Exhaust valve

An exhaust valve, valve seat technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of opening and closing valve cover, unstable airflow, small moment of inertia, etc., to facilitate manufacturing, avoid welding penetration, increase The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

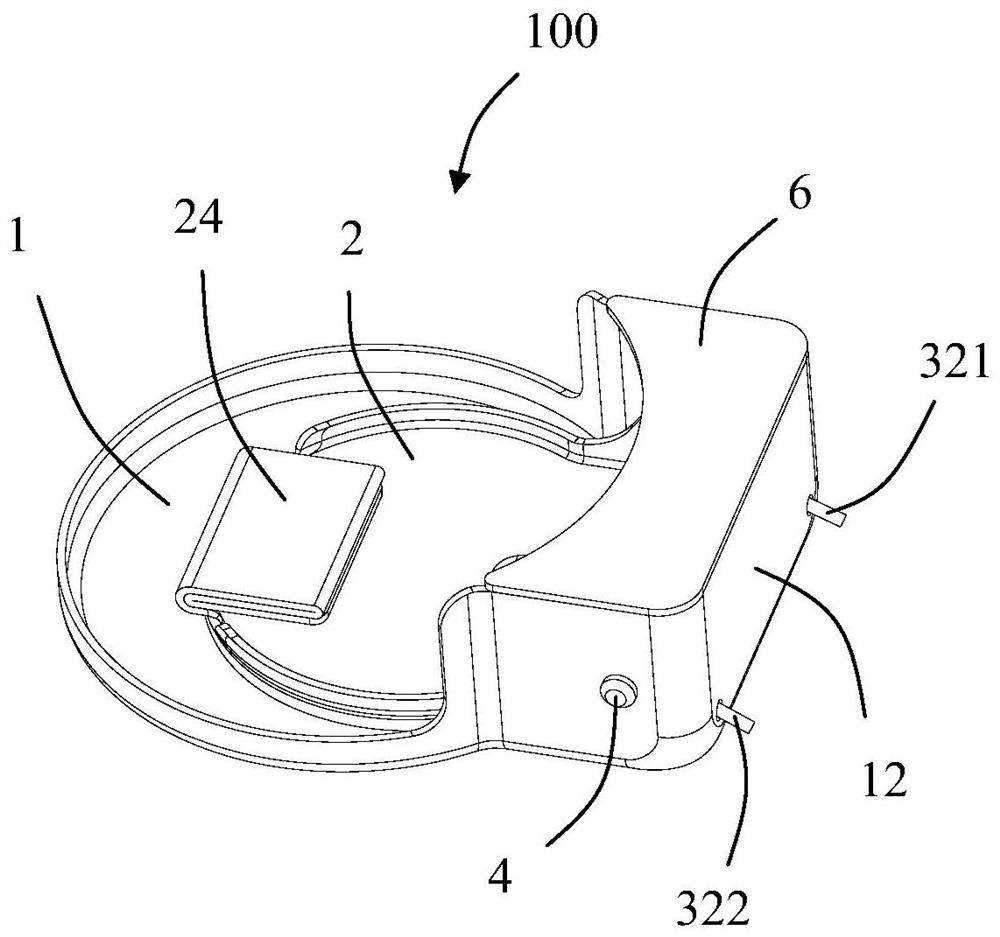

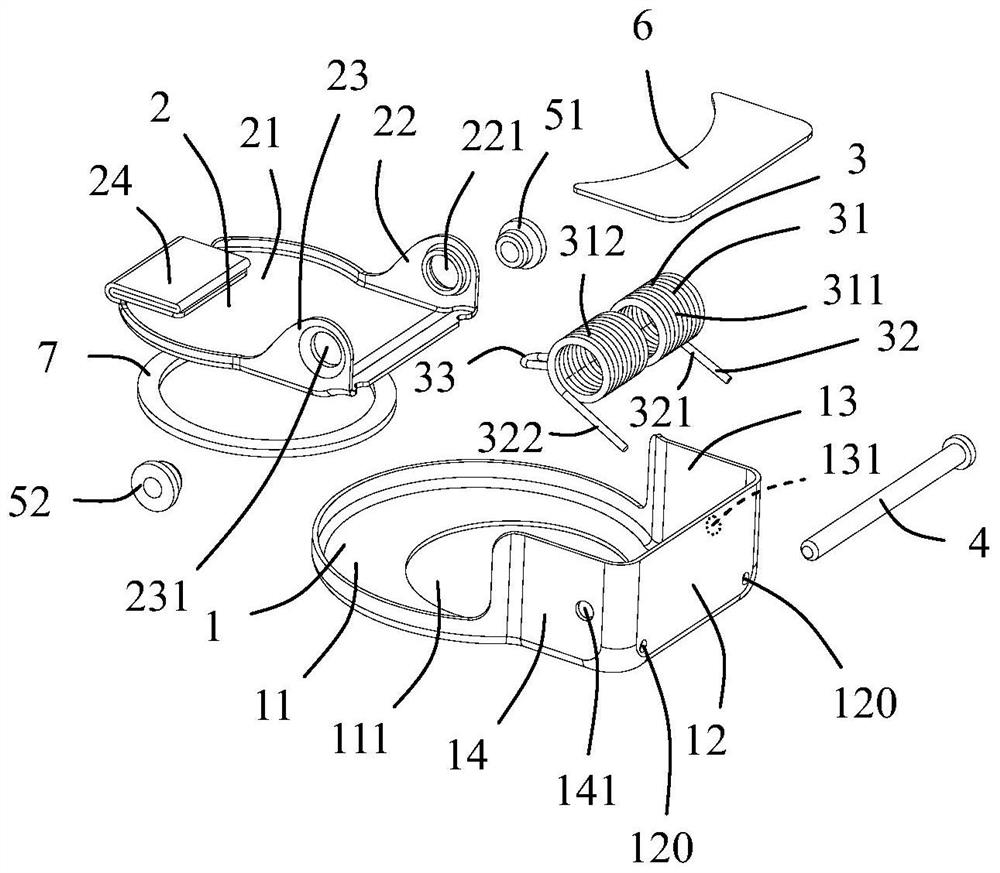

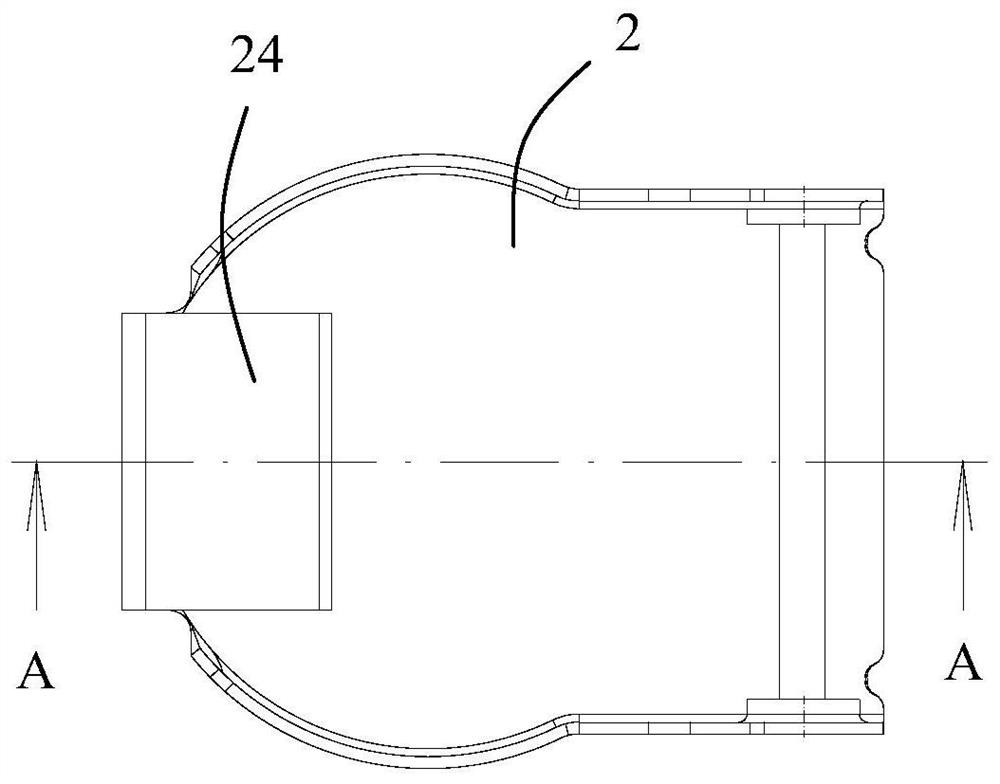

[0020] Please refer to Figure 1 to Figure 4 As shown, the present invention discloses an exhaust valve 100, which includes a valve seat 1, a valve cover 2 capable of rotating relative to the valve seat 1, an elastic member 3 for abutting against the valve cover 2, and A shaft 4 cooperating with the valve seat 1 , the valve cover 2 and the elastic member 3 .

[0021] In one embodiment of the present invention, the valve seat 1 is provided with a first main body portion 11, a support portion 12, a first side wall 13 located on one side of the support portion 12, and a first side wall 13 located on the support portion 12. The second side wall 14 on the other side. The first main body 11 defines an air inlet 111 . The first sidewall 13 defines a first through hole 131 , and the second sidewall 14 defines a second through hole 141 . The support portion 12 is provided with a plurality of installation holes 120 , and the installation rods 32 are installed in the corresponding ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com