Patents

Literature

53results about How to "Reduce the number of feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

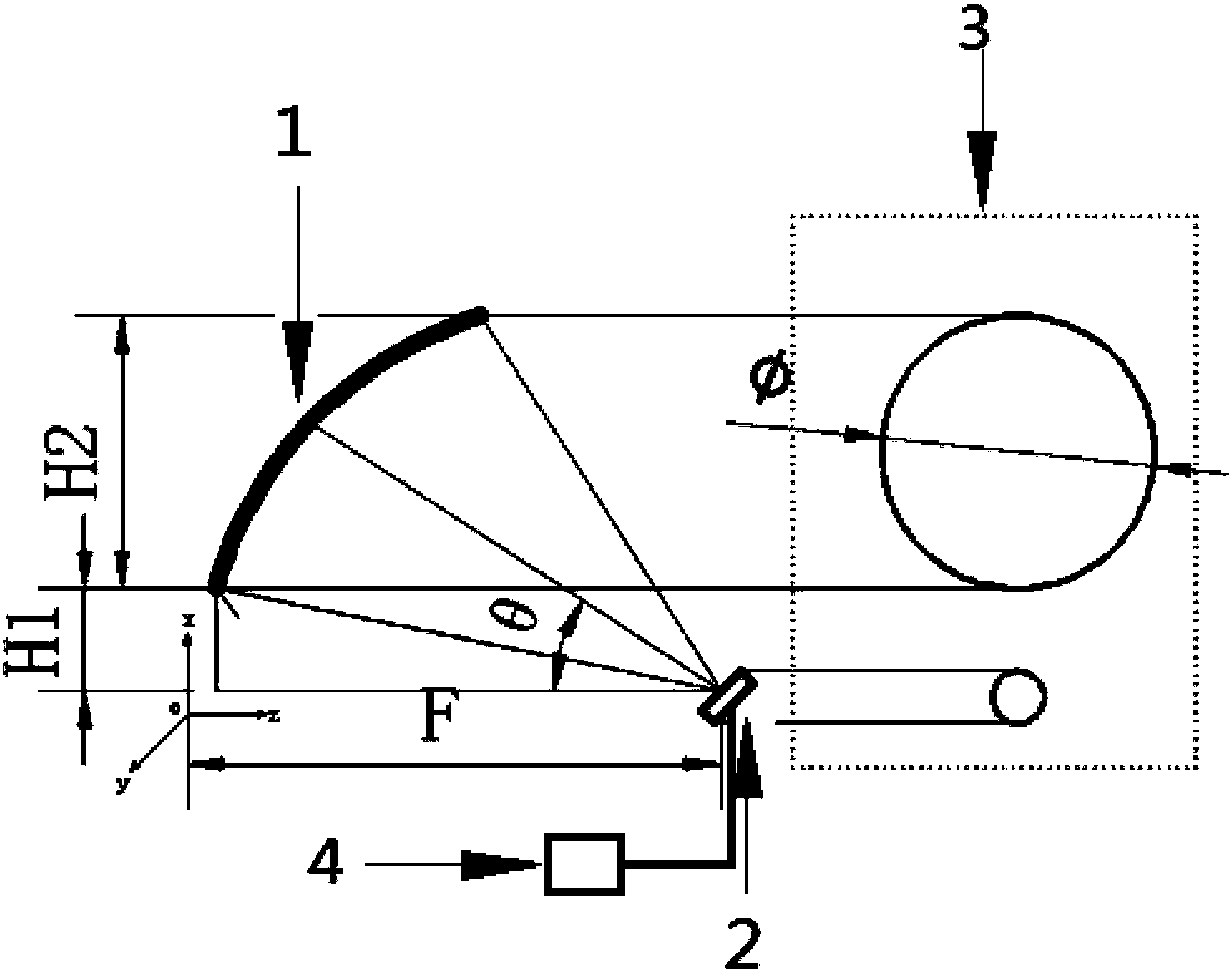

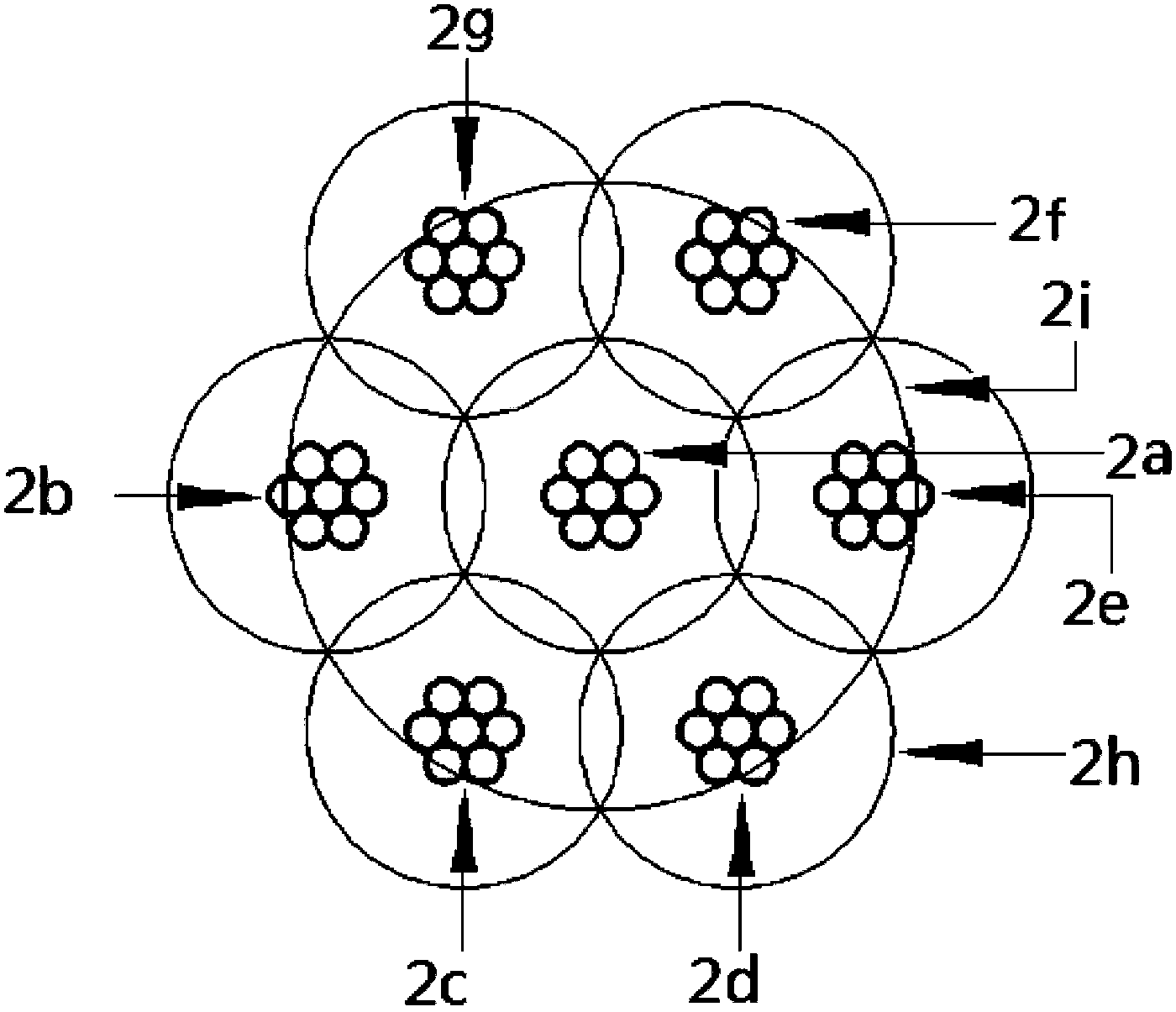

Satellite-borne sparse phased-array multi-beam antenna with reflector

InactiveCN103022699ASmall gain changeImprove radiation efficiencyAntenna arraysPhase controlControl circuit

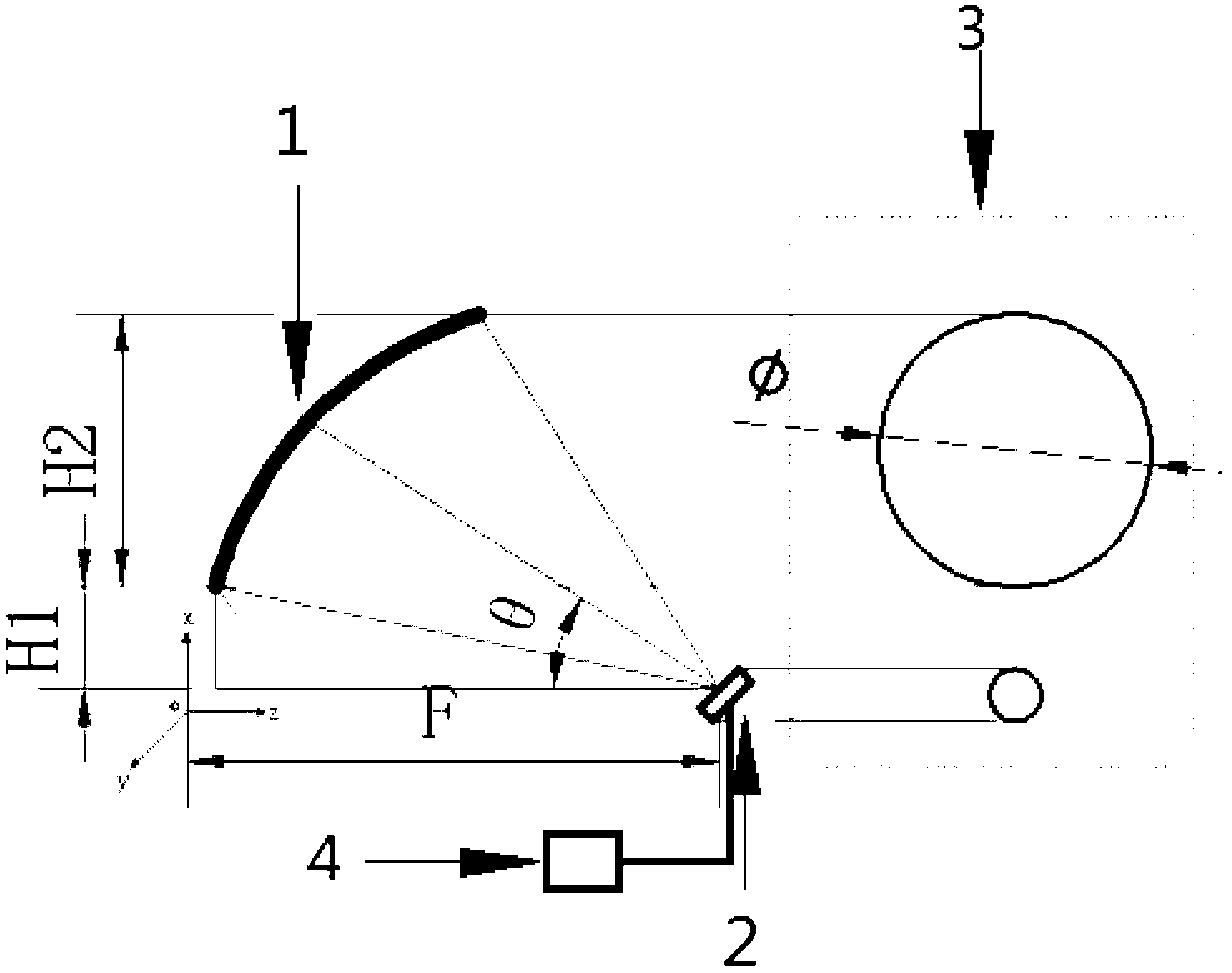

The invention relates to a satellite-borne sparse phased-array multi-beam antenna with a reflector, and belongs to the technical field of antennas. The satellite-borne sparse phased-array multi-beam antenna comprises the offset parabolic reflector, a feed source array and a master control circuit. The feed amplitude and phase of the feed source array are controlled by the master control circuit, and electromagnetic waves radiated by the feed source array are converged via the offset parabolic reflector and then are radiated to space. The quantity of required feed source units of the antenna is low, beams can be subjected to phase control, and the satellite-borne sparse phased-array multi-beam antenna can be widely applied to satellite-borne communication, detection and positioning systems.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

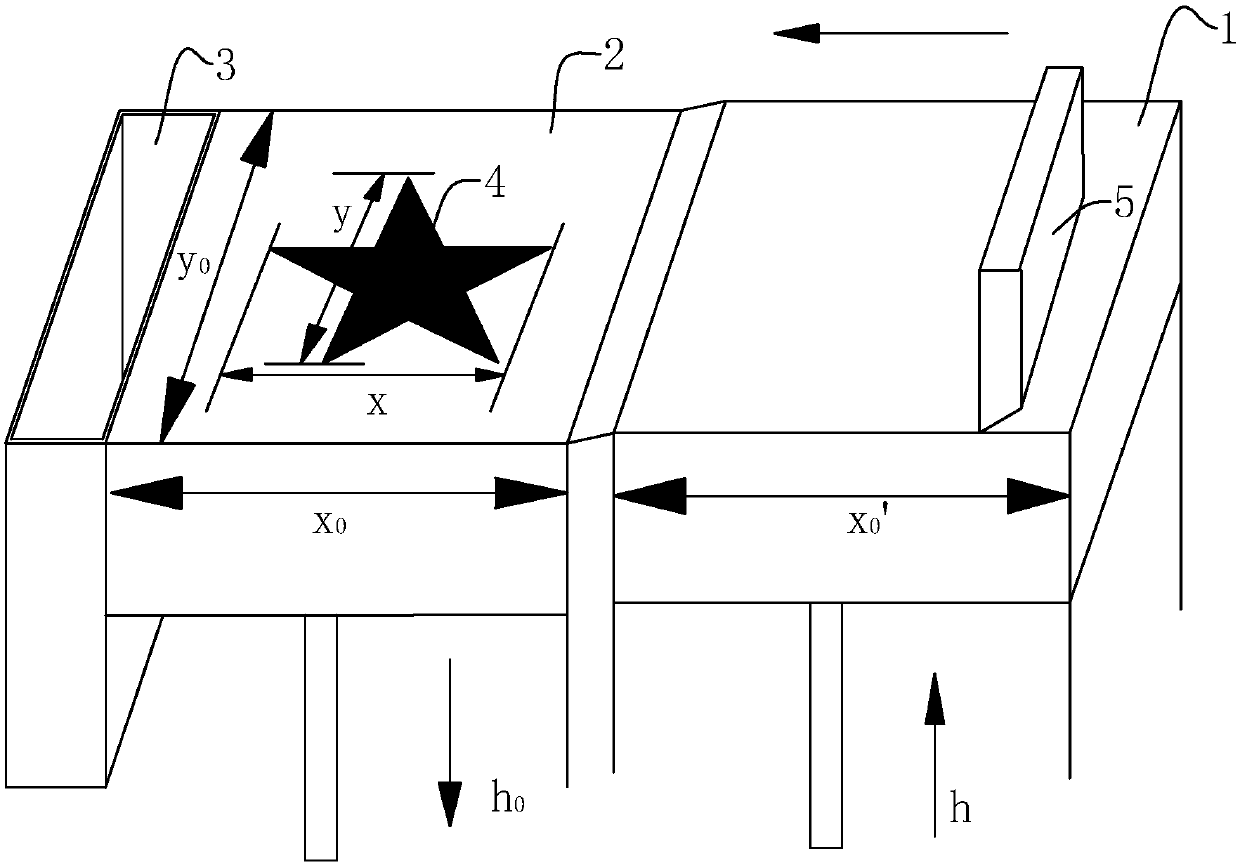

Method for automatically adjusting powder supplying amount of metal 3D printing machine

ActiveCN107774994AReduced powder supply balanceAvoid molding failureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLayer thickness

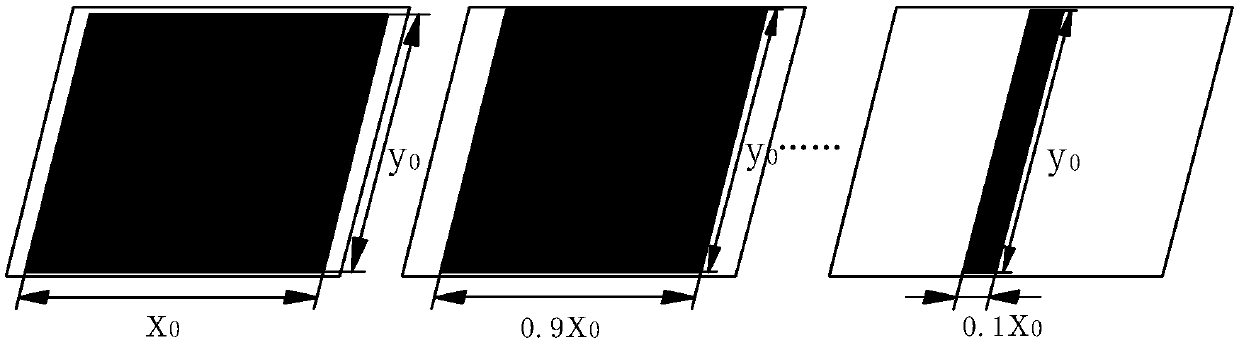

The invention discloses a formula for automatically adjusting the powder supplying height of a metal 3D printing machine. The formula includes the following steps that S1, the size parameters x0 and y0 of a forming cylinder and the size parameter x0' of a powder supplying cylinder are input; S2, the values of x and y are obtained and input according to the contour of a current printing layer; S3,the layer thickness h0 of the current printing layer is obtained; S4, the powder supplying height is changed in real time according to the formula (please see the formula in the specifications); and S5, when the S1, the S2, the S3 and the S4 are conducted for the fifteenth time, the coefficient A is multiplied before the current powder supplying height calculating formula according to the waste material amount in a waste material collecting box, the value ranges from 0.9 to 1.5, and the powder supplying height is increased or reduced according to the waste material amount. The powder supplyingheight of the current printing layer can be dynamically adjusted in real time according to the part section area, the part placing position, the powder batch, the powder density changes in the forming cylinder and the powder supplying cylinder and changes of operators and other factors, and therefore the size of waste materials can be minimized on the premise that powder is fully spread on the current printing layer.

Owner:BEIJING E PLUS 3D TECH CO LTD

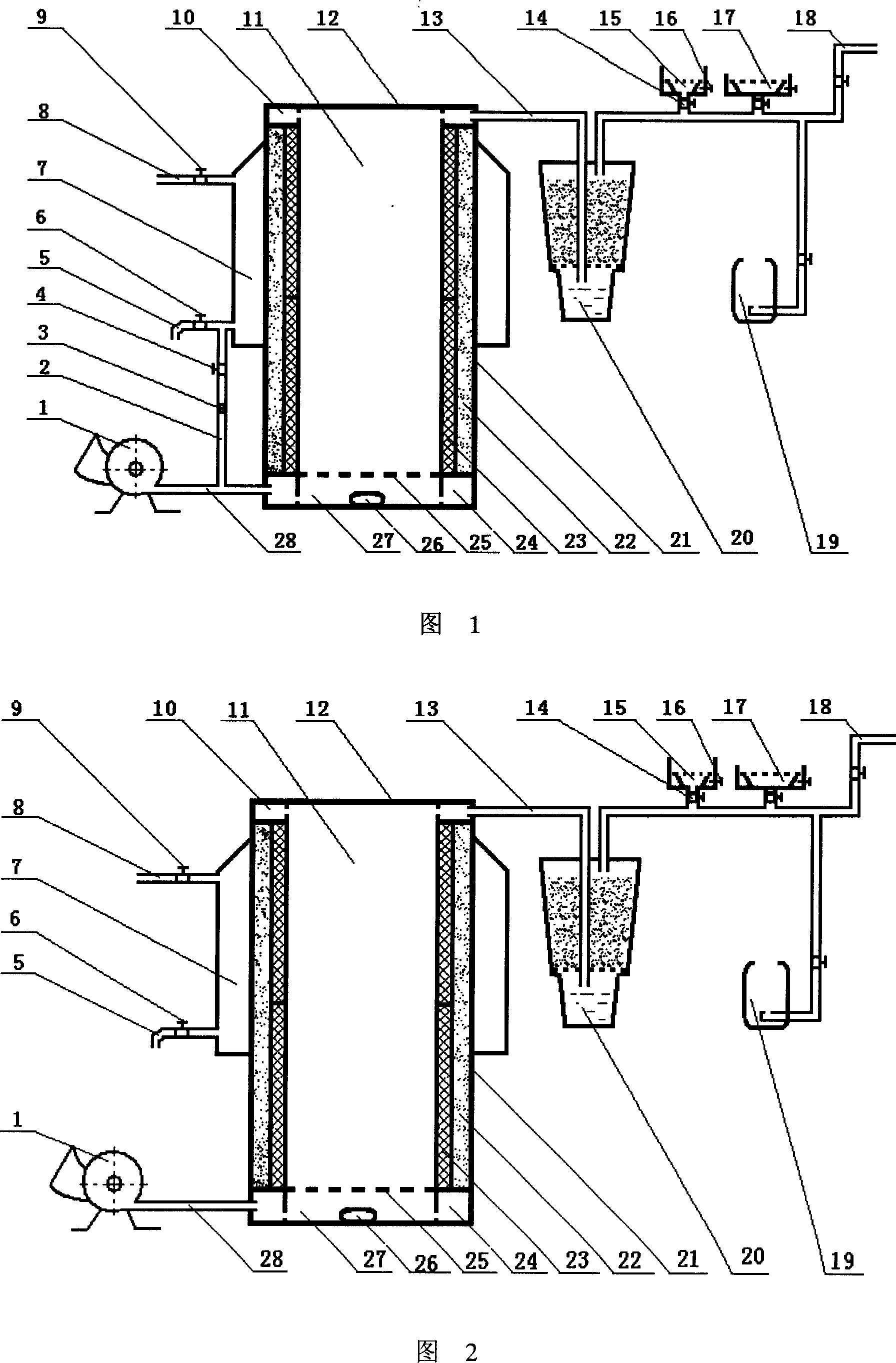

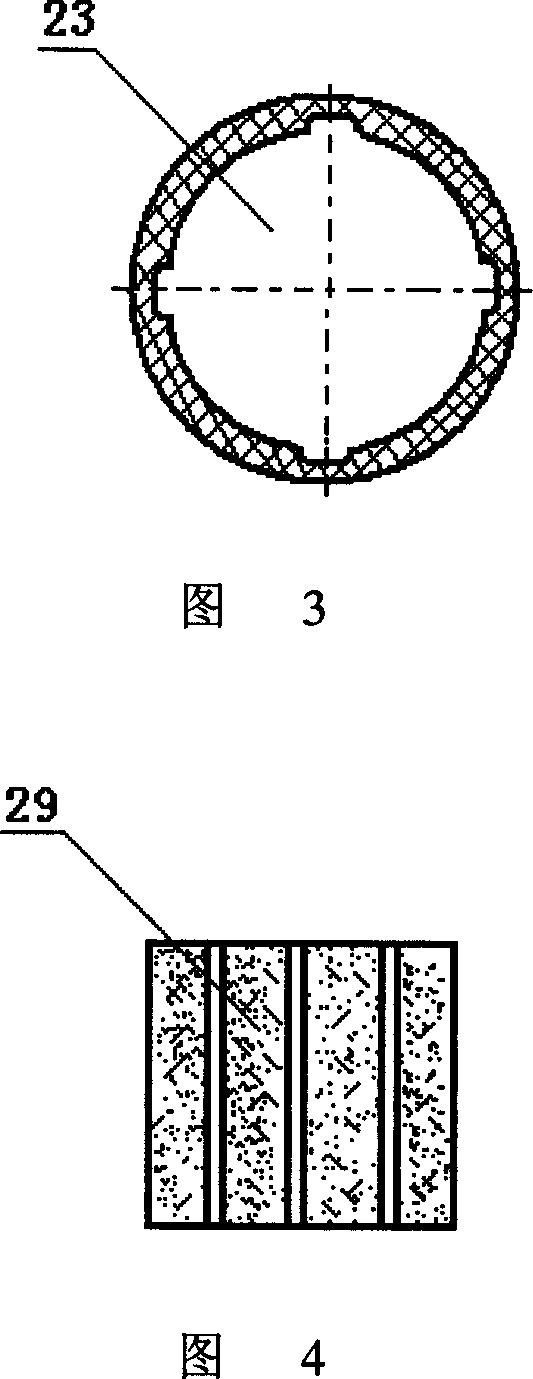

Padder used for dyeing and finishing

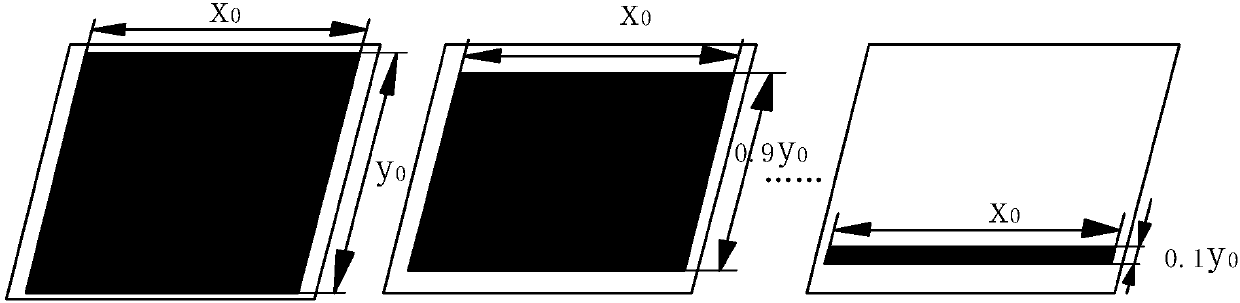

InactiveCN105369498AAchieve recyclingAutomatic replenishment in timeLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPulp and paper industryTextile dye

The invention discloses a padder used for dyeing and finishing. The padder comprises a cabinet, a dye liquor tank, double rollers, cloth guide rollers, and a controller. The double rollers are fixed in the cabinet. A diversion channel is arranged under the double rollers. The lower end of the diversion channel is connected with the dye liquor tank. The dye liquor tank is internally provided with a sensor. The sensor is electrically connected with the controller. The dye liquor tank is connected with a dye liquor cylinder. The dye liquor cylinder is internally provided with a liquid inlet relay. The liquid inlet relay is also electrically connected with the controller. Through the diversion channel, dye liquor can be recycled to the dye liquor tank, thereby reducing wastage of the dye liquor, reducing dye liquor adding times, and saving energy. The sensor in the dye liquor tank can realize automatic dye liquor adding.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

