Biological-material ball gasifying method and apparatus

A gasification equipment and biomass technology, applied in the field of biomass ball gasification method and equipment, can solve the problems of interrupted cooking, short combustion time, long cold furnace startup time, etc. content, the effect of reducing the content of fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

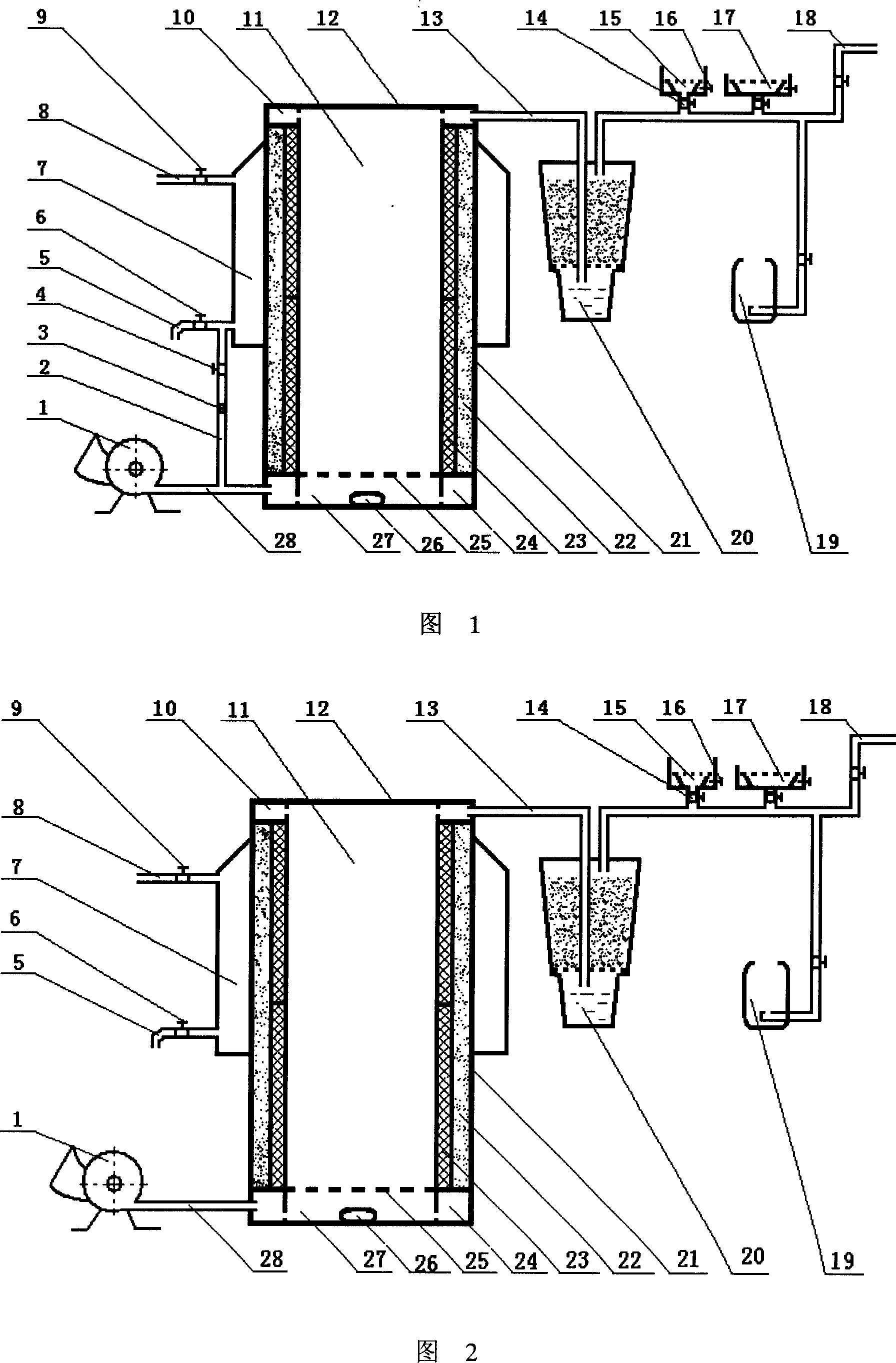

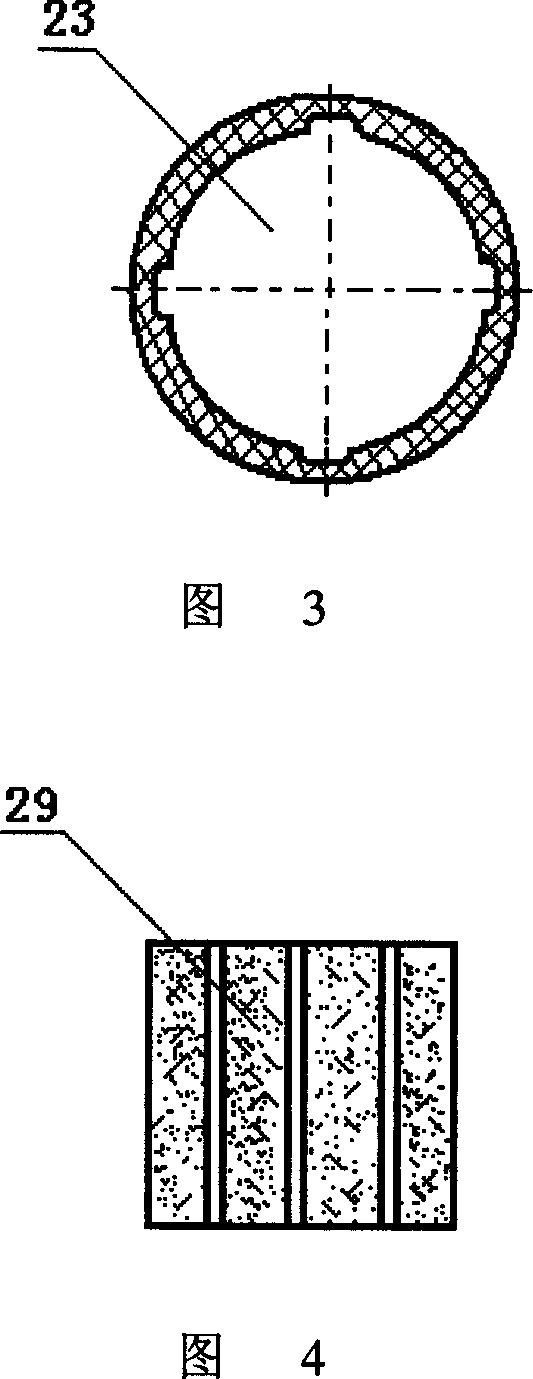

[0029] As shown in Figure 1, the upper half of body of heater (21) outside is the water tank (7) that is made by stainless steel, and water tank (7) upper end has cold water pipe (8), and the lower end has hot water pipe (5), and cold water pipe (8) and the hot water pipe (5) respectively have a valve (9), (6) to control the inlet and outlet of water, the hot water pipe (5) is connected with the gasification agent pipe (28) by the water supply pipe (2), and the water supply pipe (2) is provided with a valve (4) and a flow meter (3), the fan (1) communicates with the annular air preheating chamber (24) at the bottom of the furnace (11) through the gasification agent pipe (28), and the annular air is preheated The bottom of chamber (24) inboard side is provided with eyelet; The inside of body of heater (21) is successively insulation layer (22), liner (23), fire hearth (11), and below fire hearth (11) is fire grate (25 ), below the fire grate (25) is the ash chamber (27), the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com