Conveniently moving automatic plastering machine

A powder wall machine, automatic technology, applied in the direction of construction, building construction, etc., can solve the problems of affecting the effective working life of the main machine, the thickness of the powder wall cannot be adjusted in real time, and the door cannot be freely entered and exited, so as to achieve convenient and real-time quality monitoring and significant technological advancement Sexuality, the effect of prolonging the time of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

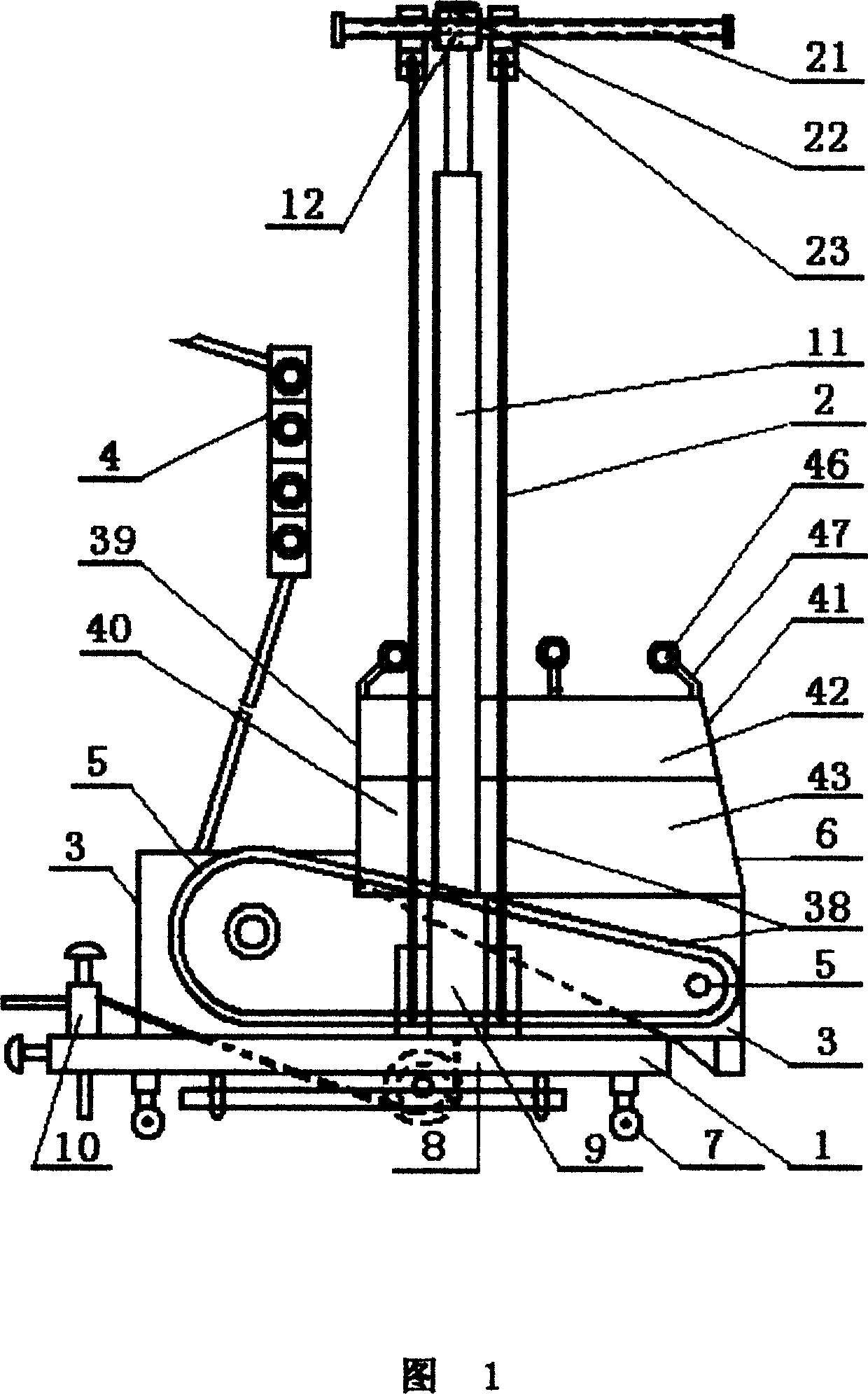

[0026] In Fig. 1, the automatic plastering machine of the present invention is mainly made up of base 1, gantry frame 2, main frame 3, electrical control mechanism 