Plastic particle mixing cooler

A plastic granule and cooling machine technology, applied in the field of plastic processing, can solve the problems of complex equipment, large dust, difficult to avoid black spots and miscellaneous material pollution, etc., and achieve the effect of strong fluidity and good mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

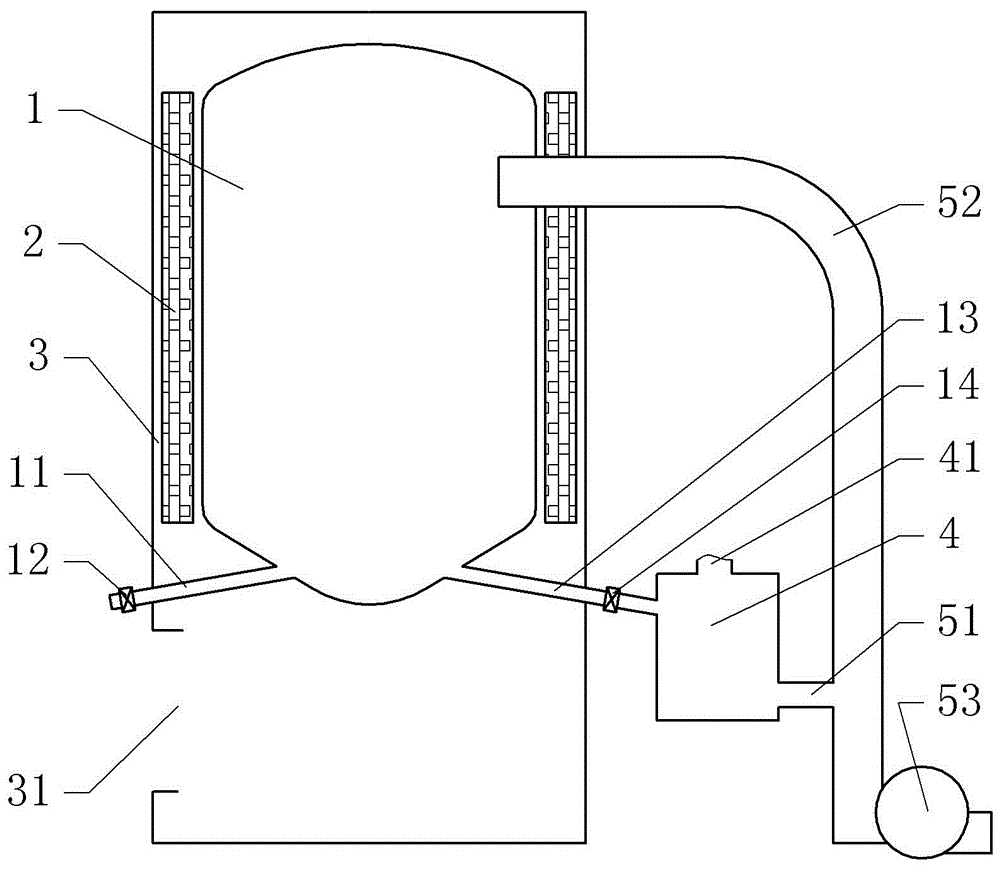

[0016] The reference signs in the drawings of the specification include: material storage cylinder 1, electrostatic precipitator 2, dust suction cylinder 3, material return cylinder 4, discharge pipe 11, discharge valve one 12, return pipe 13, discharge valve two 14. Exhaust hole 31, feed port 41, branch pipe 51, main pipe 52, blower 53.

[0017] The embodiment is basically as figure 1 Shown:

[0018] The plastic granule mixing cooler includes a material storage cylinder 1, a material return cylinder 4 and a feeding pipe. The bottom of the material storage cylinder 1 is provided with a discharge pipe 11 and a material return pipe 13, and the bottom of the material storage cylinder 1 is an inverted cone; The discharge pipe 11 and the return pipe 13 are all connected with the storage cylinder 1, and the discharge valve one 12 and the discharge valve two 14 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com