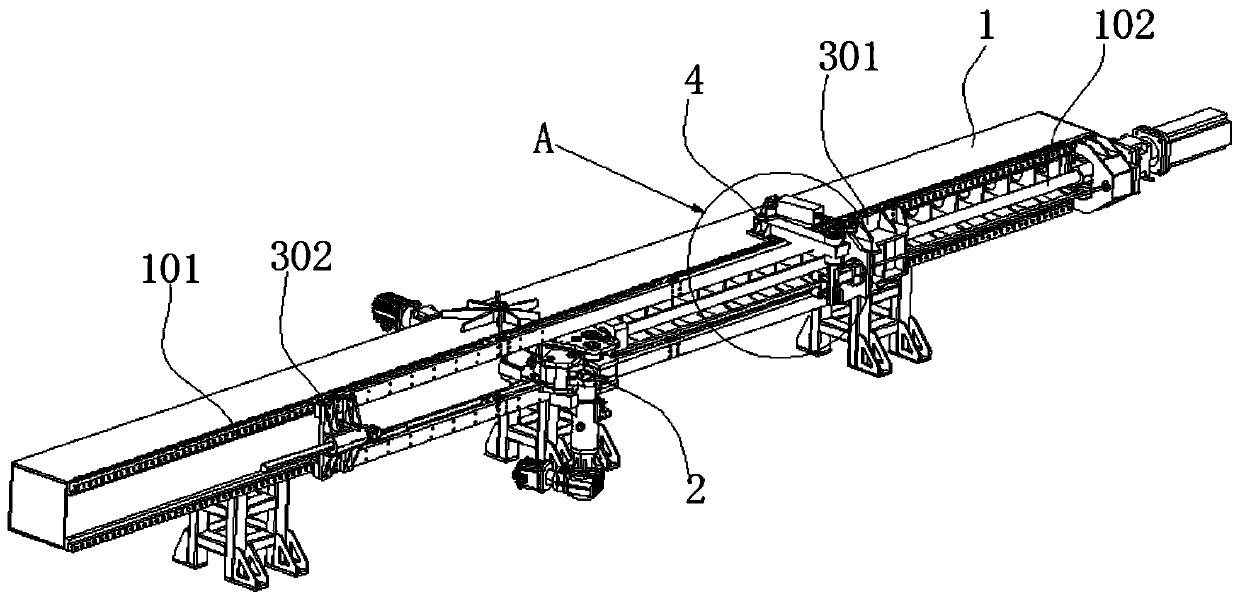

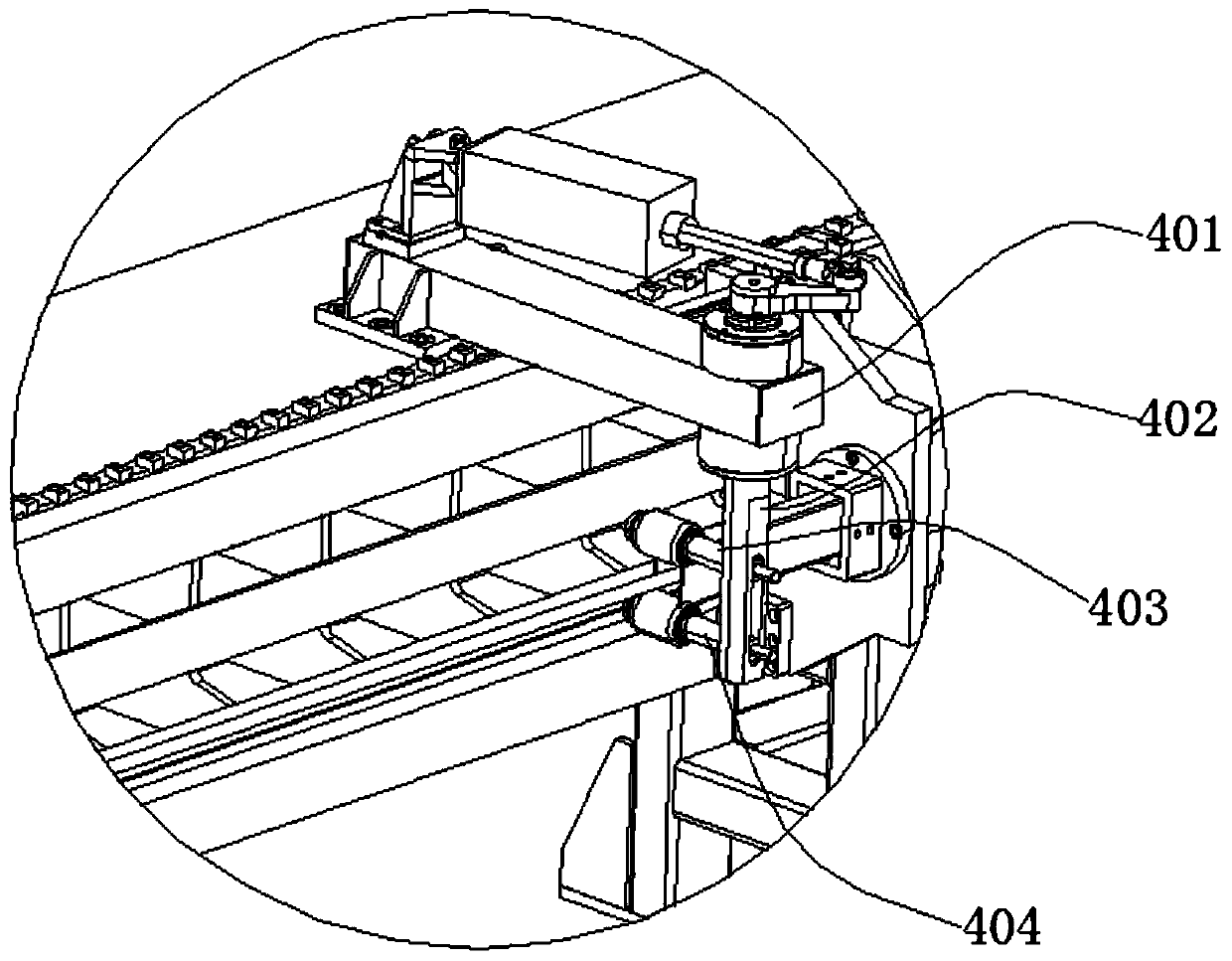

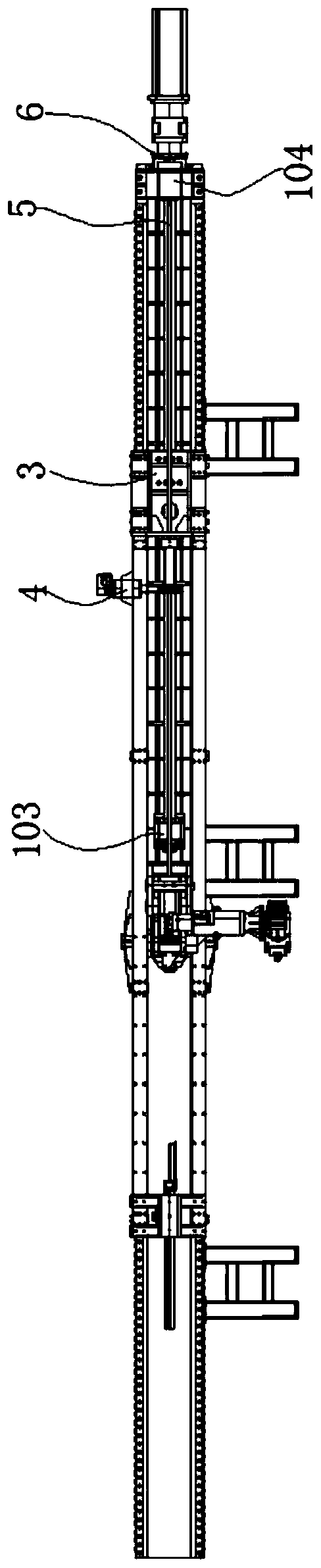

Pipe bending device and use method for same

ActiveCN109772964AReduce residual materialReduce manufacturing costMetal-working feeding devicesMetal working apparatusEngineeringProcessing accuracy

The invention discloses a pipe bending device and a use method for the same and belongs to the technical field of pipe bending machines. The pipe bending device comprises a rack, a fixation base, a pipe material channel, a fixation part, a first bending wheel and a second bending wheel, wherein the fixation base is installed on the side face of the rack; the fixation base comprises a top cover anda bottom cover; the fixation part is located between the top cover and the bottom cover; the fixation part is used to fix a pipe material and the pipe material channel is a channel disposed in the fixation part; the first bending wheel is located at an exit of the pipe material channel, and the second bending wheel is located on the side remote from the rack and inclined to a material ejection mechanism; and the first bending wheel is used to bend the pipe material horizontally and the second bending wheel is used to bend the pipe material vertically. The pipe bending device disclosed by theinvention has the advantages that bending can be realized on an X axis and a Z axis simultaneously; and processing accuracy is increased. In addition, the invention discloses the use method for the device. The method has the advantages that operations are simple; reliability is high, etc.

Owner:ANHUI DEXI DHI TECH

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com