Automatic cooling heat sink framework and refrigeration method thereof

A skeleton and heat sink technology, applied in the field of self-cooling heat sink skeleton and its refrigeration, can solve the problem of consuming expensive liquid helium, and achieve the effects of reducing liquid helium consumption, reducing test costs, reducing conduction heat leakage and thermal radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

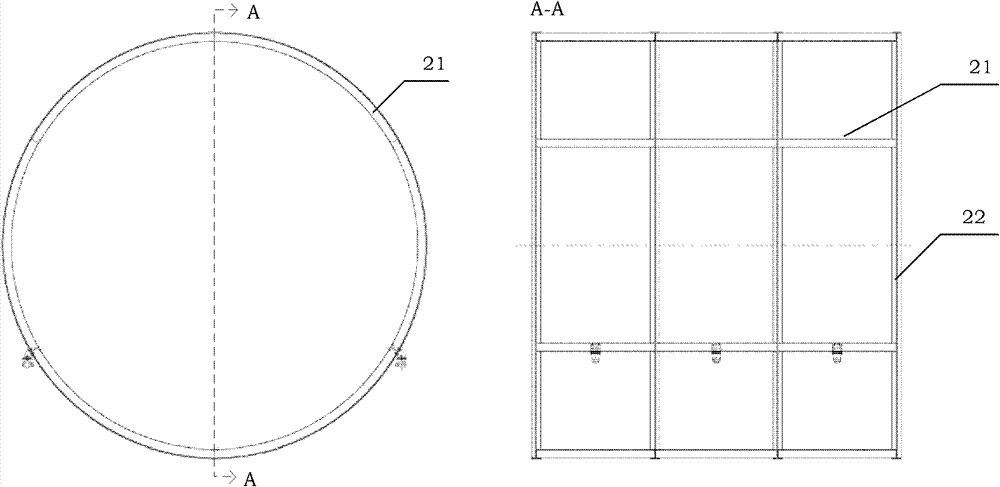

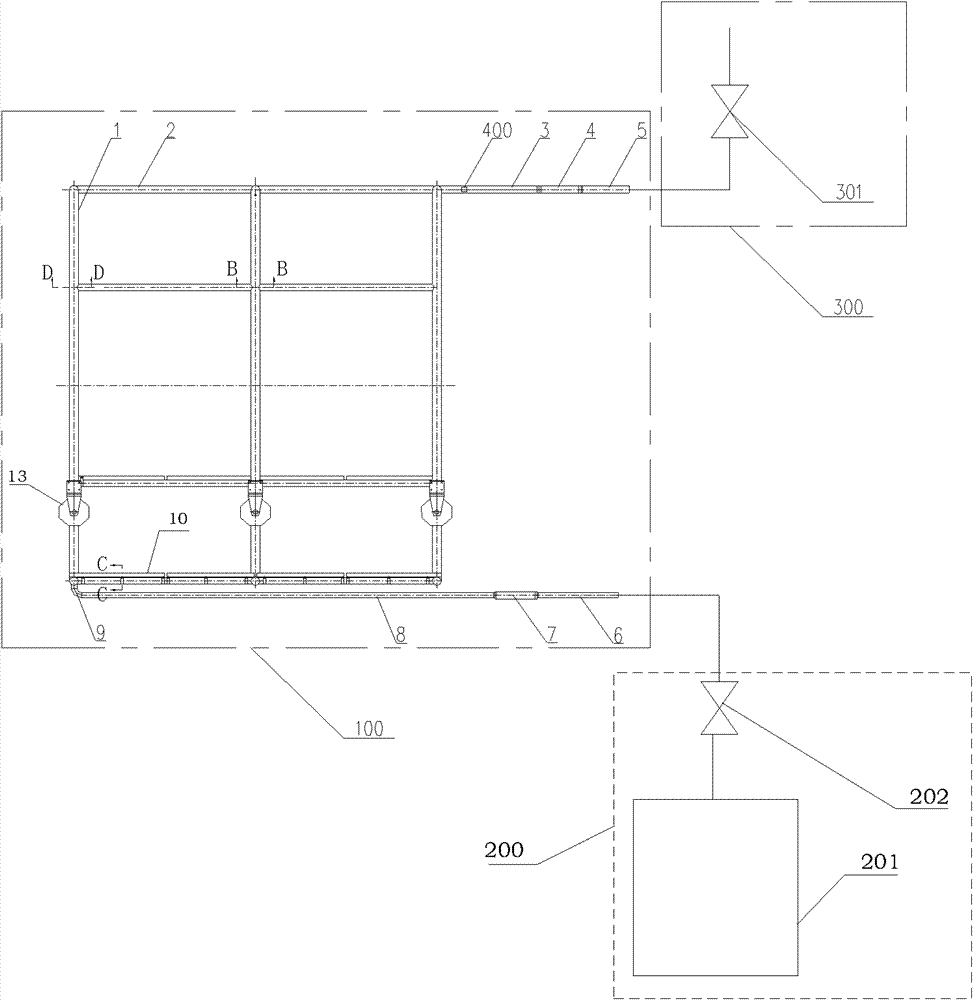

[0034] A self-cooling heat sink framework of the present invention, such as figure 2 As shown, it includes a self-cooling heat sink skeleton body 100 , a liquid nitrogen supply system 200 , a fluid discharge system 300 and a resistance temperature sensor 400 .

