Hopper

A hopper and material technology, used in containers, packaging, transportation and packaging, etc., can solve the problems of less one-time feeding, small feeding hopper capacity, and increasing feeding times, so as to increase one-time feeding and reduce labor intensity. , The effect of reducing the number of feedings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

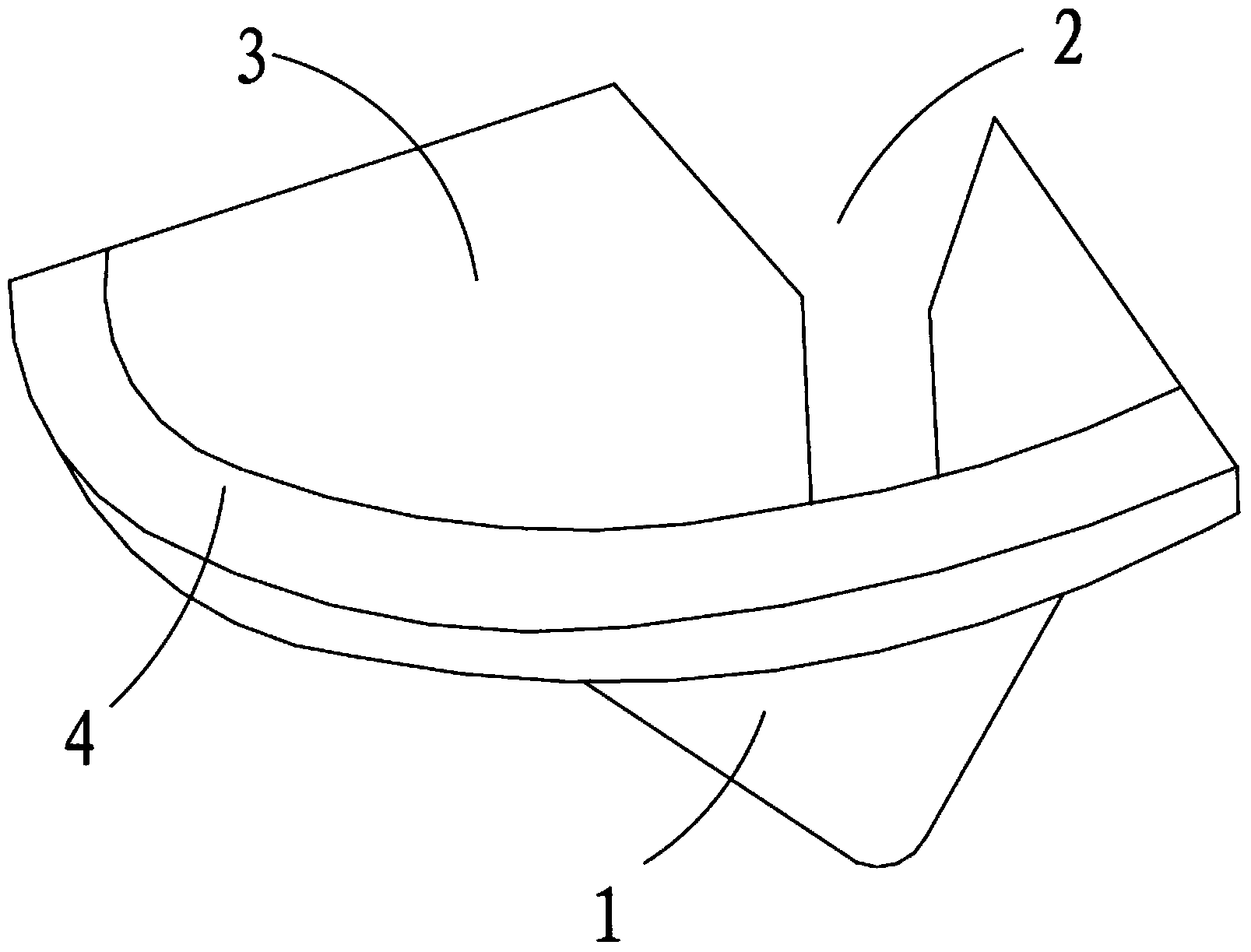

[0013] Such as figure 1 As shown, a hopper is arranged on the outside of the mixer for loading materials, including a hopper body, a discharge port is opened below the hopper body, and a feed inlet is opened above the hopper body. The cross-sectional area of the hopper body gradually decreases from top to bottom. The hopper body has a connection opening 2 for connecting with the mixer. The opposite side of the connection opening 2 has an arc surface 1. The The connecting opening 2 is connected with the arc surface 1 through two side planes 3, and the side plane 3 is connected with the arc surface 1 through a telescopic frame. The telescopic frame is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com