Energy-saving and environment-friendly screw extruder

A screw extruder, energy saving and environmental protection technology, applied in the field of extruders, can solve the problems of waste materials, residual materials, material clogging, etc., and achieve the effect of improving utilization rate, reducing possibility, and reducing residual materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

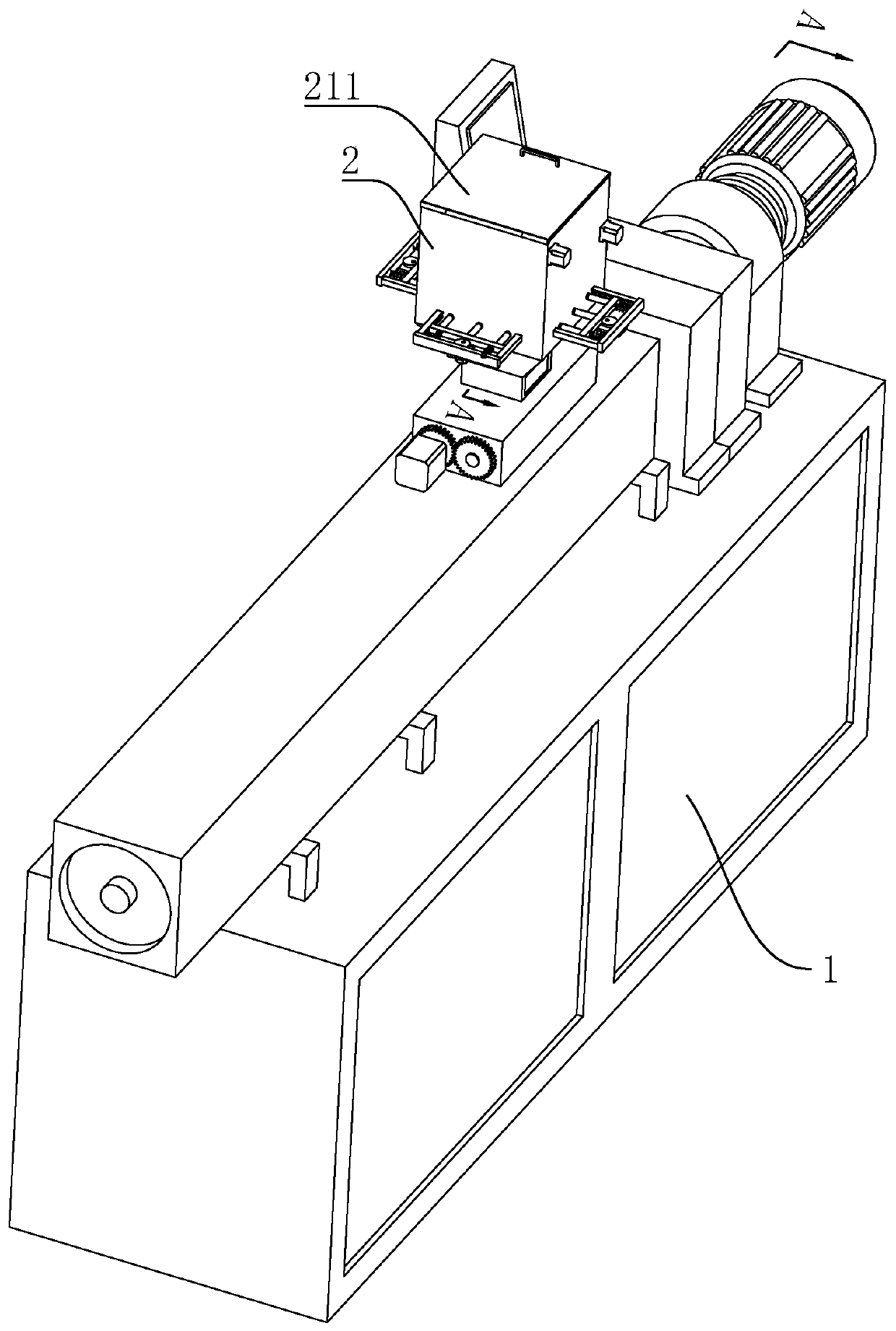