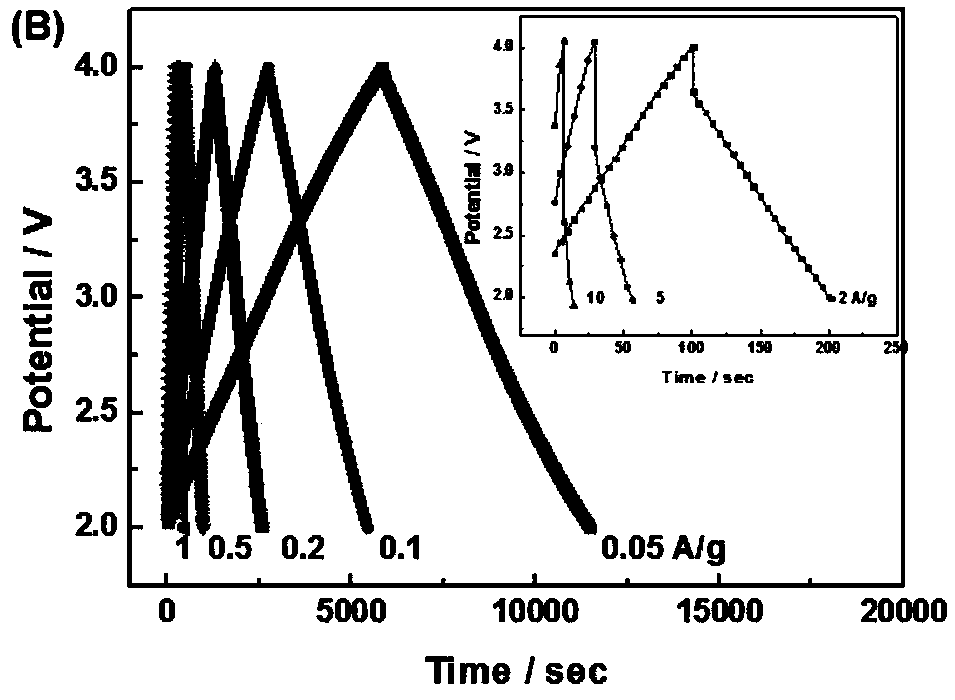

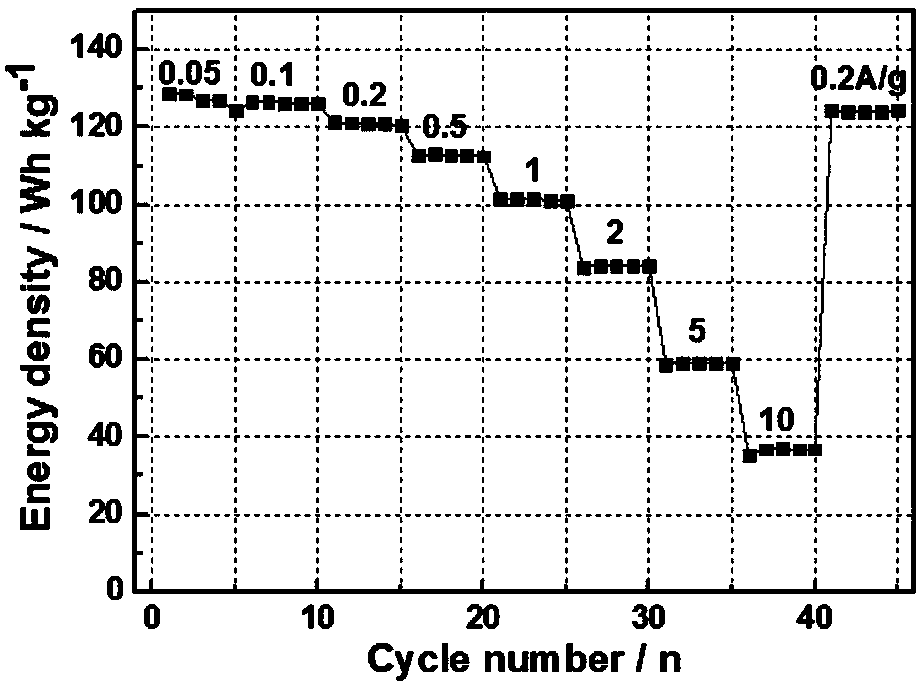

Dry slurry material preparation technology

InactiveCN108636145AReduced batching cycle timeIncrease productivityElectrode manufacturing processesRotary stirring mixersMaterials preparationLow speed

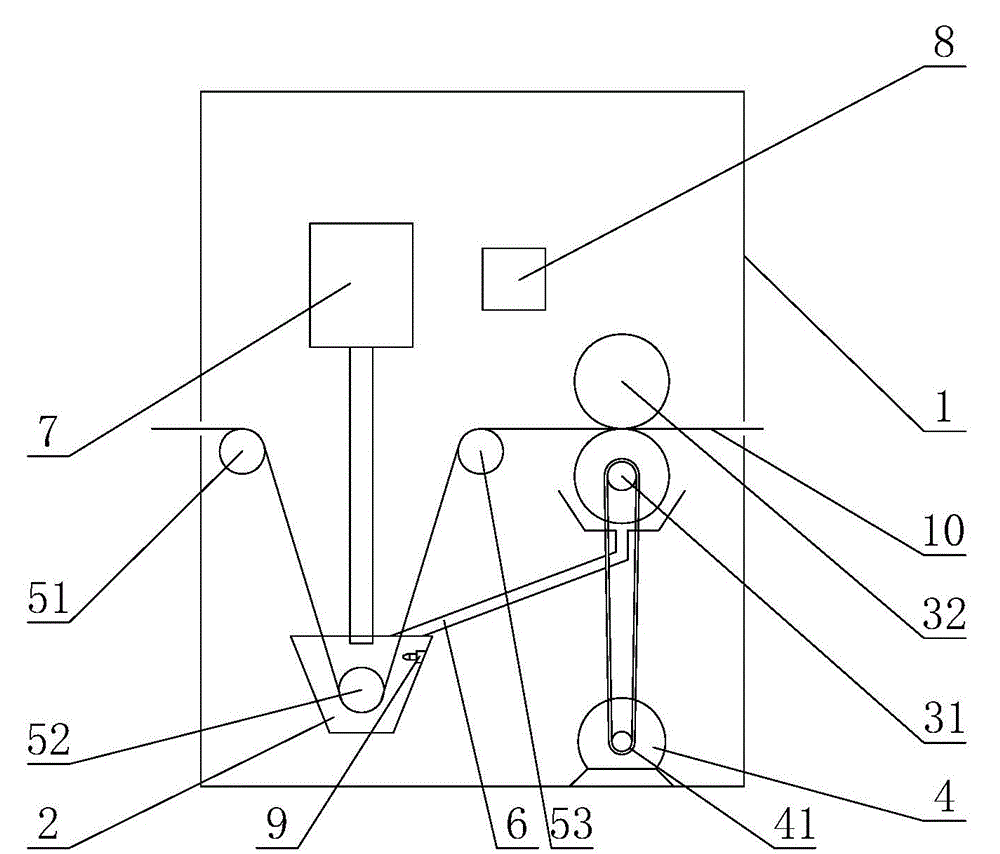

The invention discloses a dry slurry material preparation technology. The dry slurry material preparation technology comprises the following steps: a, mixing dry powders, namely adding active materials, a conducting agent and an adhesive-bonding agent into a material agitator, and carrying out medium-speed agitating for 25-45 minutes, wherein the temperature of the powder materials is controlled at 15-30 DEG C during the whole dry-agitating process; b, kneading slurry materials, namely (1) adding a solvent and carrying out agitating at a low speed for 2-5 minutes, (2) carrying out agitating ata medium-low speed for 2-5 minutes, (3) carrying out agitating at a medium speed for 15-30 minutes and (4) carrying out wall-scraping agitating at high speed for 40-50 minutes, wherein the material temperature is controlled at 15-30 DEG C during the whole kneading and agitating process of the slurry material; c, carrying out high-viscosity agitating, namely scraping the wall, adding a solvent, and carrying out high-speed agitating for 40-45 minutes, wherein the temperature of the slurry material is controlled within the range of 25-35 DEG C; d, carrying out low-viscosity agitating, namely scraping the wall, adding a solvent, and carrying out medium-speed agitating for 60-70 minutes, wherein the temperature of the slurry material is controlled within the range of 30-45 DEG C; and e, adjusting viscosity, namely adding a solvent, and carrying out medium-speed agitating for 30-32 minutes, wherein the temperature of the slurry material is controlled within the range of 30-45 DEG C. Compared with existing technologies, the dry slurry material preparation technology is capable of shortening the time of the material-blending cycle by 40-50%; and thus, material-blending operations are simplified so as to improve production efficiency and equipment utilization rate.

Owner:广州云通锂电池股份有限公司

Preparation method of carbon aerogel, carbon aerogel and lithium ion capacitor prepared from same

ActiveCN107680833ARich sourcesLow costHybrid capacitor electrodesDouble layer capacitorsFreeze-dryingWater soluble

A preparation method of carbon aerogel comprises the following steps: (1) dissolving lignin powder in alkali lye, ultrasonically dispersing the lignin powder, and adding water-soluble polymer to the alkali lye to form gel; (2) adding ferrite to the gel obtained in step (1), ultrasonically dispersing the ferrite, and obtaining a carbon aerogel precursor by freeze drying; and (3) carrying out high-temperature carbonizing, pickling, suction filtering and drying on the carbon aerogel precursor obtained in step (2) to obtain carbon aerogel. The carbon aerogel prepared in the invention has large specific surface area, high mesoporous capacity and high conductivity.

Owner:CENT SOUTH UNIV

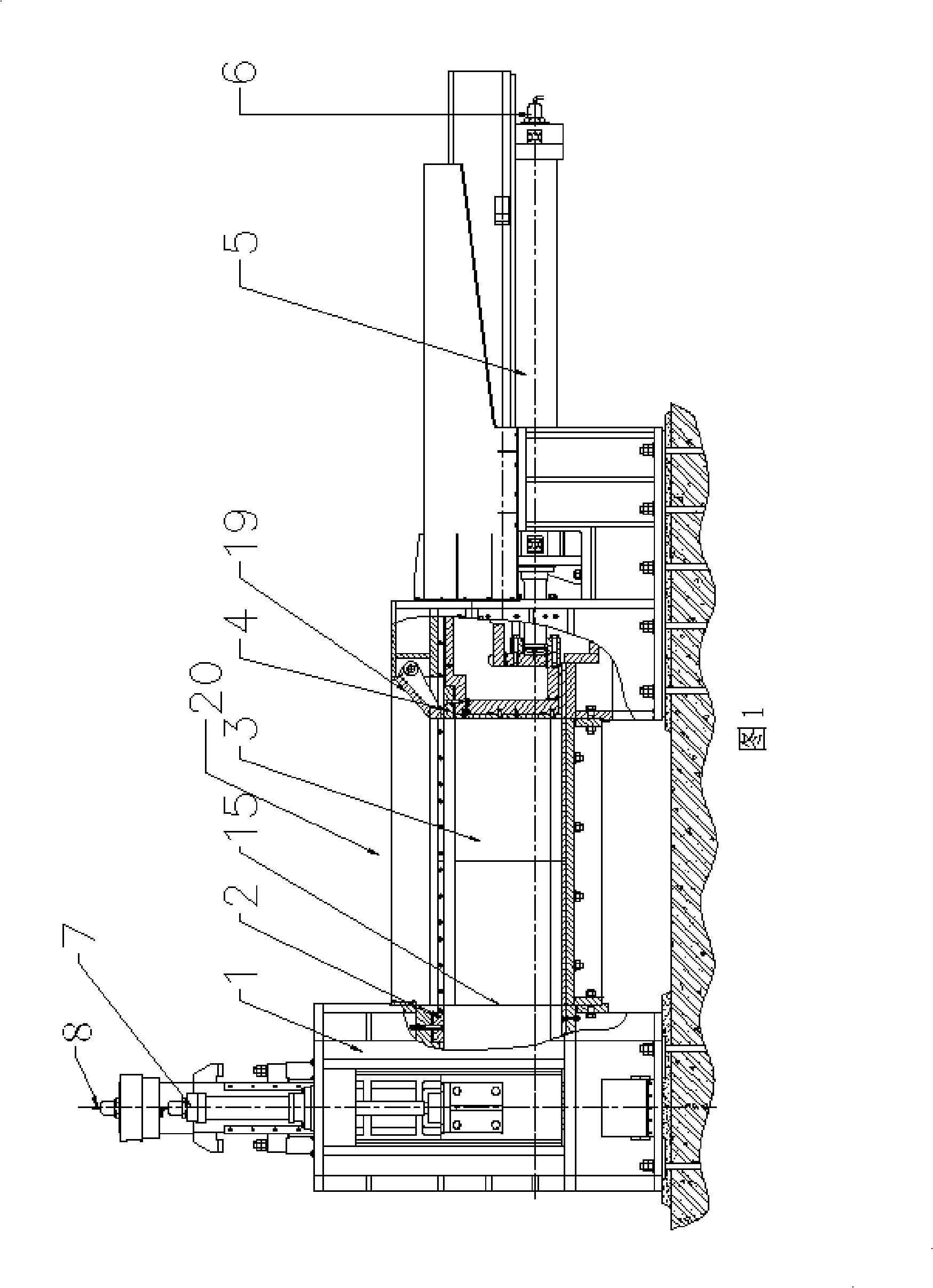

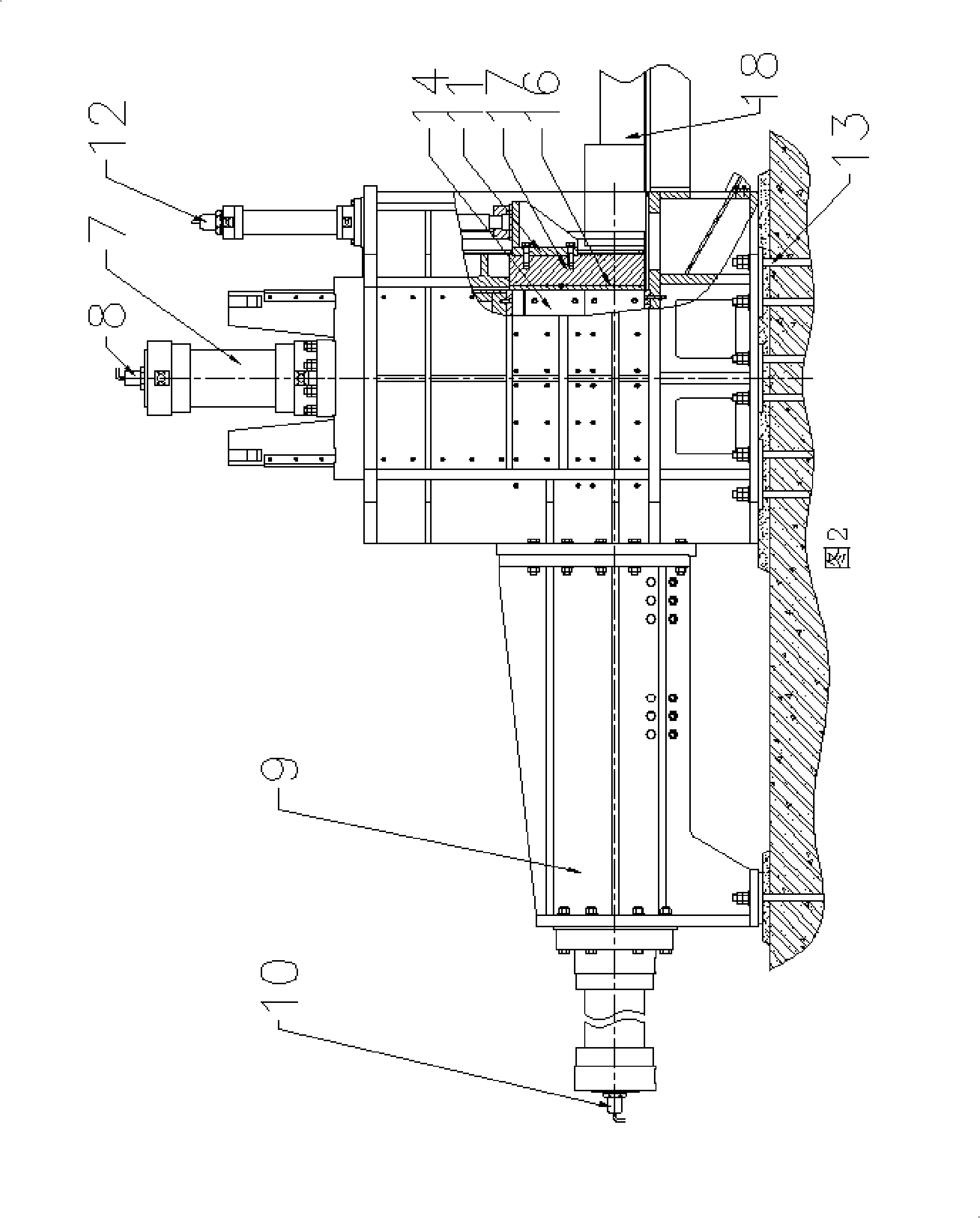

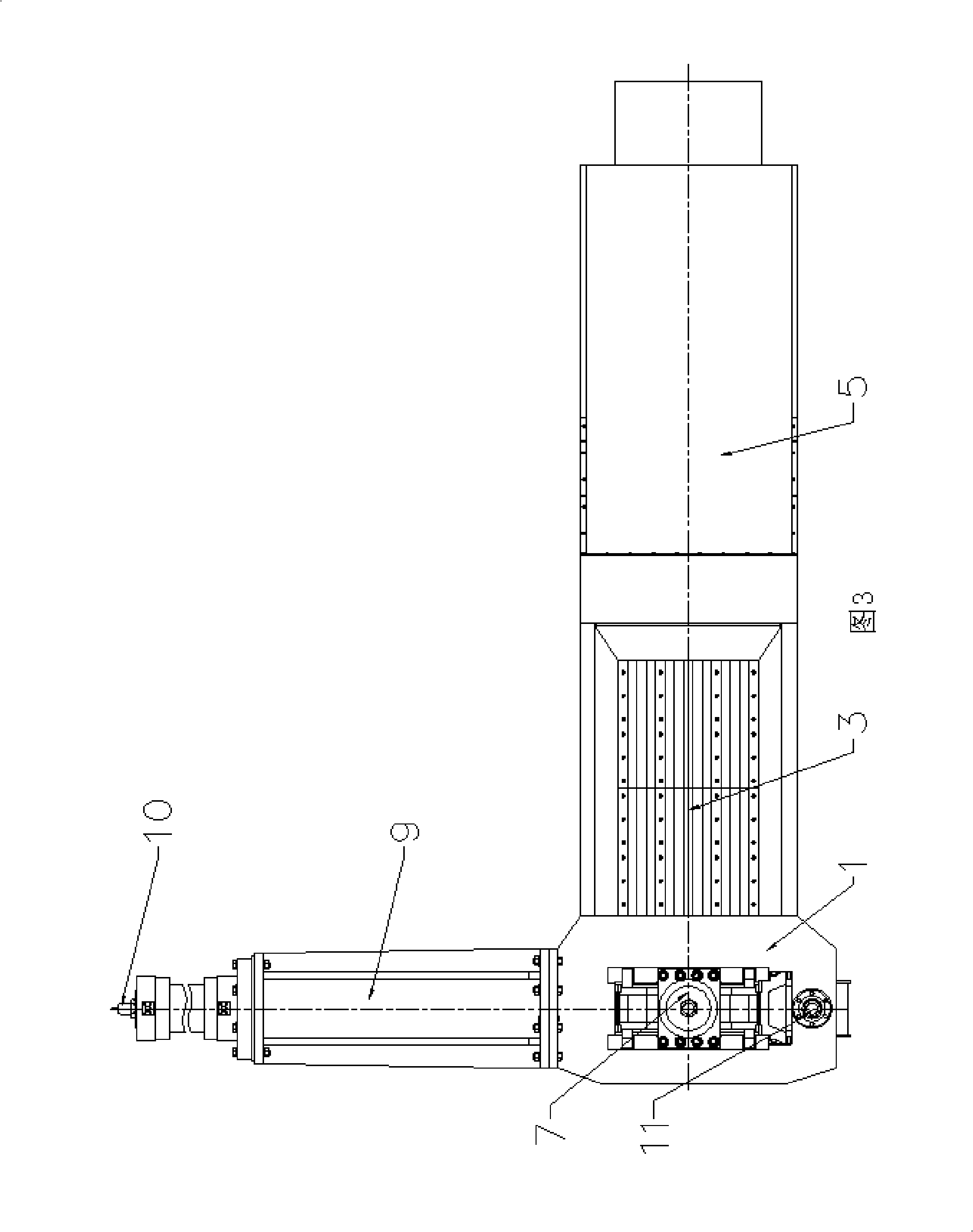

Scrap steel chipping packing machine

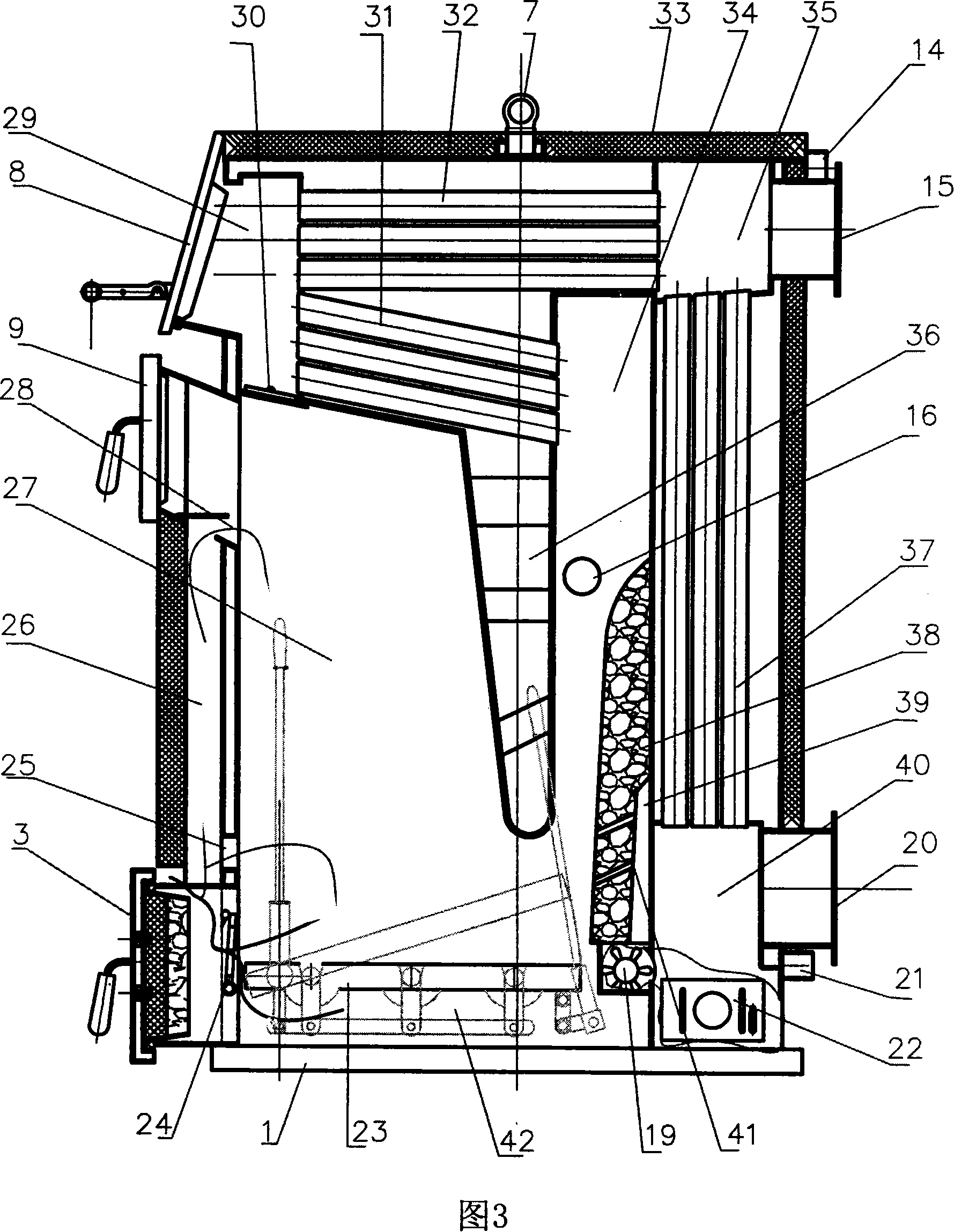

The invention discloses a chipping packager for scrap which can carry out three-dimensional compression of the scrap and has more compact packaging; the chipping packager comprises a main frame in which a packaging chamber, a feed inlet and a discharge hole which are communicated with the packaging chamber are arranged; the chipping packager also comprises a compression device connected on the main frame and the compression device comprises a first cylinder device, a second cylinder device and a third cylinder device; pushing heads of the first cylinder device and the second cylinder device are matched with the packaging chamber; the pushing heads of the first cylinder device, the second cylinder device and the third cylinder device form a closed space at the stroke end in the packaging chamber. A shearing device is also arranged on the main frame. The chipping packager can realize the three-dimensional squeezing packaging of the scarp, automatically chip the residual feed and irregular scarp and has high automation degree, high efficiency as well as good safety. The chipping packager is mainly applied to the field of processing the scrap.

Owner:ERZHONG GROUP DEYANG HEAVY EQUIP

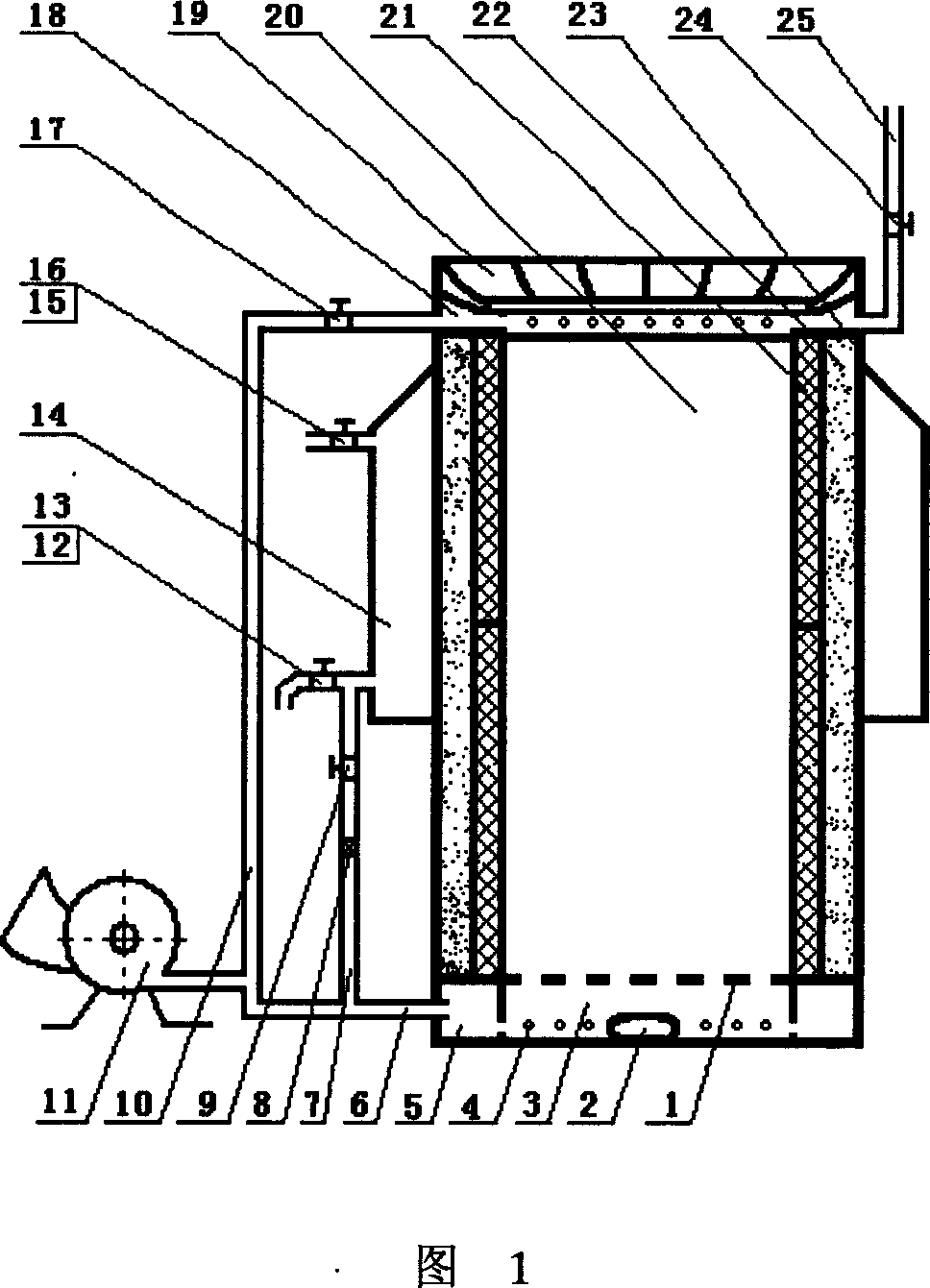

Biological-material-tall stove

InactiveCN1936429AEasy centralized processingEasy to addDomestic stoves or rangesEnergy inputHearthBiological materials

This invention relates to a biological material ball stove including a fan, a secondary wind pipe, a valve, a flowmeter, a supply pipe, a gasification agent pipe, a loop air pre-heating chamber, a loop air conduction chamber, a stove head, a stove body, a heat preservation layer, an inner container and biological material balls, in which, the upper part of outside of the stove is a water tank made of stainless steel, the fan is connected with the loop air pre-heating chamber at the bottom of the hearth via a gasification agent pipe, the heat preservation layer, the inner container and the hearth are orderly placed in the body, a grate is under the hearth and the stove head is above it, the loop air conduction chamber is at the bottom of the head, the secondary wind pipe and the chimney are at the outside wall of the conduction chamber with a stage along the internal wall for placing a stove cover.

