Extrusion device of plastic extruder

A technology for plastic extruders and sleeves, applied in the field of extruding devices, can solve problems such as easy carbonization, residual material residue, and affecting product quality, and achieve the effects of improving product quality and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

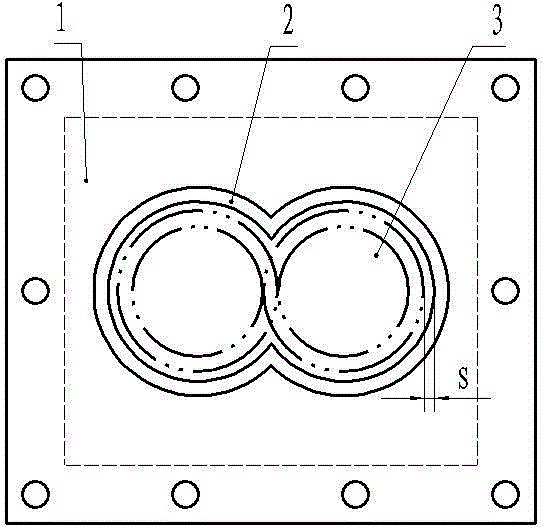

[0010] Such as figure 1 The extruding device of the plastic extruder shown includes a cylinder body 1 embedded with a sleeve, and two screw rods 3 that are intermeshed and connected with a driving device are installed in the sleeve, and the sleeve has two side walls. The arc-shaped tubes 2 are intersecting and connected, and the two arc-shaped tubes 2 are connected as a whole. The sleeve sleeve of this embodiment is made of cast steel. The gap s is 0.2 mm.

Embodiment 2

[0012] The gap s between the inner wall of the arc-shaped cylinder 2 and the generatrices of the outer circles of the two screws 3 is 0.25 mm; other features are the same as those in Embodiment 1.

[0013] Since the gap s between the inner wall of the arc-shaped barrel 2 and the outer circular generatrix of the two screws 3 is 0.2 mm to 0.25 mm, the two intermeshing screws can smoothly extrude the material forward during work, and can reduce the residue in the barrel. The remaining material on the inner wall of the sleeve can be used to improve the product quality of the modified plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com