Straight pipe welding system

A welding system and straight pipe technology, applied in welding accessories, welding equipment, welding equipment, etc., can solve the problems of unevenness, a large number of continuous pores, easy welding through welding seams, etc., to ensure quality, uniform and controllable welding speed, The effect of improving weld uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

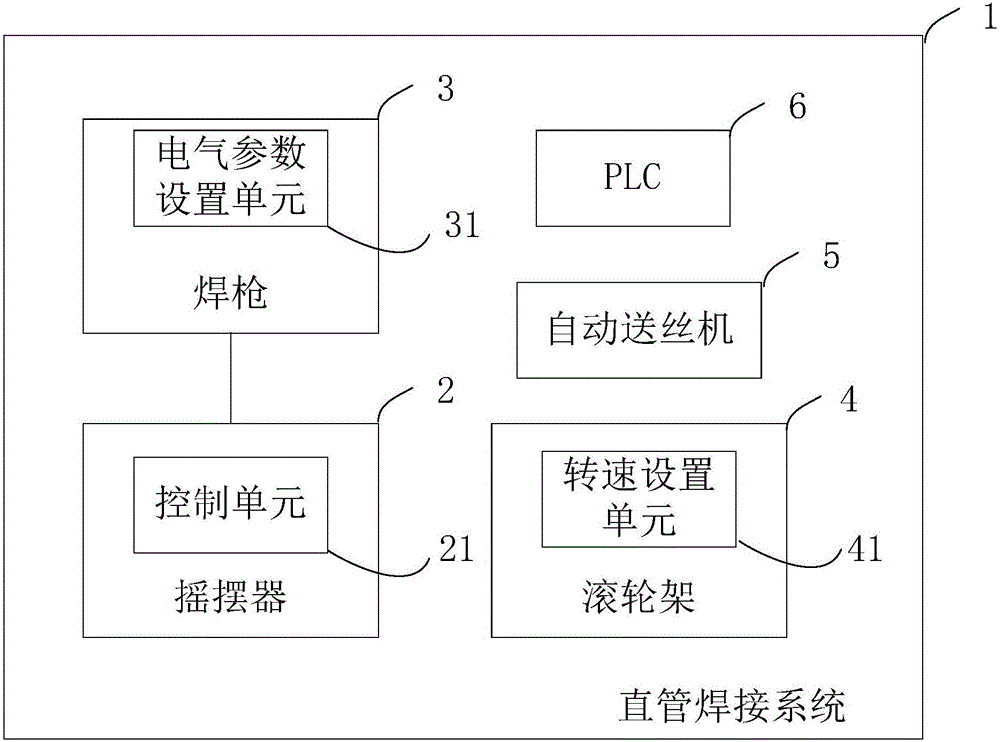

[0021] like figure 1 As shown, a straight pipe welding system 1 includes a welding torch 3, a swinger 2, an automatic wire feeder 5, a roller frame 4 and a PLC 6, the welding torch 3 is fixed on the swinger 2; the welding torch 3 includes an electrical parameter setting unit 31, The electrical parameter setting unit 31 is used to set the electrical parameters when the motor of the welding gun 3 is working; the straight pipe to be welded is arranged on the roller frame 4, and the roller frame 4 is used to drive the straight pipe to be welded to rotate at a constant speed; the roller frame 4 includes a speed setting unit 41 , the rotation speed setting unit 41 is used to set the rotation speed of the roller frame 4 . The rocker 2 is used to drive the welding torch 3 to swing at a constant speed along the weld seam between the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com