Rotor manufacturing method

A manufacturing method and rotor technology, which are used in the manufacture of motor generators, stator/rotor bodies, magnetic circuit rotating parts, etc., can solve the problems of excess and reduced yield, and achieve easy control and reduce residual solidified products. The effect of reducing the amount of residual solidified material, that is, the amount of residual material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, one embodiment of the rotor manufacturing method of the present invention will be described based on the drawings. It should be noted that the drawings are viewed along the direction of the symbols.

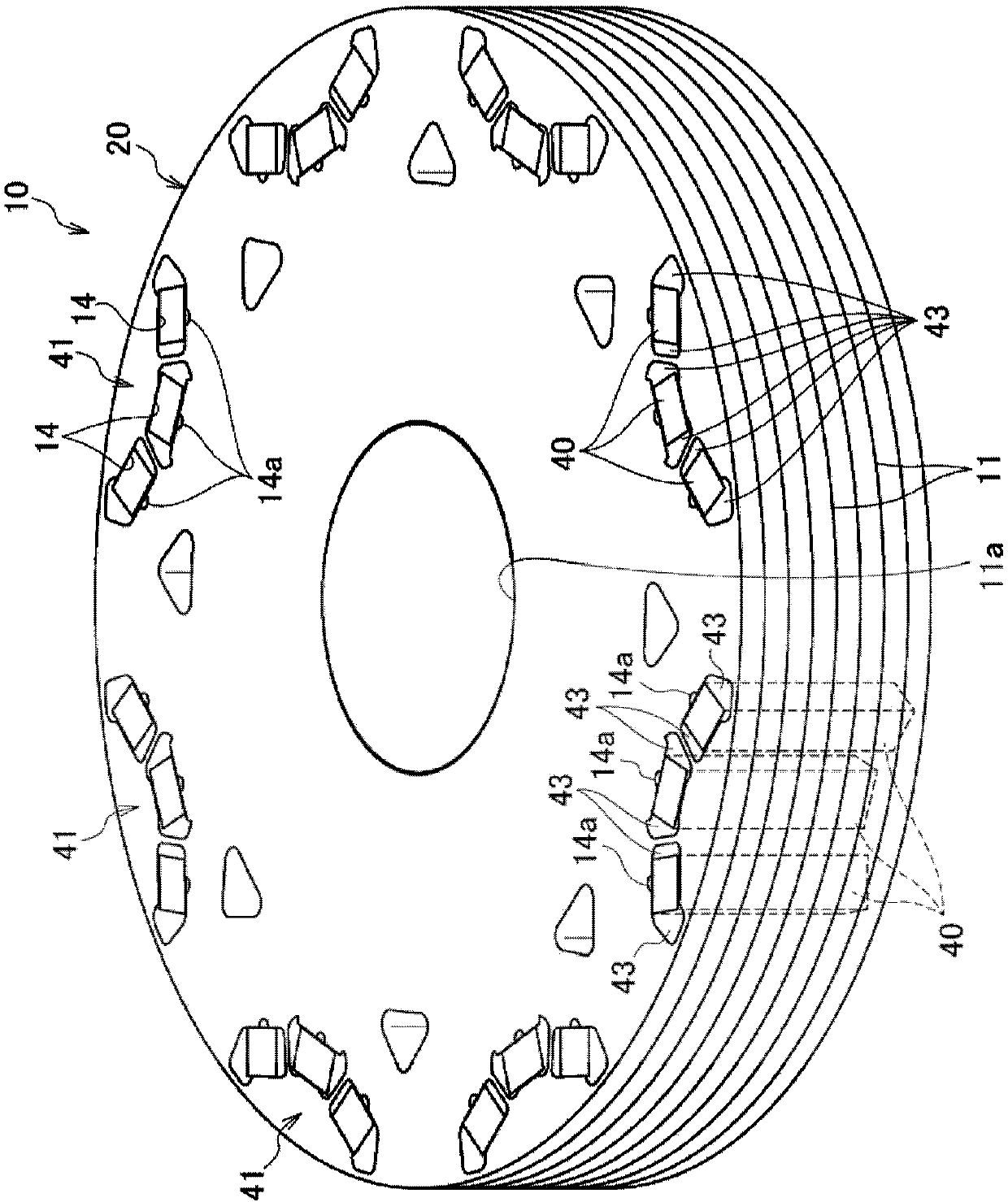

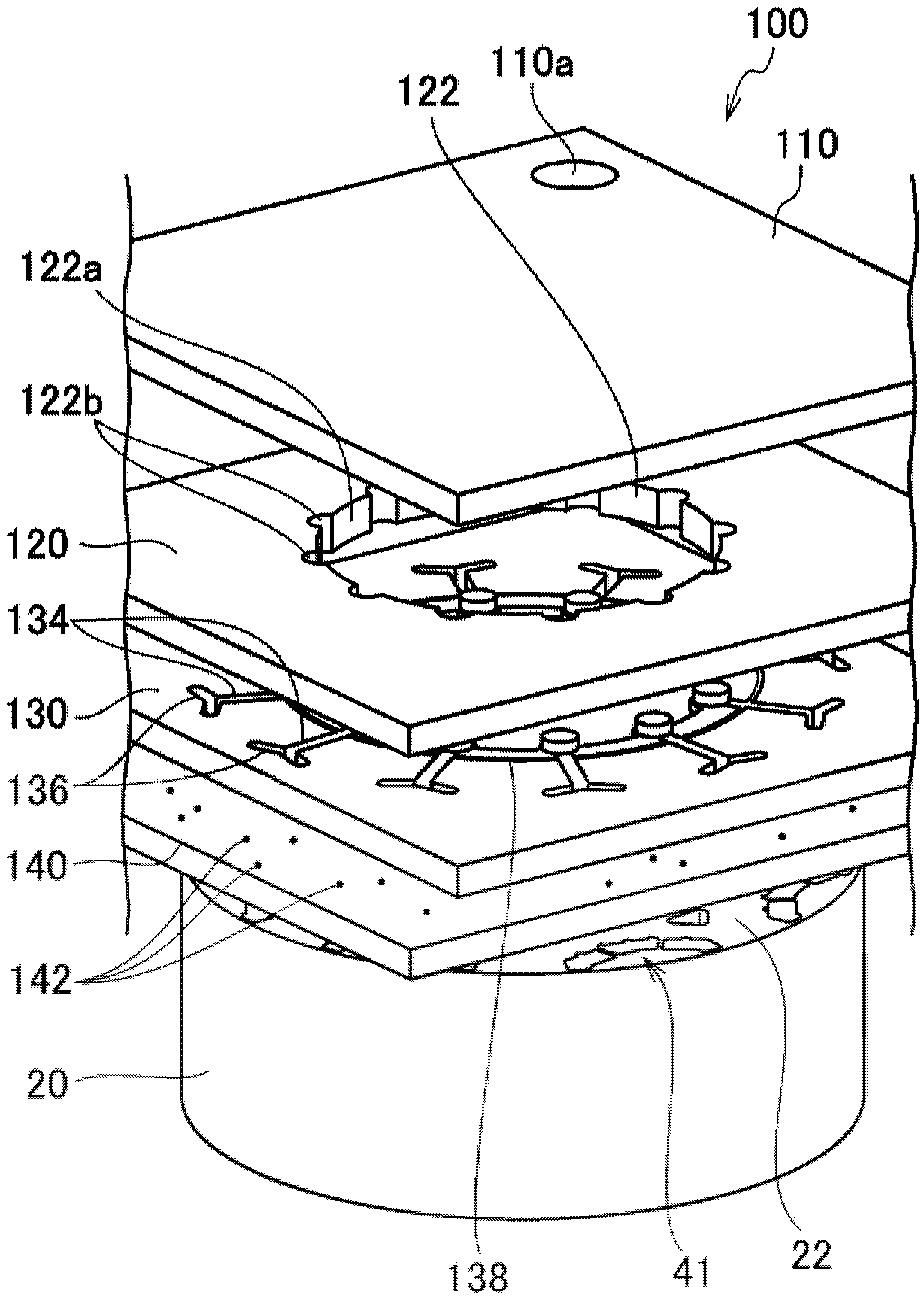

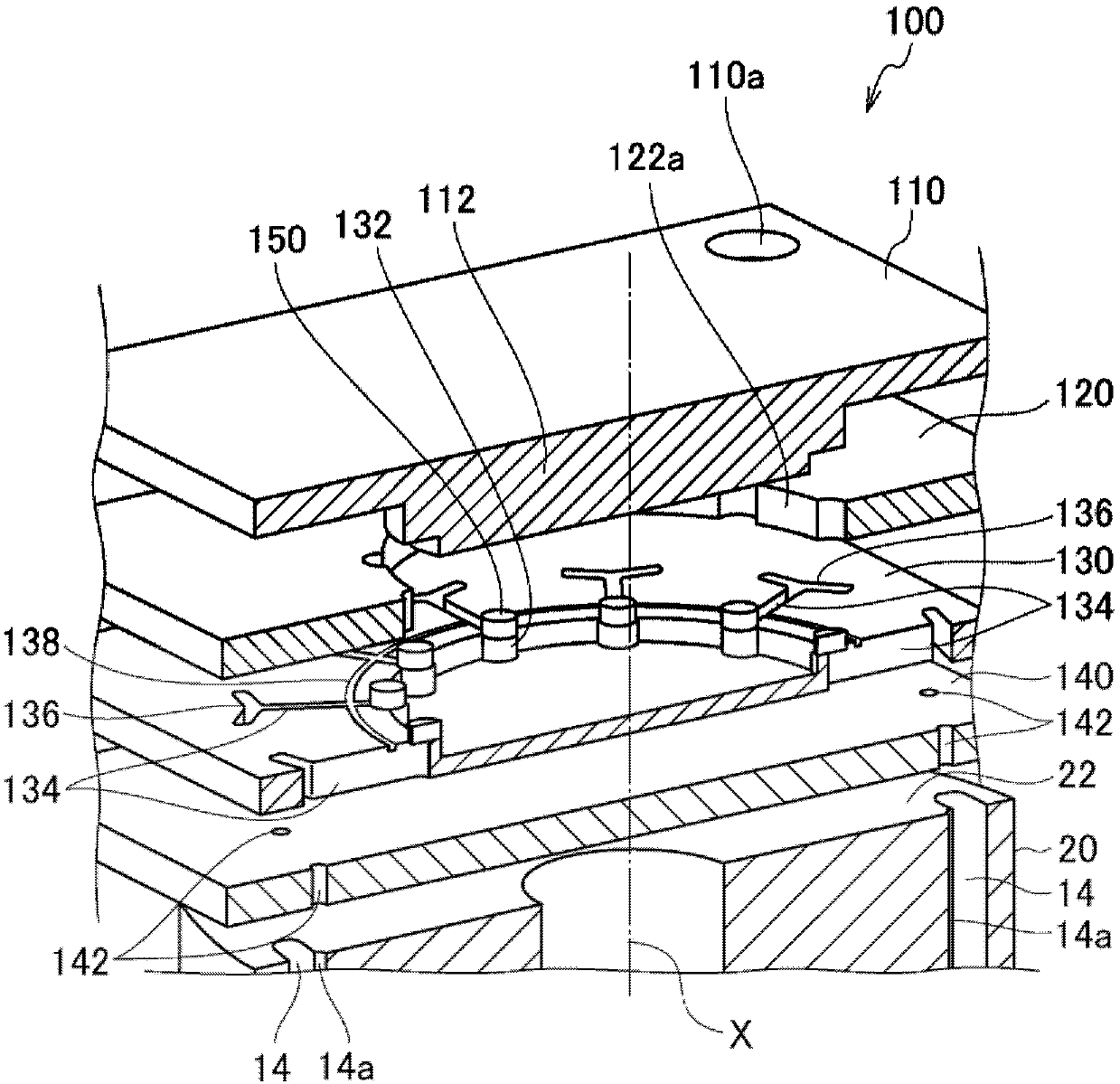

[0063] First, refer to figure 1 , the rotor core of one embodiment used in the rotor manufacturing method of the present invention will be described. A so-called embedded permanent magnet rotor 10 used in a rotating electric machine generally includes a rotor core 20 , a plurality of permanent magnets 40 , and a resin portion 43 for fixing the permanent magnets 40 to the rotor core 20 .

[0064] The rotor core 20 is formed by laminating a plurality of substantially annular electromagnetic steel sheets 11, has a shaft hole 11a in its center, and has a plurality of magnet insertion holes 14 in its outer periphery. exist figure 1 In the example shown, three magnet insertion holes 14 constitute one magnetic pole portion 41 .

[0065] A resin groove 14 a exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com