Profiling cutter and method used for inner-tooth-line gear processing

A technology for forming milling cutters and wire gears, which is applied in the direction of gear tooth manufacturing tools, components with teeth, metal processing equipment, etc., can solve the problems of poor surface processing quality and low processing efficiency, and improve processing efficiency. The effect of reducing the number of feeds and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The idea, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, scheme and effect of the present invention. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The same reference numbers are used throughout the drawings to indicate the same or similar parts.

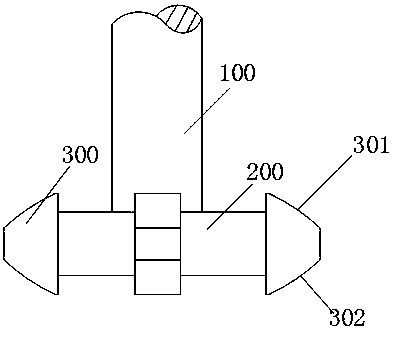

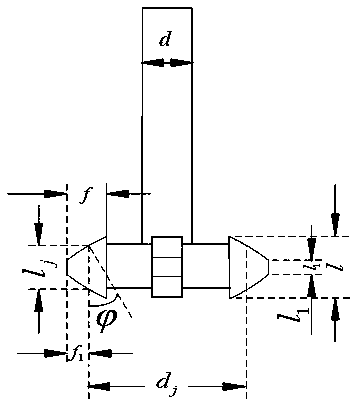

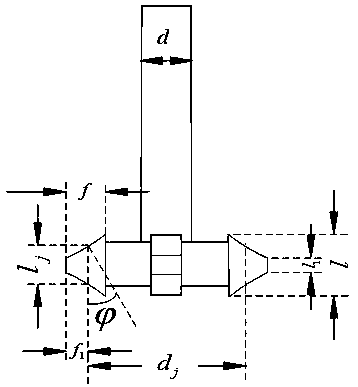

[0031] figure 1 Shown is a form milling cutter for machining internal-toothed gears, consisting of:

[0032] Cutter bar 100, described tool bar 100 is used for the clamping of milling cutter;

[0033] The cutter head 200, the cutter head 200 is fixedly arranged at the bottom of the cutter bar; generally, the cutter bar is vertically arranged in the middle of the cutter head.

[0034] Cutter teeth 300, the cutter teeth 300 are in concave or co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com