Automatic cooling box, automatic cooling power battery pack and new energy automobile

An automatic cooling and power battery technology, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of uneven cooling, low efficiency of cooling methods, unsuitable timing control, etc., and achieve the effect of simplifying the structure and reducing the time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

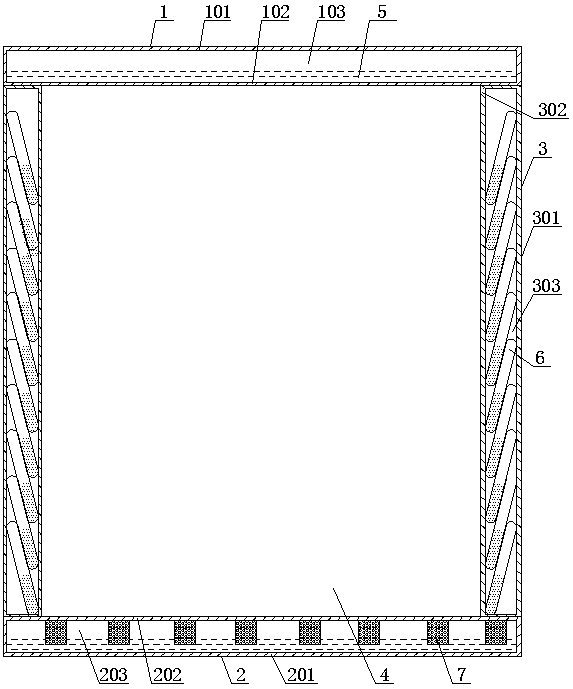

[0041] As attached figure 1 As shown, an automatic cooling box includes a top wall 1, a bottom wall 2, and a vertical wall 3, and a cavity 4 surrounded by the top wall 1, the bottom wall 2 and the vertical wall 3. The cavity 4 can accommodate a new energy battery. The side wall of the top wall 1, the bottom wall 2 and the vertical wall 3 close to the cavity 4 is the inner side wall, and the side wall of the top wall 1, the bottom wall 2 and the vertical wall opposite to the inner side wall is the outer side wall.

[0042] The top wall 1 is a hollow wall. The hollow cavity 103 of the top wall is provided with a liquid phase change medium 5. The liquid phase change medium 5 exchanges heat with the heat in the box through the inner side wall 102 of the top wall. The wall 102 is used as the heat absorption wall, and the outer side wall 101 of the top wall is used as the exothermic wall. When the temperature in the box body reaches the boiling point of the liquid phase change medium 5,...

Embodiment 2

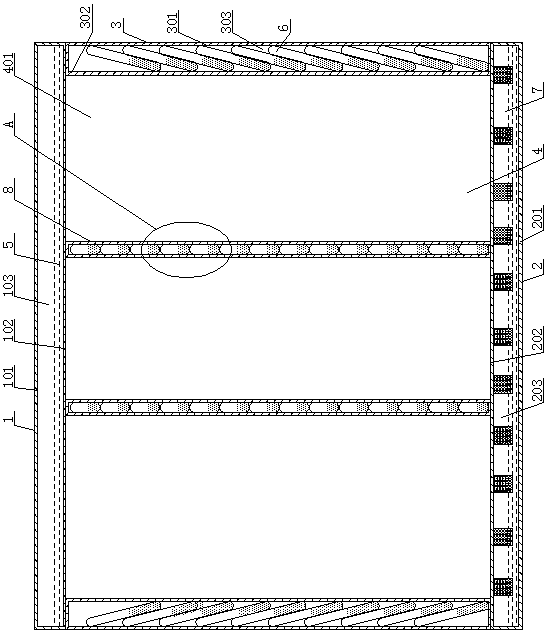

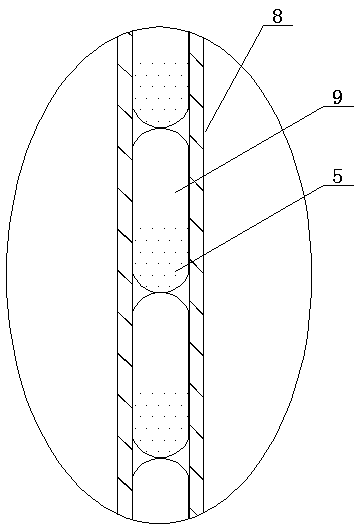

[0053] As attached figure 2 And image 3 As shown, this embodiment is a further improvement on the basis of embodiment 1. The difference between this embodiment and embodiment 1 is: the cavity 4 is equipped with two vertical partitions 8, and the two partitions 8 divide the cavity The body 4 is divided into three sub-cavities from left to right, and each sub-cavity can accommodate a new energy battery.

[0054] In order to improve the heat dissipation in the box, the partition 8 is set as a heat conducting plate. Specifically, the partition 8 is a hollow plate, and a plurality of closed heat conduction pipes 9 arranged vertically are arranged in the hollow cavity of the partition 8, and each heat conduction pipe 9 is provided with a liquid phase change medium 5, a heat conduction pipe 9 The gap is set in the hollow cavity of the partition 8, that is, one side of the heat pipe 9 is in contact with the outer side wall of the near partition 8, and the other phase side of the heat p...

Embodiment 3

[0060] As attached Figure 5 As shown, an automatic cooling power battery pack includes a power battery 11 and an automatic cooling box as described in Embodiment 1. The power battery 11 is assembled in a cavity 4. In this embodiment, the power battery 11 is three groups of power battery packs, and the three groups of power battery packs are assembled in the cavity 4.

[0061] In this embodiment, an automatic cooling battery pack can automatically cool down. The automatic cooling method is specifically as follows: when the power battery 11 generates heat and causes the temperature in the cavity 4 to rise, when the temperature reaches the boiling point of the liquid phase phase change medium, the top wall 1. The phase change medium of the liquid phase in the bottom wall 2 and the vertical wall 3 exchanges heat with the heat in the cavity 4 through the inner side wall, and the phase change medium of the liquid phase absorbs heat and vaporizes into the phase change medium of the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com