Novel convenient split door and window set and manufacturing method thereof

A manufacturing method and technology for door and window covers, applied in the field of door and window covers, can solve problems such as affecting the overall aesthetics of the door covers, cracking or deformation, and difficulty in processing, and achieve the effects of saving transportation costs, high utilization, and convenient and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Manufacture of boards with more transverse woodiness and less longitudinal woodiness

[0047] (1) Rotate the small log into 0.4cm thick slices with a rotary cutter;

[0048] (2) drying the flakes with a drier, the temperature of the drier is 120°C, so that the moisture content of the flakes reaches 14wt%;

[0049] (3) After drying, the flakes are manually trimmed to meet the size requirements for use;

[0050] (4) Carry out double-sided cloth glue to the sheet with a cloth glue machine, 28 grams / square foot;

[0051] (5) According to the required thickness of 4cm and the thickness of a single layer of 0.4cm, the number of typeset layers is determined to be 10 layers, and the laminated combination is carried out;

[0052] (6) Carry out pre-pressing to form embryo through pre-pressing machine, the time is 60 minutes;

[0053] (7) Then send the pre-pressed semi-finished product to the hot press, control the temperature of the hot press at 100°C, the pressure ...

Embodiment 2

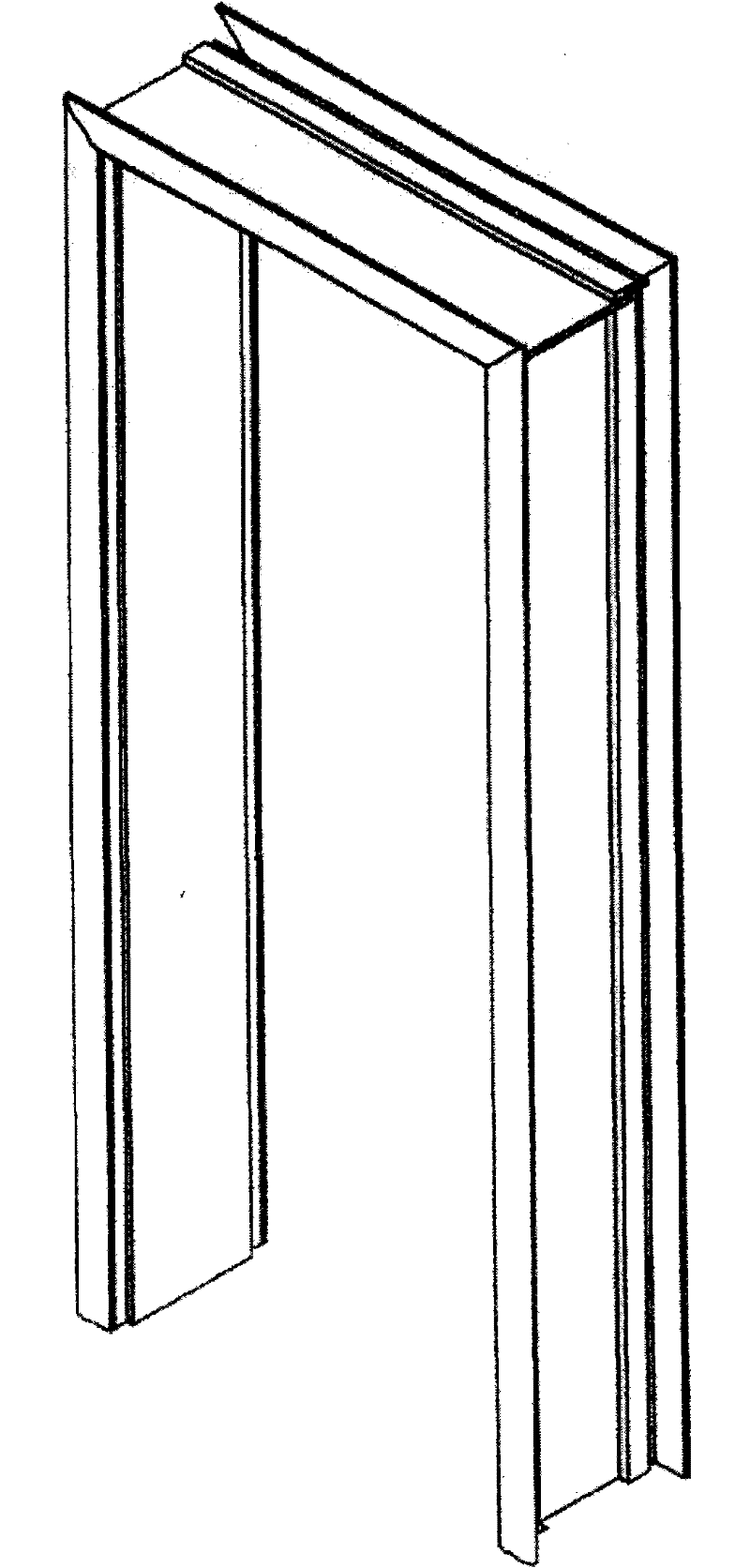

[0058] The manufacture of embodiment 2 door and window cover

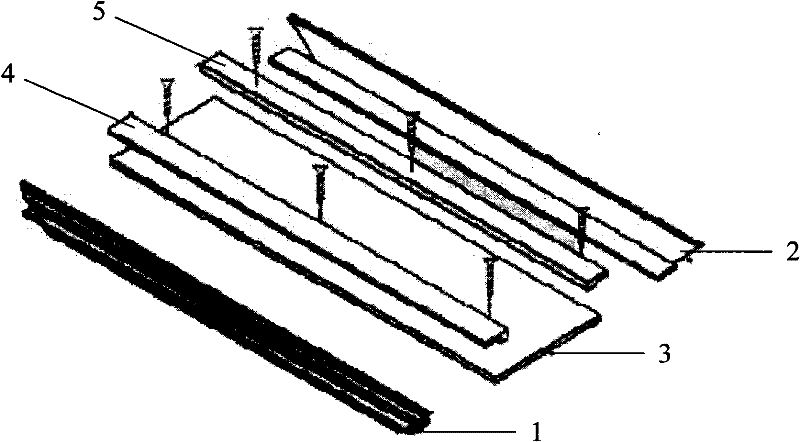

[0059] Such as Figure 2-4 As shown, the plates obtained in Example 1 are used to make gussets 1, 6, 13, 2, 8, 11, inner plates 3, 7, 12 and connecting strips 4, 5, 9, 10, 14, 15;

