Automatic welding gun head for tube-shell thin tube plate embedded deep hole welding

An embedded, automatic welding technology, applied in the characteristics of electrodes, welding equipment, arc welding equipment, etc., can solve the problems of inconvenient manual operation, poor performance, and the quality of welding seam is affected by the level of welders, and achieve the effect of preventing welding penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

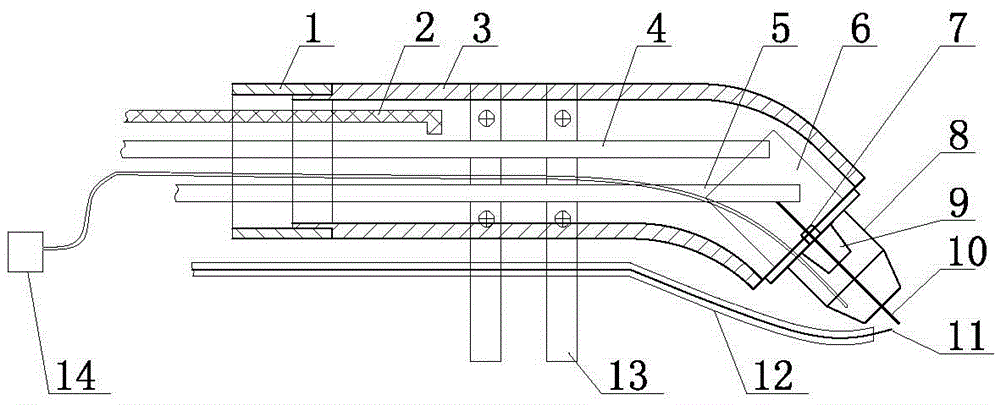

[0036] A kind of automatic welding torch head of this embodiment is used for embedded deep hole welding of shell-and-shell type thin tube plate, and this automatic welding torch head is mainly used for deep hole welding, as figure 1 As shown, the automatic welding torch head includes an introduction cavity 1, an insulating cavity 2 and a nozzle assembly, the introduction cavity 1 is made of stainless steel, the insulation cavity 2 is made of insulating Bakelite, and the left end of the insulation cavity 2 is connected to the introduction cavity The end of the tube 1 is threaded, so that the length of the torch head is lengthened by introducing the tube 1 into the cavity, so as to facilitate deep hole welding in the air inserted into the tube sheet.

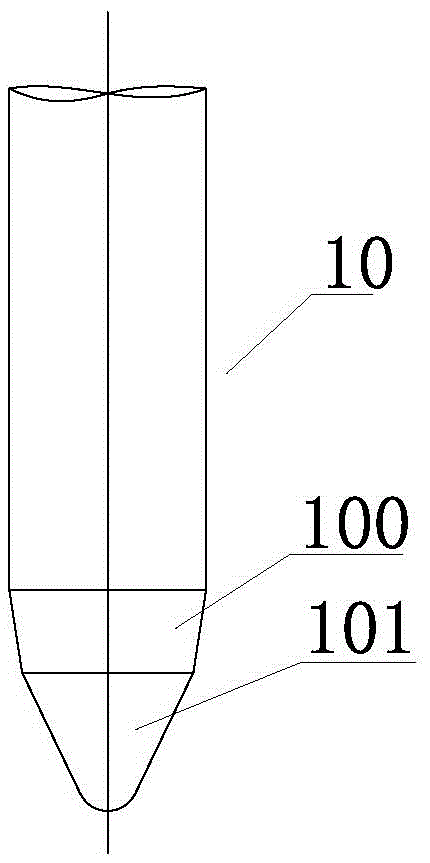

[0037] Such as figure 1 and figure 2 As shown, the cavity at the right end of the insulating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com