Rare earth automatic weighing and feeding device, feeding method and rare earth automatic weighing and feeding system

An automatic weighing and feeding device technology, applied in packaging, wrapping paper, loading/unloading, etc., can solve the problems of inability to quantitatively add rare earth materials at a certain time, and easy agglomeration of rare earth materials when unloading, so as to achieve accurate detection and reduce the number of feedings. , the effect of reducing the overall loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

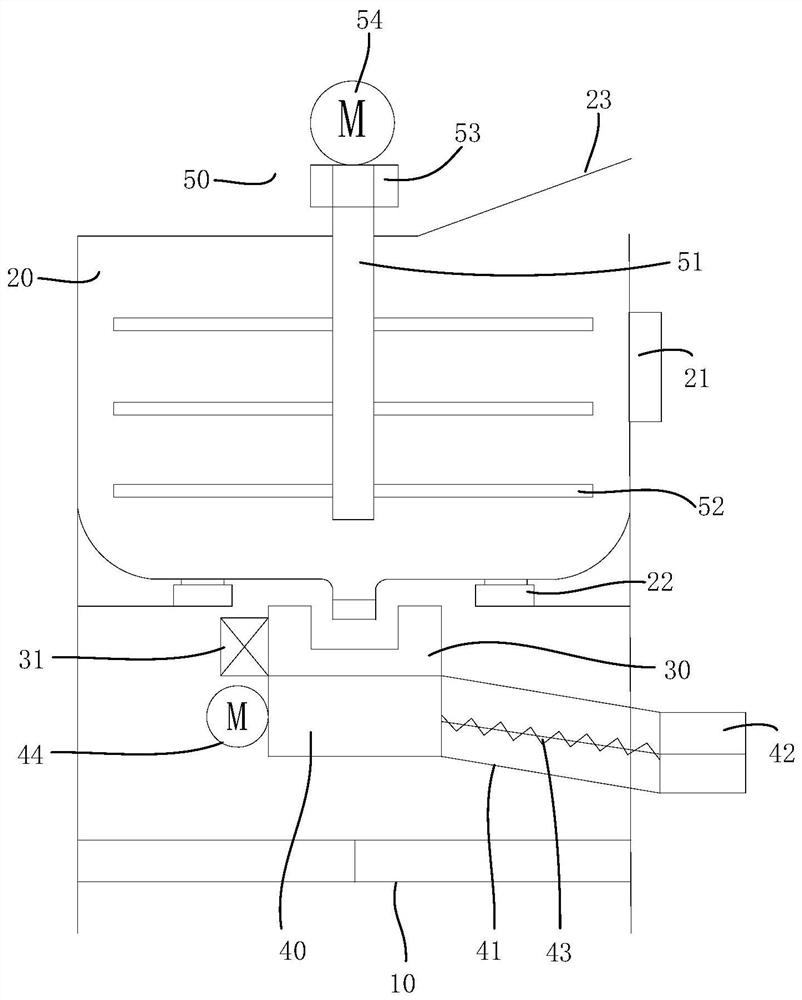

[0043] The rare earth automatic weighing and feeding device provided in this embodiment combines figure 1 It includes a bracket 10 and a bin 20 arranged on the bracket 10 , and also includes: a material shifting device 50 , a controller 21 and a weighing device 22 .

[0044] The shifting device 50 includes a shifting drive device and a shifting device, and the shifting device is arranged in the silo 20, and is used to stir the rare earth materials in the hopper 20, so that the rare earth materials can be fed smoothly without agglomeration; 22 is arranged at the bottom of the silo 20, and is used to detect the weight of the rare earth material in the silo 20 and output a weight signal. The controller 21 is connected to the material dial driving device and the weighing device 22 for controlling the operation of the material dial driving device . Among them, the controller can be a single-chip microcomputer or PLC. The controller 21 is configured to: after receiving a weighing ...