[0060]Take three inner panels 3, 7, and 12 according to the actual size, wherein the inner panel 3 is used as the inner panel of the upper door and window cover, the inner panel 7 is used as the inner panel of the left door and window cover, and the inner panel 12 is used as the inner panel of the right door and window cover; The left connecting strips 4, 9, 15 and the right connecting strips 5, 10, 14 are respectively fixed on the inner panels 3, 7, 12 with self-tapping screws, and form grooves with the inner panels 3, 7, 12, and the three inner panels Plates 3, 7, and 12 are fixed as the inner frame of the door and window cover;

[0061] Take three gussets 2, 8, and 11 according to the actual size, of which gusset 2 is used as the u...

Embodiment 3

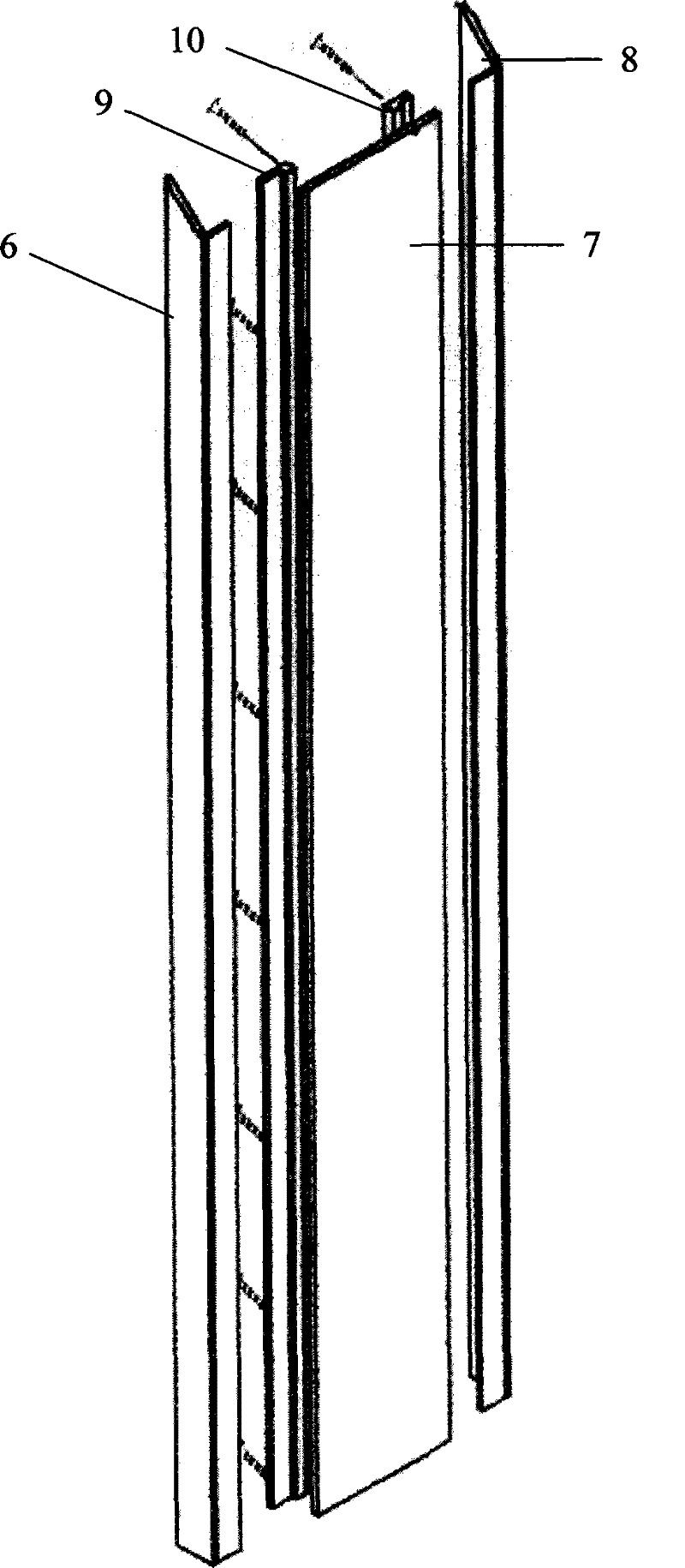

[0064] The installation of embodiment 3 door and window cover

[0065] The installation of the door and window cover is carried out by buckling the inner door and window cover and the outer door and window cover into the groove as a whole, but from a local point of view, taking the left side of the door and window cover as an example, as Figure 5 As shown, its installation is to fix the left connecting strip 9 and the right connecting strip 10 on the left and right sides of the inner panel 7 of the left door and window cover with self-tapping screws respectively, and be fixed on the body of wall. The fixing here can be by self-tapping screws. Screw or apply glue to fix; then apply glue to the left gusset plate 6 of the outer door and window cover and the left gusset plate 8 of the inner door and window cover, and buckle it into the left connecting strip 9 and right connecting strip 10 and the inner panel of the left door and window cover 7 respectively formed in the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com