Hydraulic rotary koji pressing machine and pressing method thereof

A koji machine and hydraulic technology, which is applied to the koji machine for brewing liquor and its buckling field. It can solve the problems that the pressure and speed of the koji machine cannot be adjusted at any time, cannot be pressed continuously at multiple points, and the transmission system is complicated. , to achieve the effect of avoiding mechanical failure, simple structure and improving pulp quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

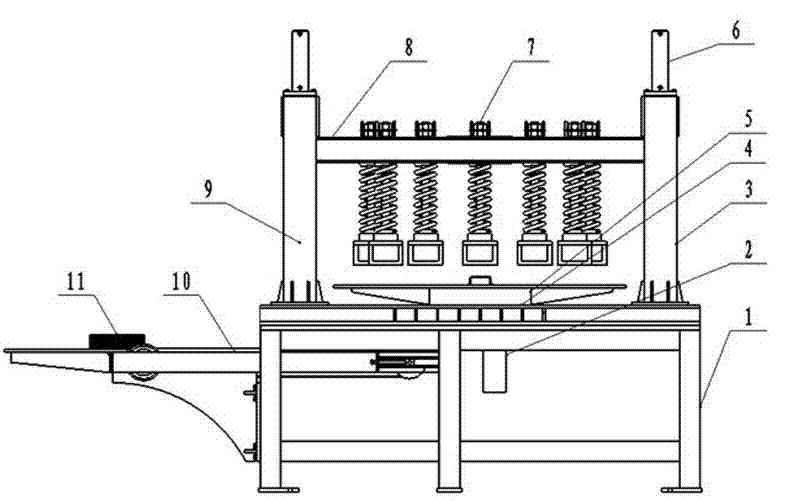

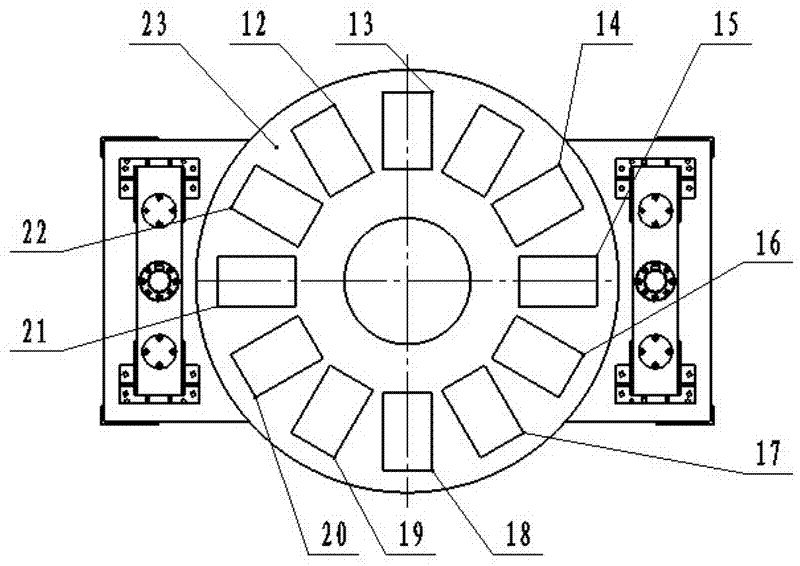

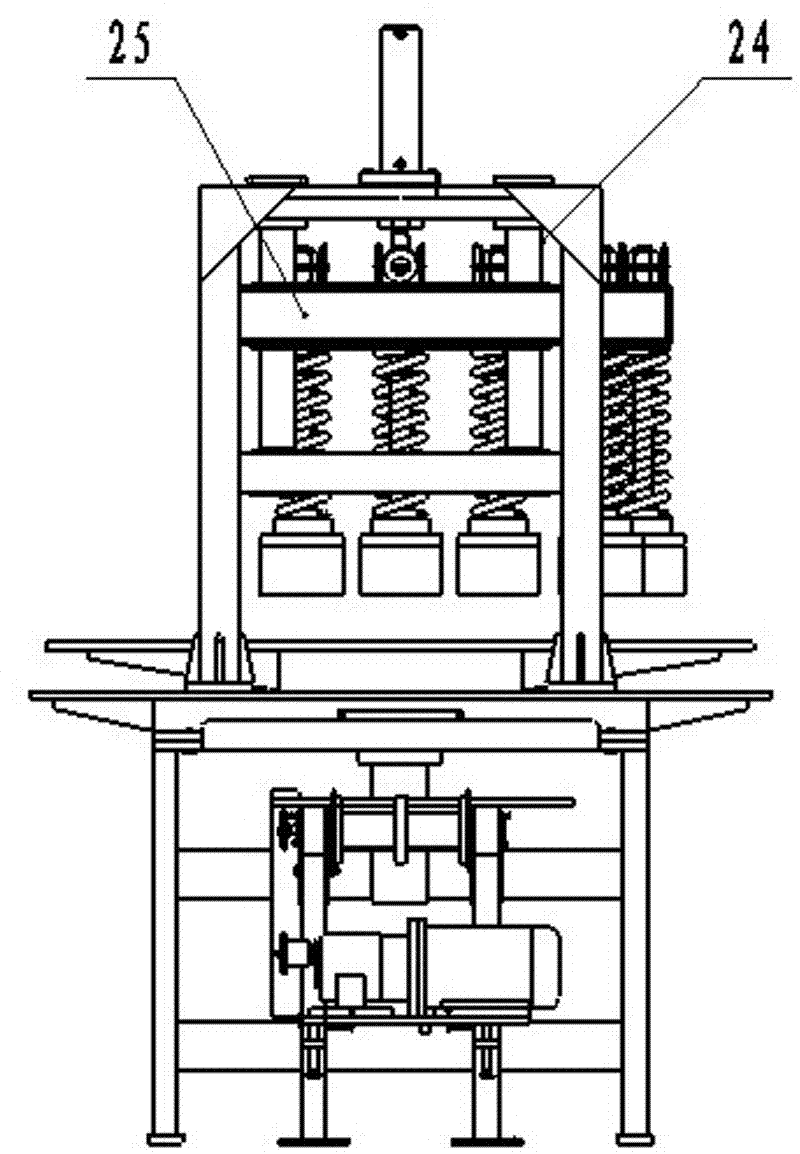

[0023] Such as Figure 1-10 As described above, a hydraulic rotary koji press according to the present invention includes a frame 1 , a hydraulic motor 2 , a pressure assembly 3 , a rotary assembly 4 and a bent material output table 10 . The hydraulic motor 2 is mounted on the lower part of the platform of the frame 1, and the external spline at the shaft end of the hydraulic motor cooperates with the internal spline installed in the center of the turntable support 31, and the hydraulic motor 2 drives the turntable assembly 23 to rotate through the spline cooperation; the inner ring of the slewing support 5 passes through the The No. 1 installation hole 27 is fixed to the turntable, and the outer ring of the slewing support is installed on the frame 1 to support and help the turntable when the turntable rotates; the turntable 28 is equipped with 11 curved material mold boxes 26, which are the feed mold boxes in turn. Box 12, pre-press mold box 13, first hammer mold box 14, sec...

Embodiment 2

[0027]A buckling method used in the hydraulic rotary buckling machine of Embodiment 1. The hydraulic motor 2 provides power, and the hydraulic motor 2 is connected with a sensor to control the start and stop of the operation of the very precise control device to meet the needs of the buckling work. The crushed bent material enters the feeding mold box 12 directly below through the bent material input device, the hydraulic motor 2 drives the turntable 28 to rotate, and the bent material is transferred to the position of the pre-pressing mold box 13, and the initial rolling is carried out by the bending rollers. Press, the turntable 28 continues to rotate, and forwards to the position of the first hammer material mold box 14, and the pressure hammer beam 8 moves downward under the action of the hydraulic cylinder 6 to press the material. Under the action of 6, it moves upwards and returns to the initial position, the hydraulic motor 2 starts to continue to rotate, and turns to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com