High-sound-insulation carpet as well as preparation method and application thereof

A technology of sound insulation and carpet, applied in the field of high sound insulation carpet and its preparation, can solve the problems of heavy weight of sound insulation mat, increase of production cost, complicated production process, etc., to ensure safety and accuracy, save manufacturing cost, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

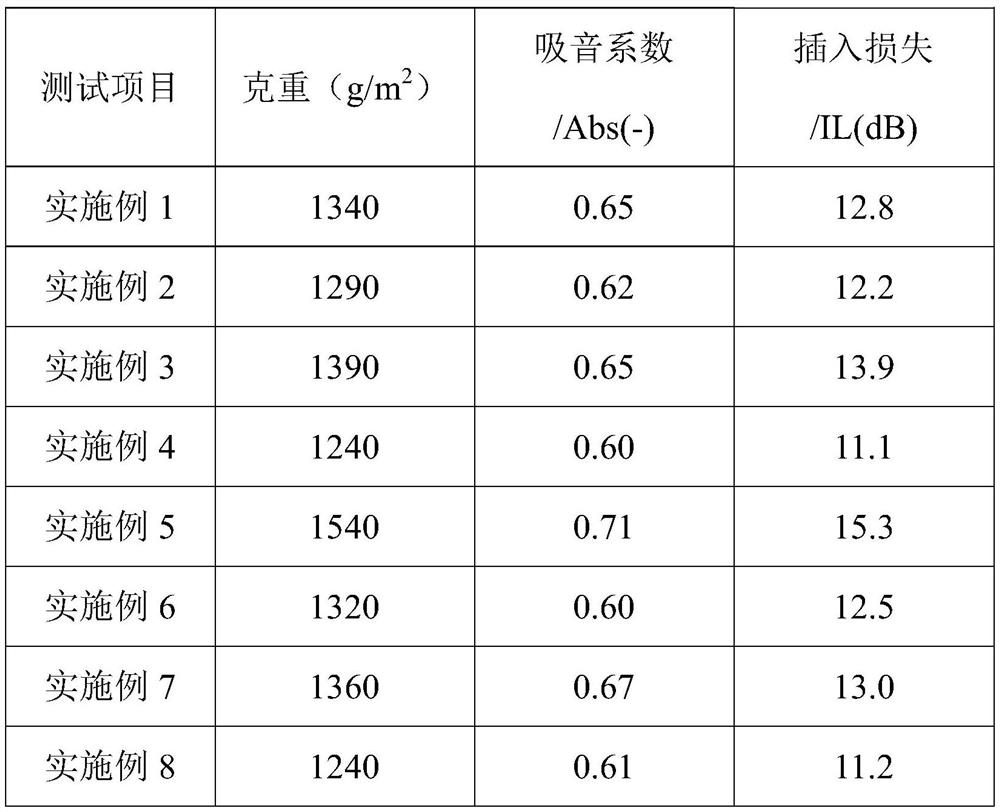

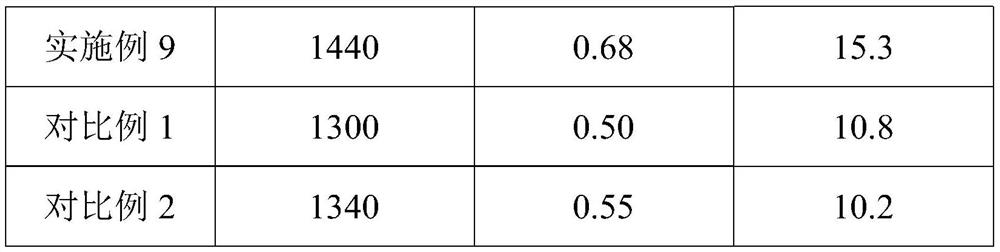

Examples

Embodiment 1

[0039] This embodiment provides a high-sound-insulation carpet, which includes a face carpet layer, a heavy coat layer and a thermoplastic back-spun cotton layer stacked in sequence. The material of the blanket layer is PET, and the grammage is 700g / m 2 ; The material of the heavy coating is EPDM, and the grammage is 2kg / m 2 ; The grammage of the thermoplastic back-spun cotton layer is 600g / m 2 .

[0040] The preparation method of the high sound insulation carpet described in the present embodiment comprises the following steps:

[0041] (1) The blanket layer, the heavy coating layer and the thermoplastic back-spun cotton layer are sequentially laid on the laying platform to form the base material;

[0042] (2) Clamp the base material obtained in step (1) and send it into an oven for drying. The upper oven temperature of the oven is 320°C, and the lower oven temperature of the oven is 280°C. Warm time is 125s;

[0043] (3) putting the base material after step (2) baking t...

Embodiment 2

[0047] This embodiment provides a high-sound-insulation carpet, which includes a face carpet layer, a heavy coat layer and a thermoplastic back-spun cotton layer stacked in sequence. The material of the blanket layer is LPET, and the grammage is 600g / m 2 ; The material of the heavy coating is EVA, and the grammage is 2kg / m 2 ; The grammage of the thermoplastic back-spun cotton layer is 650g / m 2 .

[0048] The preparation method of the high sound insulation carpet described in the present embodiment comprises the following steps:

[0049] (1) The blanket layer, the heavy coating layer and the thermoplastic back-spun cotton layer are sequentially laid on the laying platform to form the base material;

[0050] (2) The base material obtained in step (1) is clamped and sent to an oven for drying. The upper oven oven temperature of the oven is 325°C, and the lower oven oven oven temperature is 285°C. Warm time is 120s;

[0051] (3) putting the base material after step (2) bakin...

Embodiment 3

[0055] This embodiment provides a high-sound-insulation carpet, which includes a face carpet layer, a heavy coat layer and a thermoplastic back-spun cotton layer stacked in sequence. The material of the blanket layer is PET, and the grammage is 800g / m 2 ; The material of the heavy coating is EPDM, and the grammage is 2kg / m 2 ; The grammage of the thermoplastic back spinning cotton layer is 550g / m 2 .

[0056] The preparation method of the high sound insulation carpet described in the present embodiment comprises the following steps:

[0057] (1) The blanket layer, the heavy coating layer and the thermoplastic back-spun cotton layer are sequentially laid on the laying platform to form the base material;

[0058] (2) Clamp the base material obtained in step (1) and send it into an oven for drying. The upper oven temperature of the oven is 330°C, and the lower oven temperature of the oven is 290°C. Warm time is 115s;

[0059] (3) putting the base material after step (2) baki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com