Scrap steel chipping packing machine

A chip and main frame technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increased labor intensity, poor compaction effect, and high labor intensity of workers, and achieve the goals of improving packaging efficiency, equipment reliability, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

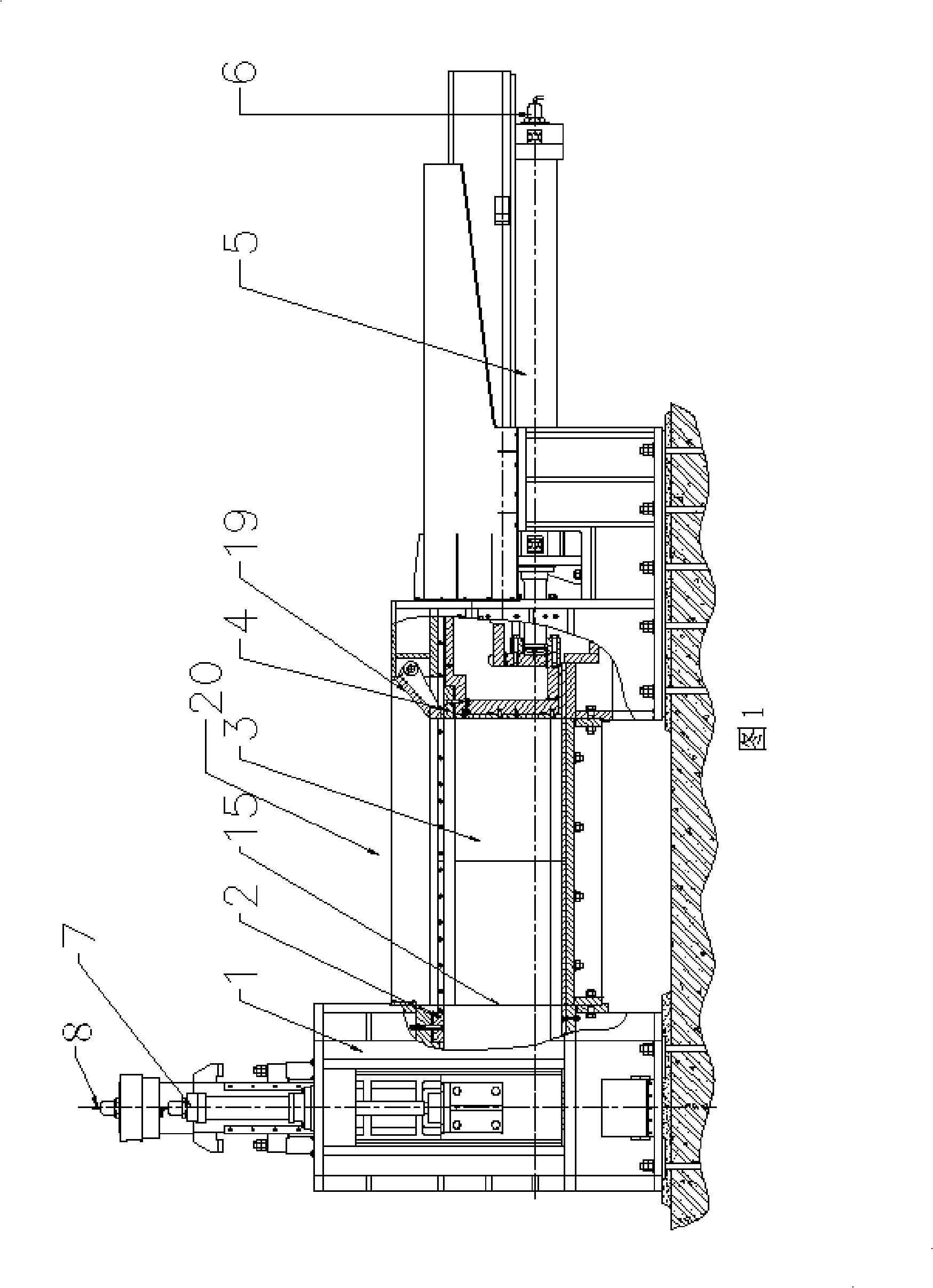

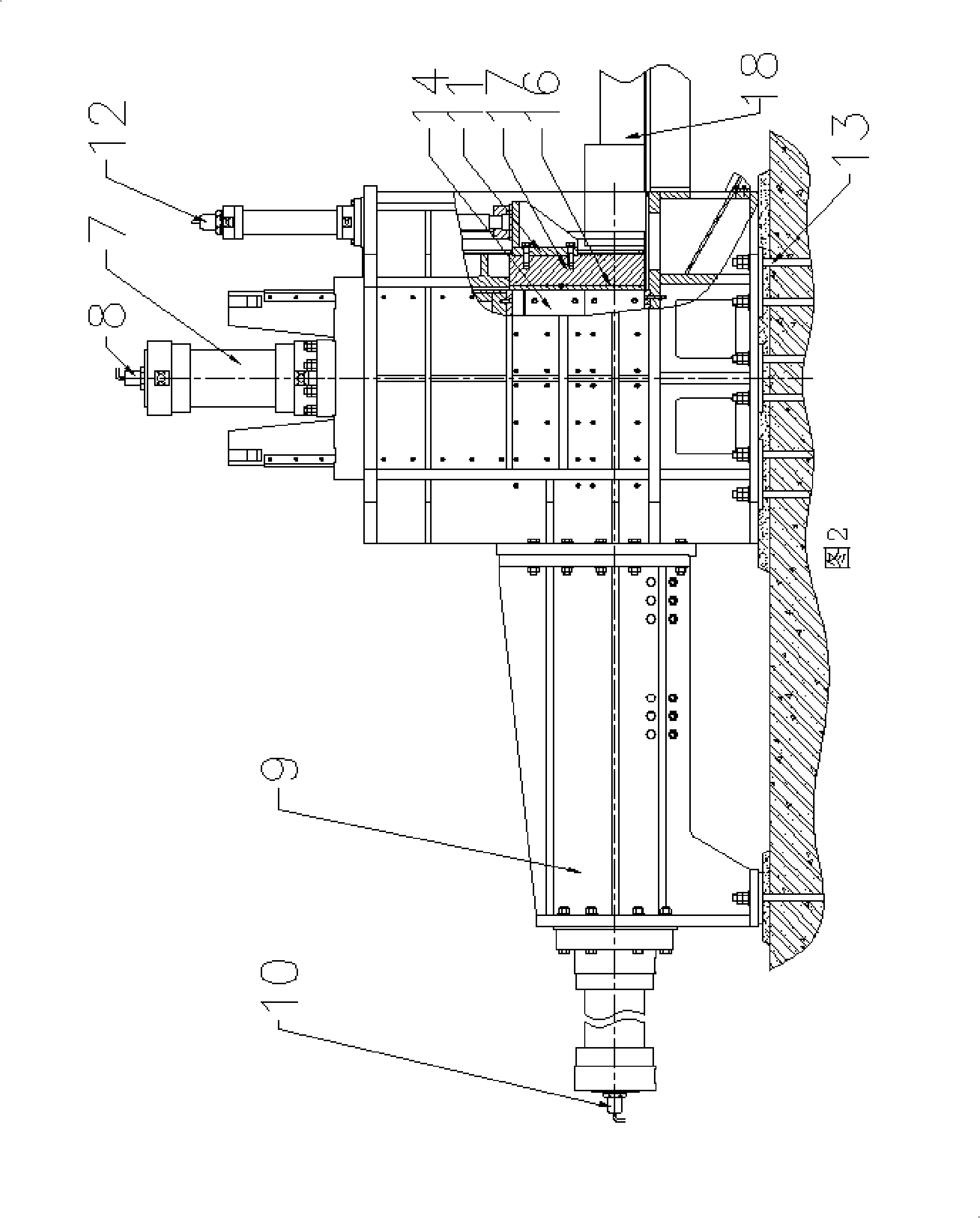

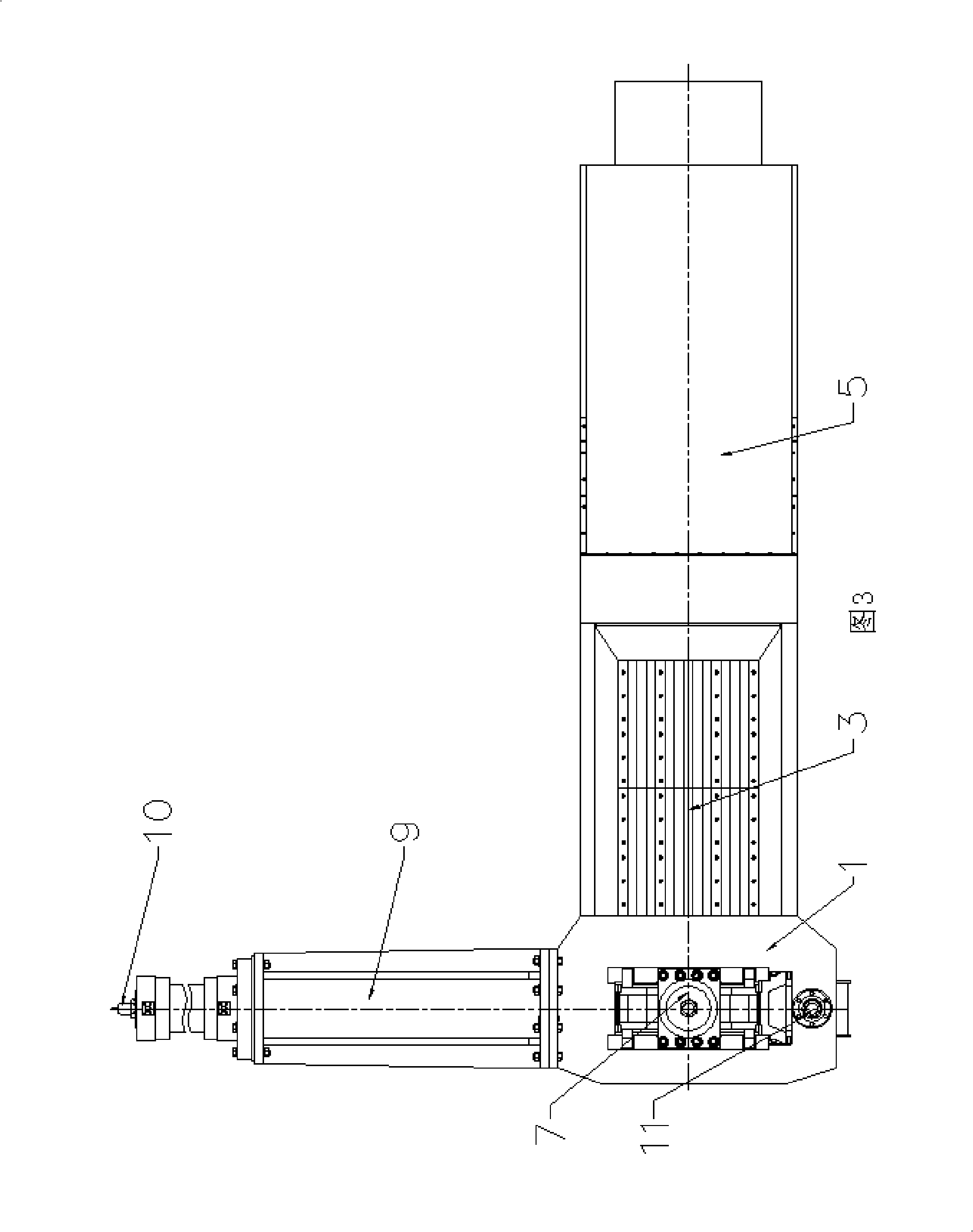

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] As shown in Fig. 1, Fig. 2 and Fig. 3, the scrap steel chip packing machine of the present invention comprises a main frame 1, a packing room 14 is arranged in the main frame 1, and a packing box communicating with the packing room 14 is also arranged on the main frame 1. Chamber feed port 15 and packing chamber discharge port 16; Also comprise the compression device that is connected on the mainframe 1, compression device comprises the first oil cylinder device 5, the second oil cylinder device 7 and the 3rd oil cylinder device (9), the first The push heads of the oil cylinder device 5, the second oil cylinder device 7 and the third oil cylinder device 9 form a closed space at the stroke end in the packing chamber.

[0014] Since the compressing device also includes a vertically installed second oil cylinder device 7, the push heads of the first oil cylinder de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com