Owner:刘春生

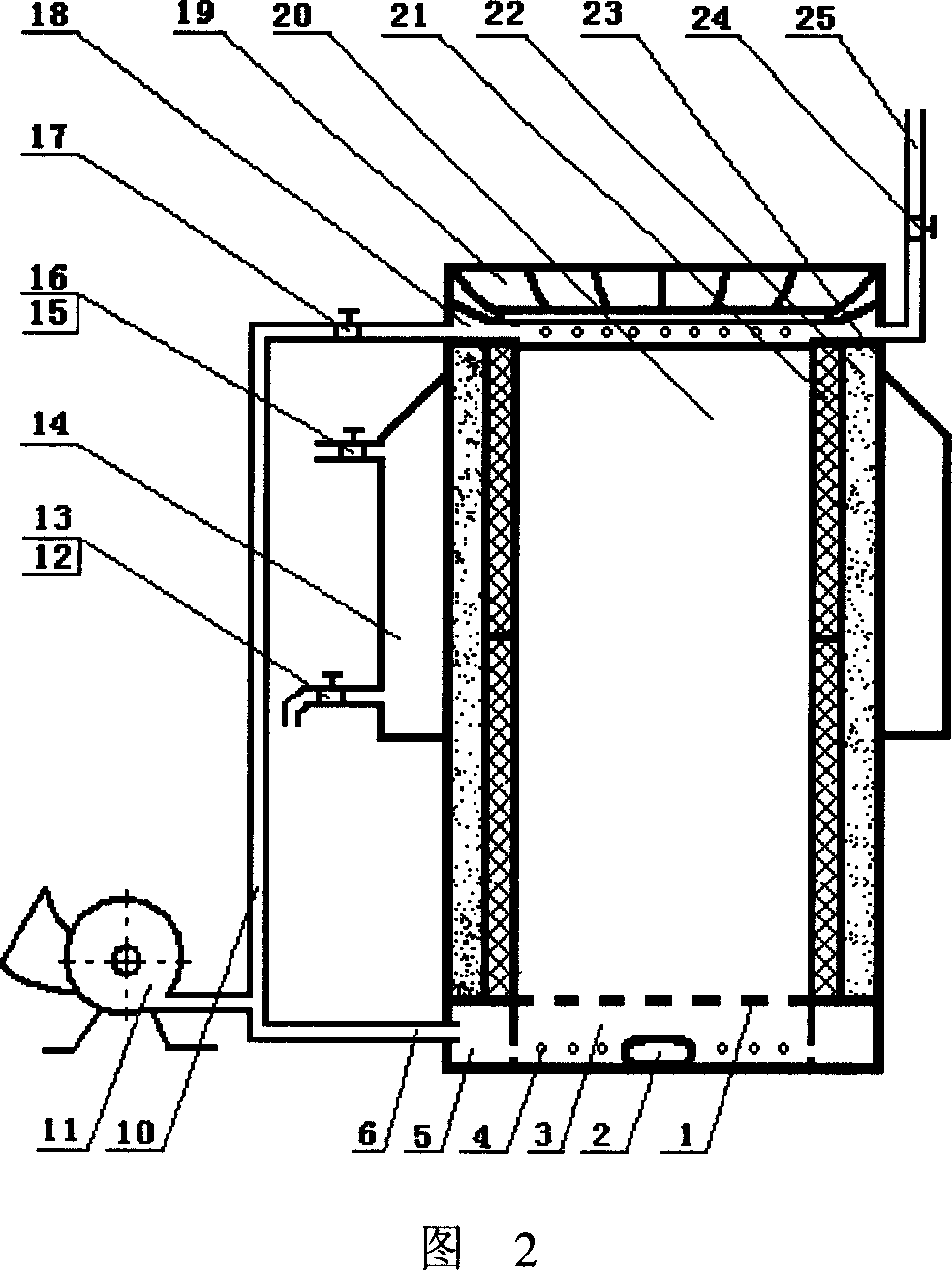

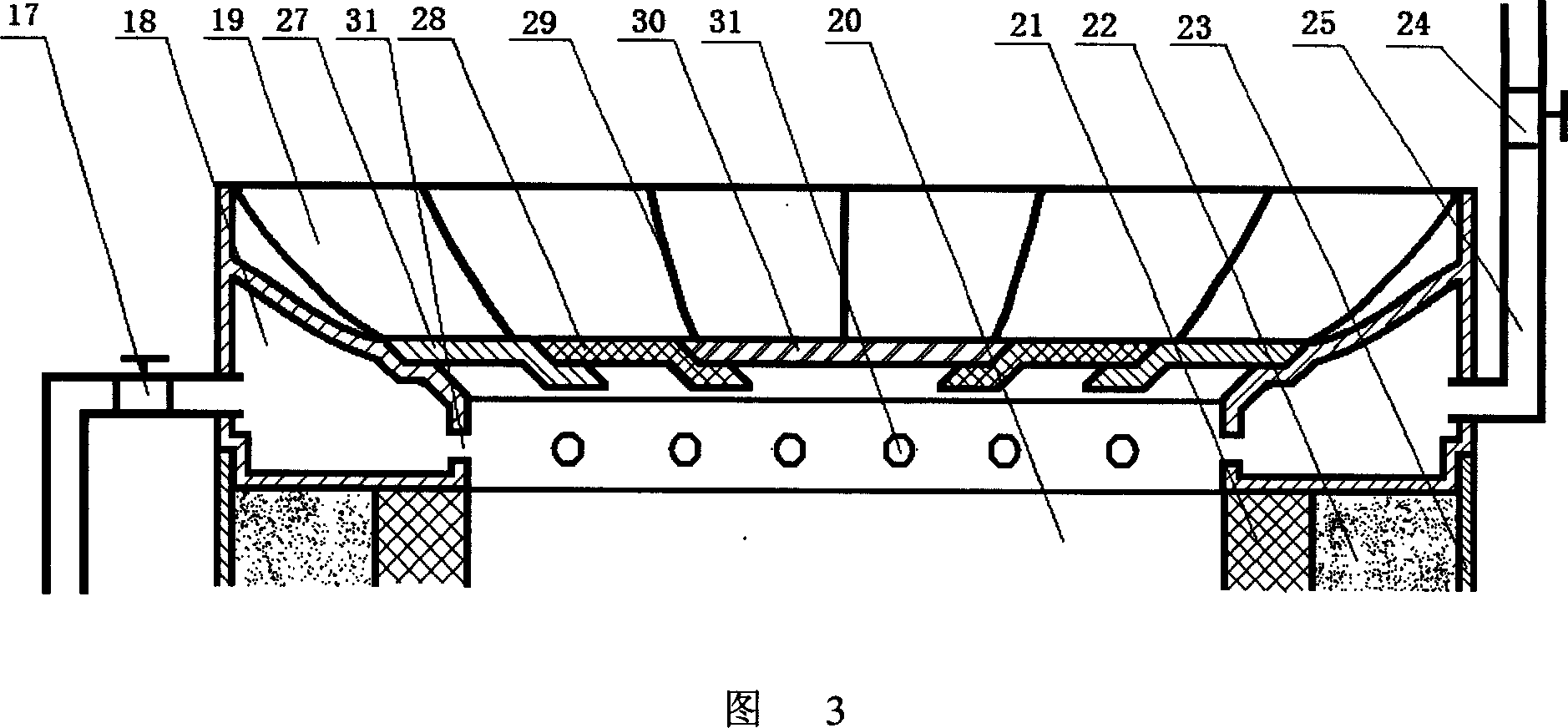

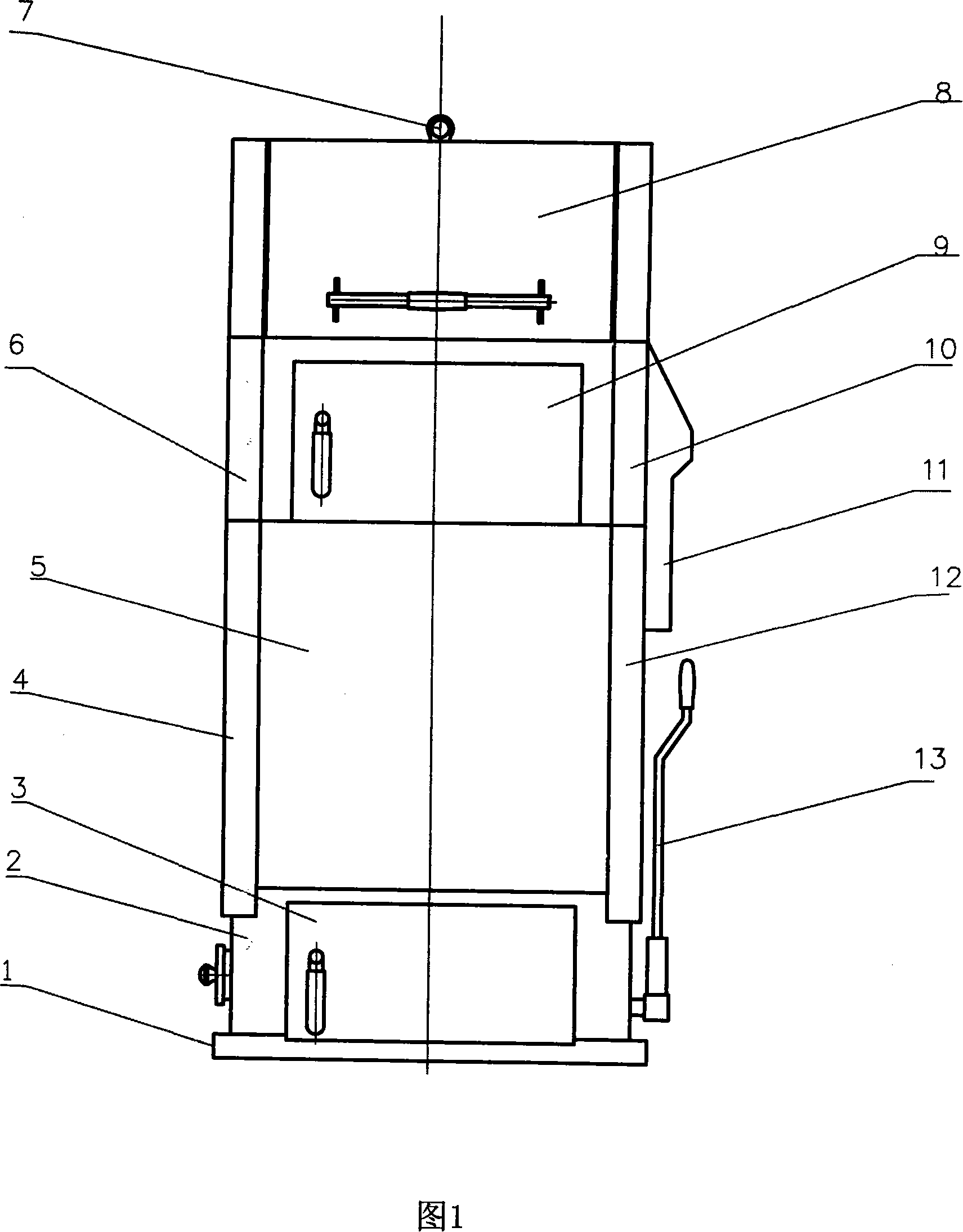

Biomass gasification automatic-control boiler

InactiveCN101122417AReduce the overall heightReduce generationSolid bar grateSolid fuel combustionAutomatic controlCombustion chamber

The invention discloses a biomass gasification automatic control boiler. A furnace is arranged above an ash removal grate. A secondary combustion chamber is arranged above the back of the ash removal grate. The middle is equipped with a fireproof plate with a sandwich structure. A flue gas channel is arranged between the lower end of the fireproof plate and the ash removal grate. Sandwich water jackets, which are mutually communicated, are arranged on the periphery and the top of the furnace, the fireproof plate and the secondary combustion chamber. A primary air is supplied into the furnace from a plurality of directions of the furnace. A secondary air is supplied into the secondary combustion chamber through a secondary air channel and a ventilating hole on a spoiler. An upper settling chamber is arranged above the furnace, which is communicated with the secondary combustion chamber through a fire tube. In addition, a settling and flue conversion chamber and a lower settling chamber, which are communicated through a fire tube is arranged above the furnace. The ash removal grate is a lifting grate, which can rotate around an anterior location pin and is used to adjust the height of the opening arranged between the lower end of the fireproof plate and the ash removal grate. A microcomputer control device can automatically control the operation of the boiler according to the set requirements. Using biomass fuels and coals, the invention has the advantages of high efficiency and low emission, which accords with the requirements of environmental protection and energy saving.

Owner:SHANDONG DUOLE HEATING EQUIP

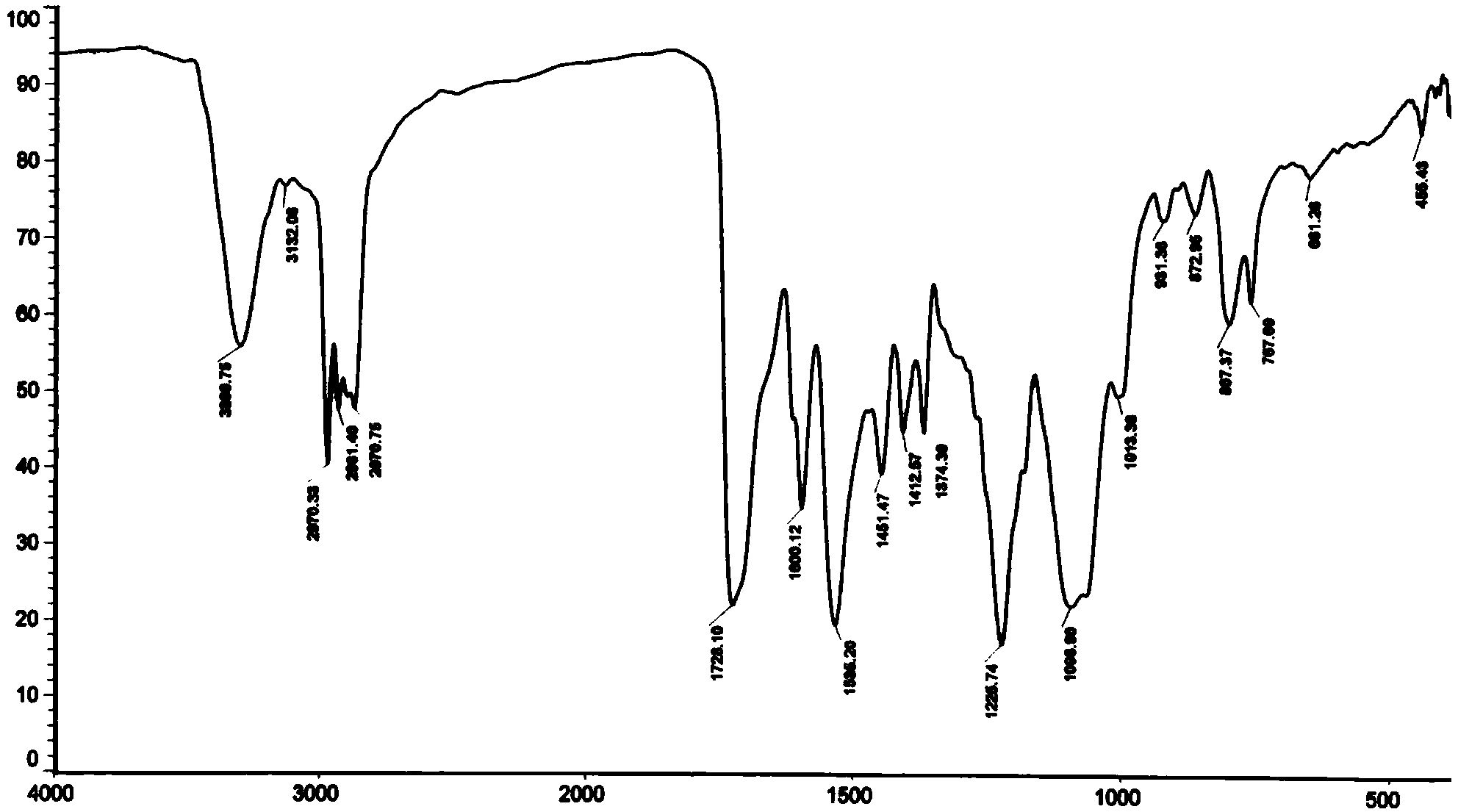

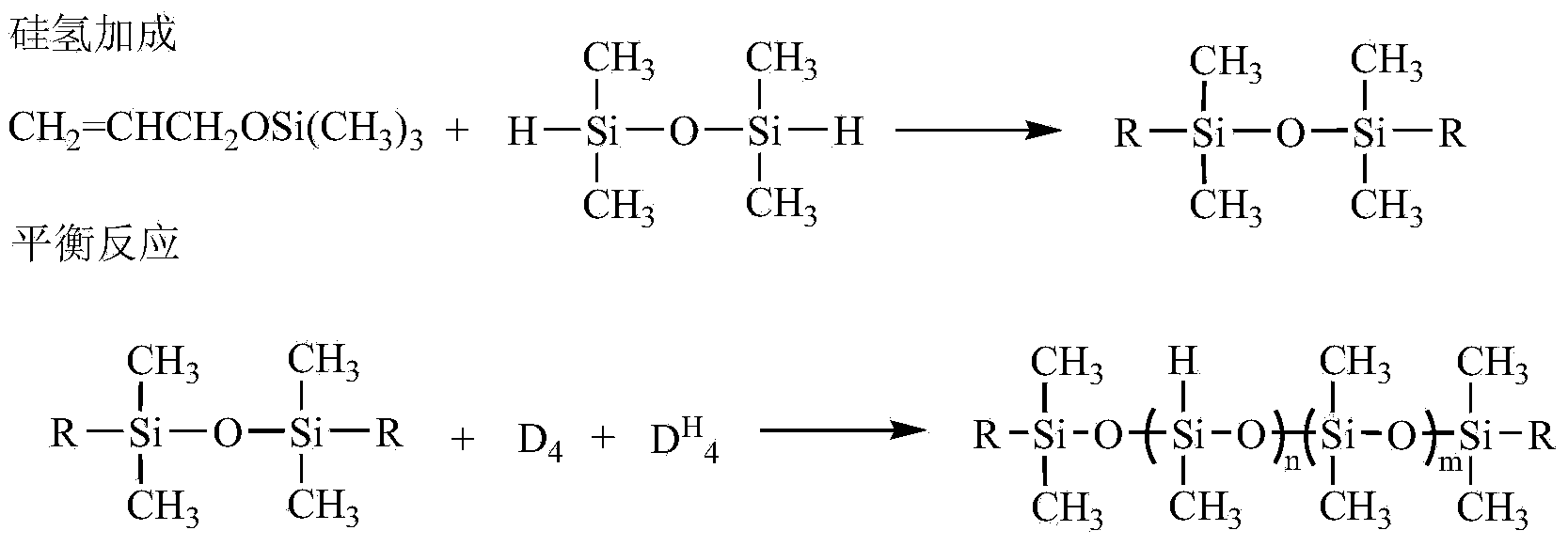

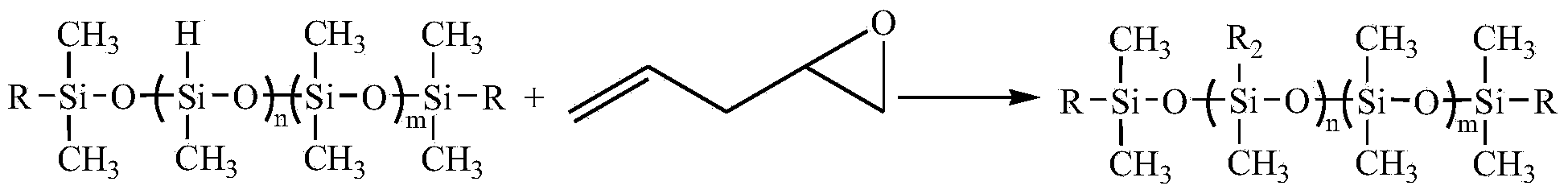

Method for preparing organosilicon modified cationic waterborne polyurethane

The invention discloses a method for preparing organosilicon modified cationic waterborne polyurethane. The method comprises the steps: firstly, reacting organosilicon (of which the two terminals contain hydroxyalkyl groups and side groups contain epoxy groups) with polyisocyanate, so as to introduce a principal chain of organosilicon into a polyurethane structure; next, reacting an ordinary chain extender and mono-hydroxyl glycidyl ether (or mono-hydroxyl glycidyl ester or a mixture of the mono-hydroxyl glycidyl ether and the mono-hydroxyl glycidyl ester at any ratio) with the organosilicon modified polyurethane prepolymer; then, adding an organic amine compound (or an organophosphorus compound or organosulfur compound) and organic acid into organosilicon modified polyurethane diluted with butanone, so as to carry out ionization reaction; finally, dispersing the ionized organosilicon modified polyurethane into water through self-emulsifying, distilling at reduced pressure so as to remove butanone, thus obtaining the organosilicon modified cationic waterborne polyurethane.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

