Method for welding stainless steel optical units without cutting steel belt and corresponding tool structure

A technology of stainless steel and optical unit, which is applied in the field of optical communication, can solve the problems of increased production cost due to the cost of the cutter, low steel strip utilization rate, and high production cost, so as to avoid secondary welding, improve utilization rate, and meet the requirements of laser welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

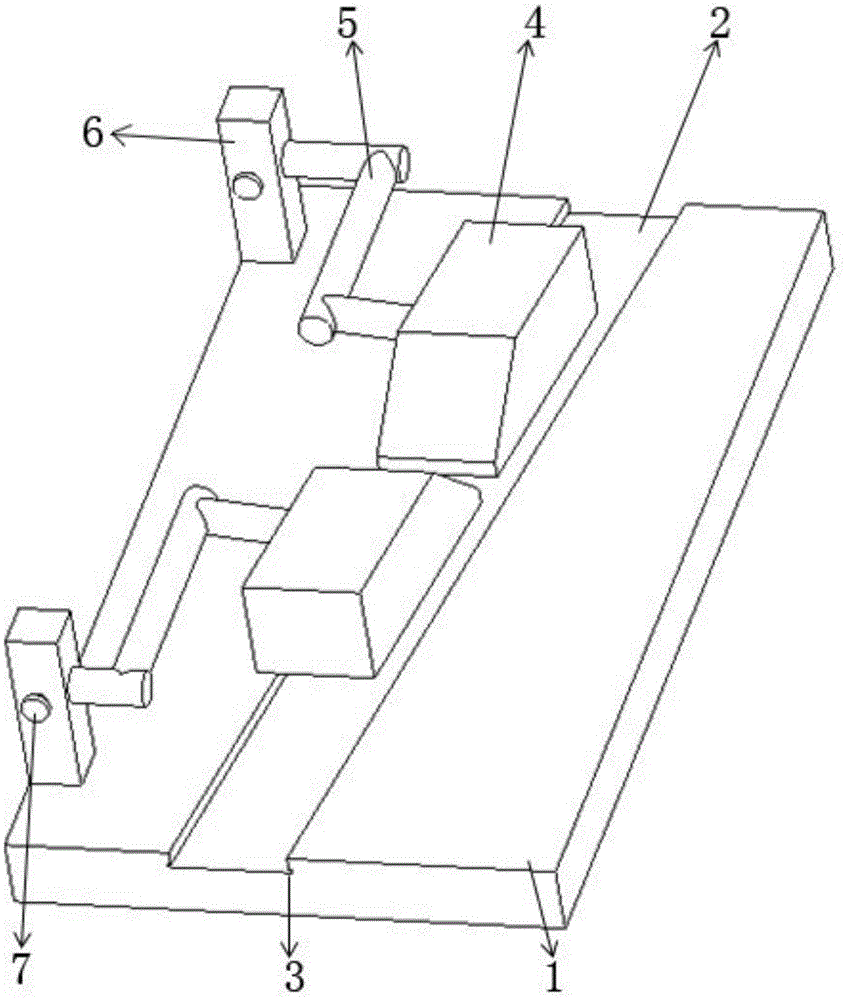

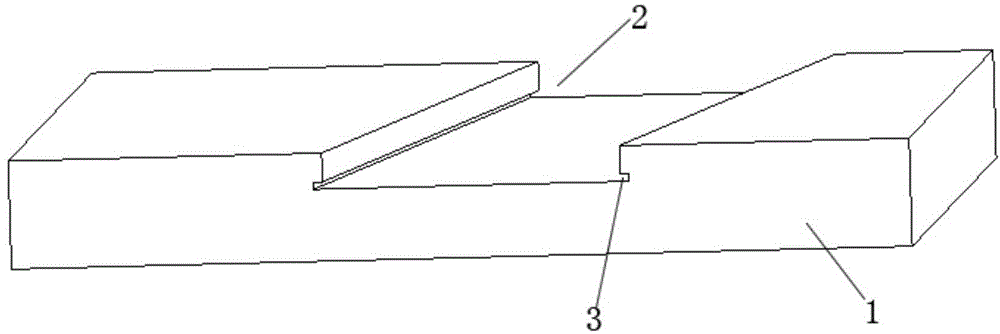

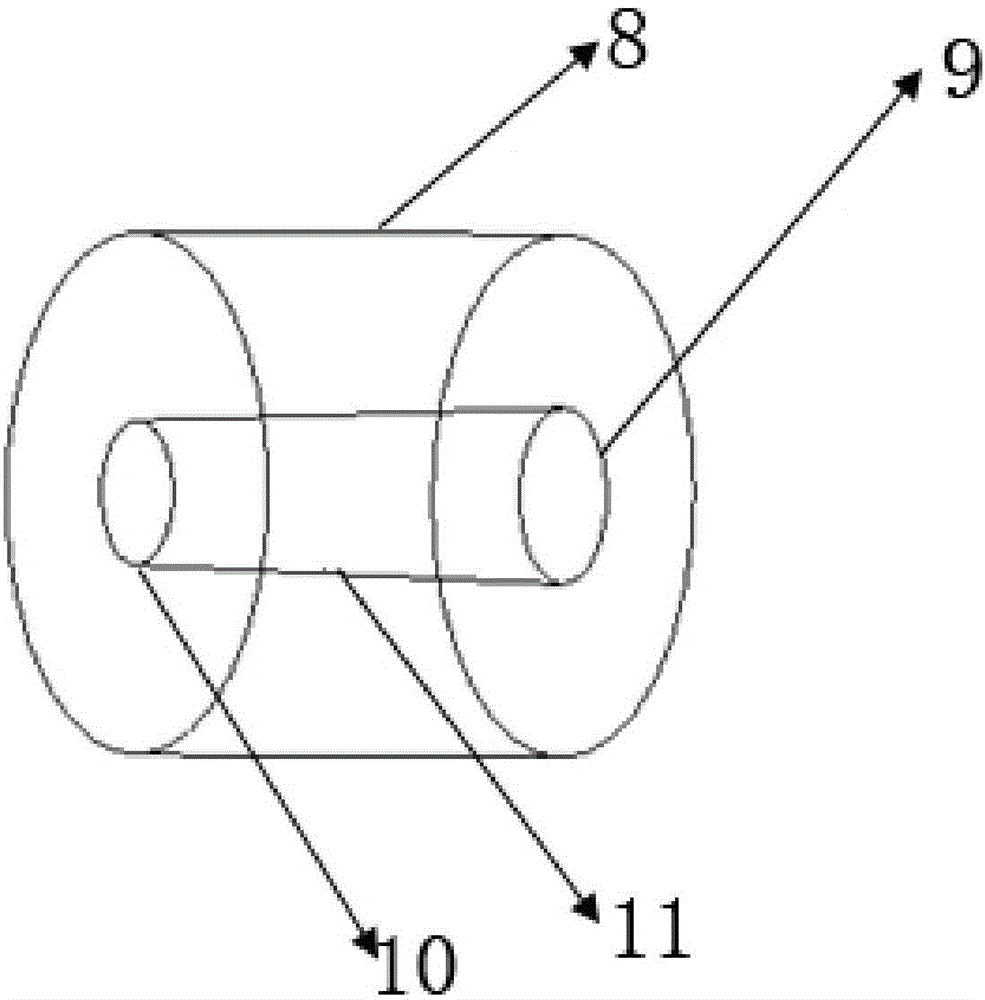

[0029] A method for welding stainless steel light units without cutting strips. After covering the edge positions on both sides of two sections of steel strips that need to be connected on opposite sides, and then welding the exposed opposite side connection positions through welding equipment, the two sections of steel strips are completed. The opposite side is connected, and then the steel strip formed as a whole is placed on the steel strip rack. After the steel strips are released by the two steel strip racks at the same time, the stainless steel tube is formed through the longitudinal wrapping mold, and the stainless steel tube is formed in the longitudinal wrapping mold. During the forming process, the laser continuous welding device welds the edge positions on both sides of the covered steel strip.

[0030] After covering the edge positions on both sides of the two steel strips that need to be connected on opposite sides, the operation of welding the exposed opposite sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com