Heavy water reactor spent fuel basket welding center column butt joint welding 1#-1 comparison test block

A technology of spent fuel and central column, which is applied in the field of spent fuel transmission in nuclear power plants to achieve the effects of convenient use, good welding and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

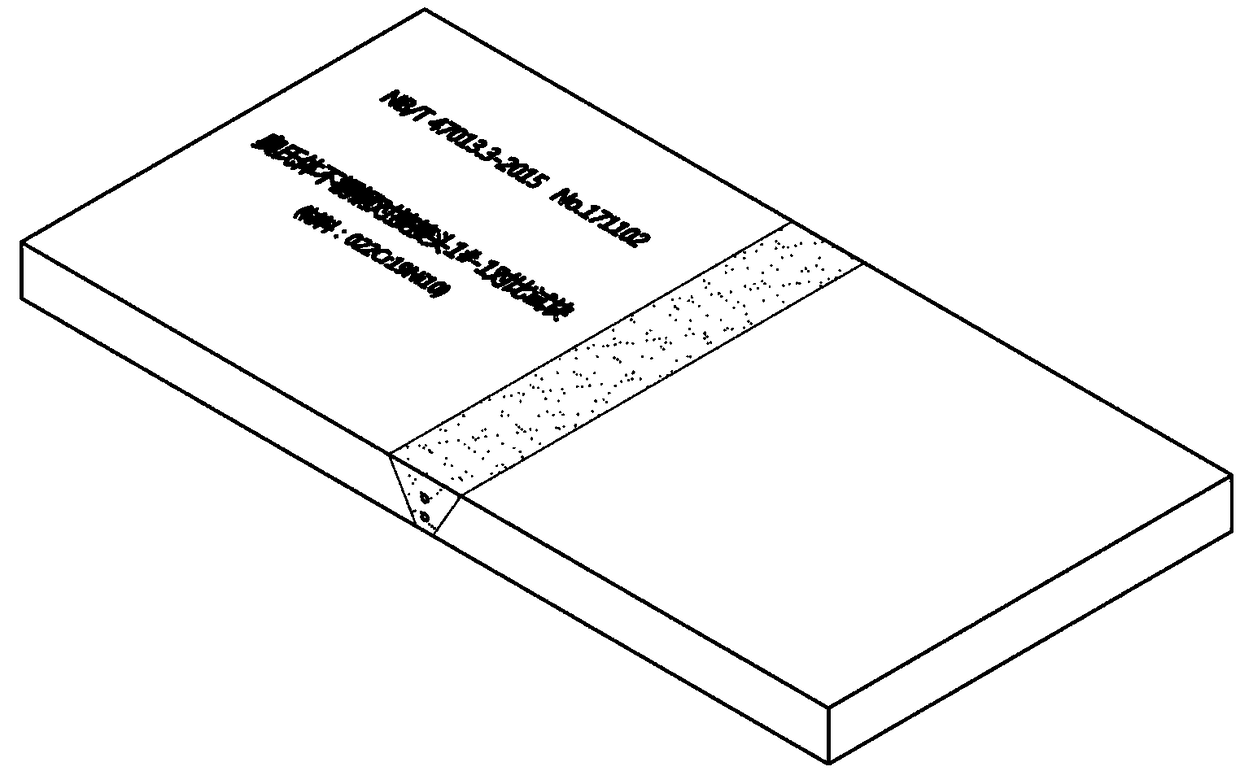

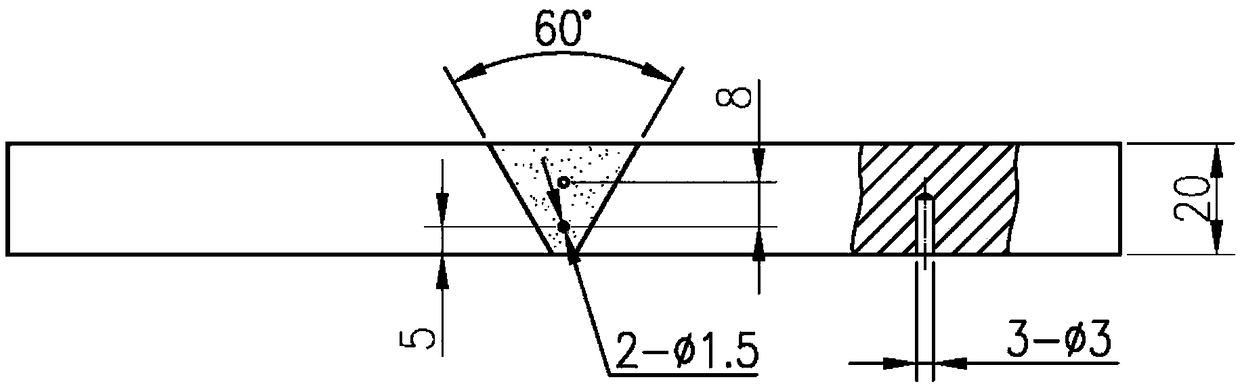

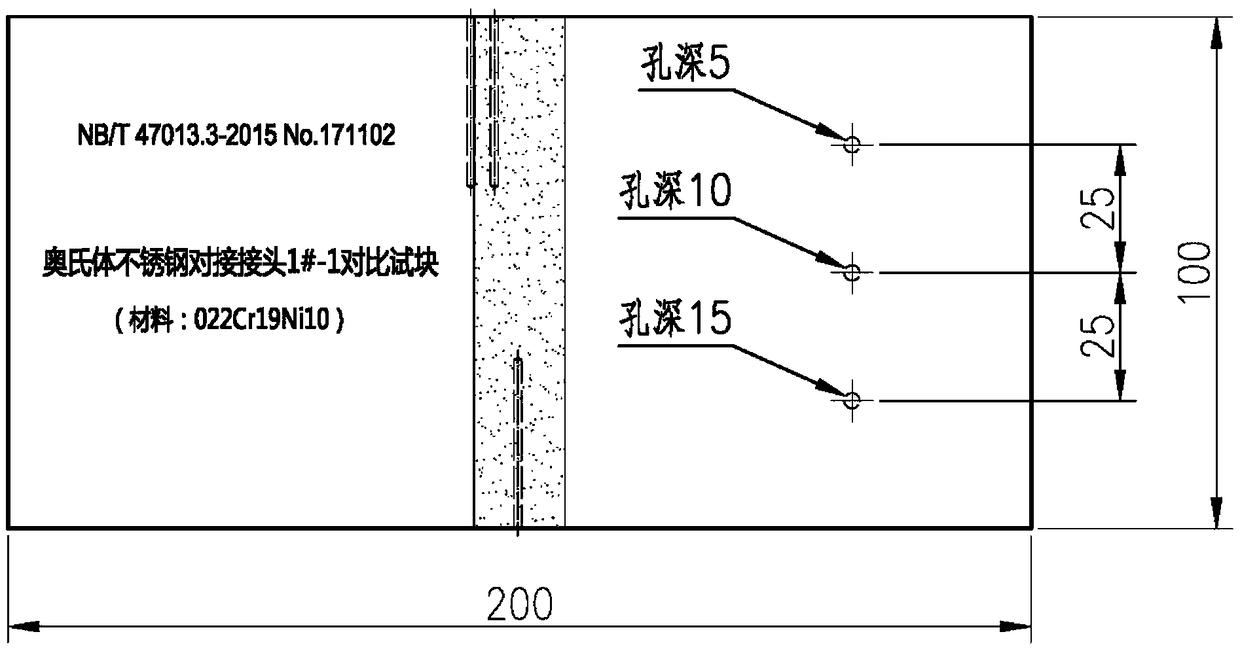

[0019] like Figure 1 to Figure 4 As shown, a 1#-1 comparison test block for welding the center column butt joint of the spent fuel basket of the heavy water reactor is in the shape of a cuboid as a whole. A first detection hole and a second detection hole are opened in sequence from bottom to top at the centerline position of the front end face of the test block. A third detection hole and a fourth detection hole are sequentially opened on the rear end surface of the test block from bottom to top along an oblique direction. A fifth detection hole, a sixth detection hole and a seventh detection hole are sequentially opened on the right part of the lower end face of the test block from the back to the front. The above inspection holes are used to simulate the defects existing in the weld.

[0020] The overall length of the test block is 200mm, the width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com