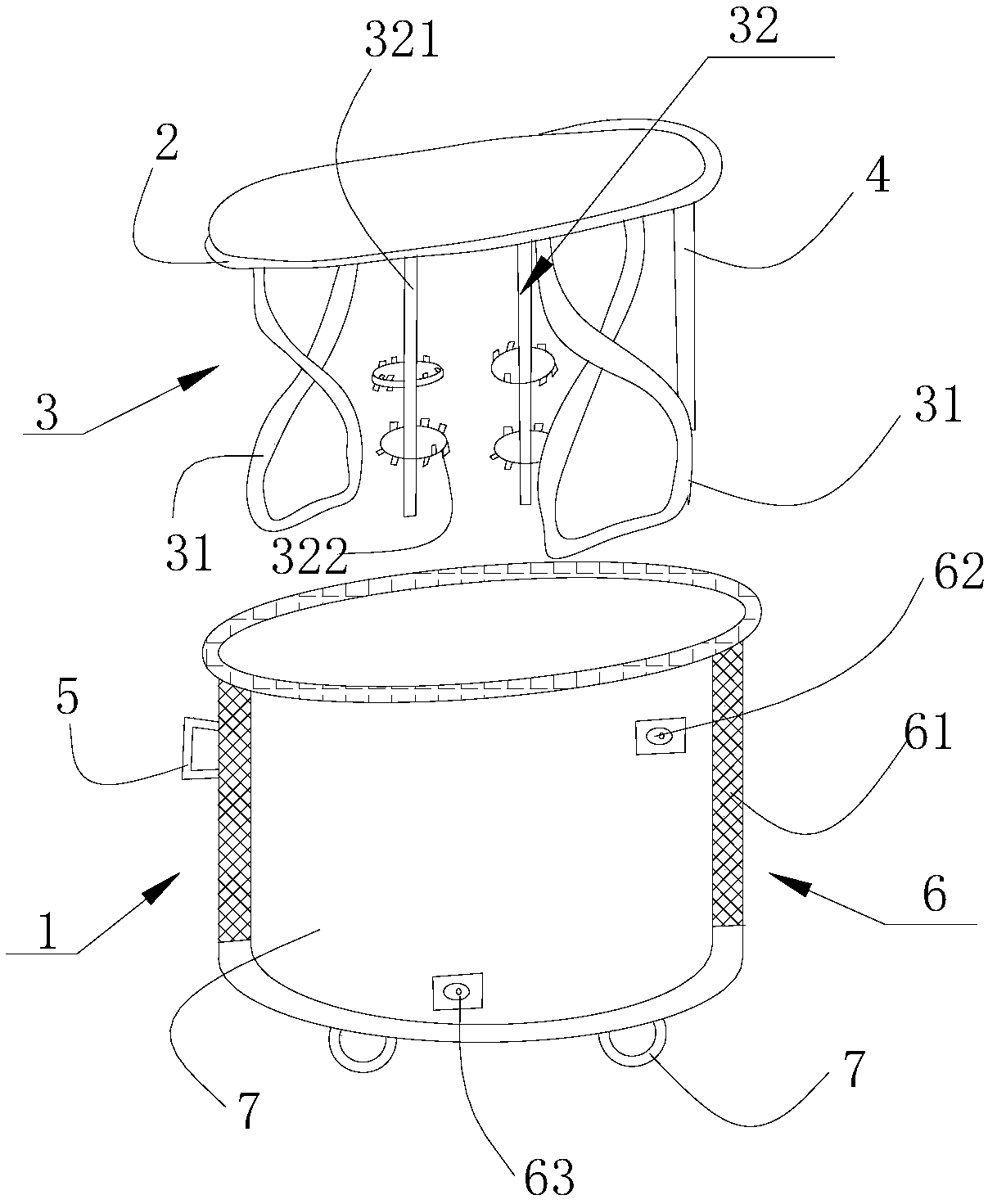

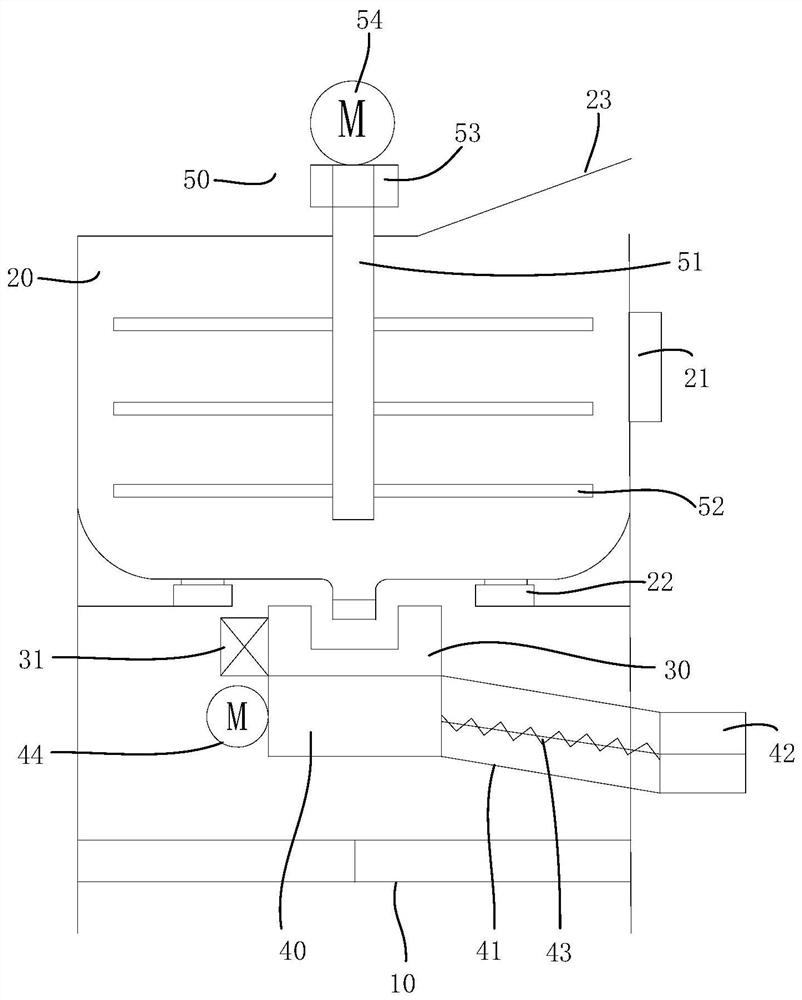

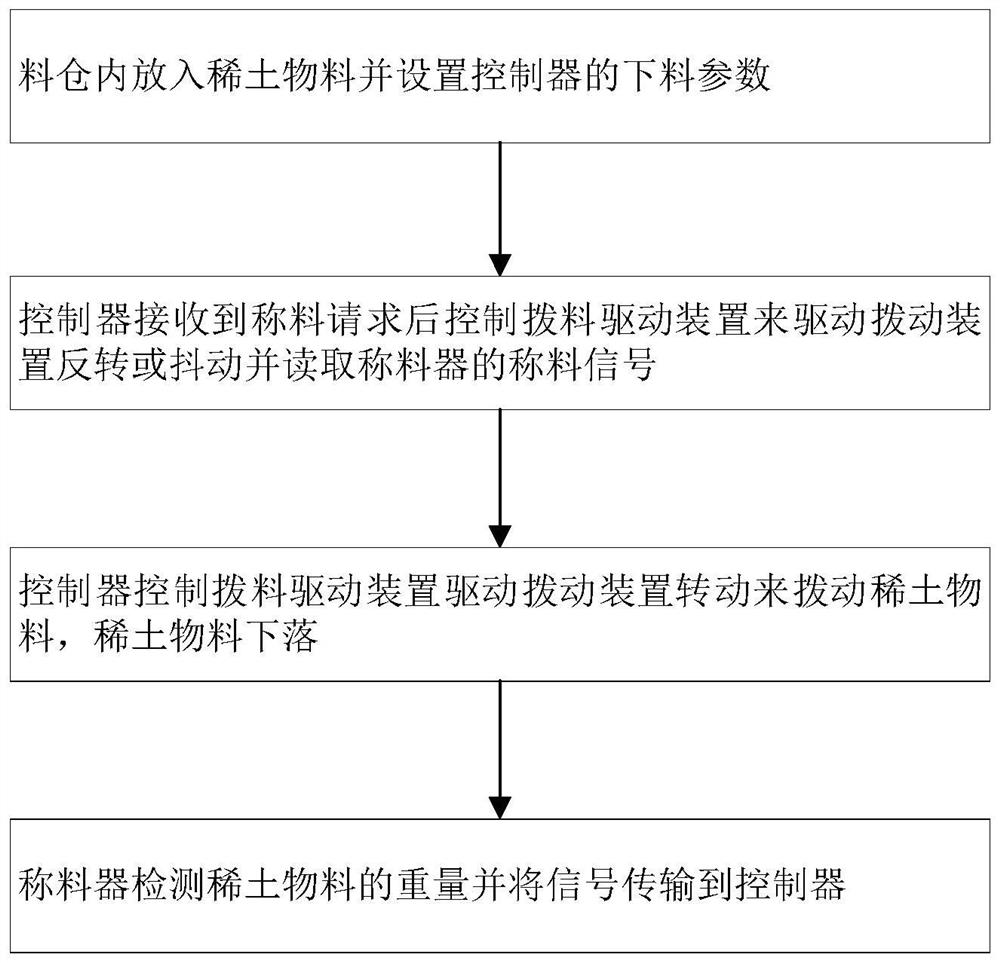

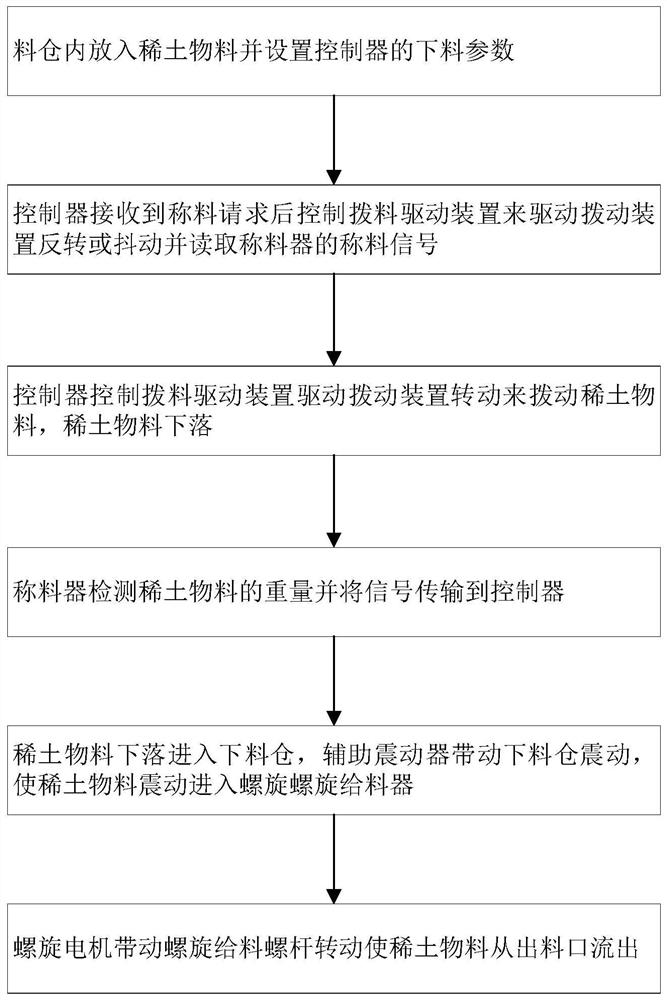

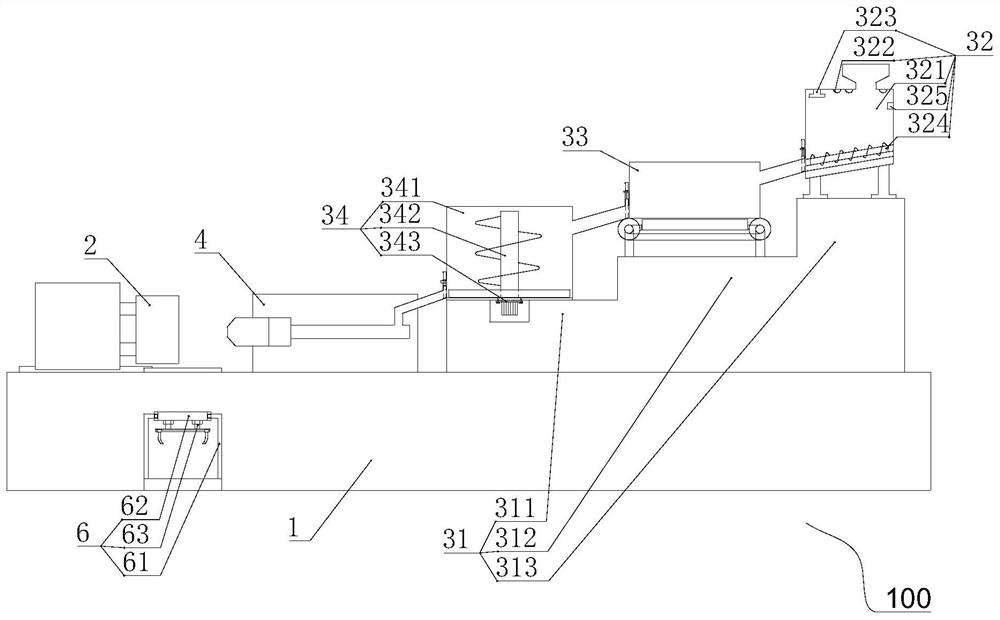

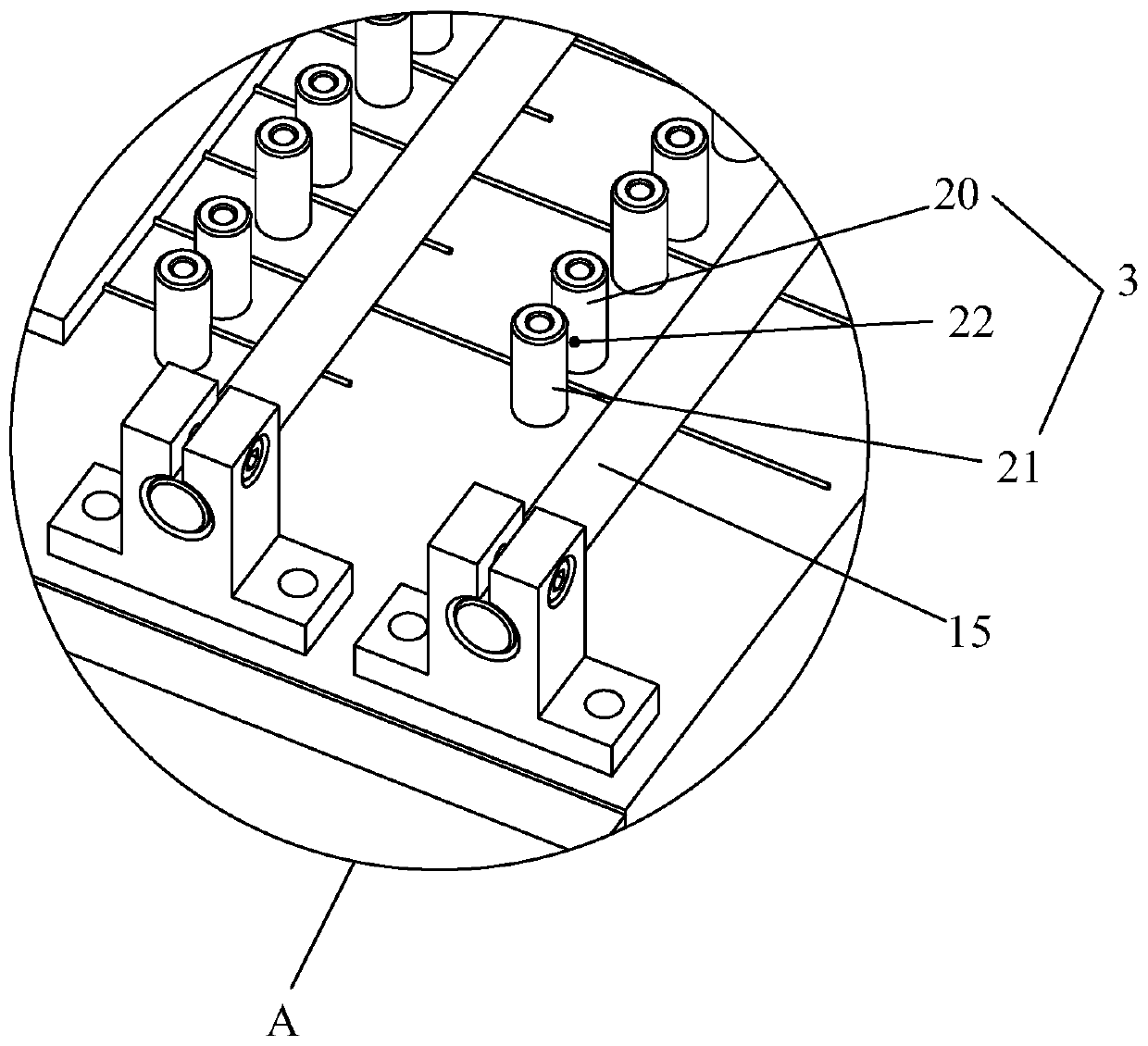

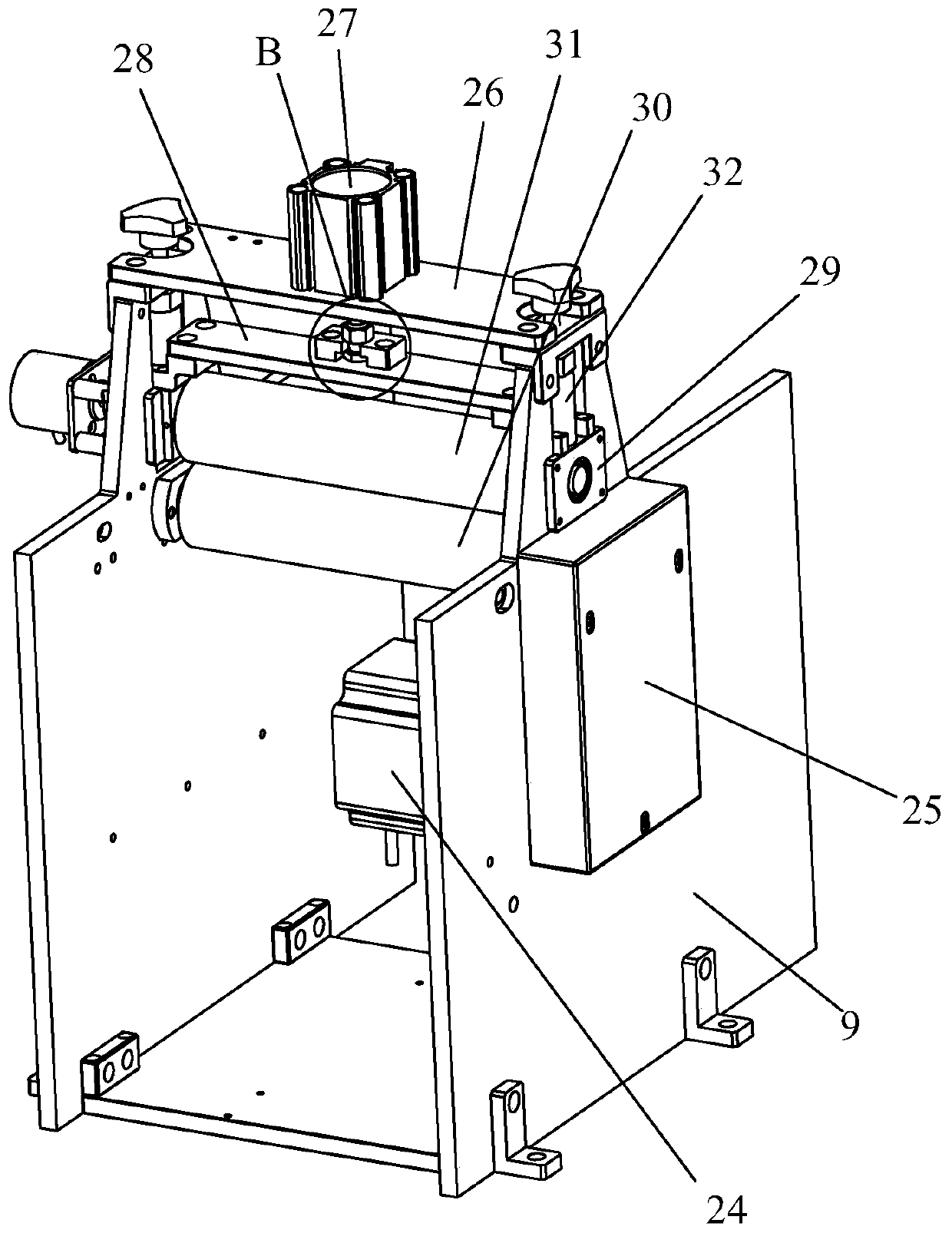

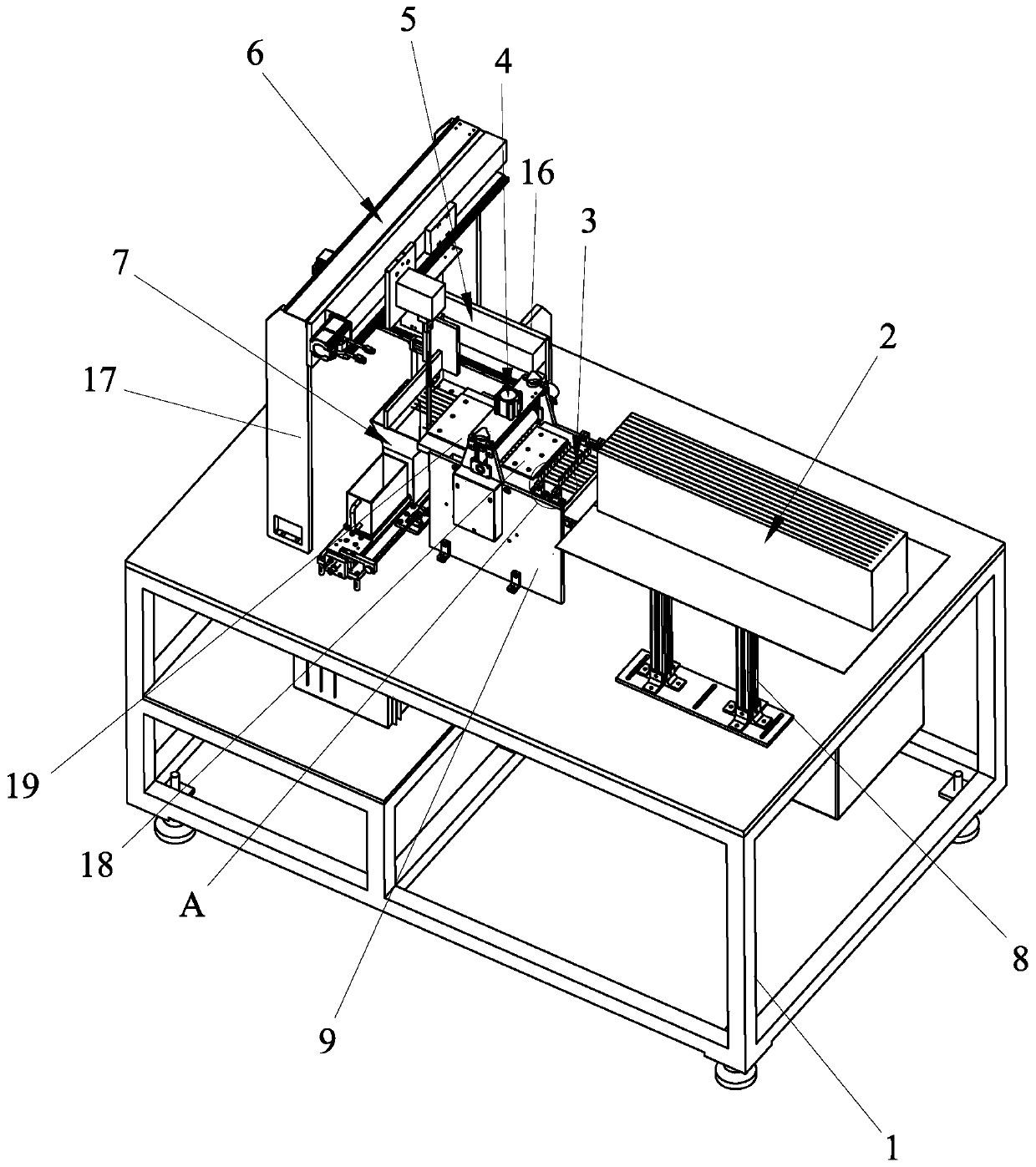

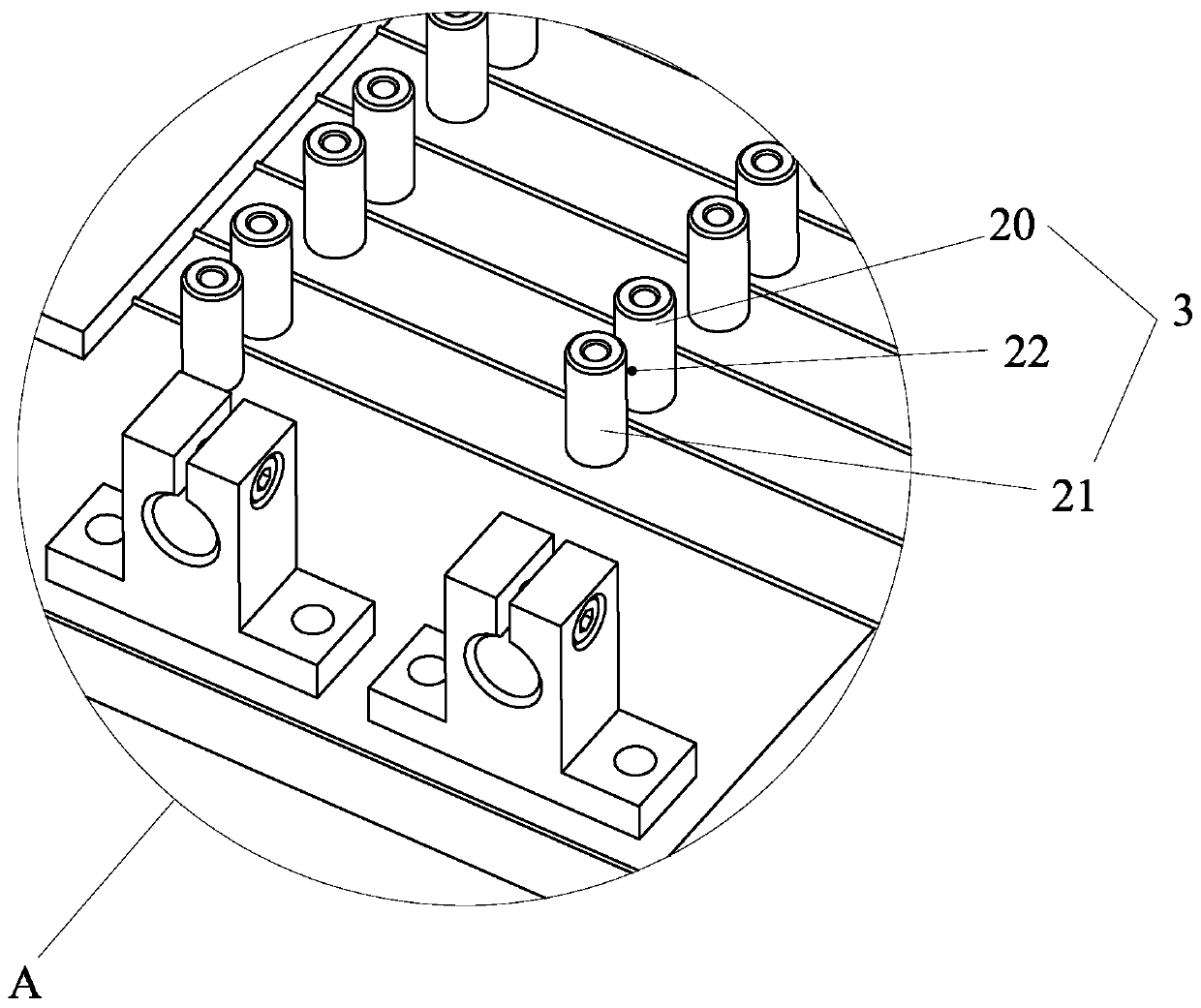

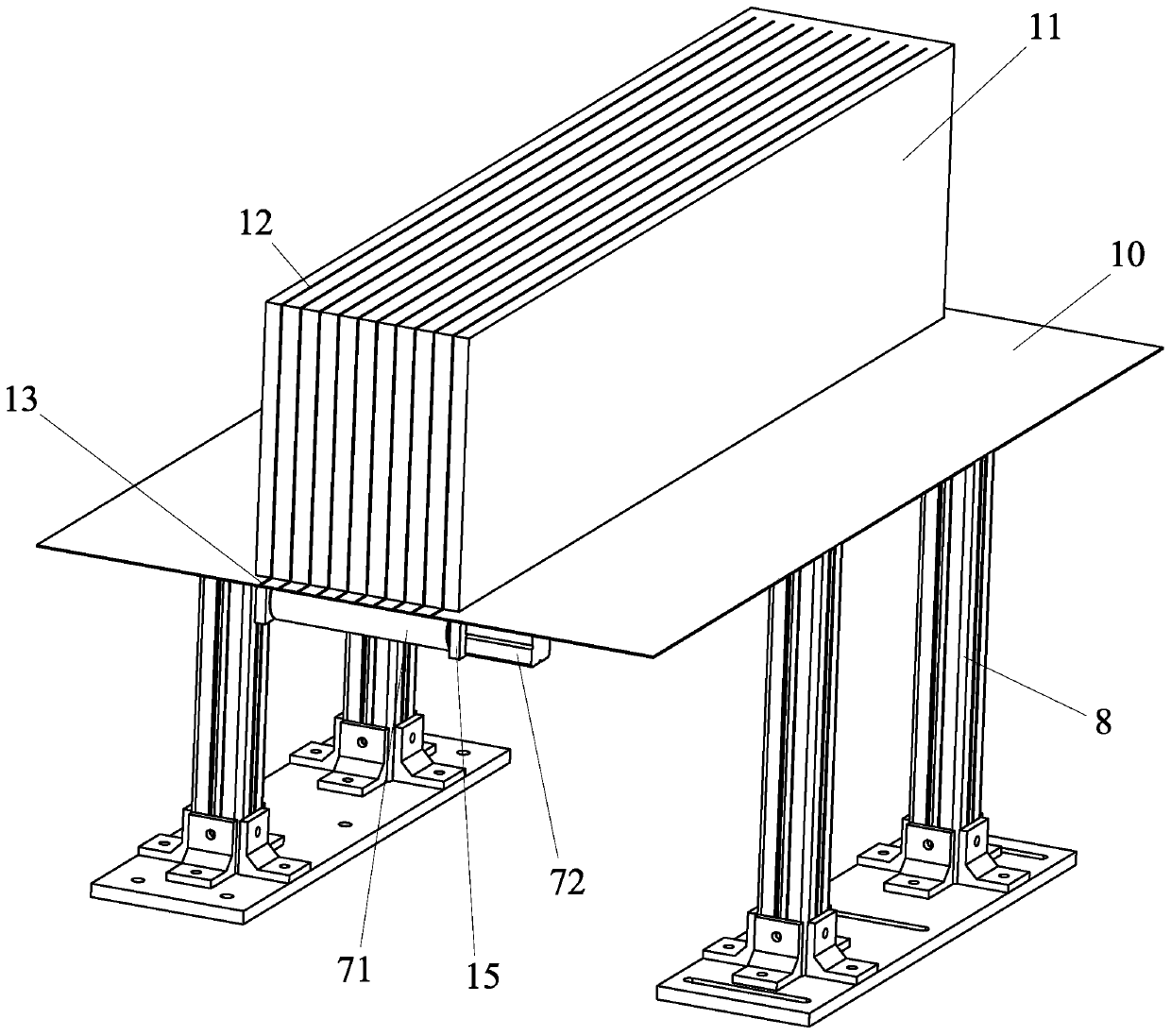

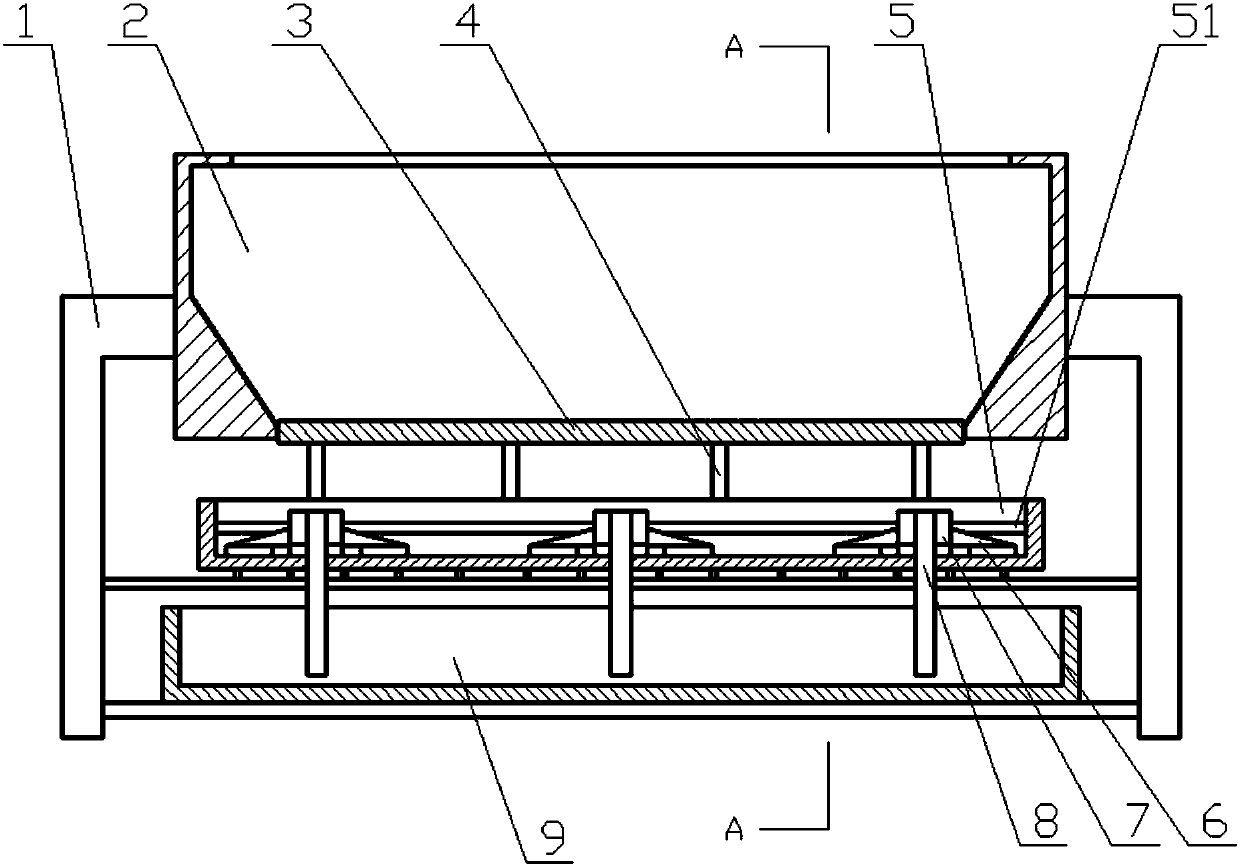

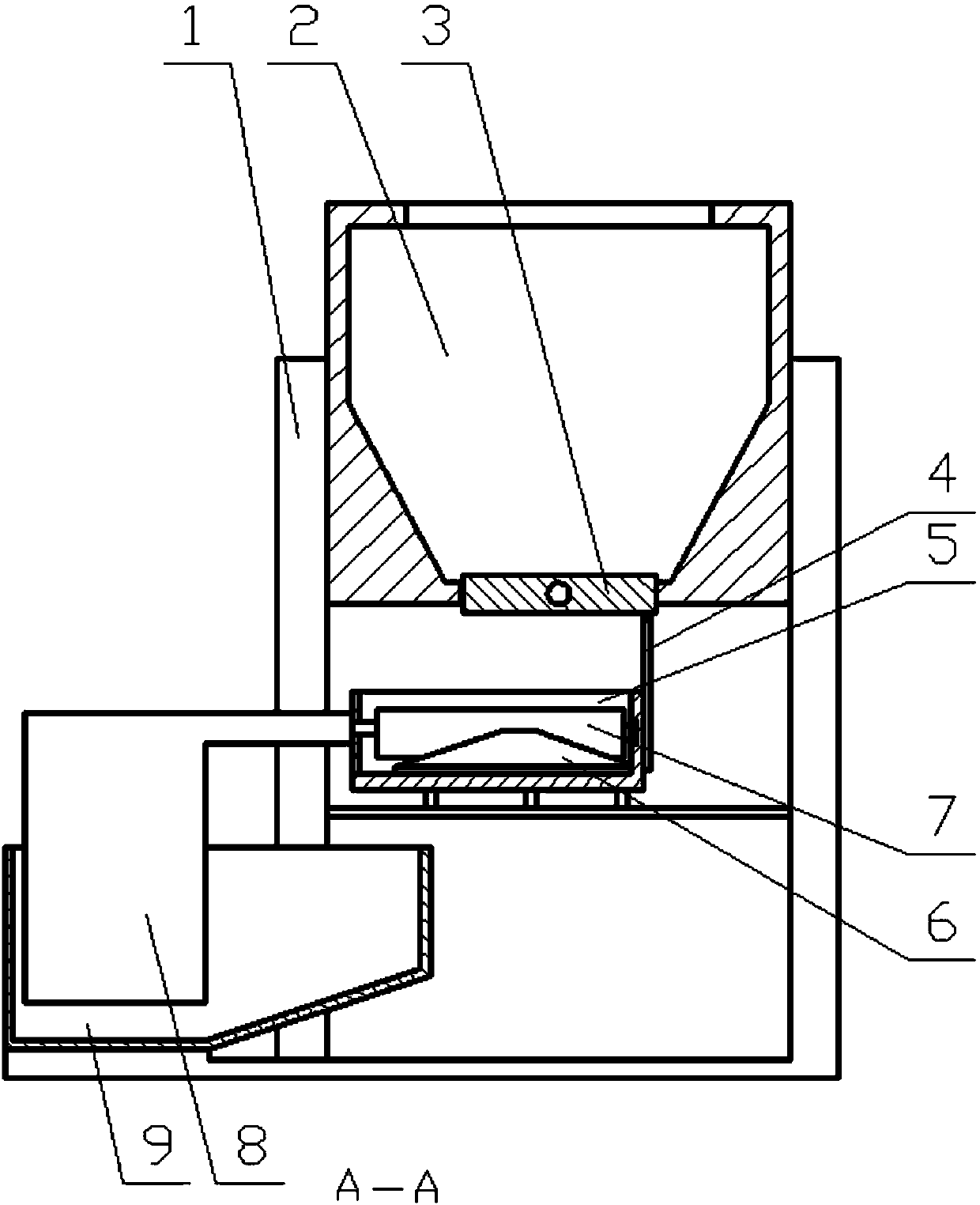

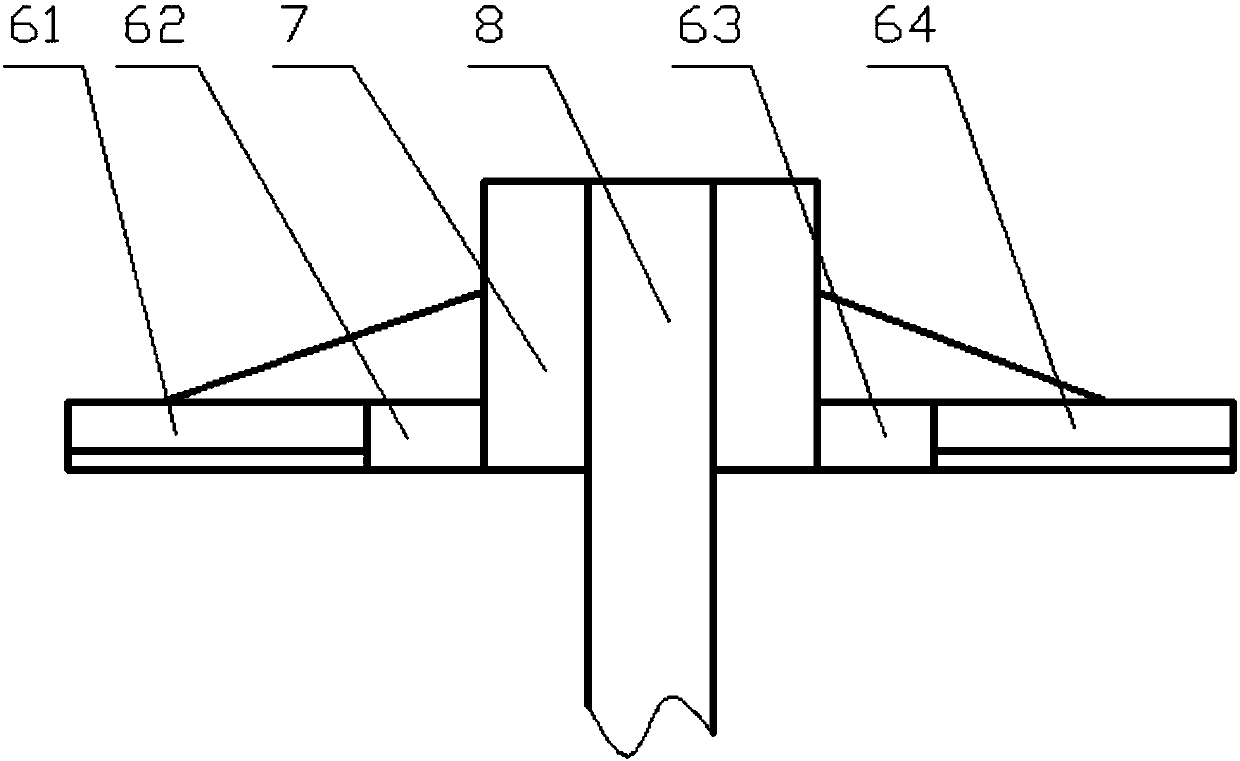

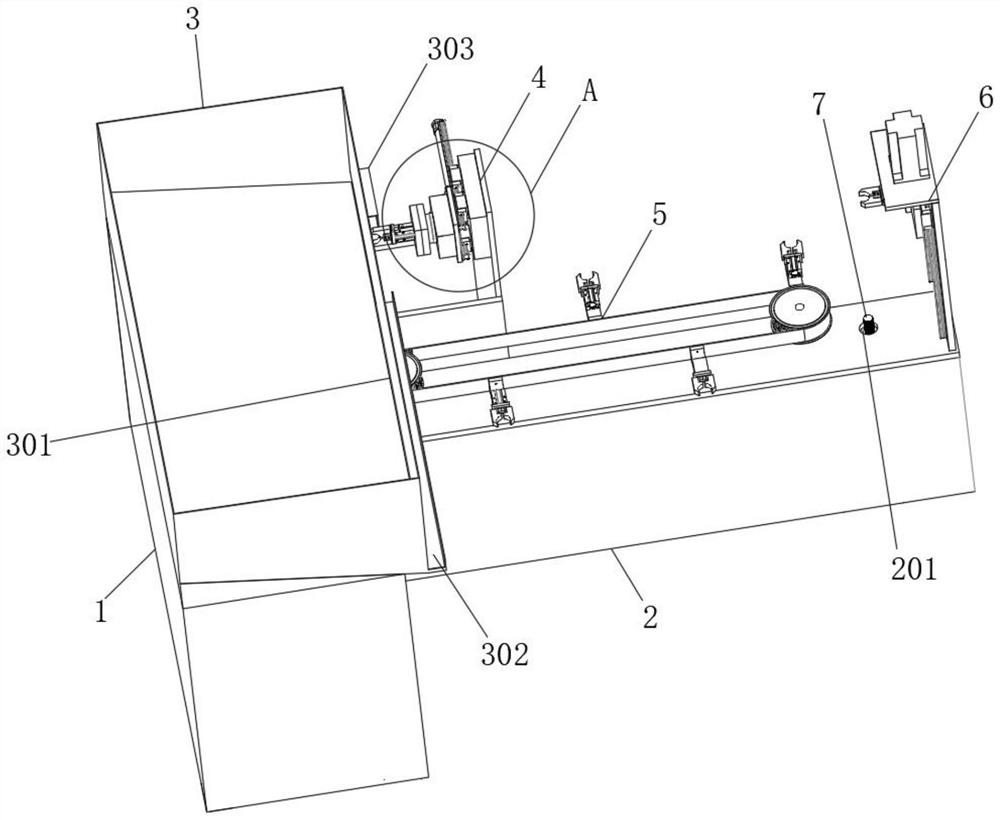

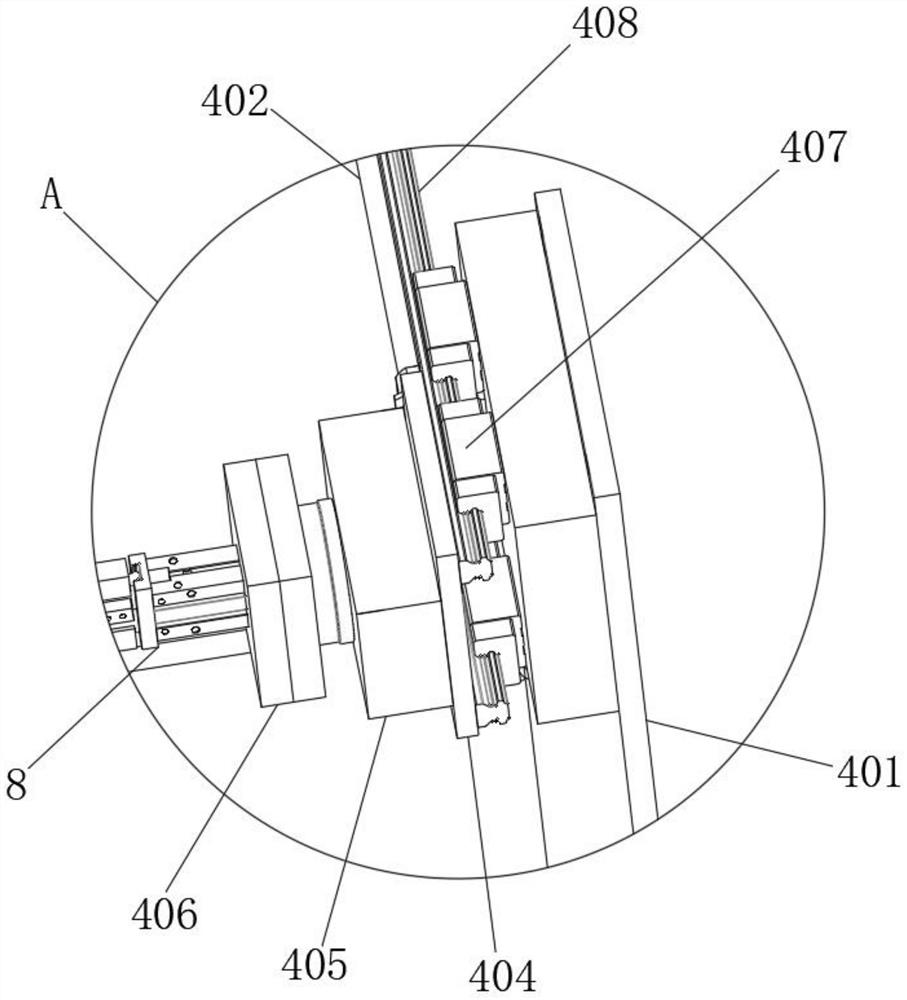

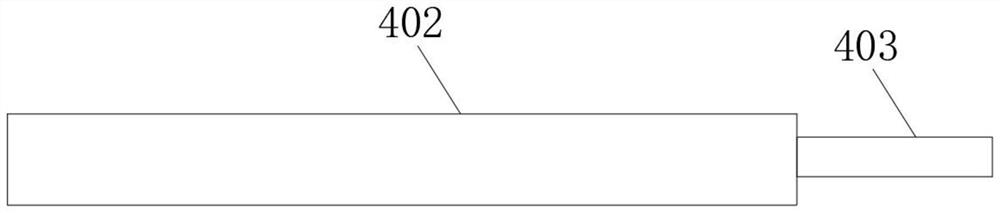

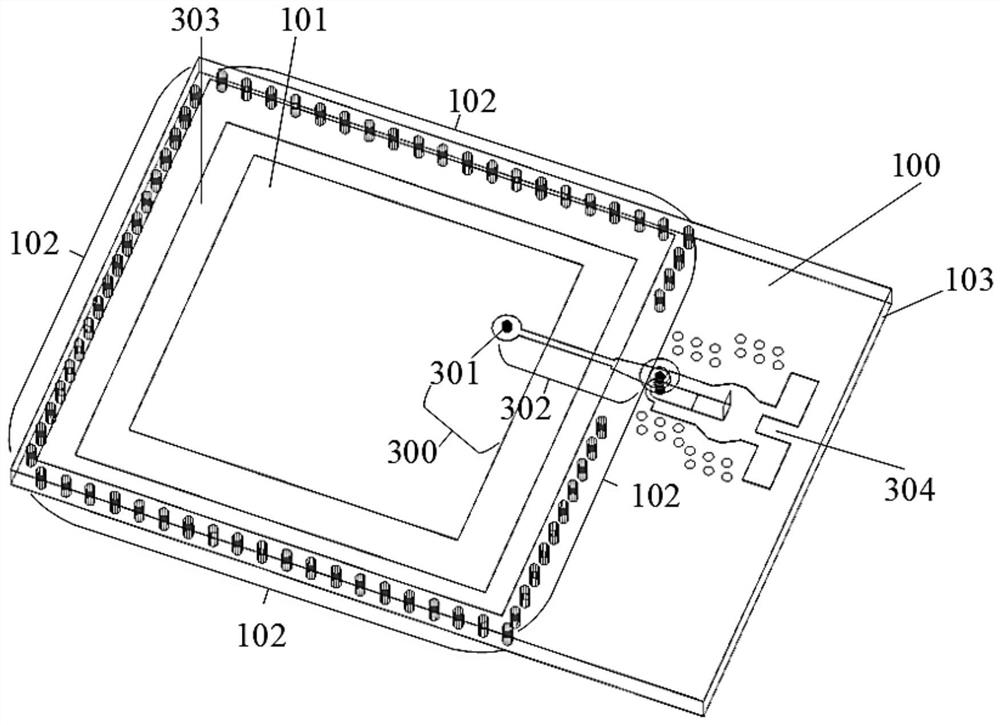

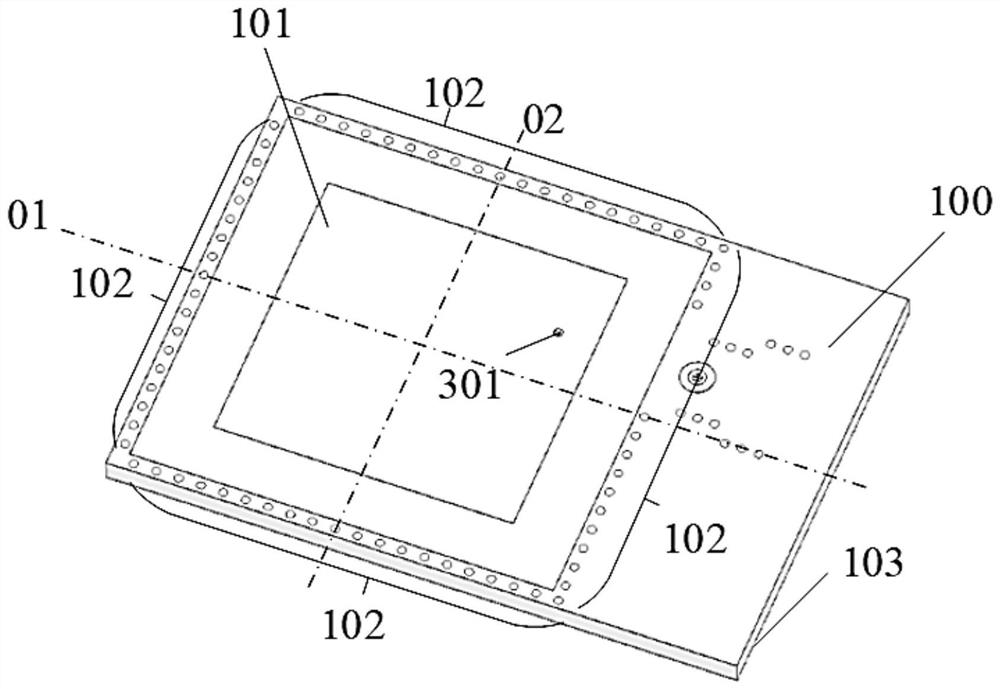

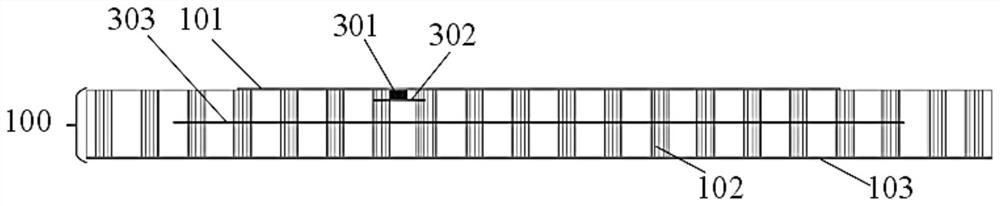

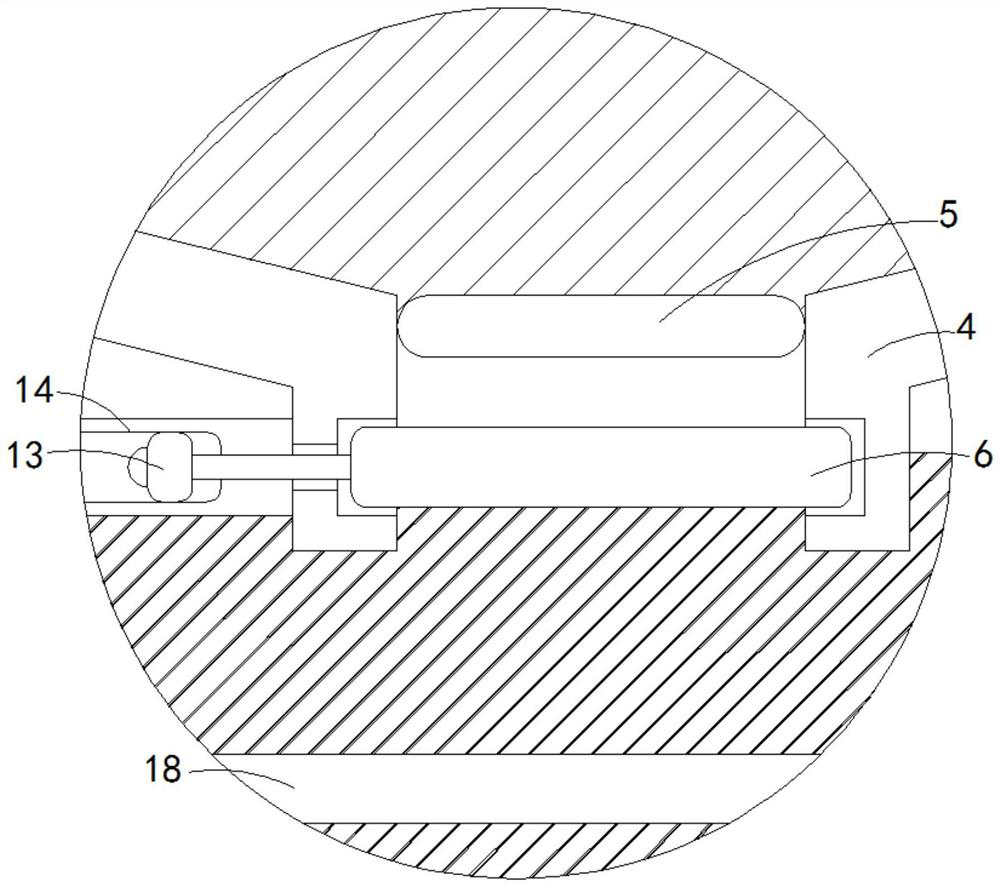

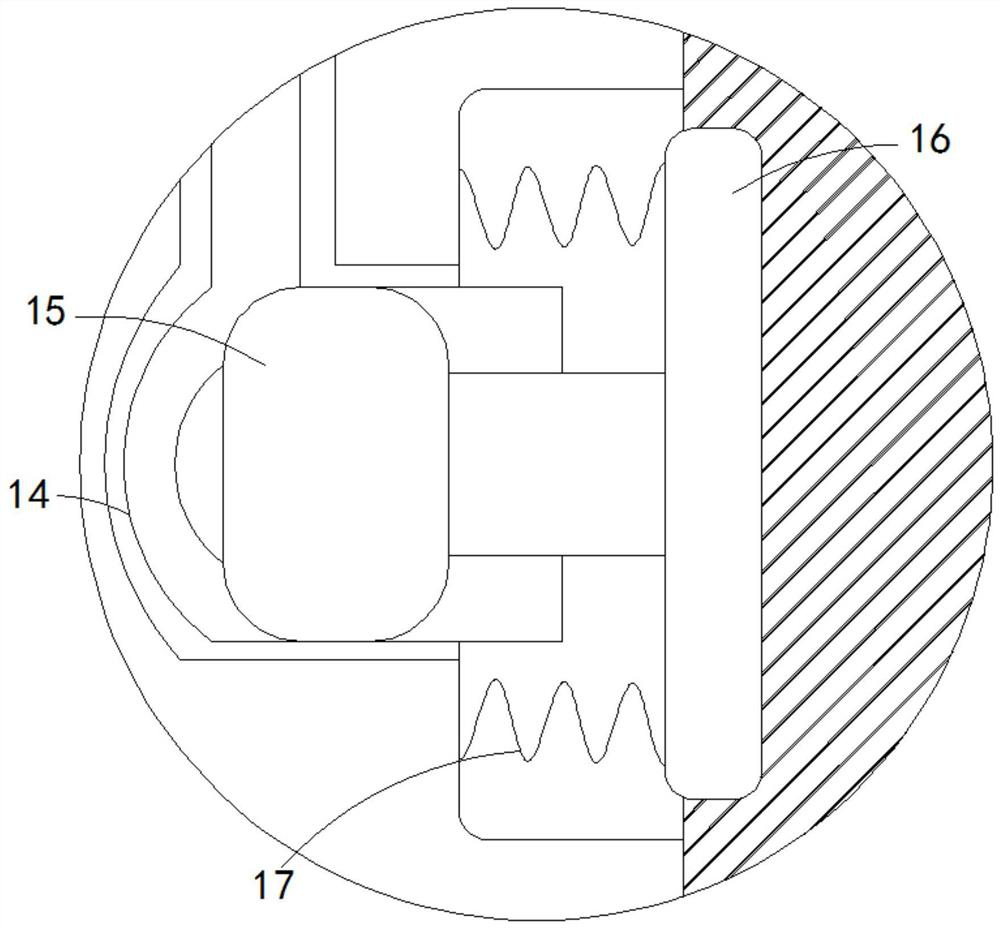

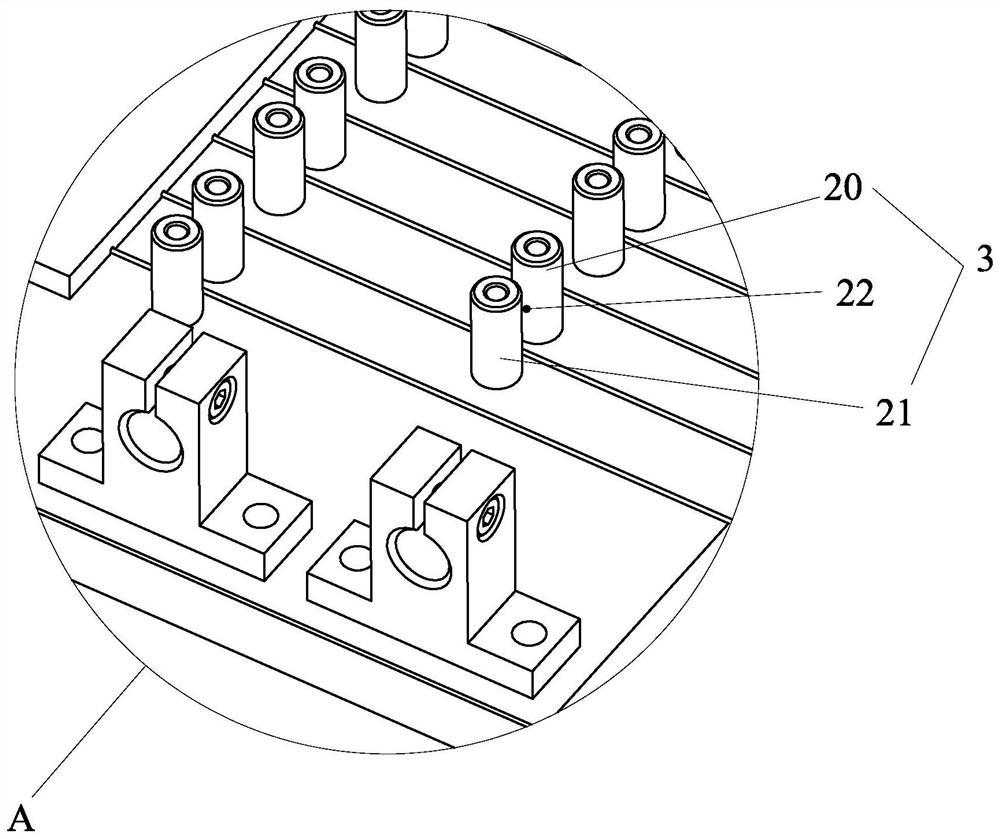

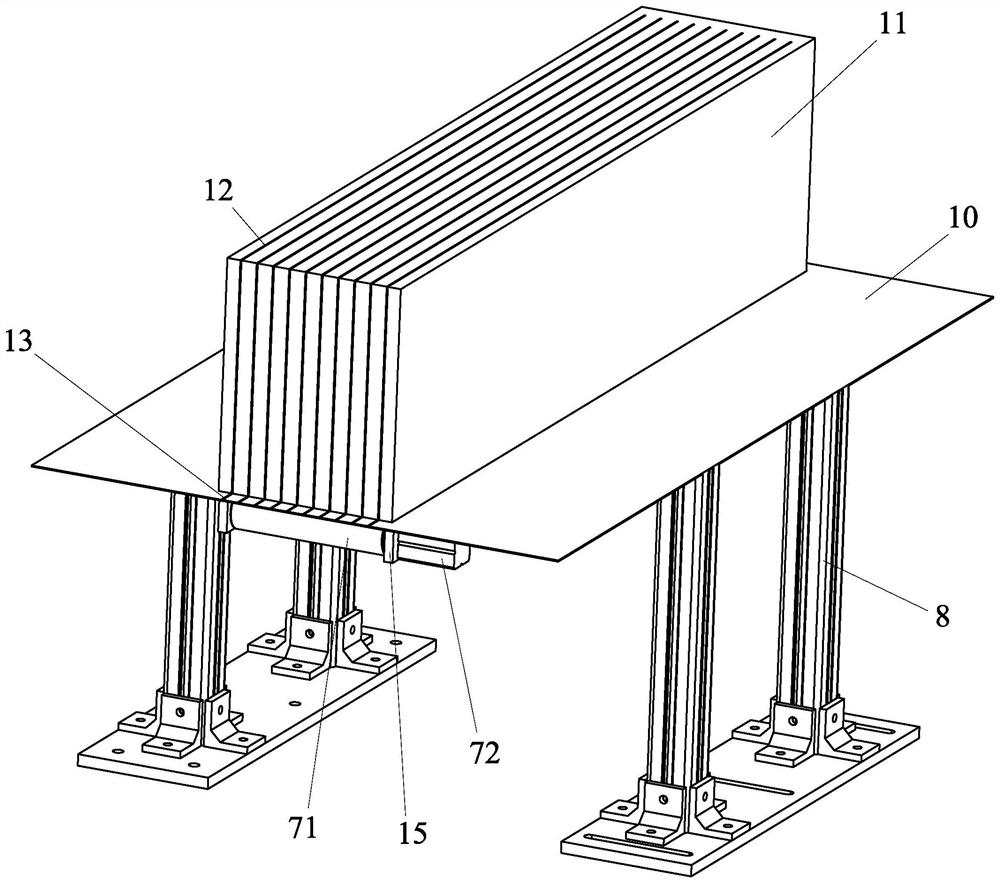

Rare earth automatic weighing and feeding device, feeding method and rare earth automatic weighing and feeding system

PendingCN111674950AReduce the number of feedingReduce overall lossFlexible coversConveyorsElectrical and Electronics engineeringMechanical engineering

The invention discloses a rare earth automatic weighing and feeding device, a feeding method and a rare earth automatic weighing and feeding system. The device comprises a support frame and a stock bin arranged on the support frame, and also comprises a material shifting device, a weighing device and a controller, the material shifting device comprises a material shifting driving device and a shifting device, and the shifting device is arranged in the stock bin; the weighing device is arranged at the bottom of the stock bin, and is used to detect the weight of rare earth materials in the stockbin and output weight signals; the controller is connected with the material shifting driving device and the weighing device in a signal mode, and is used to receive the weight signals and control the operation of the material shifting driving device, the controller is configured that when a weighing request is received, the material shifting driving device drives the shifting device to reverse or shake, and then the weight signals of the weighing device are read. The material shifting device is arranged to shift the rare earth materials, so that the rare earth materials are smoothly discharged, the controller is connected with the material shifting driving device and the weighing device in a signal mode, and controls the operation of the material shifting driving device, timing and quantitative automatic feeding is achieved, and blocking of an outlet caused by agglomeration during discharging is avoided.

