Workpiece welding clamp

A technology for welding fixtures and workpieces, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity and unguaranteed welding quality, and achieve the goal of ensuring welding accuracy, improving welding quality and welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

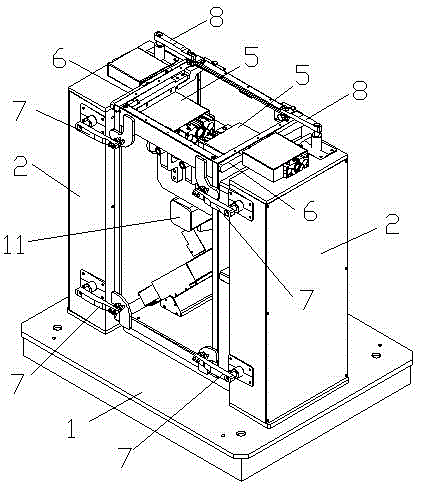

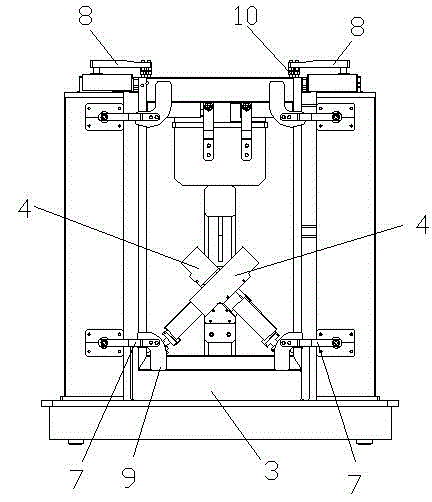

[0015] like figure 1 and figure 2 As shown, a workpiece welding fixture includes a base 1 and two columns 2 fixed on the base 1, a U-shaped seat 3 is also arranged on the base 1 between the two columns 2, and the two columns 2 are also provided with two mutually perpendicular lower inner braces 4 and two opposite upper inner braces 5, the angle between the lower inner braces 4 and the bottom surface of the U-shaped seat 3 is 45°, the tops of the two uprights 2 are provided with a limit strip 6 for limiting the workpiece and cooperating with the upper inner support member 5 . The workpiece is placed in the U-shaped seat 3, and the bottom of the workpiece is fixed by two lower inner support members 4, and the two sides of the workpiece are perpendicular to the bottom surface, and at the same time, two upper inner support members 5 are used to cooperate with the limit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com