Welding and Repairing Method for the Outer Cylinder of the Preheating Boiler

A technology for preheating boilers and outer cylinders, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of welding leakage, welding penetration, and poor welding at the welding place, and achieve high welding efficiency, good repair effect, The effect of convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained in conjunction with the accompanying drawings and specific examples:

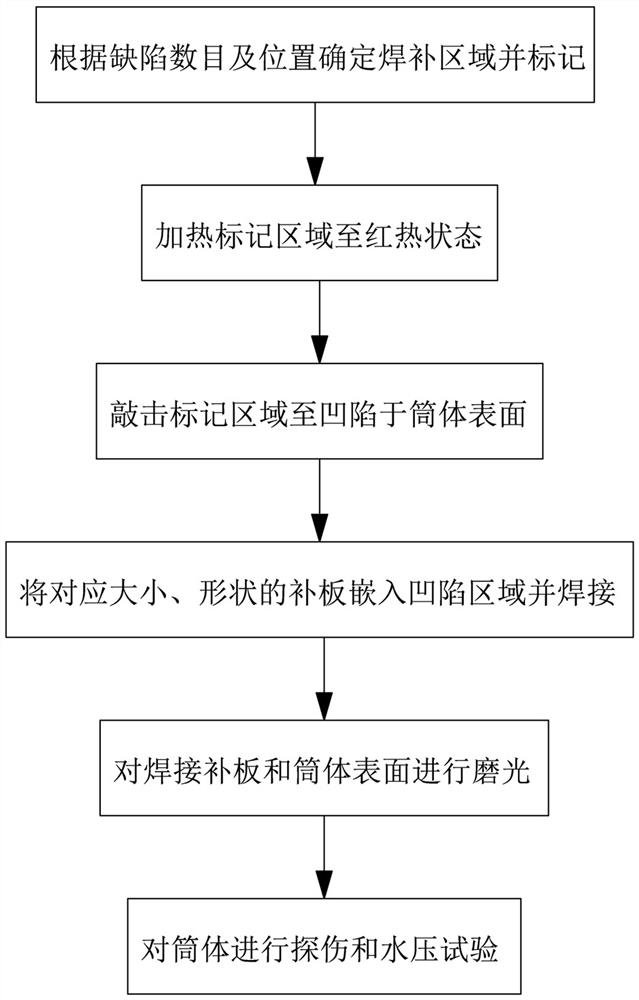

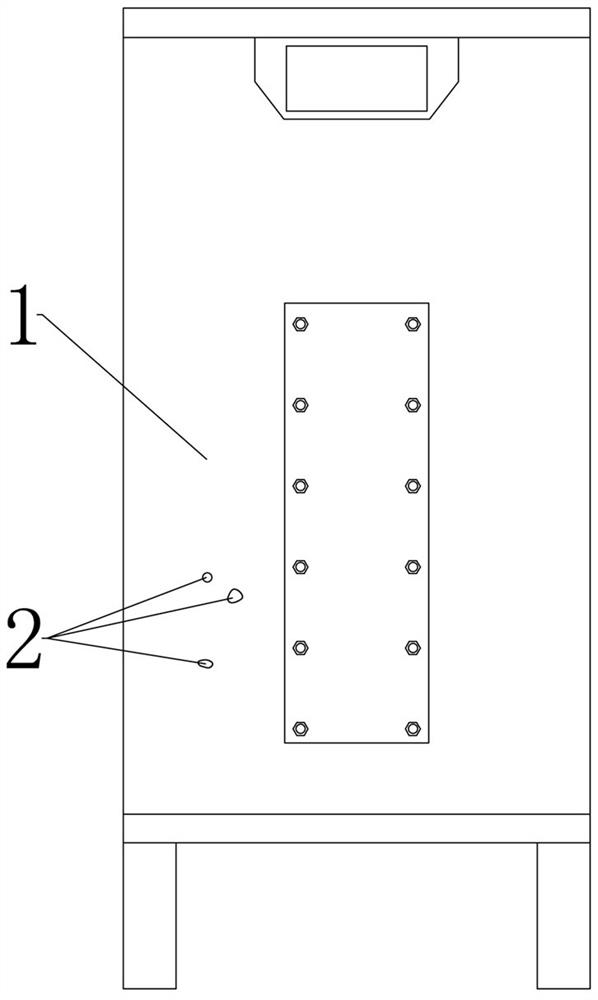

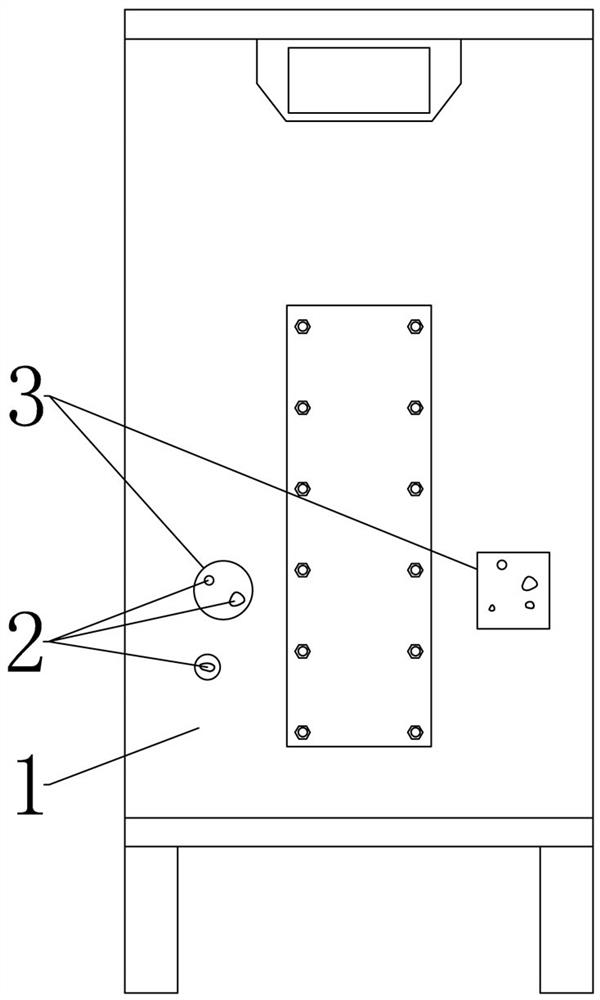

[0030] like Figure 1 ~ 4 As shown in the preheating boiler outer cylinder welding method, there are several corrosion defects in the inner wall of the boiler, including the following steps:

[0031] In the first step, determine the position of the defect, the cleaning defect, determine the soldering area according to the shape and size of the defect, and mark the soldering area;

[0032] In the second step, heating the labeling area, the heating area size is added to the center of 10 to 15 mm from the center of the soldering area;

[0033] In the third step, tap the marker area in the red hot state, so that the marking area is concavely concave on the surface of the cylinder;

[0034] In the fourth step, according to the size of the recess area, the corresponding patch panel is inlaid in the recessed area, and the recess is welded within the recessed region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com