Knife handle and welding method of the knife handle and cutter body

A welding method and tool holder technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as deformation, affecting welding quality and efficiency, and achieve the effect of simplifying the process, eliminating thermal stress, and solving deformation problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. It should be noted that in the drawings of this embodiment, the words "SBZZ" and "SHIBAZI" shown are only used to illustrate that the handle of the knife handle has inset fonts, which can increase the anti-slip effect, and are not used for Protect the specific content and meaning of fonts, and are not used to designate product trademarks.

[0039] Handle embodiment

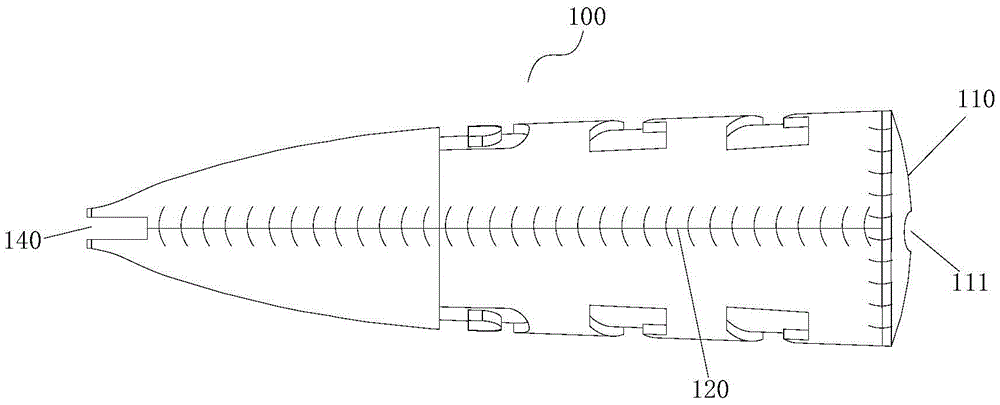

[0040] combine Figure 1-4 , The invention provides a knife handle for welding on the knife body.

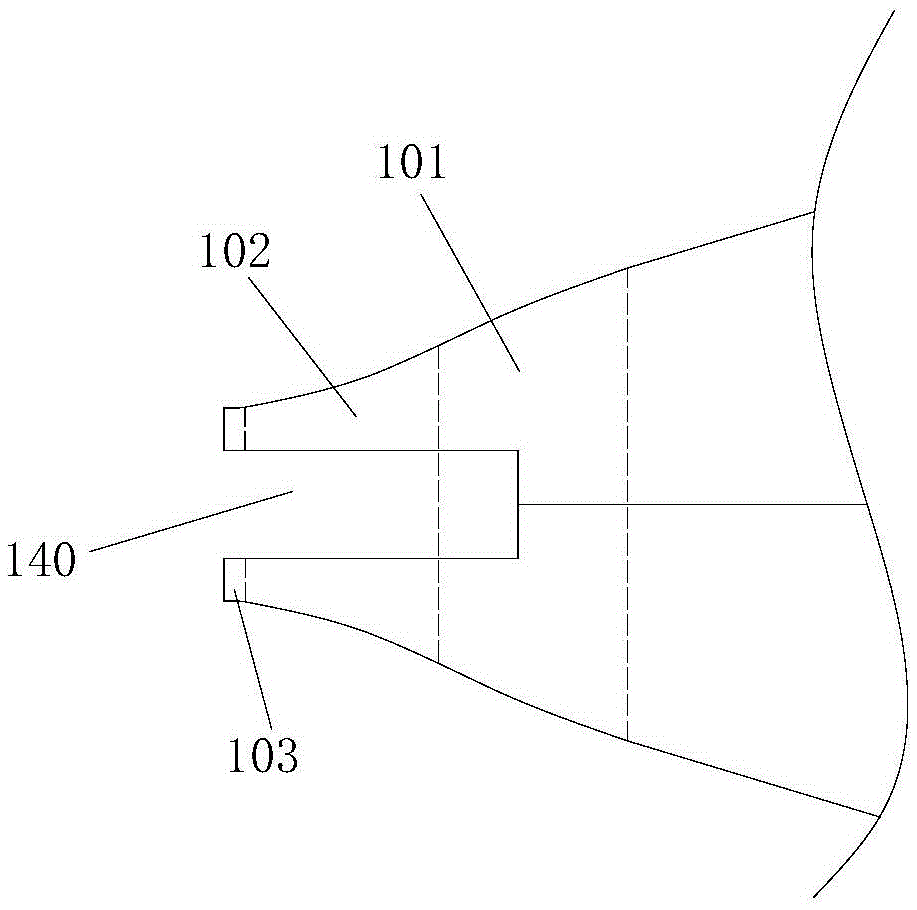

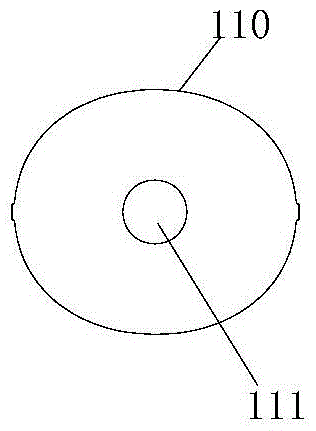

[0041] The knife handle 100 is a hollow structure, and the head end of the knife handle 100 is a tapered portion, and the end of the knife handle 100 is encapsulated with a handle plug 110 . The tapered part along the axis of the handle 100 has a smoothly connected outer convex area 101, inner concave area 102 and straight extension area 103, see figure 2 and 4 , in orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com