Method for producing curved article and skeleton structure member for automobile body shell

一种制造方法、零部件的技术,应用在骨架结构构件领域,能够解决未公开制造等问题,达到减小余料、防止褶皱、改善材料利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention is described with reference to the drawings.

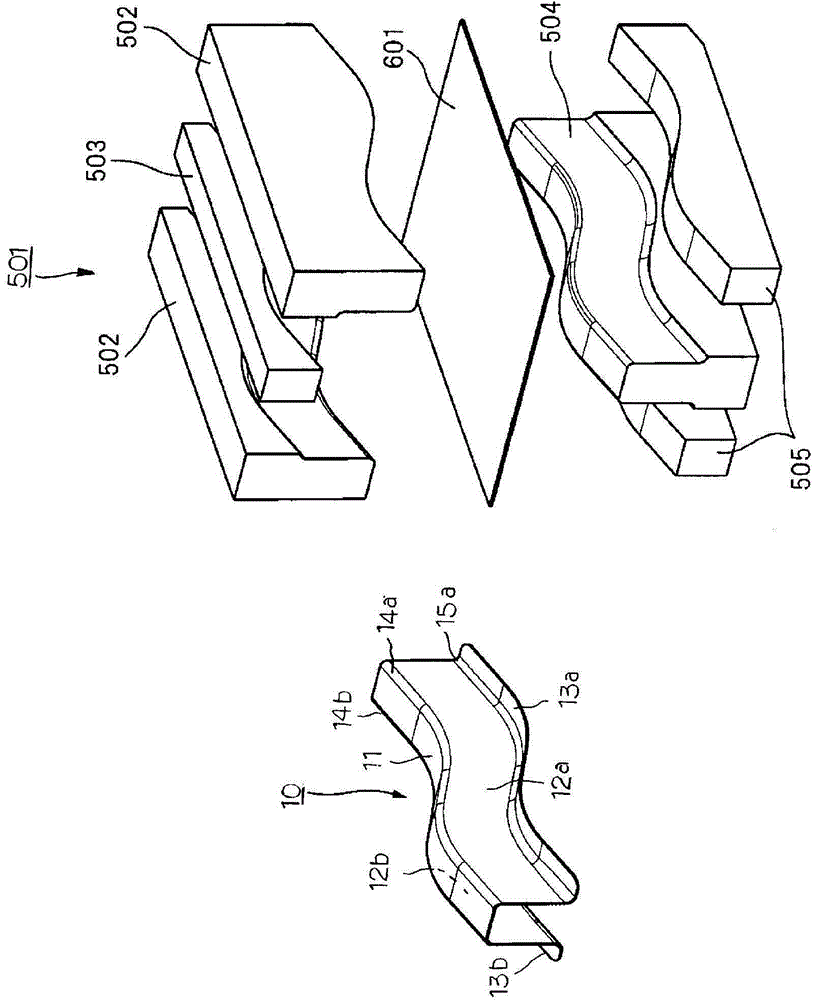

[0108] With the present invention it is possible to produce Figure 18A ~ Figure 18E The curved part 10 is shown.

[0109] Such as Figure 18A ~ Figure 18E As shown, the curved parts 10 are made of a top plate 11, longitudinal walls 12a, 12b, and outward flanges 13a, 13b, wherein the longitudinal walls 12a, 12b are connected to the two sides of the top plate 11 respectively, and the outward flanges 13a, 13b are connected to the two sides of the top plate 11. The ends of the vertical walls 12a and 12b on the side opposite to the top plate 11 are connected to each other, and extend in a direction opposite to the top plate 11, and the curved member 10 has a hat-shaped cross-sectional shape.

[0110] Ridge lines 14a, 14b are formed between the top plate 11 and the vertical walls 12a, 12b. Further, concave lines 15a, 15b are formed between the vertical walls 12a, 12b and the outward flanges 13a, 13b. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com