Material blending/supplying device and method

A supply device and mixing technology, which is applied in the field of material mixing supply device, can solve the problems of difficulty in reusing and increasing the amount of waste, and achieve the effect of reducing residual materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

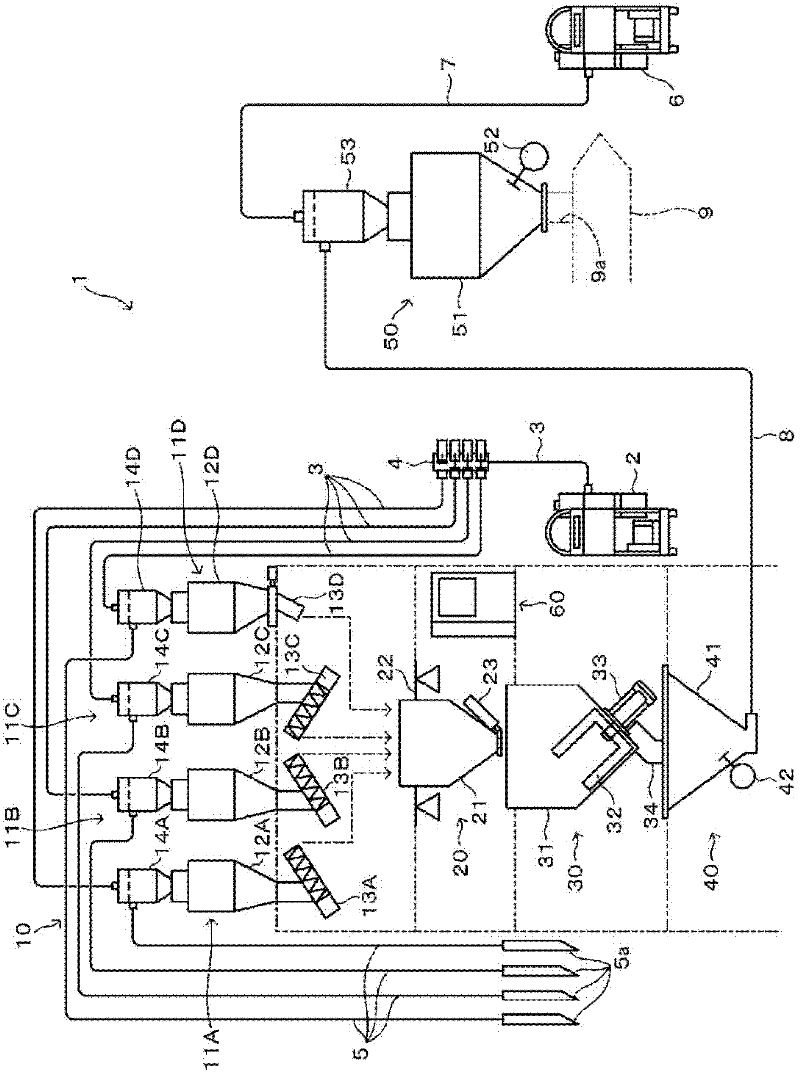

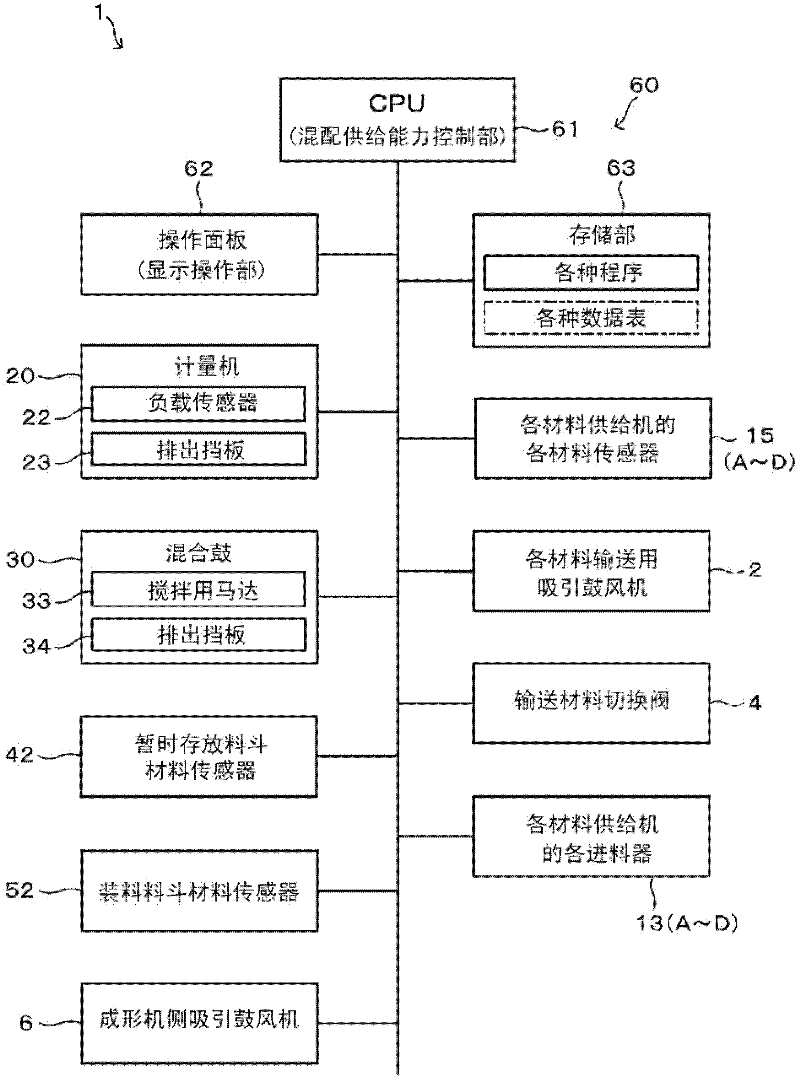

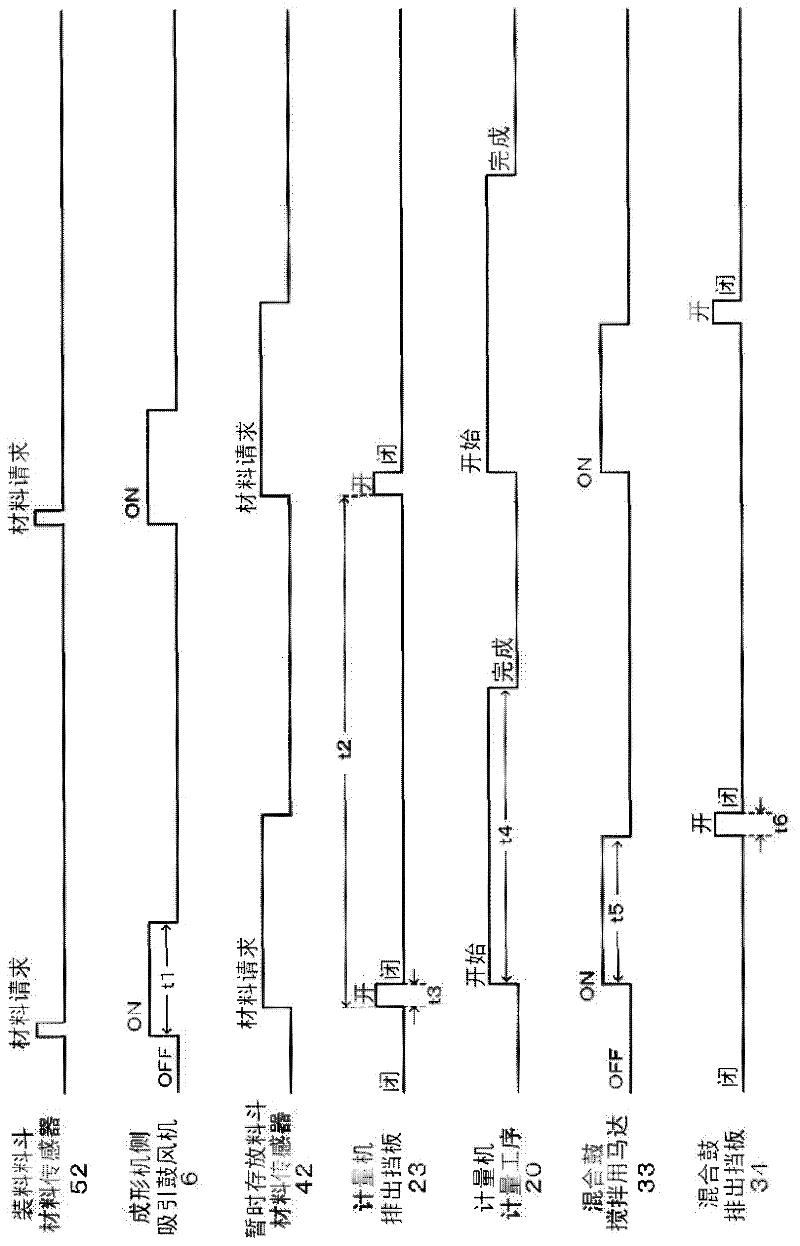

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0043] Figure 1 to Figure 11 It is an explanatory drawing for demonstrating the compounding supply apparatus of the powdery or granular material of this embodiment, its operation example, a modified operation example, and a modification.

[0044] in addition, figure 1 , Figure 10 and Figure 11 In , pipelines (gas pipelines, powder and granular material transportation pipelines, etc.) through which gas (conveying air) and powdery or granular materials circulate are schematically indicated by solid lines.

[0045] in addition, Figure 10 and Figure 11 Some detailed symbols are omitted.

[0046] The mixing and supplying device 1 for the powder and granular material of the illustration is as figure 1 As shown, it is equipped with: a material supply part 10, which supplies the powdery or granular material before mixing to the downstream side; a single weighing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com