Owner:BAOTOU XIJUN RARE EARTH

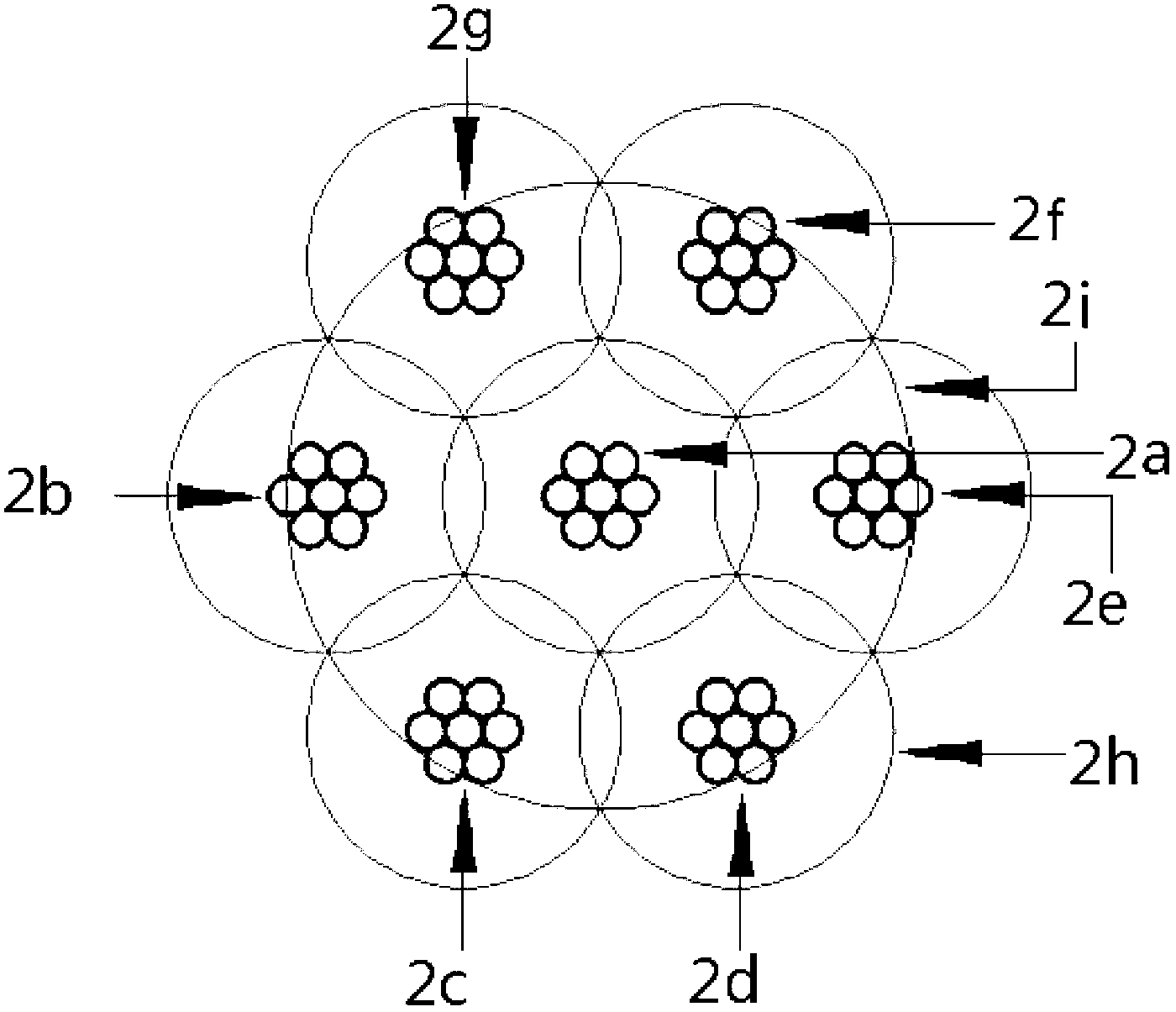

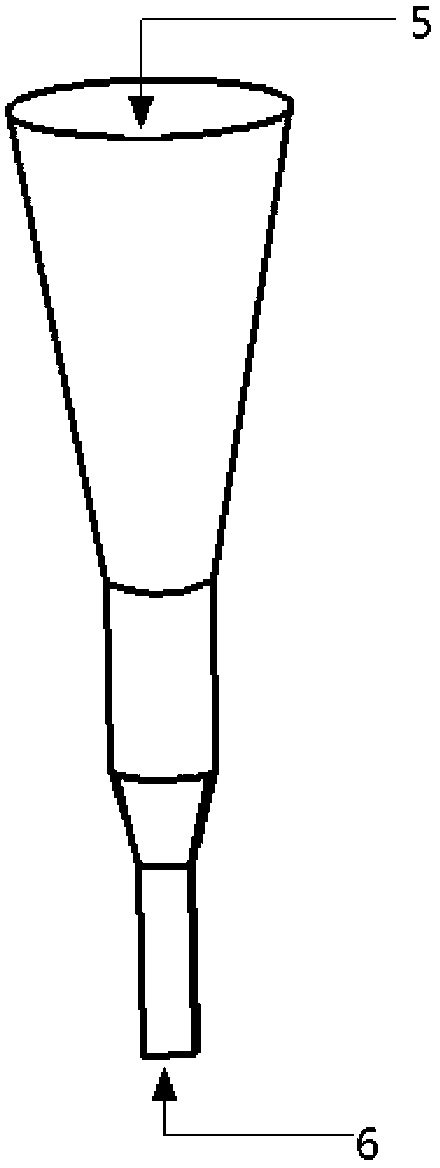

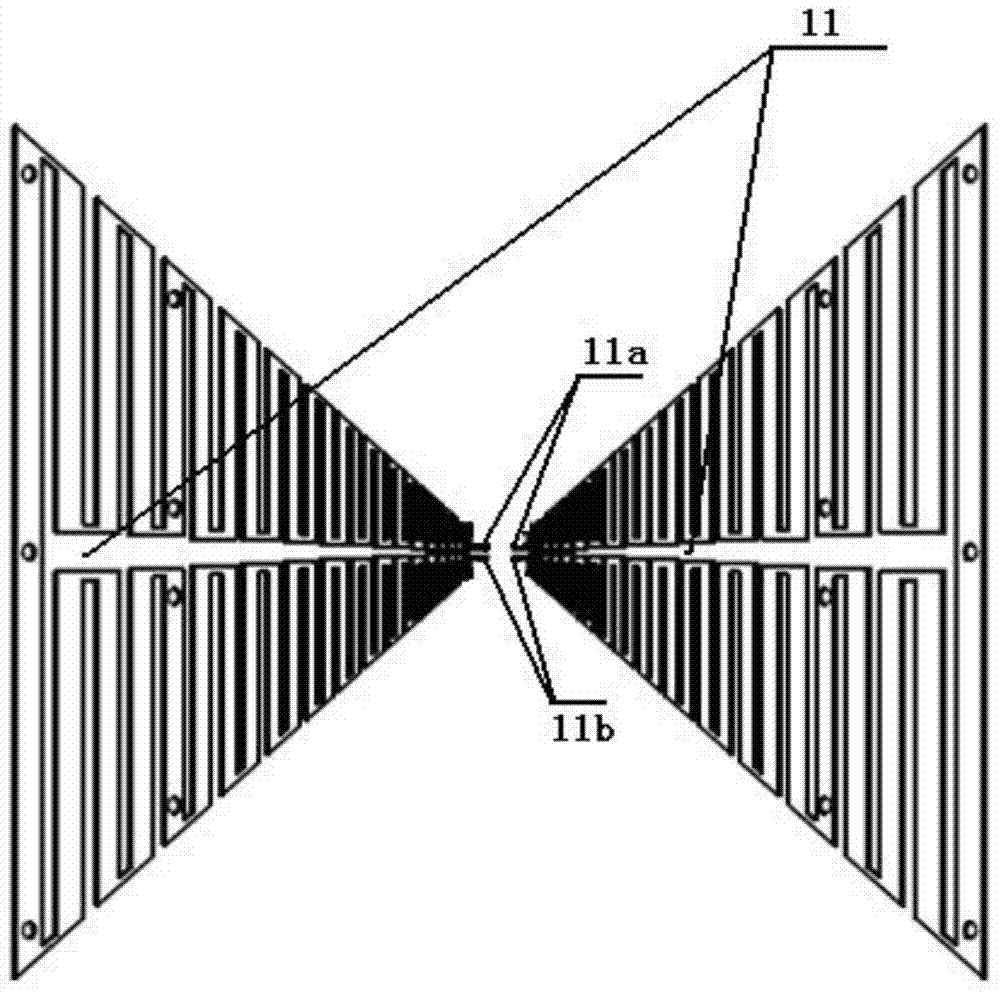

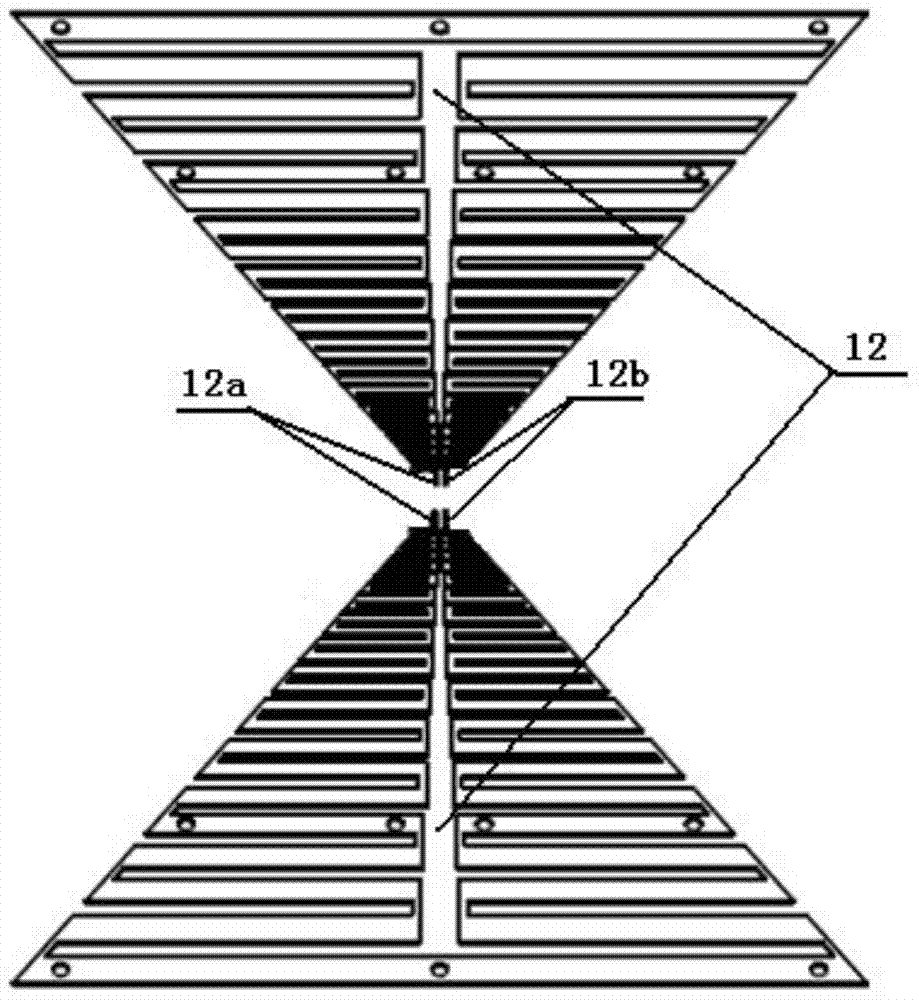

Broadband dual-linearly-polarized or dual-circularly-polarized feed source

ActiveCN104505591APhase center stableReduce the number of feedingAntenna arraysSimultaneous aerial operationsDual linear polarizationImpedance matching

The invention discloses a broadband dual-linearly-polarized or dual-circularly-polarized feed source in the fields of wireless communication and radio astronomy. The broadband feed source consists of four groups of radiation oscillators, 2 impedance-matched printed boards and a circularly-polarized electric bridge, wherein the radiation oscillators are log periodic dipole arrays, and are connected with the two impedance-matched printed boards which are orthogonally arranged, so that impedance values of the wide ends of metal microstrip lines of the impedance-matched printed boards are 1 / 4 of impedance values between left and right pins of the radiation oscillators, so that feeding is simplified, and high performance is achieved. The broadband feed source is simple and compact in structure, low in feed loss and machining cost, high in feed efficiency and particularly applicable to a feed network of a feed source or antenna working under a broadband dual-linear-polarization or dual-circular-polarization application condition.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

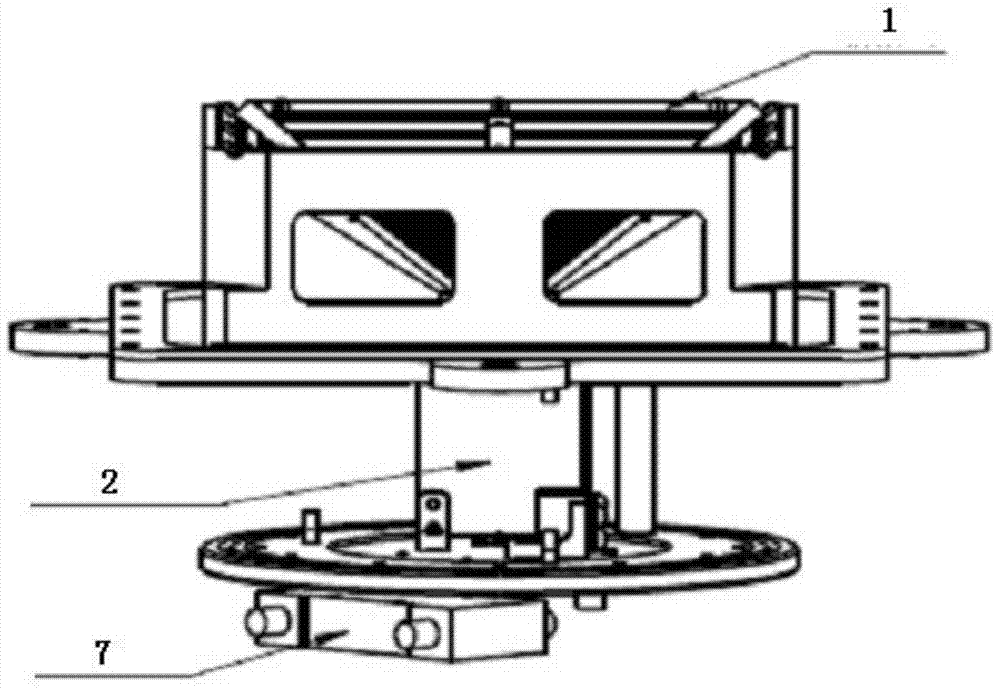

Satellite-borne sparse phased-array multi-beam antenna with reflector

The invention relates to a satellite-borne sparse phased-array multi-beam antenna with a reflector, and belongs to the technical field of antennas. The satellite-borne sparse phased-array multi-beam antenna comprises the offset parabolic reflector, a feed source array and a master control circuit. The feed amplitude and phase of the feed source array are controlled by the master control circuit, and electromagnetic waves radiated by the feed source array are converged via the offset parabolic reflector and then are radiated to space. The quantity of required feed source units of the antenna is low, beams can be subjected to phase control, and the satellite-borne sparse phased-array multi-beam antenna can be widely applied to satellite-borne communication, detection and positioning systems.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

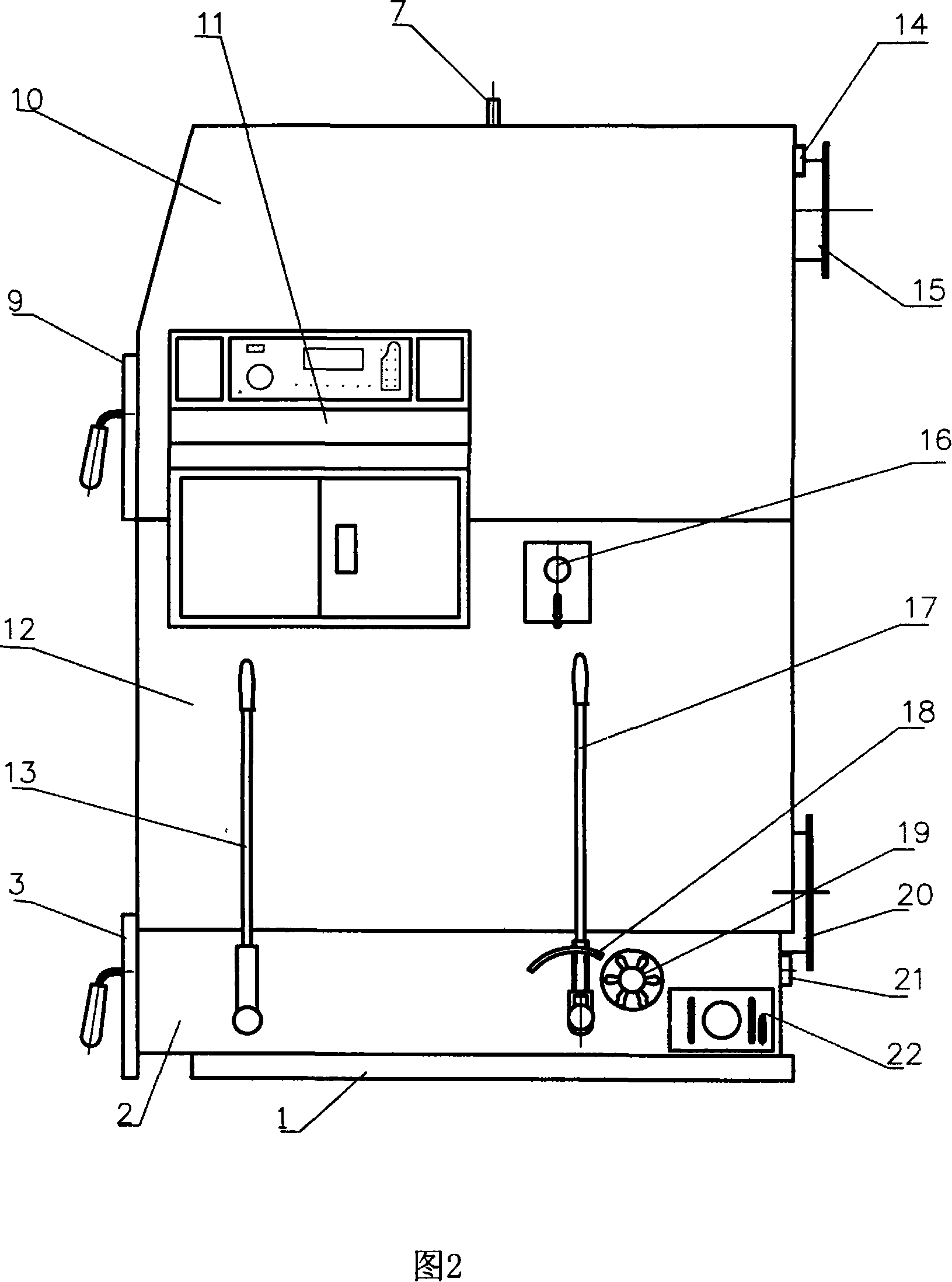

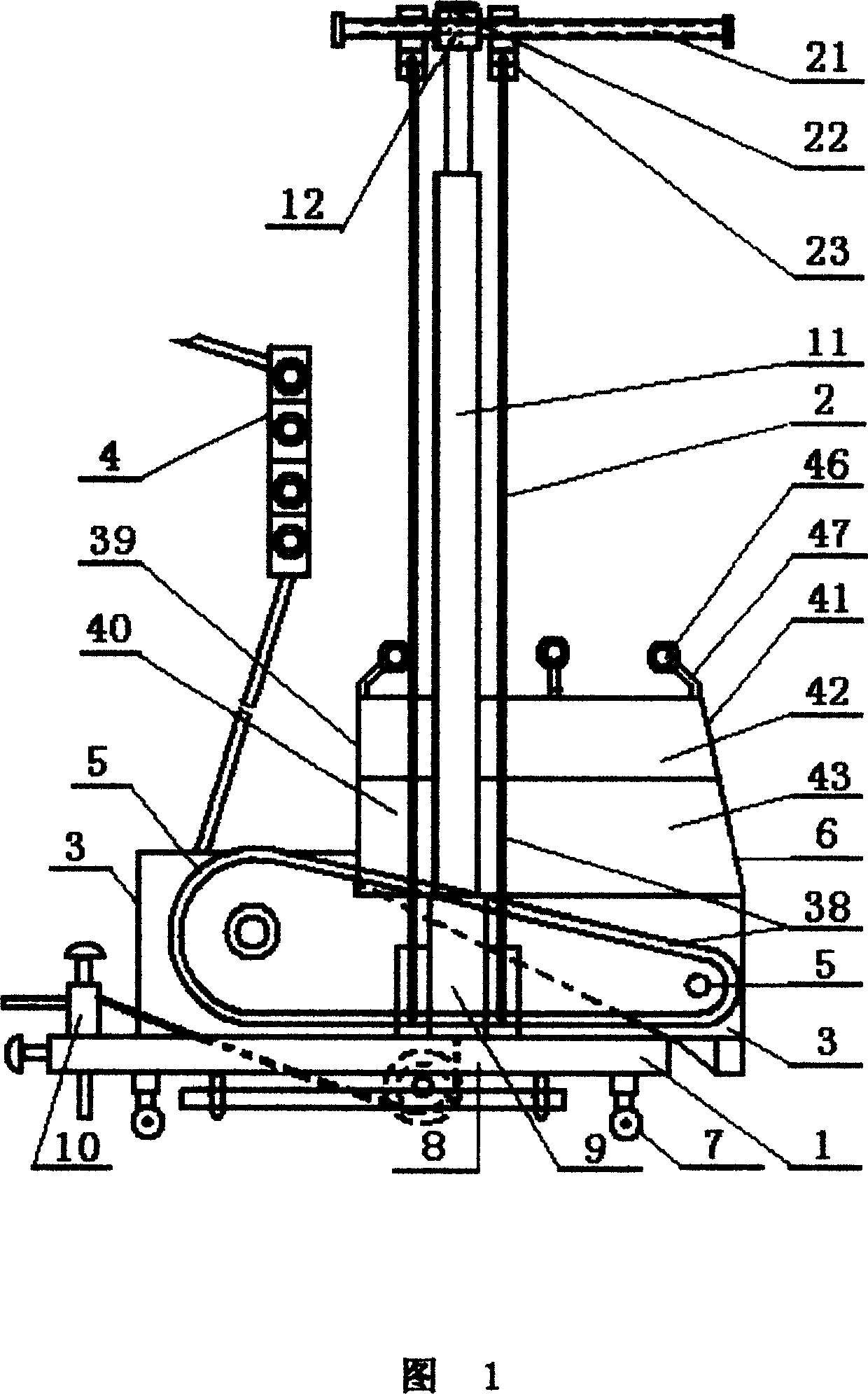

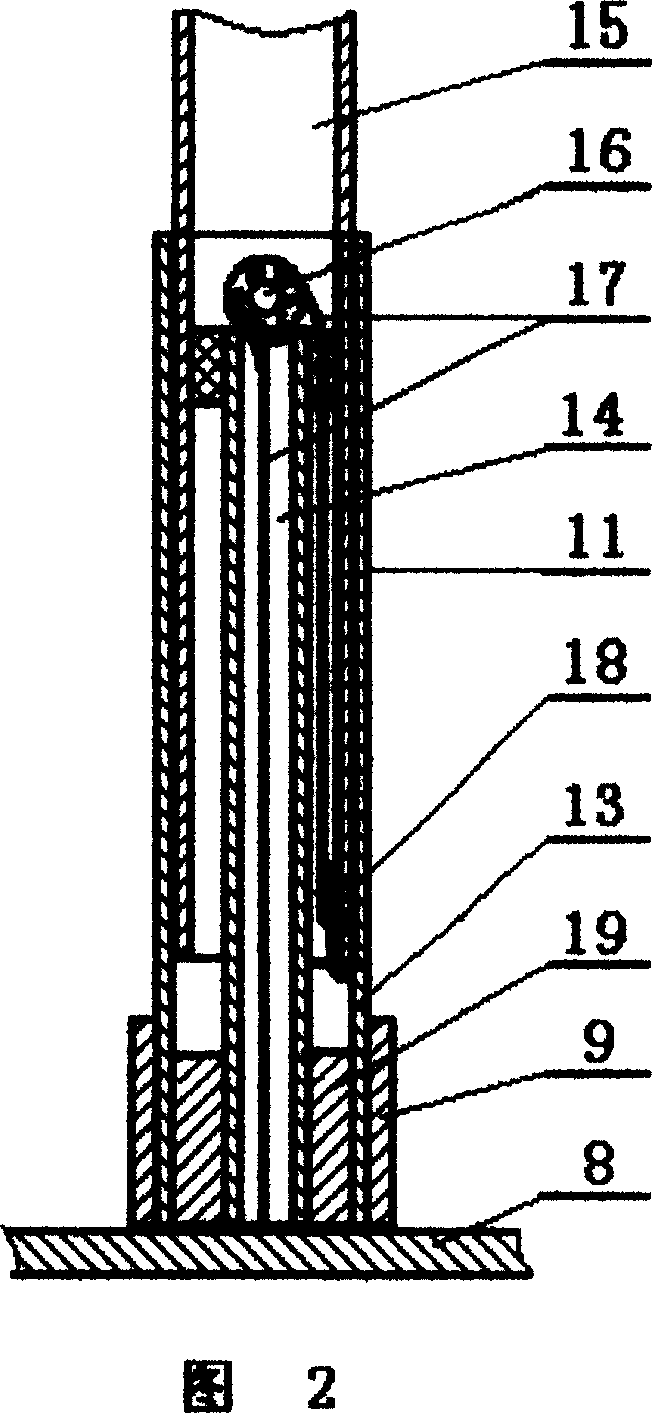

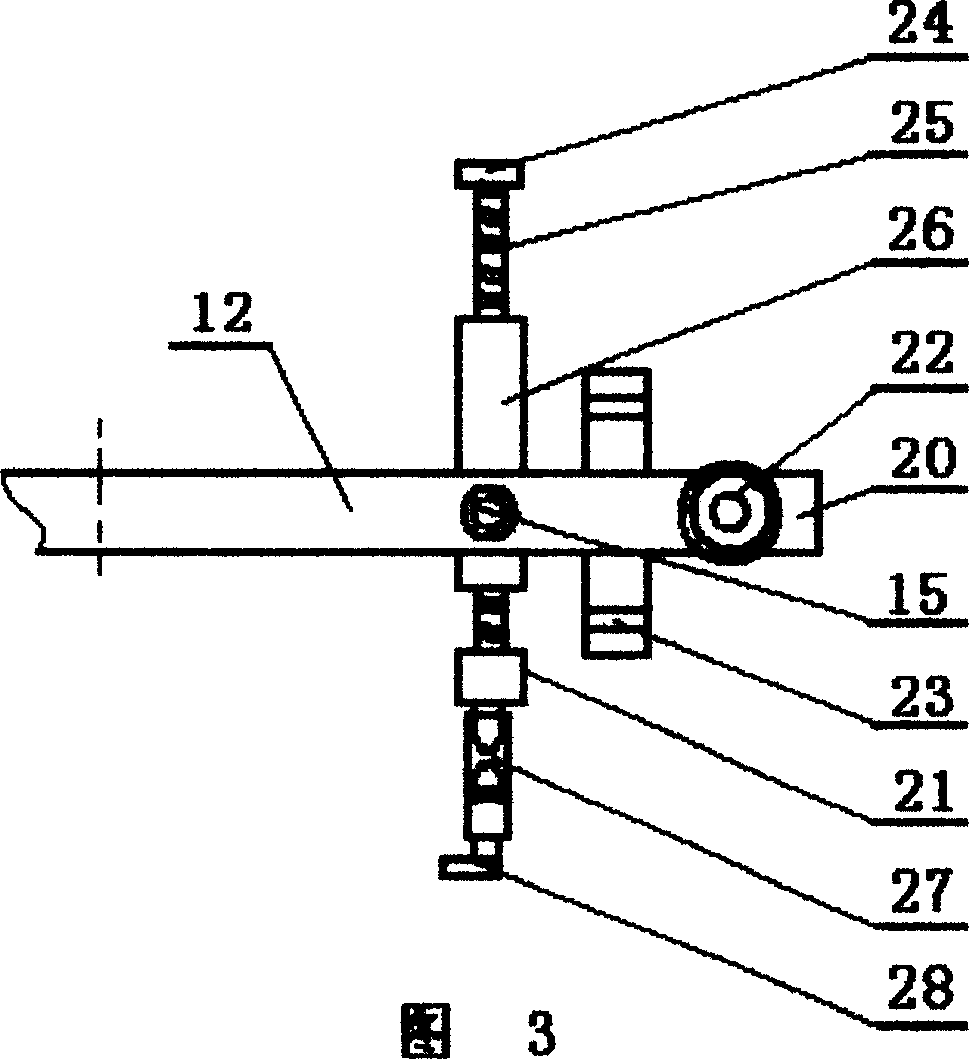

Conveniently moving automatic plastering machine

InactiveCN1924254APrecise positioningStrong job securityBuilding constructionsElectrical and Electronics engineeringMaterial volume

This invention relates to one automatic printing machine, which comprises bottom socket, gate rack, main frame, control structure, drive structure and printing structure, wherein, the bottom socket is set with direction move leg, gate rack and left and right tightening rope; the gate rack is composed of process tube, stand tube, lift tube cover, left and right column with contract function and printing thickness adjust structure with prompt thickness adjusting function, top limit parts against position wall function and beam hanging from main frame; the control structure is formed by process switch with overflow protection function; the materials bin is formed by basic bin and aid bin; the aid bin is set on bin formed by side board to add materials volume to top position.