4, transmission mechanism 5 and painting mechanism 6. The main body of the base 1 is in the shape of a square frame, with universal moving feet 7 on the four corners below, a gantry mounting seat 9 near the middle position above the left and right frame edges 8, and a near front position on the left and right frame edges 8 Also be provided with left and right rope tightening device 10 on.

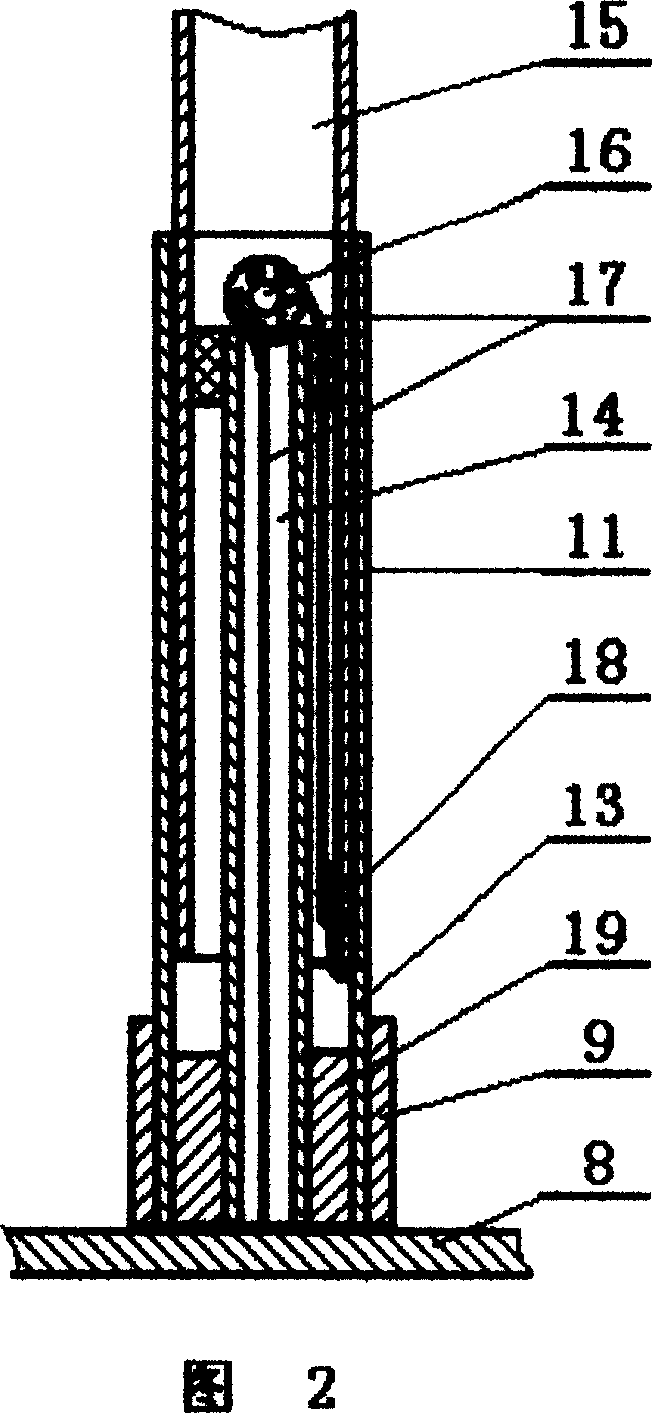

[0027] In Fig. 2, the gantry 2 is mainly composed of left and right columns 11 and beams 12, and the left and right columns 11 are assembled by a stroke tube 13, a standpipe 14, and a lift tube 15 which are mutually nested. The standpipe 14 is located at the innermost, and a steel wire pulley 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com