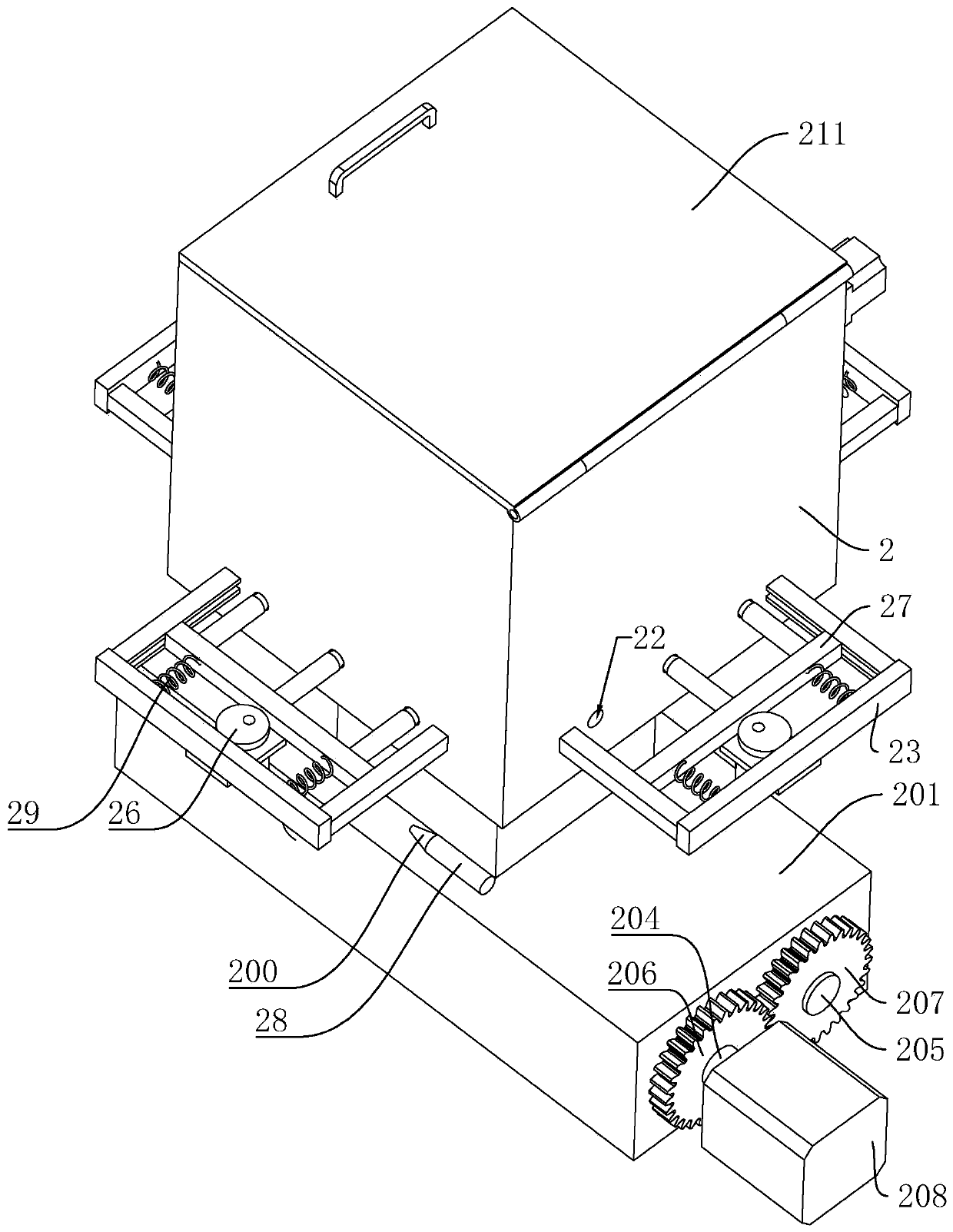

[0033] refer to figure 1 , an energy-saving and environment-friendly screw extruder, which includes an extruder body 1 and a hopper 2 arranged on the extruder body 1, the cross section of the hopper 2 is rectangular, and a cover plate 211 is hinged on the top wall of the hopper 2 , when the production is stopped, turn the cover plate 211 to close the hopper 2 to prevent dust from falling into the hopper 2.

