Horizontal long-distance superfine powder pneumatic conveying device

A conveying device and ultra-fine powder technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve problems such as sticking to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

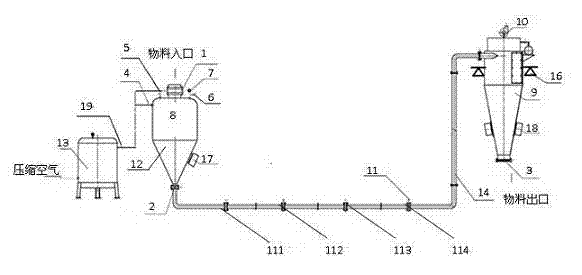

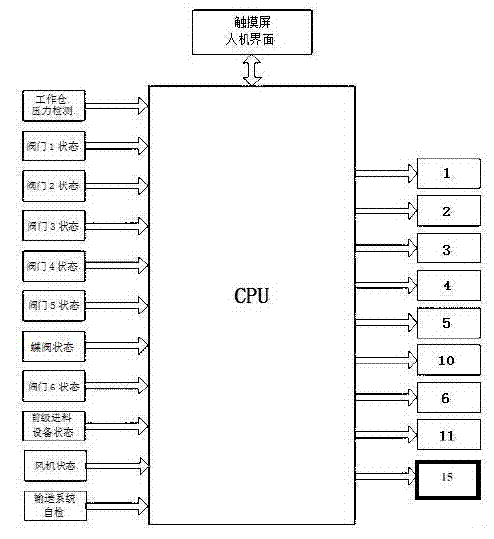

[0036] figure 1 It is a schematic diagram of the structure of the present invention, a pneumatic conveying device, connected with the front-stage feeding equipment, used for long-distance transportation of ultra-fine powder or toxic and corrosive materials, including air source machinery, working chamber 12, and feeding pipe 14 With the controller with CPU, the air source machinery is made of air storage tank 13, air compressor and blower fan 10. in,

[0037] The working chamber 12 is equipped with a pressure sensor 7 on the outside, and a rotating cleaning conveying device 8 (not shown in the structural diagram) inside, and the material inlet and the working chamber 12 are connected by the first valve 1;

[0038] One end of the feed pipe 14 communicates with the working chamber 12 and is controlled by the second valve 2, and the other end of the feed pipe 14 communicates with the separator 9 connected with the fan 10, and the horizontal section of the feed pipe 14 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com