Owner:SHANGHAI DARONG MACHINERY DEVICE

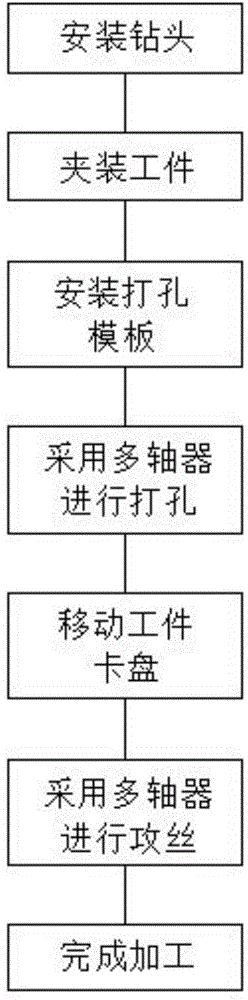

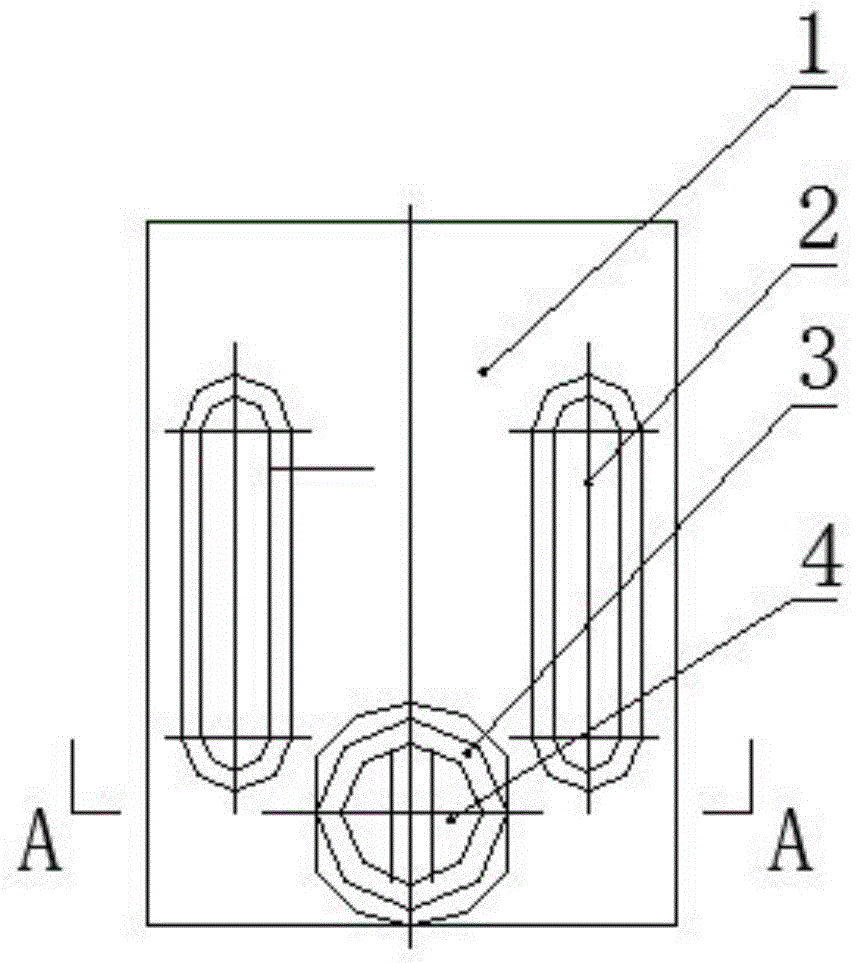

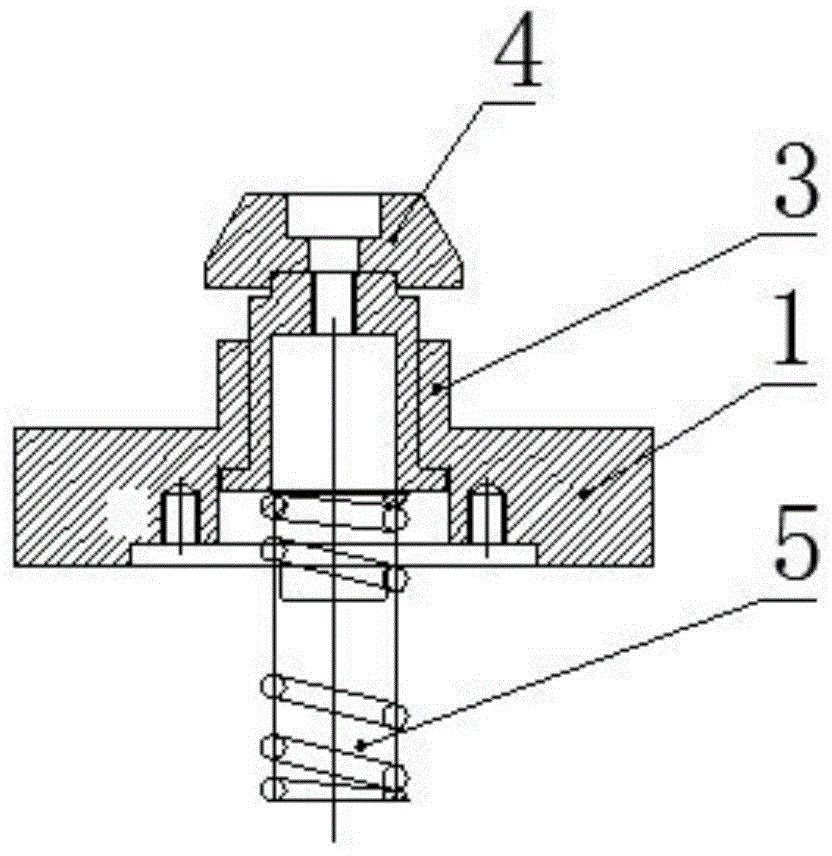

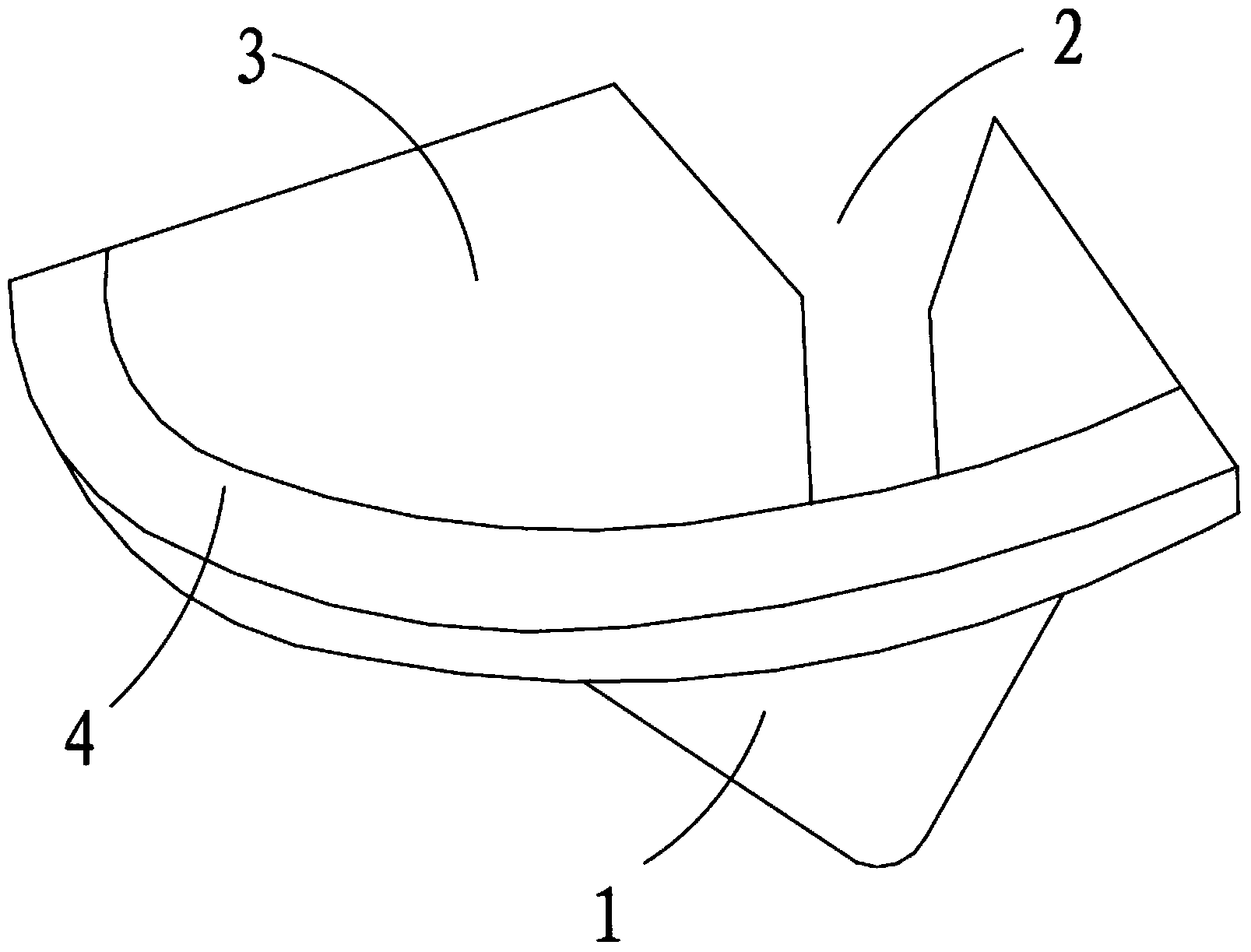

Aluminum alloy wheel punching method

ActiveCN104475795AReduce the number of feedingImprove processing efficiencyThread cutting machinesChucksPunchingProduct processing

The invention relates to an aluminum alloy wheel punching method. The aluminum alloy wheel punching method includes 1, mounting a drill bit; 2, clamping a workpiece; 3, mounting a punching die plate; 4, performing punching by a multi-spindle tool; 5, moving a workpiece chuck; 6, adopting the multi-spindle to perform tapping; 7, finishing process and detaching wheel workpiece. According to the arrangement, one-piece product processing time is saved by 70 seconds, machining efficiency and yield are effectively increased, scrapping caused by hole deviation is reduced, output is increased, and production cost is lowered.

Owner:BAODING CITY LIZHONG WHEEL MFG

Sponge iron for furnace charge and its manufacturing method

A spongy iron for burden is proportionally prepared from the iron ore concentrate powder with iron content more than 66%, or iron scales and spongy iron additive prepared proportionally from carbon powder, carbonate of alkali metal or alkali-earth metal and the halide of alkali metal or alkali-earth metal.

Owner:张和起

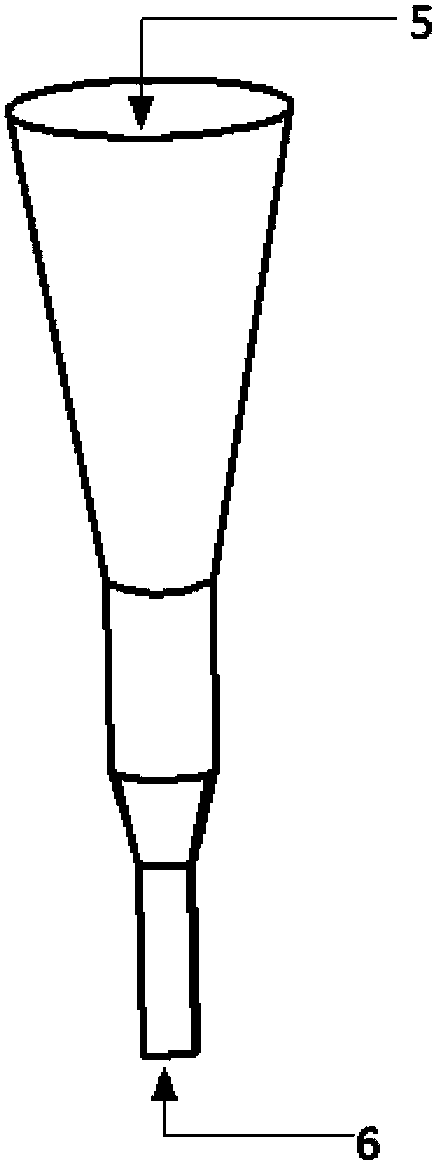

Hopper

Owner:山东未来城建筑工程有限公司

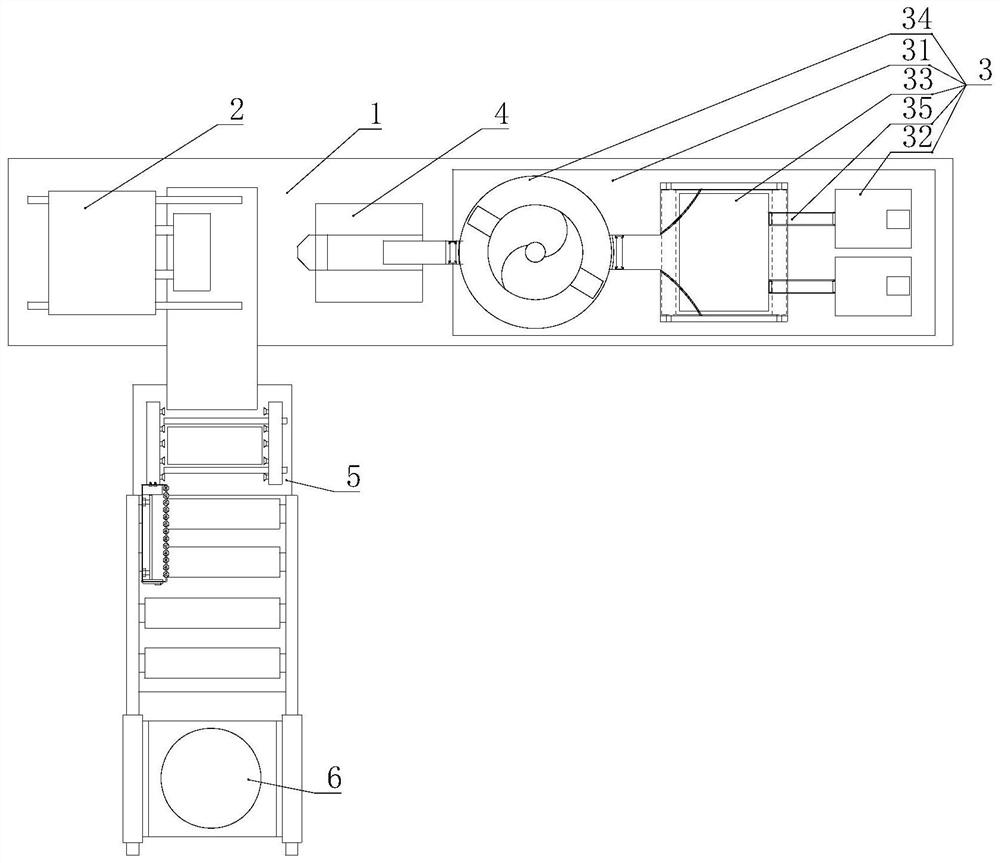

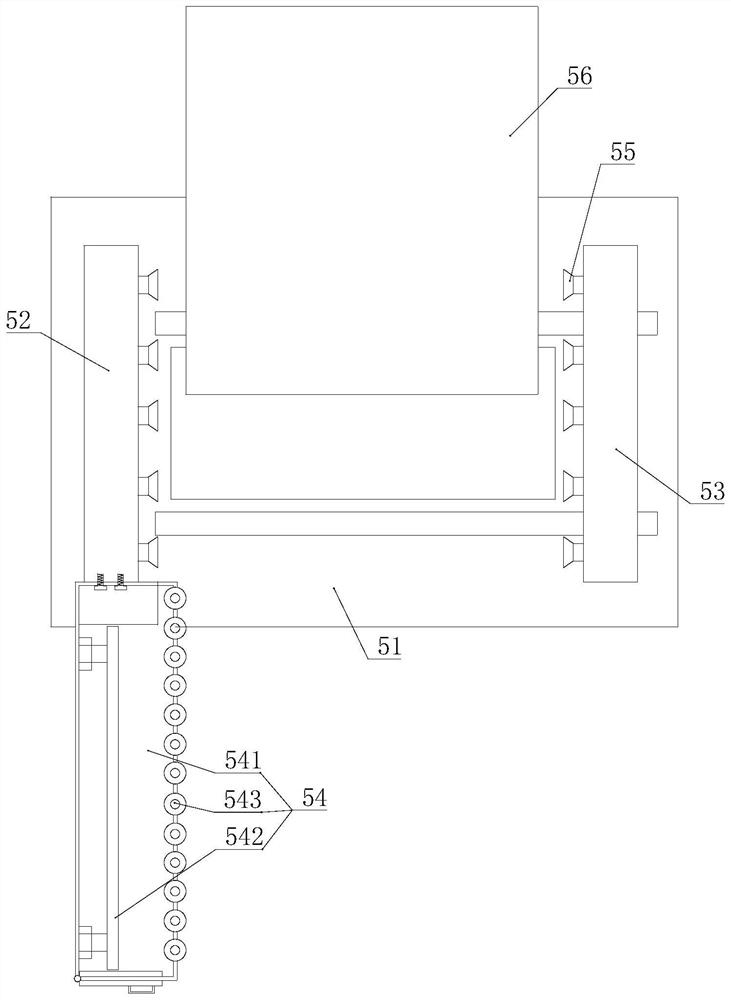

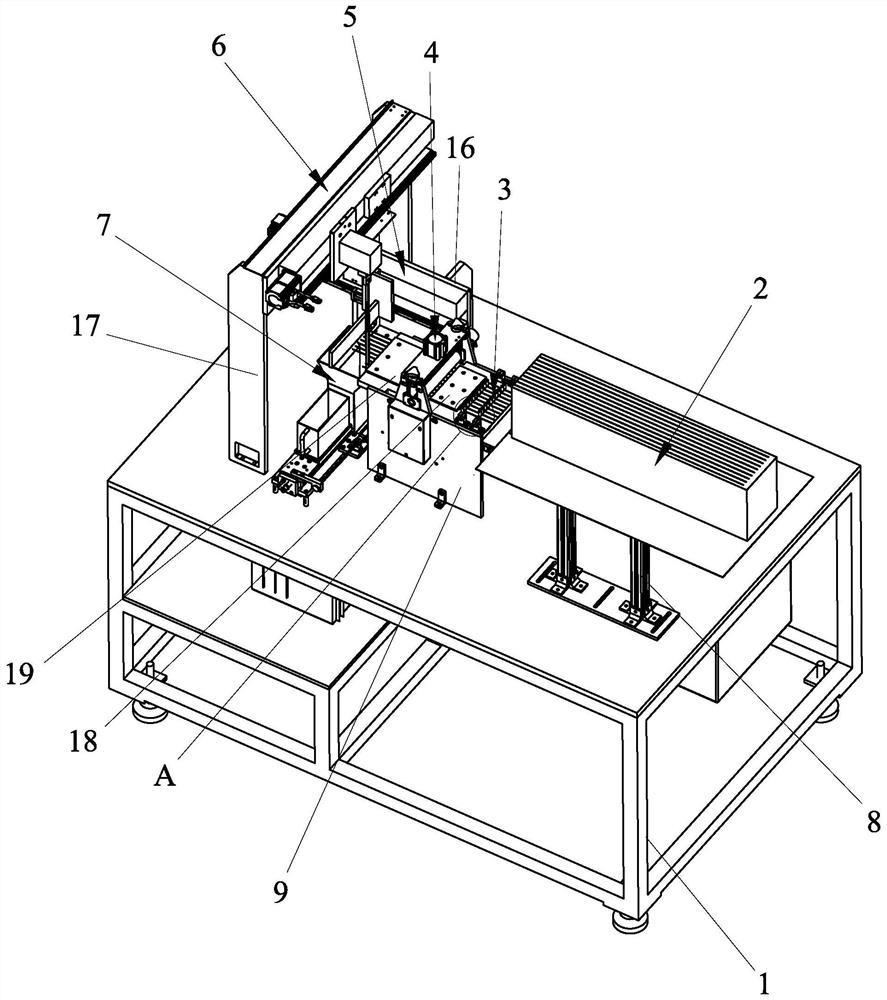

Automatic feeding, packaging and injection molding equipment and application method thereof

The invention discloses automatic feeding, packaging and injection molding equipment and an application method thereof. The automatic feeding, packaging and injection molding equipment comprises a mounting table, an injection mold, an automatic feeding device, an injection component and a receiving device; the injection mold is arranged on one side of the mounting table; the automatic feeding device comprises a mounting step, a dewatering and storing component, a weighing component, a mixing component and a conveying channel; the mounting step is arranged on the other side of the mounting table; the mounting step comprises a first step, a second step and a third step which are arranged from low to high; the mixing component, the weighing component and the dewatering and storage component are sequentially arranged on the first step, the second step and the third step; the injection component is arranged between the injection mold and the automatic feeding device; the receiving device comprises a base, a fixed frame, a movable frame, a bag storage component and a suction cup; the base is arranged on one side of the mounting table; the fixed frame and the movable frame are oppositelyarranged on the two sides of the base; the bag storage component is fixedly arranged on one side of the fixed frame; and the suction cup is arranged on the side, opposite to the movable frame, of thefixed frame.

Owner:太仓市冬鑫塑料制品有限公司

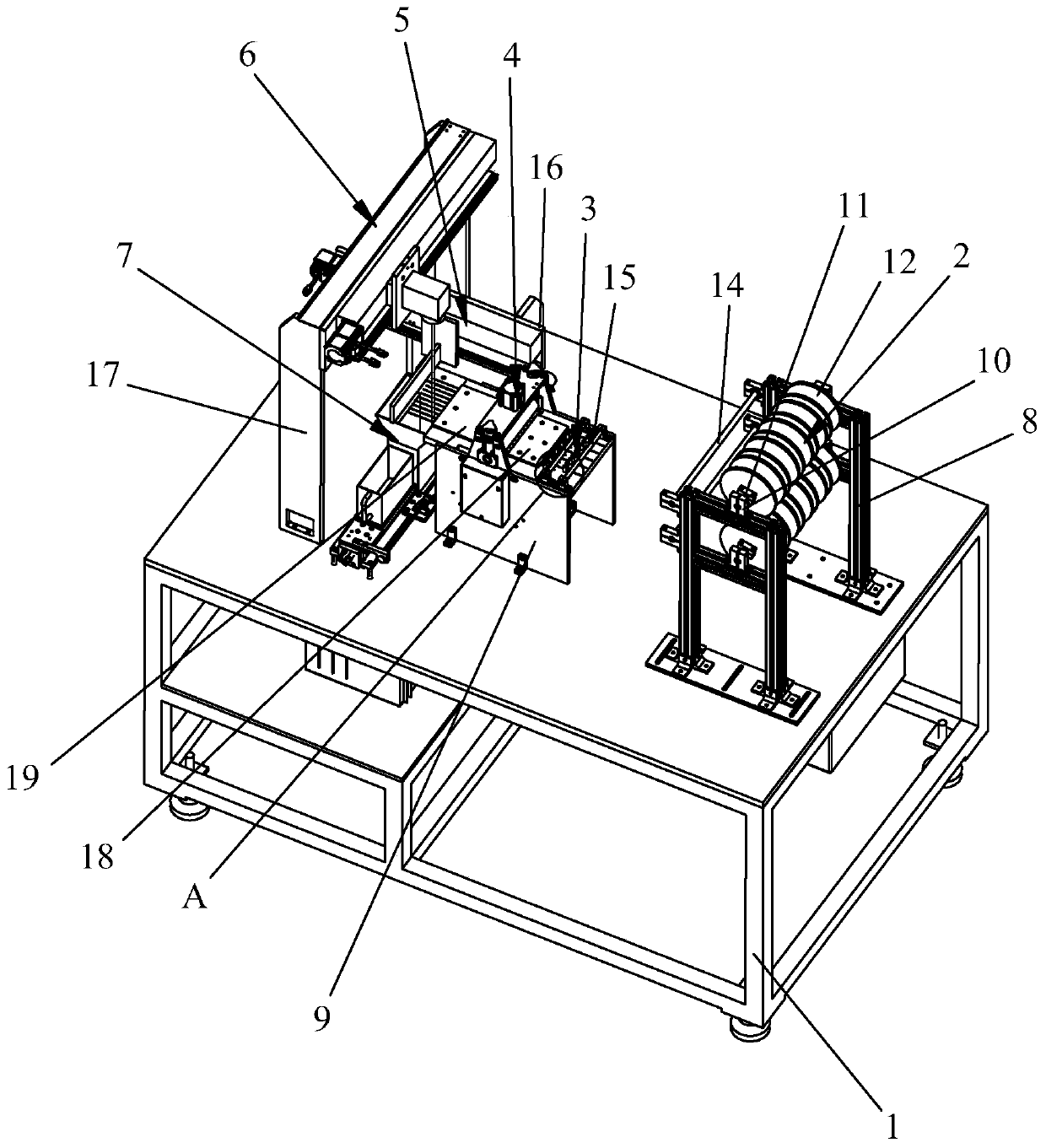

Stainless steel pipe cutting device for pen

ActiveCN110948037AQuick cutGuarantee the safety of lifeTube shearing machinesShearing machine accessoriesEngineeringStructural engineering

The invention discloses a stainless steel pipe cutting device for a pen. The device comprises a cabinet body, a winding mechanism, a guiding mechanism, a feeding mechanism, a size limiting mechanism,a cutting mechanism and a material receiving mechanism, wherein a fixing frame is arranged on the cabinet body, the winding mechanism is arranged on the fixing frame and is used for winding a stainless steel pipe, a supporting table is arranged on the position, located on one side of the fixing frame, of the cabinet body, the guiding mechanism and the feeding mechanism are arranged on the supporting table, the feeding mechanism pulls the stainless steel pipe and is guided through the guiding mechanism, and when the head end of the stainless steel pipe is conveyed above the material receiving mechanism and abuts against the size limiting mechanism, the cutting mechanism cuts the stainless steel pipe and the cut stainless steel pipe is collected through the material receiving mechanism. Thedevice has the advantages of high processing efficiency, good processing precision, high safety, and can guarantee the life safety of employees.