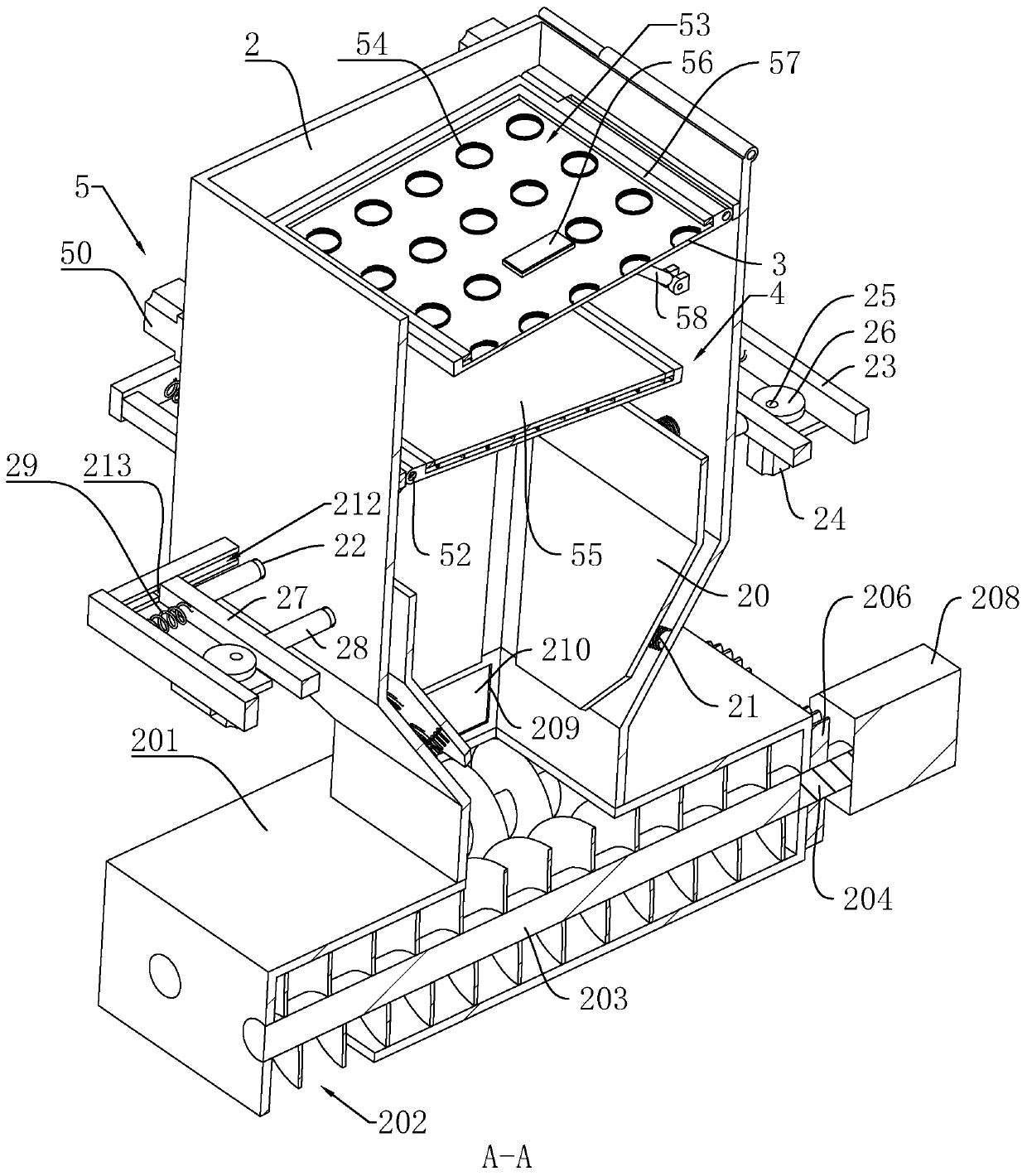

[0034] refer to figure 2 There are at least two receiving plates 3 for conveying materials, preferably two, rotating in the hopper 2. The receiving plates 3 are located below the feed inlet of the hopper 2, and there is a supply of material between the receiving plates 3 and the inner side wall of the hopper 2. The feeding space 4 for conveying is set up and down adjacent to the receiving plate 3, and the adjacent feeding space 4 is staggered. The bottom wall of the receiving plate 3 is rotated with a hydraulic support rod 58. The inner side wall of the hopper is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com