Preparation method of carbon aerogel, carbon aerogel and lithium ion capacitor prepared from same

A carbon aerogel and gel technology, which is applied in capacitors, electrolytic capacitors, double-layer capacitors, etc., can solve the problems of low conductivity of carbon aerogels, poor material rate performance, complicated operation, etc. The effect of high pore capacity and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of carbon airgel, comprising the following steps:

[0031] (1) Dissolve lignin powder in potassium hydroxide solution, then ultrasonically disperse for 1 h, then add polyvinylpyrrolidone to the potassium hydroxide solution to form a gel, wherein the mass ratio of lignin to potassium hydroxide is 0.5, polyvinylpyrrolidone The quality of vinylpyrrolidone is 5% of lignin quality;

[0032] (2) Add potassium ferrate to the gel obtained in step (1), and ultrasonically disperse it for 0.5h, and after standing for 5h, obtain a carbon airgel precursor through freeze-drying, wherein the quality of potassium ferrate is wood 5% of prime quality;

[0033] (3) Heat the carbon airgel precursor obtained in step (2) to 250°C and keep it warm for 1h, then continue to heat up to 700°C and keep it warm for 2h, then acid wash, suction filter, and dry to get the carbon aerogel .

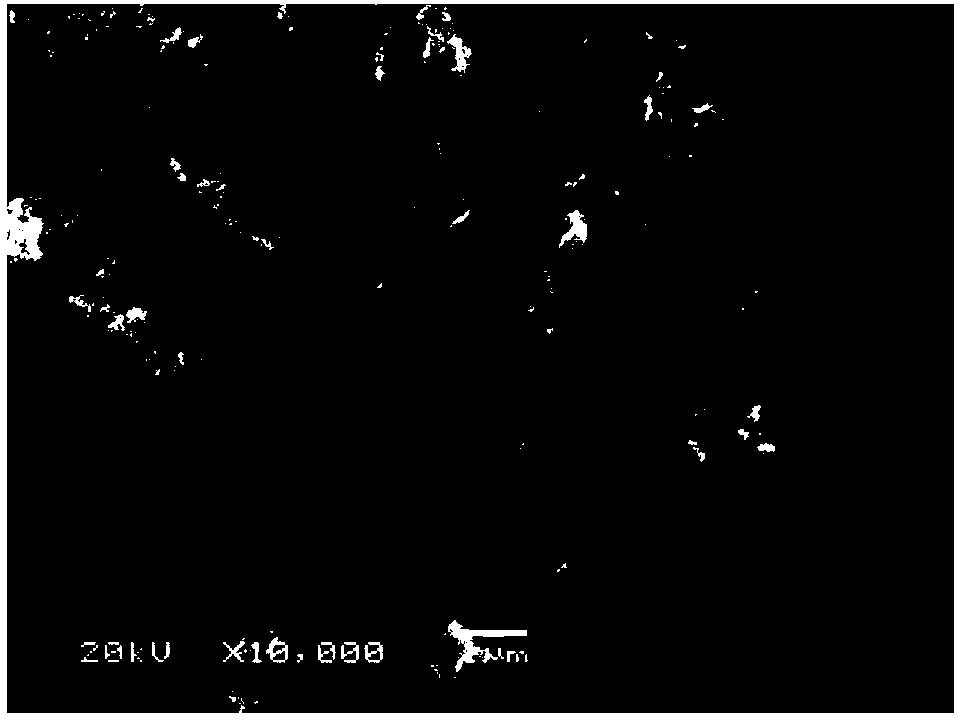

[0034] The specific surface area of the carbon airgel prepared in this example is 600m...

Embodiment 2

[0036] A preparation method of carbon airgel, comprising the following steps:

[0037] (1) Dissolve lignin powder in potassium hydroxide solution, then ultrasonically disperse for 1 h, then add polyacrylamide to the potassium hydroxide solution to form a gel, wherein the mass ratio of lignin to potassium hydroxide is 2, polyacrylamide The quality of acrylamide is 10% of the quality of lignin;

[0038] (2) Add potassium trioxalate ferrate to the gel obtained in step (1), and ultrasonically disperse it for 0.5h, and after standing for 5h, obtain a carbon airgel precursor through freeze-drying treatment, wherein ferric trioxalate The quality of potassium acid is 15% of lignin quality;

[0039] (3) Heat the carbon airgel precursor obtained in step (2) to 300°C and keep it warm for 1h, then continue to heat up to 800°C and keep it warm for 2h, then acid wash, suction filter, and dry to get the carbon aerogel .

[0040] The specific surface area of the carbon airgel prepared in...