Embodiment 2

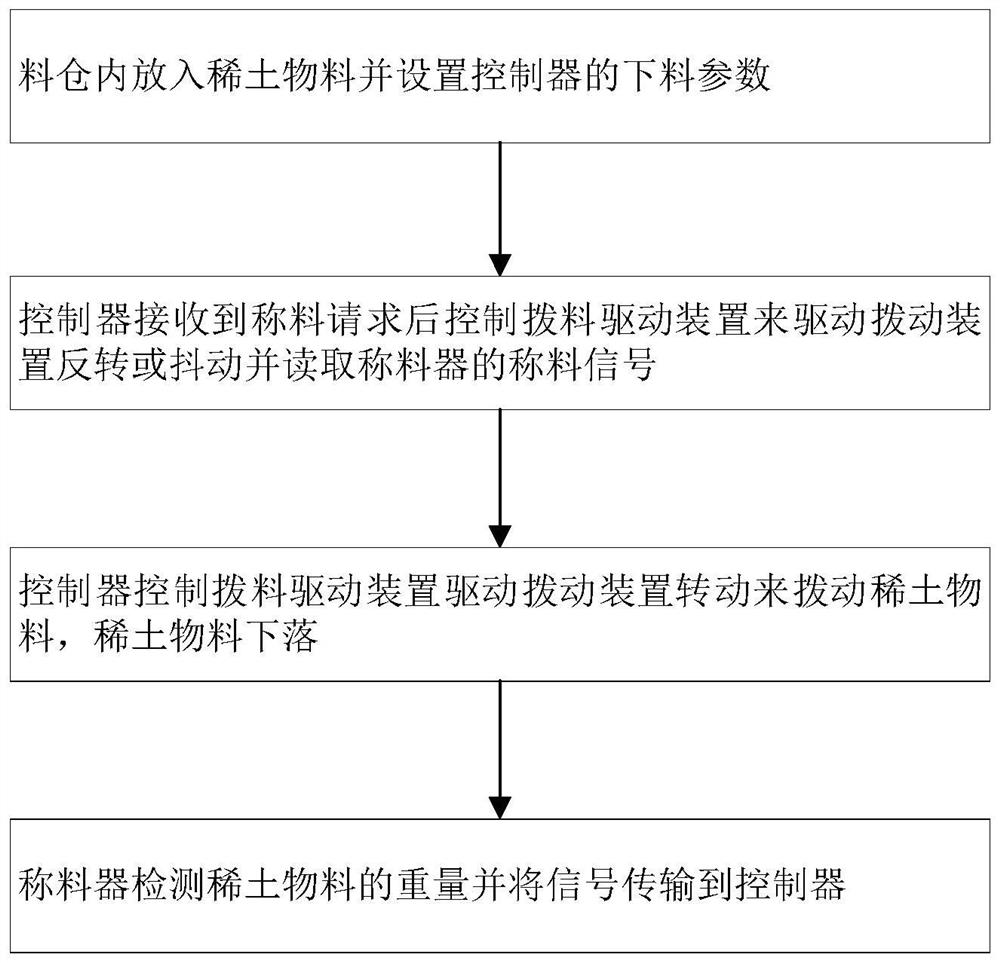

[0054] This embodiment provides a feeding method utilizing a rare earth automatic weighing feeding device, combining figure 2 include:

[0055] Put the rare earth material in the feed bin 20, and set the cutting parameters through the controller 21;

[0056] After receiving the weighing request, the controller 21 controls the dial driving device to drive the dial device to reverse or vibrate and read the weight signal of the weighing device 22;

[0057] The controller 21 controls the material shifting driving device to drive the shifting device to rotate, and moves the rare earth material in the silo so that the rare earth material can fall;

[0058] The weighing device 22 detects the weight of the rare earth material, and transmits the signal to the controller 21 .

Embodiment 3

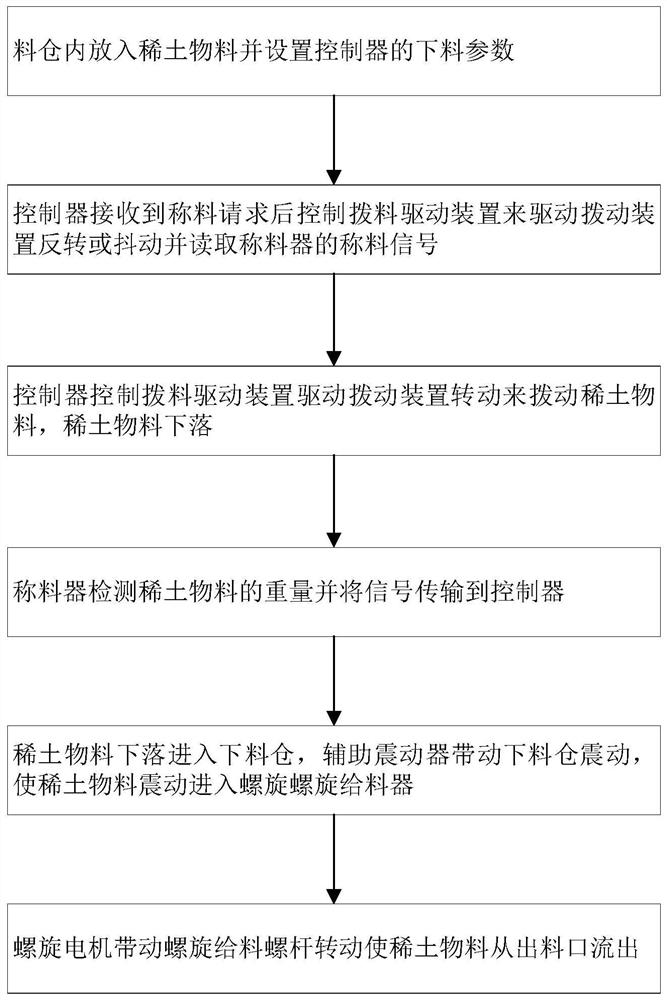

[0060] This embodiment provides a feeding method utilizing a rare earth automatic weighing feeding device, combining image 3 include:

[0061] Put the rare earth material in the feed bin 20, and set the cutting parameters through the controller 21;

[0062] After receiving the weighing request, the controller 21 controls the dial driving device to drive the dial device to reverse or vibrate and read the weight signal of the weighing device 22;

[0063] The controller 21 controls the material shifting driving device to drive the shifting device to rotate, and moves the rare earth material in the silo so that the rare earth material can fall;

[0064] The weighing device 22 detects the weight of the rare earth material, and transmits the signal to the controller 21;

[0065] The rare earth material falls into the lower hopper, and the auxiliary vibrator 31 drives the lower hopper 30 to vibrate, so that the rare earth material vibrates and enters the screw feeder 41;

[0066]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com