Novel limiting frame for mounting precipitating-preventing rainwater strainer and construction method of novel limiting frame

A rainwater grate and limit frame technology, which is applied in water supply devices, waterway systems, drainage structures, etc., can solve the problems of difficult removal of coverings, waste of asphalt materials, waste of labor, etc., to avoid the process of removing asphalt, reduce pollution, Easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

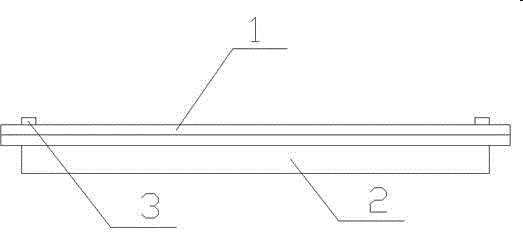

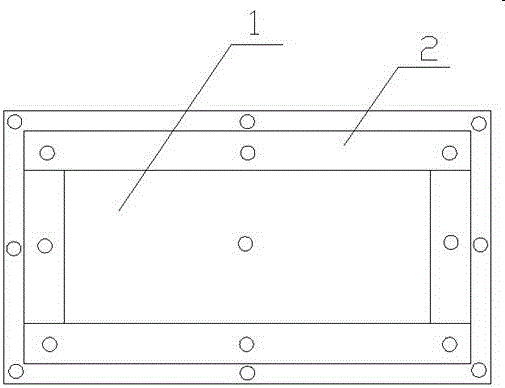

[0023] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a panel 1 and a frame 2, and the frame 2 is fixed below the panel 1; both the panel 1 and the frame 2 are rectangular, the size of the frame 2 is smaller than that of the panel 1, and the four corners of the upper surface of the panel 1 are respectively fixed with a A sling 3, the size of the panel 1 is 73cm×41cm×0.03cm; the size of the frame 2 is 35cm×67cm×0.04cm, and the distance between the four sides of the frame 2 and the four sides of the panel 1 is 3cm.

[0024] The construction method of the novel anti-precipitation rainwater grate of the present embodiment is installed with the limit frame, comprises the following steps:

[0025] 1) The production of the limit frame: two pieces of bamboo plywood with a size of 73cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com