Method for automatically adjusting powder supplying amount of metal 3D printing machine

A 3D printer, automatic adjustment technology, applied in the direction of improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of insufficient powder supply and large volume of residual materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

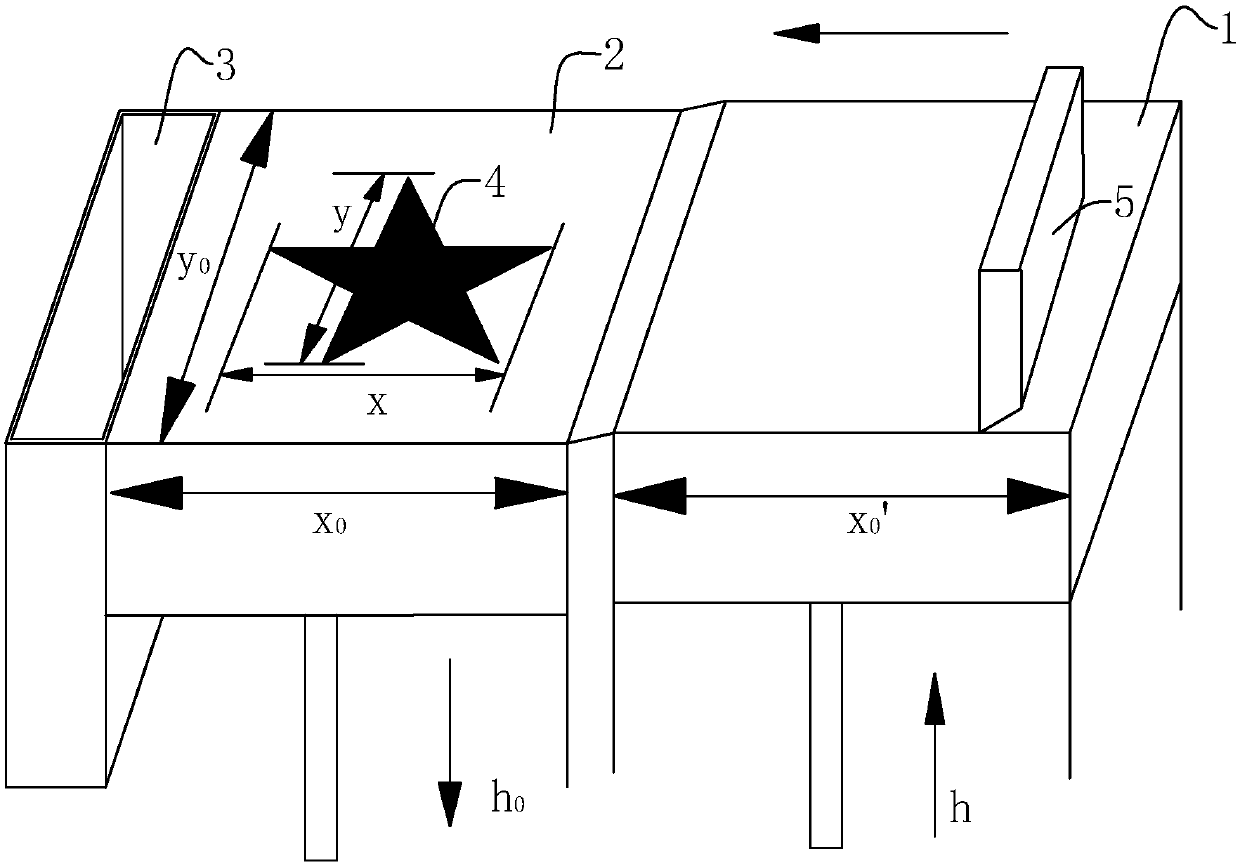

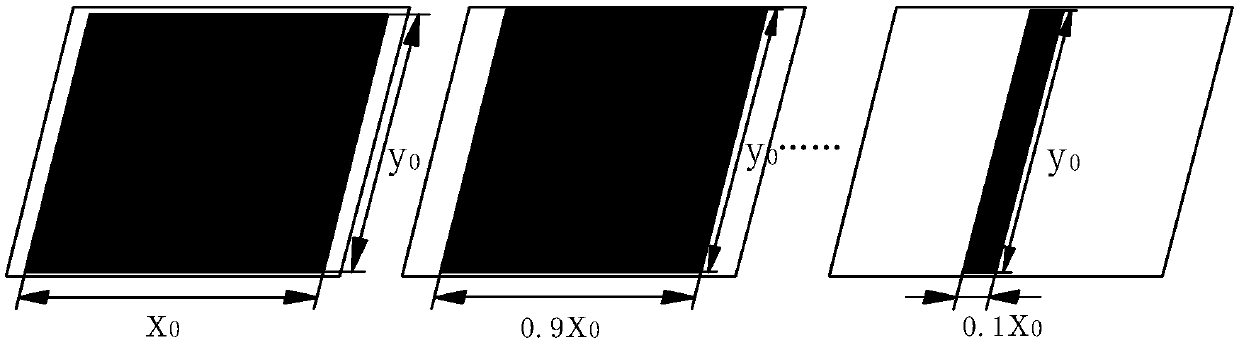

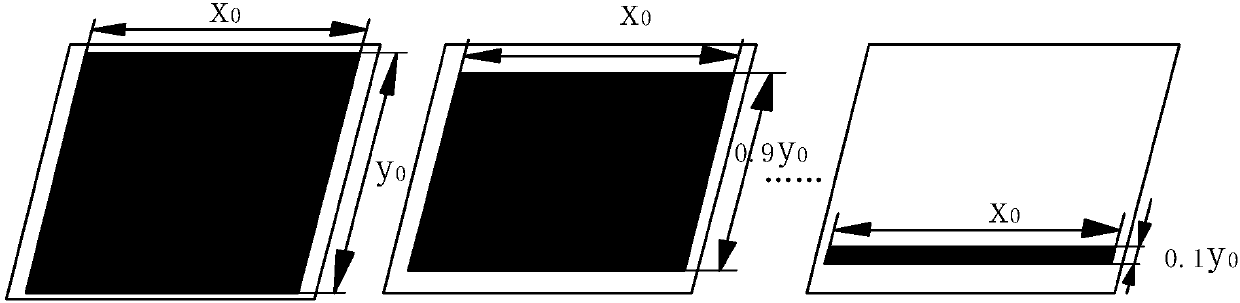

[0079] first according to Figures 1 to 3 The 3D printing process and the derivation process of the powder supply height calculation formula are described.

[0080] Such as figure 1 As shown in , the forming platform of the 3D printing equipment includes a powder supply cylinder 1, a forming cylinder 2, a residual material collection box 3, and a powder spreading scraper 5 for feeding and spreading powder. During printing, the powder supply cylinder 1 rises for a distance of h to supply powder, and the forming cylinder 2 descends for a thickness h of the current printing layer 0 , the powder spreading scraper 5 pushes the powder with a thickness of the actual powder supply height h to the molding cylinder 2 along the direction from the powder supply cylinder 1 to the residual material collection box 3, and the powder passing through the part 4 forms a metal entity, and the residual material is continuously moved The powder spreading scraper 5 is pushed into the surplus mater...

Embodiment 2

[0103] Such as Figure 5 Shown in, its difference with embodiment 1 is: in steps S1 and S3, increase read parameter x0 and x, and with reference to formula (3): Calculate the optimum toner supply height h of the current printing layer.

[0104] It should be pointed out that no matter it is embodiment 1 or 2, only the influence of the contour shape of the part 4 during the printing process on the toner supply height is considered, but, in actual printing, the operator's operation during the printing process and during the printing process The previous treatment of the powder in the powder supply tank 1 (for example, whether it is dried or not) will affect the value of the powder supply height h to a certain extent. Therefore, before the calculation formula is multiplied by a correction factor A, its value should be 0.9 To 1.5, to adapt to the current operation and further adjust the powder supply height h value.

[0105] During the 3D printing process, the amount of remainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correction factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com