Glue injection machine for unsaturated polyester resin glass fiber reinforced plastic production and process

A technology of polyester resin and fiberglass, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of easy sticking to workers' clothes and skin, polluting the production environment, and difficult cleaning. , to achieve the effect of easy cleaning equipment, reducing pollution and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

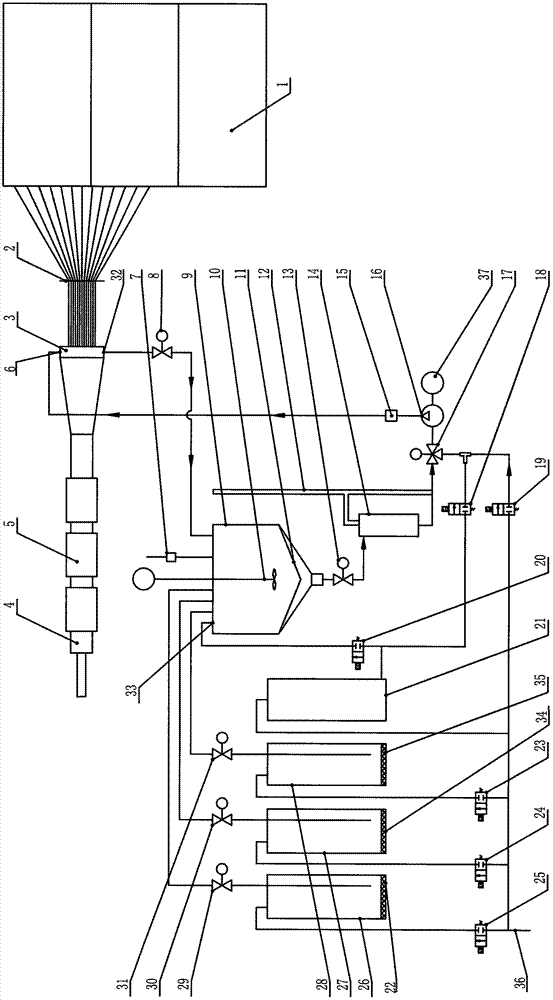

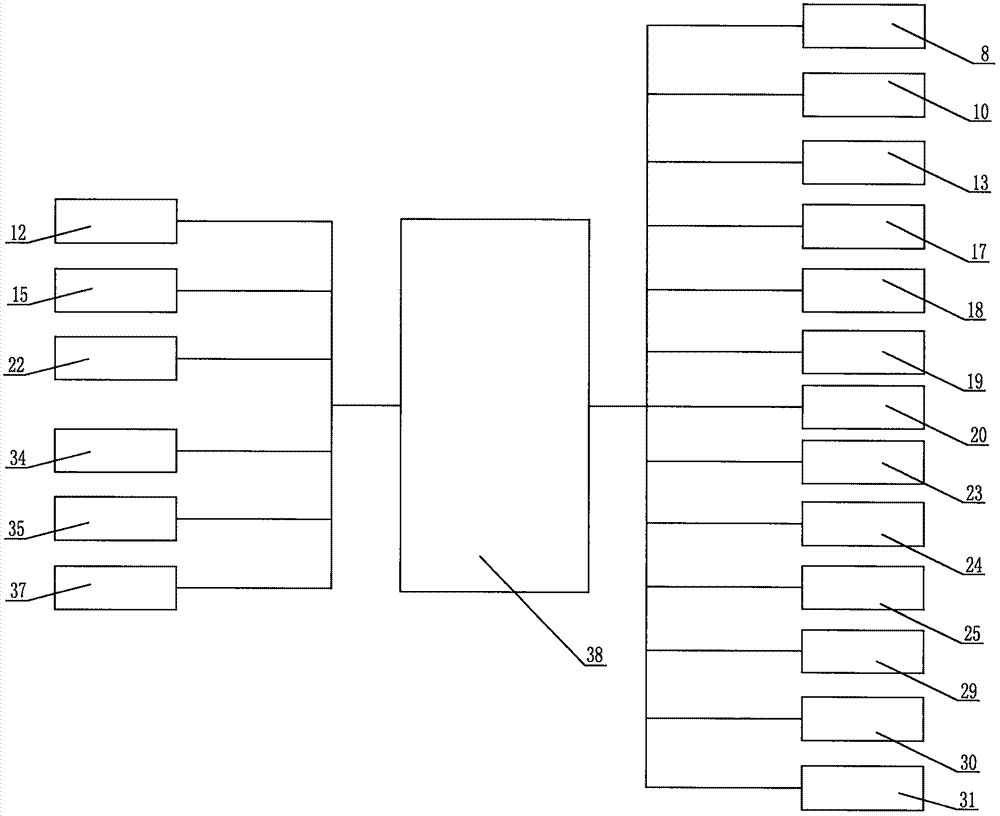

[0063] A process of a glue injection machine for unsaturated polyester resin FRP production, the process includes a glue production method and a glue injection method;

[0064] A, the production method of glue solution comprises the steps:

[0065] Step 1: PLC programmable controller 38 controls the second pneumatic two-way valve 29, the third pneumatic two-way valve 30 and the fourth pneumatic two-way valve 31 to open, and simultaneously controls the first solenoid valve 25, the second solenoid valve 24 and the second solenoid valve The three electromagnetic valves 23 are respectively communicated with the compressed gas pipeline 36, and the resin inside the resin tank 26, the filler inside the stuffing tank 27 and the curing agent inside the curing agent tank 28 enter the mixing tank 9 under the action of the compressed gas, and the first weight sensor 22. The second weight sensor 34 and the third weight sensor 35 monitor the weight data in real time, and transmit the above ...

Embodiment 2

[0070] A process of a glue injection machine for unsaturated polyester resin FRP production, the process includes a glue production method and a glue injection method;

[0071] A, the production method of glue solution comprises the steps:

[0072] Step 1: PLC programmable controller 38 controls the second pneumatic two-way valve 29, the third pneumatic two-way valve 30 and the fourth pneumatic two-way valve 31 to open, and simultaneously controls the first solenoid valve 25, the second solenoid valve 24 and the second solenoid valve The three electromagnetic valves 23 are respectively communicated with the compressed gas pipeline 36, and the resin inside the resin tank 26, the filler inside the stuffing tank 27 and the curing agent inside the curing agent tank 28 enter the mixing tank 9 under the action of the compressed gas, and the first weight sensor 22. The second weight sensor 34 and the third weight sensor 35 monitor the weight data in real time, and transmit the above ...

Embodiment 3

[0078] A process for the glue injection machine used in the production of unsaturated polyester resin glass fiber reinforced plastics, the process comprises a glue production method, a glue injection method, a glue injection pump 16 and a glue injection box 3 cleaning method and a stirring tank 9 cleaning method;

[0079] A, the production method of glue solution comprises the steps:

[0080] Step 1: PLC programmable controller 38 controls the second pneumatic two-way valve 29, the third pneumatic two-way valve 30 and the fourth pneumatic two-way valve 31 to open, and simultaneously controls the first solenoid valve 25, the second solenoid valve 24 and the second solenoid valve The three electromagnetic valves 23 are respectively communicated with the compressed gas pipeline 36, and the resin inside the resin tank 26, the filler inside the stuffing tank 27 and the curing agent inside the curing agent tank 28 enter the mixing tank 9 under the action of the compressed gas, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com