Method used for efficiently welding straight seams of air conditioner compressor shell

A technology for air-conditioning compressors and shells, applied in welding media, welding equipment, welding equipment and other directions, can solve the problems of low welding efficiency and poor welding quality, and achieve the increase in the probability of rapid welding and undercut defects. Effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

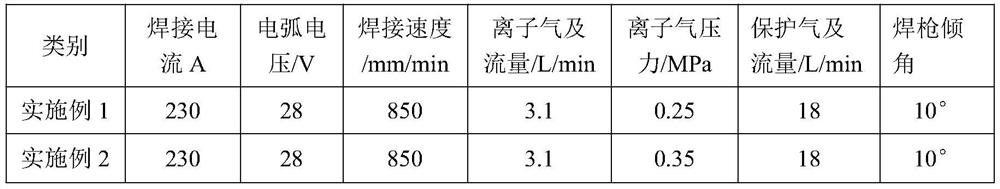

Embodiment 1

[0028] Embodiment 1, a method for improving the quality of plasma welding joints and welding efficiency, comprising the following steps:

[0029] 1) Clean the surface of the steel plate to be welded. The hot-rolled pickled steel SPHC steel plate for air-conditioning compressors with a thickness of 3.2mm is processed into small plates according to the size of the shell, and the burrs and oil stains at the cuts are removed;

[0030] 2) Prepare the shell blank of the air conditioner compressor, and use the rolling device to roll the small plate to form a compressor shell blank. The opening of the shell blank is 5-7 mm, and the shell blank enters the welding station for butt joint. Use fixtures to respectively fix the two sides of the butt joint of the air conditioner compressor shell blank, so that the steel plate does not slide during the welding process, the butt joint gap is 0, and the thickness direction of the steel plate on both sides of the butt joint is less than or equal ...

Embodiment 2

[0033] Embodiment 2, a method for improving the quality and welding efficiency of plasma welding joints, comprising the following steps:

[0034] 1) Clean the surface of the steel plate to be welded. The hot-rolled pickled steel SPHC steel plate for air-conditioning compressors with a thickness of 3.2mm is processed into small plates according to the size of the shell, and the burrs and oil stains at the cuts are removed;

[0035] 2) Prepare the shell blank of the air conditioner compressor, and use the rolling device to roll the small plate to form a compressor shell blank. The opening of the shell blank is 5-7 mm, and the shell blank enters the welding station for butt joint. Use fixtures to respectively fix the two sides of the butt joint of the air conditioner compressor shell blank, so that the steel plate does not slide during the welding process, the butt joint gap is 0, and the thickness direction of the steel plate on both sides of the butt joint is less than or equal ...

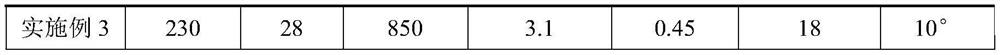

Embodiment 3

[0038] Embodiment 3, a method for improving the quality and welding efficiency of plasma welding joints, comprising the following steps:

[0039] 1) Clean the surface of the steel plate to be welded. The hot-rolled pickled steel SPHC steel plate for air-conditioning compressors with a thickness of 3.2mm is processed into small plates according to the size of the shell, and the burrs and oil stains at the cuts are removed;

[0040] 2) Prepare the shell blank of the air conditioner compressor, and use the rolling device to roll the small plate to form a compressor shell blank. The opening of the shell blank is 5-7 mm, and the shell blank enters the welding station for butt joint. Use fixtures to respectively fix the two sides of the butt joint of the air conditioner compressor shell blank, so that the steel plate does not slide during the welding process, the butt joint gap is 0, and the thickness direction of the steel plate on both sides of the butt joint is less than or equal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com