Embodiment 3

[0042] A preparation method of carbon airgel, comprising the following steps:

[0043] (1) Dissolve lignin powder in potassium hydroxide solution, then ultrasonically disperse for 1 h, then add chitosan to the potassium hydroxide solution to form a gel, wherein the mass ratio of lignin to potassium hydroxide is 3, and the shell The mass of polysaccharides is 15% of the mass of lignin;

[0044] (2) Add potassium ferrate to the gel obtained in step (1), and ultrasonically disperse it for 0.5h, and after standing for 5h, obtain a carbon airgel precursor through freeze-drying, wherein the quality of potassium ferrate is wood 30% of prime mass;

[0045] (3) The carbon airgel precursor obtained in step (2) was first heated to 400°C and kept for 1h, then continued to be heated to 850°C and kept for 2h, then acid washed, suction filtered, and dried to obtain carbon aerogel .

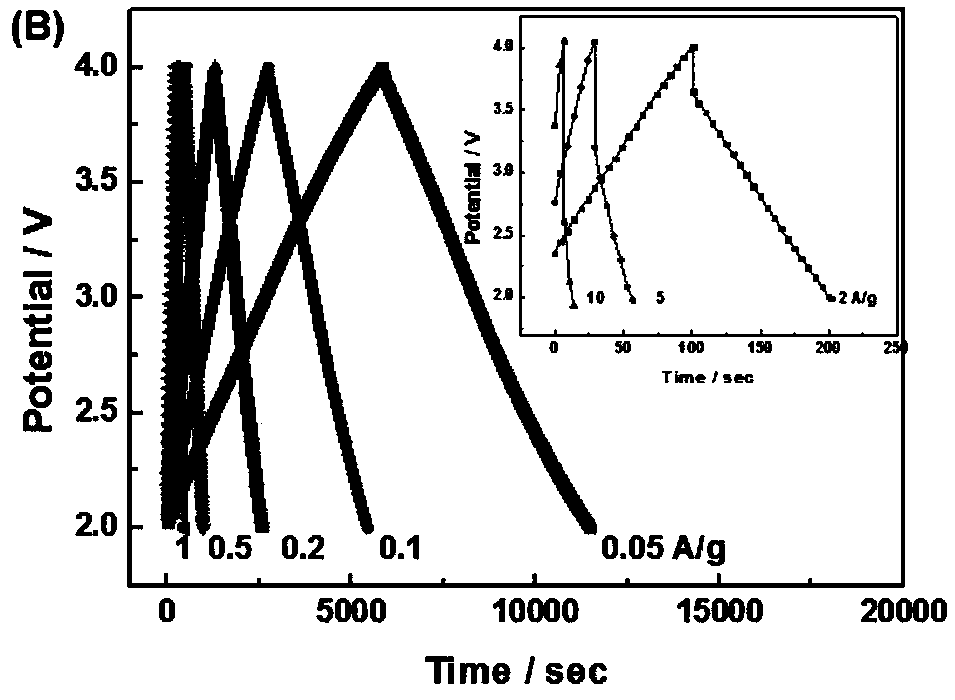

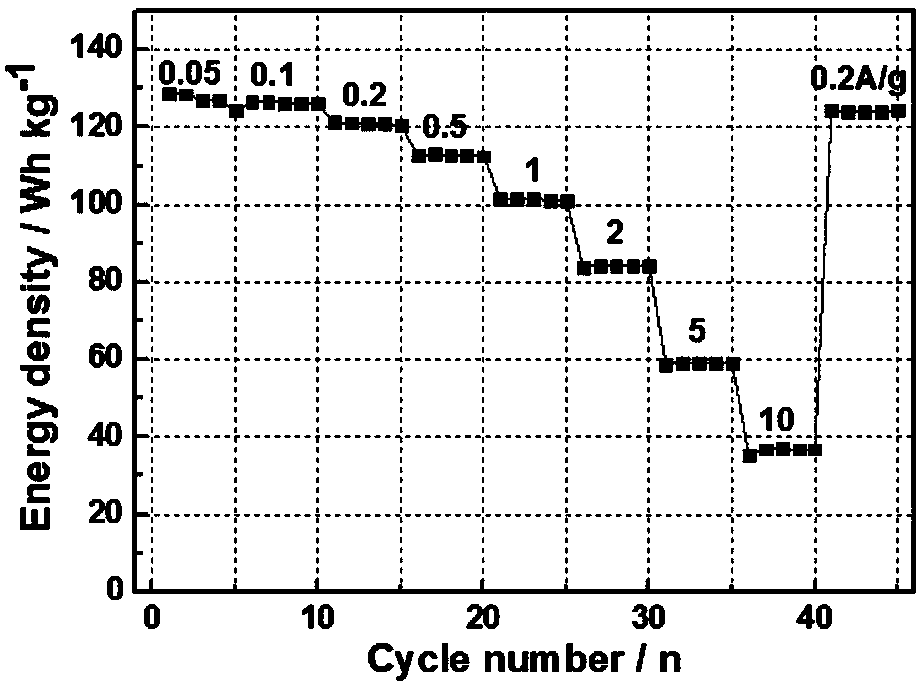

[0046] The specific surface area of the carbon airgel prepared in this example is 2513m 2 g -1 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com