Fully automatic device for sweet potato vermicelli sheets

A fully automated, sweet potato powder technology, applied in heating devices, household refrigeration devices, dryers, etc., can solve the problems of large labor costs, low production efficiency, and increased production costs, and achieve the goal of reducing production costs and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

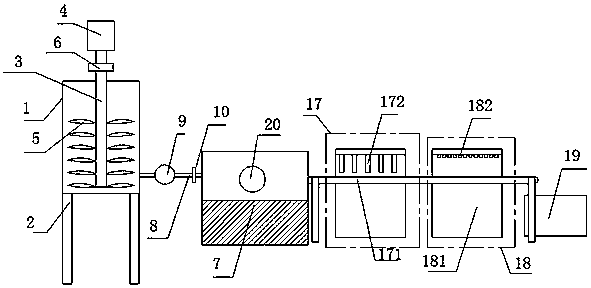

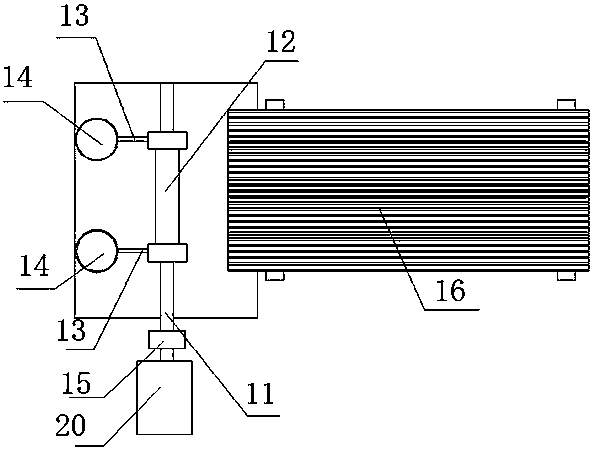

[0015] Such as Figure 1-2 Shown, a kind of fully automatic sweet potato powder flakes device comprises mixing tank 1, installation frame one 2, transmission shaft 3, motor one 4, stirring blade 5, speed reducer 6, liquid tank 7, connecting pipe 8, material pump 9, Electromagnetic valve 10, rotating shaft 11, axle sleeve 12, connecting rod 13, heating tank 14, gearbox 15, conveyor belt 16, cooling device 17, drying device 18, collection box 19, it is characterized in that: described mixing bucket 1 Installed on the mounting frame one 2, the transmission shaft 3 is installed in the mixing bucket 1, the stirring blade 5 is installed on the transmission shaft 3, the speed reducer 6 is connected with the transmission shaft 3, and the motor - 4 is connected to the reducer 6, the liquid tank 7 is connected to the mixing tank 1 through the connecting pipe 8, the material pump 9 is installed on the connecting pipe 8, and the electromagnetic valve 10 is installed on the connecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com