Microphone polar plate assembly and method for machining polar plate unit by using same

A microphone and plate technology, applied in the field of microphones, can solve the problems of increased fixed part area, material waste, etc., and achieve the effects of reducing parasitic capacitance, saving waste materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

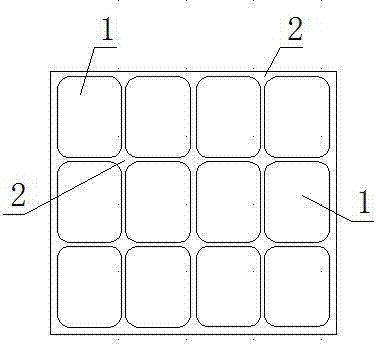

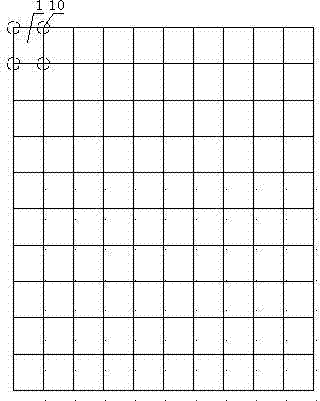

[0021] Embodiment one: if figure 2 As shown, a microphone plate assembly includes 100 plate units 1, and the plate units 1 are square, wherein two adjacent plate units 1 are closely arranged, saving the cost of fixing the plate unit 1. fixed part.

[0022] As a preferred technical solution for realizing the present invention, the corners of each square plate unit 1 form a pre-punched portion 10, and the pre-punched portion 10 in the present invention is a circle formed by combining the angles of each plate unit ( only partially marked in the figure).

[0023] As a preferred technical solution for realizing the present invention, the distance between the polar plate units 1 is less than or equal to 0.5 mm.

[0024] The distance between the pole plate units in this embodiment is 0.3 mm.

[0025] The present invention also provides a method for processing the pole plate unit 1 by using the microphone pole plate assembly: the method includes the following steps: the first step...

Embodiment 2

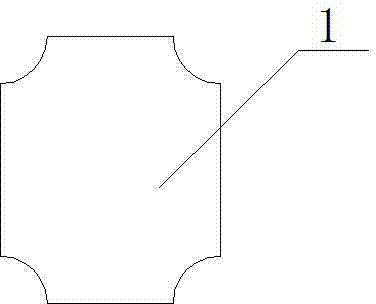

[0027] Embodiment two: if Figure 5 As shown, a microphone pole plate assembly includes 100 pole plate units 1 , and the pole plate units 1 are square, wherein two adjacent pole plate units 1 are closely arranged.

[0028] As a preferred technical solution for realizing the present invention, the corners of each square plate unit 1 form a pre-punching portion 10, and the four corners of each square plate unit 1 in the present invention are provided with arc-shaped chamfers 11. The pre-punched part 10 in the invention is the pre-punched part 10 surrounded by the arc-shaped chamfers 11 of each electrode plate unit.

[0029] As a preferred technical solution for realizing the present invention, the distance between the polar plate units 1 is less than or equal to 0.5mm.

[0030] The distance between the pole plate units in this embodiment is 0.3mm.

[0031] The present invention also provides a method for processing the pole plate unit 1 by using the microphone pole plate asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com