Owner:WENZHOU UNIVERSITY

Device for automatically cutting off fiber nibs

ActiveCN110978072AImprove processing efficiencyImprove machining accuracyMetal working apparatusStructural engineeringFiber

The invention discloses a device for automatically cutting off fiber nibs. The device comprises a cabinet, a discharging mechanism, a guiding mechanism, a feeding mechanism, a size limiting mechanism,a cutting mechanism and a collecting mechanism, wherein a fixing frame is arranged on the cabinet, the discharging mechanism is arranged on the fixing frame and is used for guiding out fiber strips,the portion, located at one side of the fixing frame, of the cabinet is provided with a supporting platform, the guiding mechanism and the feeding mechanism are arranged on the supporting platform, and the feeding mechanism pulls the fiber strips and conducts guiding through the guiding mechanism. When the head ends of the fiber strips are conveyed to the position above the conveying mechanism andabut against the size limiting mechanism, the cutting mechanism cuts the fiber strips, and the fiber strips which are cut off are collected through the collecting mechanism. The device has the advantages of being high in machining efficiency and machining precision, high in safety and capable of guaranteeing life security of employees.

Owner:WENZHOU UNIVERSITY

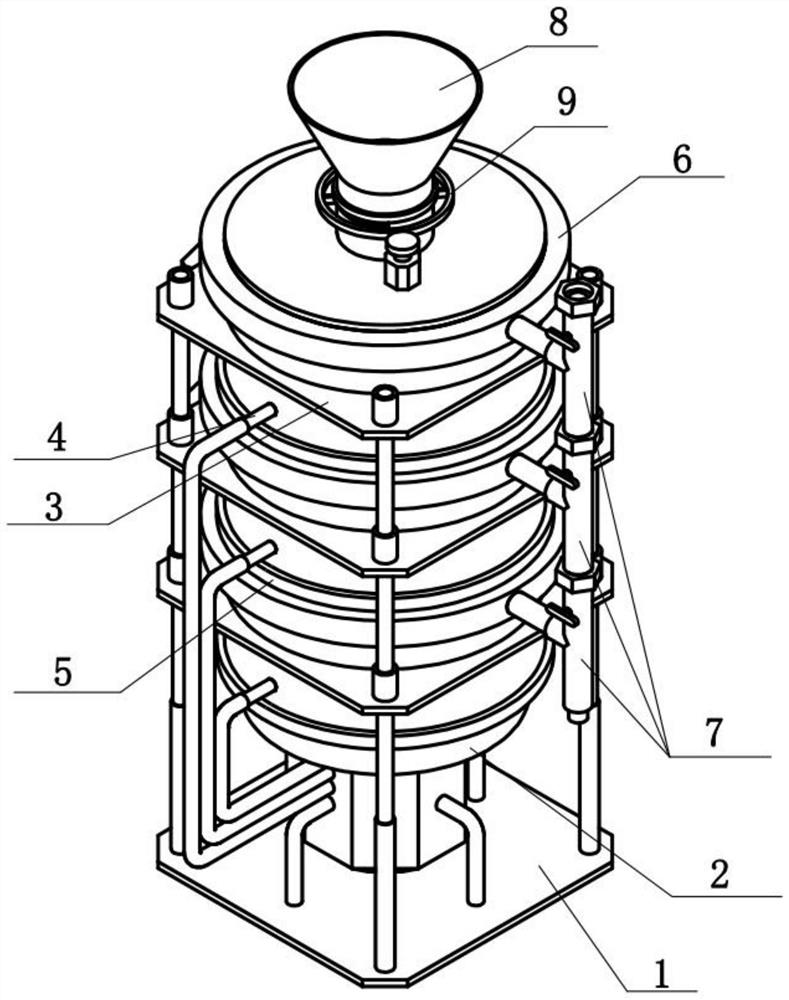

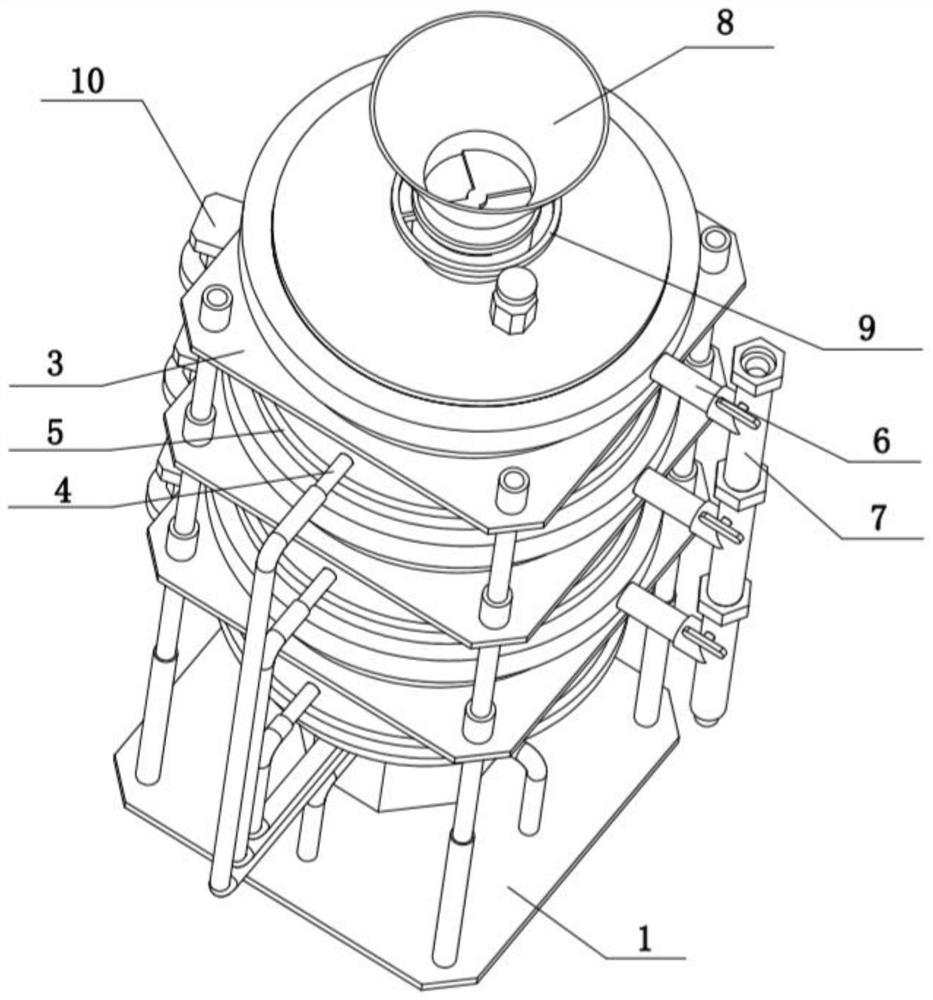

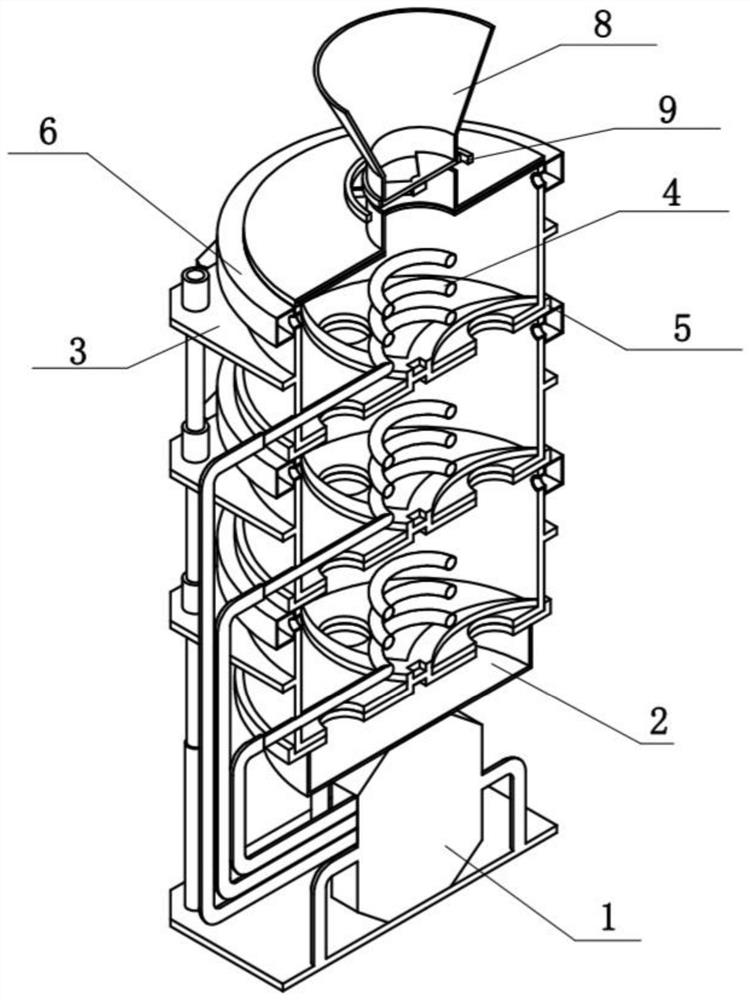

Garbage thermal cracking gasifier

ActiveCN111748378AKeep dryPromote pyrolysisGasification processes detailsGasification with fuel pre-distillationThermodynamicsProcess engineering

The invention relates to the technical field of garbage treatment equipment and relates to a garbage thermal cracking gasifier. The gasifier comprises a high-temperature heating assembly, an ash box,reaction outer frame assemblies, heating assemblies, discharging assemblies, an air outlet assembly, a guiding assembly, a storage assembly, a feeding assembly and driving assemblies; modular rapid assembly can be carried out; reaction places with different temperatures can be provided for a garbage thermal cracking gasification process through the multiple reaction outer frame assemblies; different temperatures can be provided for the plurality of heating assemblies through the high-temperature heating assembly; a plurality of processes of drying, thermal cracking and oxygenolysis of garbageare convenient to carry out; in addition, the multiple discharging assemblies can be driven by the multiple driving assemblies to rotate, so that the discharging of processed garbage of the multiple reaction outer frame assemblies corresponding to one another in a veridical direction is achieved; the requirements of multiple treatment processes needed by garbage treatment can be met through rapidmodular assembly of the multiple reaction outer frame assemblies, and installation is rapid and convenient.

Owner:湖南美中环境生态科技有限公司

Biological-material ball gasifying method and apparatus

InactiveCN1936428AEasy centralized processingEasy to addDomestic stoves or rangesEnergy inputCombustible gasHoneycomb

This invention relates to a biological material gasifying field including: a fan, a flowmeter, a water tank, a loop gas-collecting chamber, a hearth, a purifier, a stove, a heat preservation layer, a loop air-preheating room, a grate, a gasification agent tube and biological balls characterizing in applying vapor and air or air as the gasification agent and applying specially made biological balls of honeycomb balls as the raw material to produce combustible gas, in which, the upper part of the outside of the stove is a water tank made of stainless steel, the fan is connected with a loop air preheating chamber at the bottom of the hearth via the gasification agent tube, the heat preservation layer, the inner container and the hearth are orderly set in the stove, the grate is under the hearth and an ash chamber is under the grate, the loop gas collecting chamber is above the inner container and is connected with a strong fire stove, a gas stove and a heating stove via the gas conduction tube and the purifier, the end of the gas conduction tube is the chimney with a valve on it.

Owner:刘春生

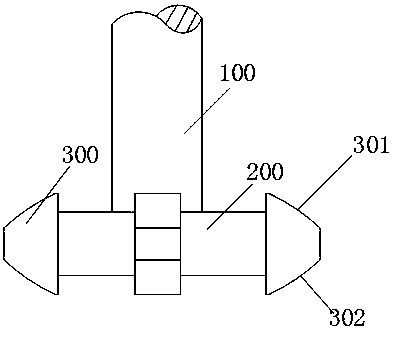

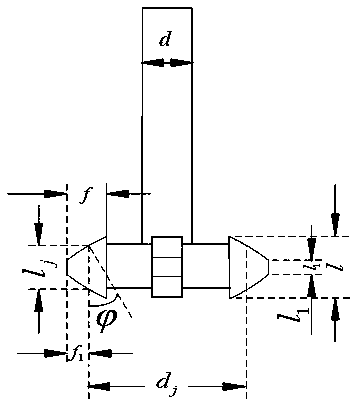

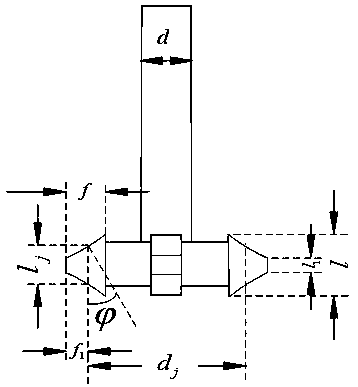

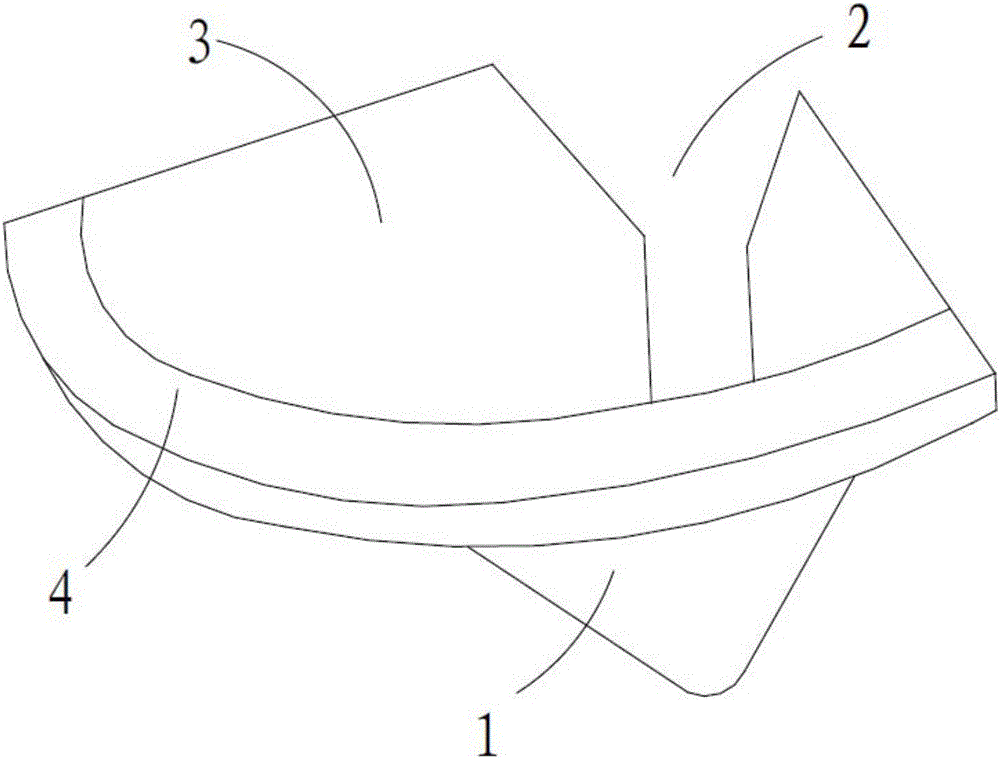

Profiling cutter and method used for inner-tooth-line gear processing

InactiveCN110014196AQuality improvementReduce the number of feedingGear teeth manufacturing toolsGear teethMilling cutterEngineering

The invention discloses a profiling cutter and a method used for inner-tooth-line gear processing. The profiling cutter comprises a cutter bar, a cutter disc and cutter teeth, wherein the cutter bar is used for clamping a milling cutter; the cutter disc is fixedly arranged on the bottom of the cutter bar; the cutter teeth are internally concave or externally convex; the cutter teeth with internalconcave shapes are used for processing the inner-tooth-line gear of a tooth profile external convex form; the cutter teeth of external convex shapes are used for processing the inner-tooth-line gear of a tooth profile internal concave form; and the cutter teeth are fixedly arranged at left and right ends of the cutter disc. The cutting edge profile shape of the profiling cutter is conjugated witha gear surface generatrix of a linear gear, and a mathematical relationship of movement track of a milling cutter in a milling process is given. The profiling cutter has relatively good adaption to the linear gear with the gear surface inside a gear body, and improves processing efficiency and processing quality of a milled gear.

Owner:佛山市二轴半科技有限公司

Rocking feeder

The invention discloses a rocking feeder, comprising: a frame; a storage barrel mounted on the frame and having a discharge port; a conveying mechanism comprising a rocking plate, connection rods, a storage trough and a plurality of springs, wherein the rocking plate is mounted on the storage barrel and corresponds to the discharge port, the storage trough is positioned below the discharge port, the upper ends of the connection rods are hinged to the rocking plate, the lower ends of the connection rods are connected to the storage trough, the springs are mounted at the lower end of the storagetrough, the springs are used for driving the storage trough to lift, and the storage trough drives the rocking plate to rotate during lifting; sliding scraping mechanisms each of which comprises a sliding bottom plate, a scraper plate and a driving blade, wherein the sliding bottom plate is mounted in the storage trough, the scraper plate is mounted on the sliding bottom plate, and the driving blade is connected with the sliding bottom plate; and a feeding trough that is mounted on the frame below the storage trough. The conveying mechanism herein can automatically supplement feedstuff, the number of adding feedstuff is decreased for staff, and labor intensity is reduced.

Owner:TIANE COUNTY PINGCHANG ECOLOGICAL AGRI

Pipeline inner wall silicone rubber section coating equipment and working method thereof

InactiveCN114308554AHigh speedAvoid scratchesLiquid surface applicatorsCoatingsPolymer sciencePolymer chemistry

The invention relates to the technical field of pipeline inner wall silicone rubber section coating, in particular to pipeline inner wall silicone rubber section coating equipment and a working method thereof.The pipeline inner wall silicone rubber section coating equipment comprises a first base table, a second base table, a material storage box, a pipe taking assembly, a pipe conveying assembly, a pipe drawing assembly and a coating assembly; meanwhile, the inner wall of the pipeline is subjected to section coating of silicon rubber through rotation of the section coating rotary drum, the same pressure can be applied to the inner wall of the pipeline at each position of the section coating rotary drum, and then the inner wall of the pipeline is subjected to section coating more evenly through the equipment; the sleeve brush can prevent the section coating rotary drum from scratching the inner wall of the pipeline, the inner wall of the pipeline is protected, the coating box and the coating pipe are arranged, silicone rubber coating can be continuously provided for the section coating rotary drum, and silicone rubber coated on the inner wall of the pipeline in a section mode can be thick enough.

Owner:苏州睿杰特电子科技有限公司

hopper

Owner:山东未来城建筑工程有限公司

A multi-layer dual-frequency broadband antenna and communication equipment

ActiveCN112838357BSmall sizeReduce thicknessSimultaneous aerial operationsAntenna supports/mountingsAxis of symmetryDielectric substrate

The invention discloses a multi-layer dual-frequency broadband antenna and communication equipment, comprising: a dielectric substrate, a first radiating patch, a second radiating patch, a feeding part, and a signal input piece; the feeding part includes a feeding probe, a gradient The transmission line, the two ends of the feeding probe are respectively electrically connected to the first radiation patch and the tapered transmission line, and the other end of the tapered transmission line is electrically connected to the signal input chip; wherein, both the first radiation patch and the second radiation patch have two symmetrical axis, the length of the first radiating patch along one of its symmetry axes is greater than that along its other symmetry axis, the length of the second radiating patch along its one symmetry axis is greater than its length along its other symmetry axis, and the length of the first radiating patch along its other symmetry axis, along the dielectric substrate The surface normal direction of the first radiation patch overlaps with the second radiation patch, and the first radiation patch is smaller than the second radiation patch; the feeding position of the feeding probe electrically connected to the first radiation patch deviates from the first radiation patch The two symmetry axes of the patch are set. The invention has the technical characteristics of ultra-low profile, dual-frequency broadband and simple structure.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

A graphene paint spraying device for repairing double-layer storage tanks

ActiveCN111167632BAvoid uneven sprayingReduce the number of feedingLiquid spraying apparatusGraphene coatingEngineering

The invention provides a graphene paint spraying device for double-layer storage tank repairing. The graphene paint spraying device comprises a tank body, a stirring machine, a feeding port, a partition plate, a baffle plate, a leaking plate, leaking holes, a rotating rod, a gear, connecting rods, stopping plates, a toothed rod, a piston I, a reducing U-shaped pipe, a piston II, a pressing plate,springs, a filter screen and a supercharger. The graphene paint spraying device for double-layer storage tank repairing has the beneficial effects that when mixed graphene paint is almost used up, thepressing plate is ejected under the action of the springs; due to the principle of a communicating vessel, the toothed rod moves to the left, and the gear and the rotating rod are driven to rotate counterclockwise by 30 degrees; at the time, the stopping plates are staggered from the leaking holes; the paint positioned above the partition plate leaks downward through the leaking holes and can beused after being screened, and thus the paint sufficiency can always be kept; and accordingly, the effect that the paint is always sufficient can be achieved, the situations of paint insufficiency andspraying non-uniformity can be avoided, the adding frequency can be reduced, and the working efficiency can be improved.

Owner:长园泽晖新能源材料研究院(珠海)有限公司

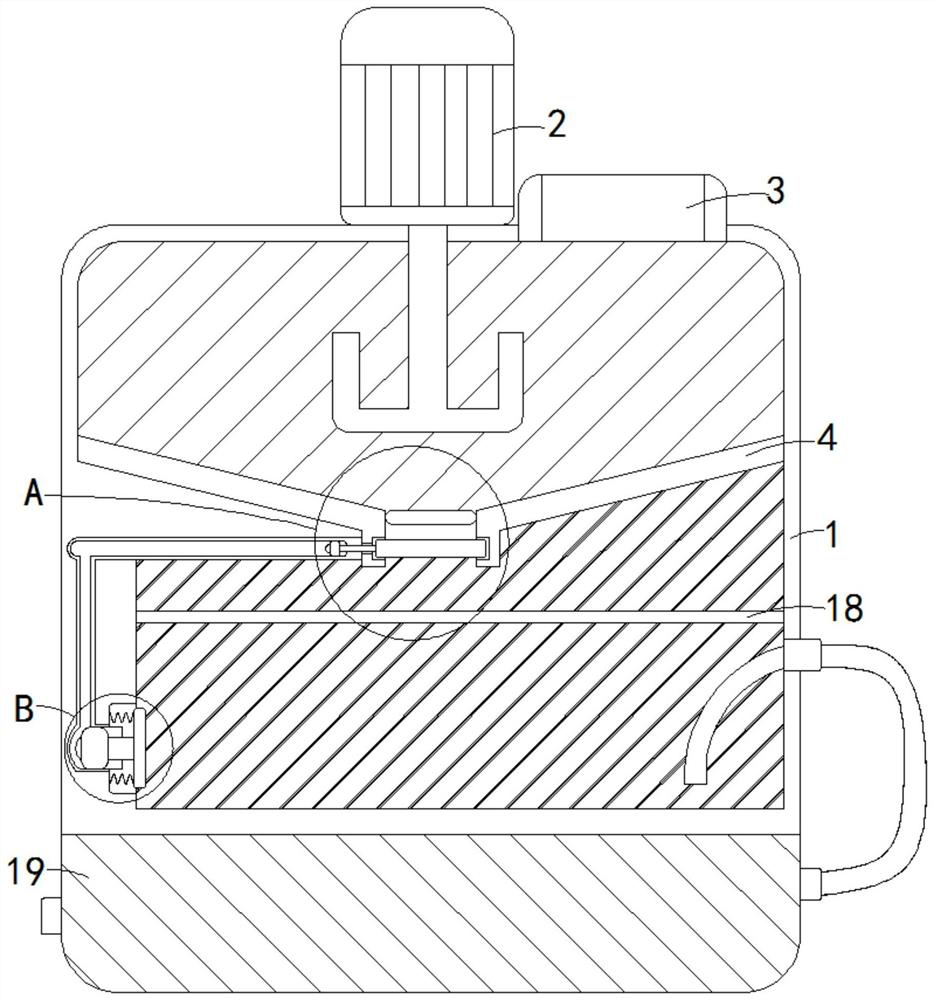

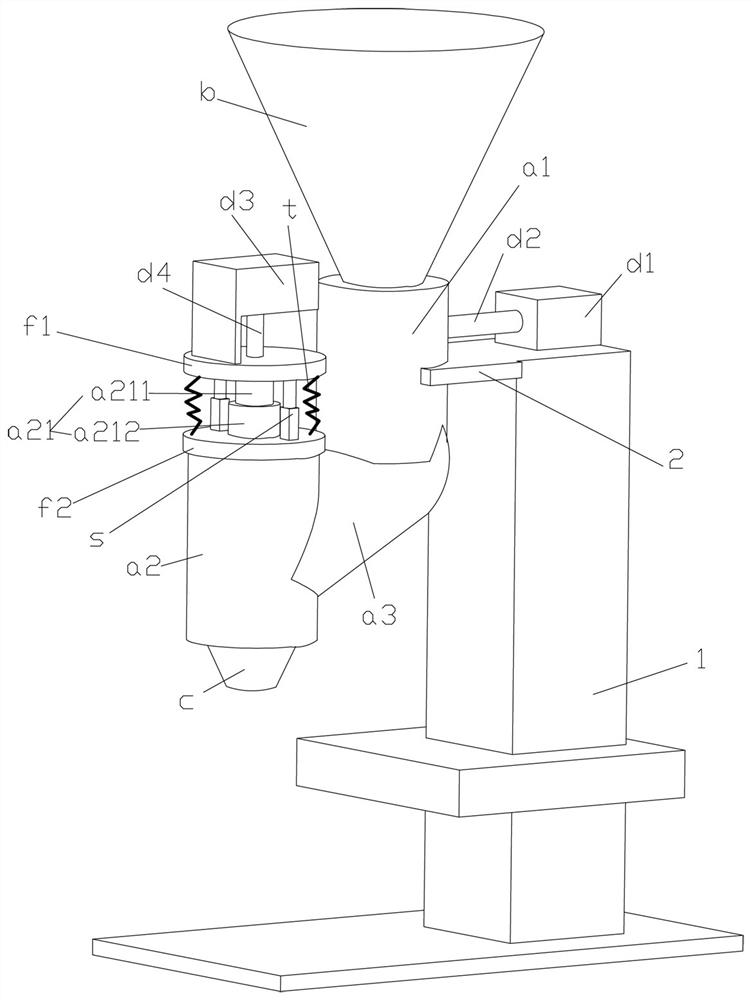

Selenium drum automatic powder filling system

PendingCN112506016AReduce the number of feedingStir thoroughlyElectrographic process apparatusComputer printingEngineering

The invention relates to the technical field of printer equipment, in particular to a selenium drum automatic powder filling system, which comprises a supporting rod and a supporting plate connected to the supporting rod and extending forwards. A first vertical material passing pipe communicating up and down is fixed to the supporting plate, the upper end of the first vertical material passing pipe communicates with a hopper, the lower end of the first vertical material passing pipe communicates with an oblique material passing pipe extending towards the front lower portion, a lower pipe opening of the oblique material passing pipe communicates with a second vertical material passing pipe located below the first vertical material passing pipe, a discharging nozzle is installed and connected to an outlet in the lower end of the second vertical material passing pipe, and the powder filling effect is better.

Owner:ZHEJIANG BESDA OFFICE EQUIP

An automatic fiber cutting device

ActiveCN110978072BGuarantee the safety of lifeImprove processing efficiencyMetal working apparatusFiberStructural engineering

The invention discloses a device for automatically cutting off fiber nibs. The device comprises a cabinet, a discharging mechanism, a guiding mechanism, a feeding mechanism, a size limiting mechanism,a cutting mechanism and a collecting mechanism, wherein a fixing frame is arranged on the cabinet, the discharging mechanism is arranged on the fixing frame and is used for guiding out fiber strips,the portion, located at one side of the fixing frame, of the cabinet is provided with a supporting platform, the guiding mechanism and the feeding mechanism are arranged on the supporting platform, and the feeding mechanism pulls the fiber strips and conducts guiding through the guiding mechanism. When the head ends of the fiber strips are conveyed to the position above the conveying mechanism andabut against the size limiting mechanism, the cutting mechanism cuts the fiber strips, and the fiber strips which are cut off are collected through the collecting mechanism. The device has the advantages of being high in machining efficiency and machining precision, high in safety and capable of guaranteeing life security of employees.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com