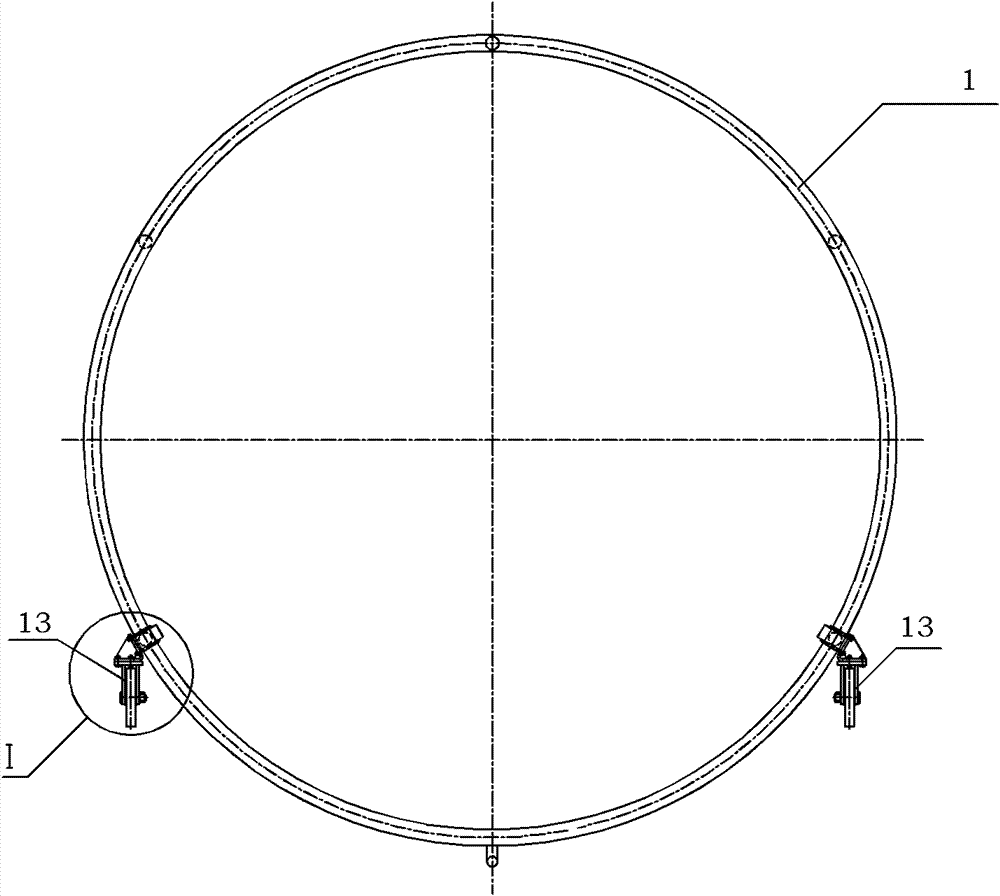

[0035] The main body 100 of the self-cooling heat sink skeleton is a horizontal cylinder, mainly composed of an annular pipe 1, a horizontal pipe 2, a long liquid outlet pipe 3, a short liquid outlet pipe 5, a short liquid inlet pipe 6, a long liquid inlet pipe 8 and a roller assembly 13 composition. like figure 2 As shown, the annular pipe 1 is welded and connected by a plurality of horizontal pipes 2 to form a cylindrical shape, and the interior of the annular pipe 1 and the interior of the horizontal pipe 2 communicate with each other to facilitate the flow of the refrigerant medium. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com