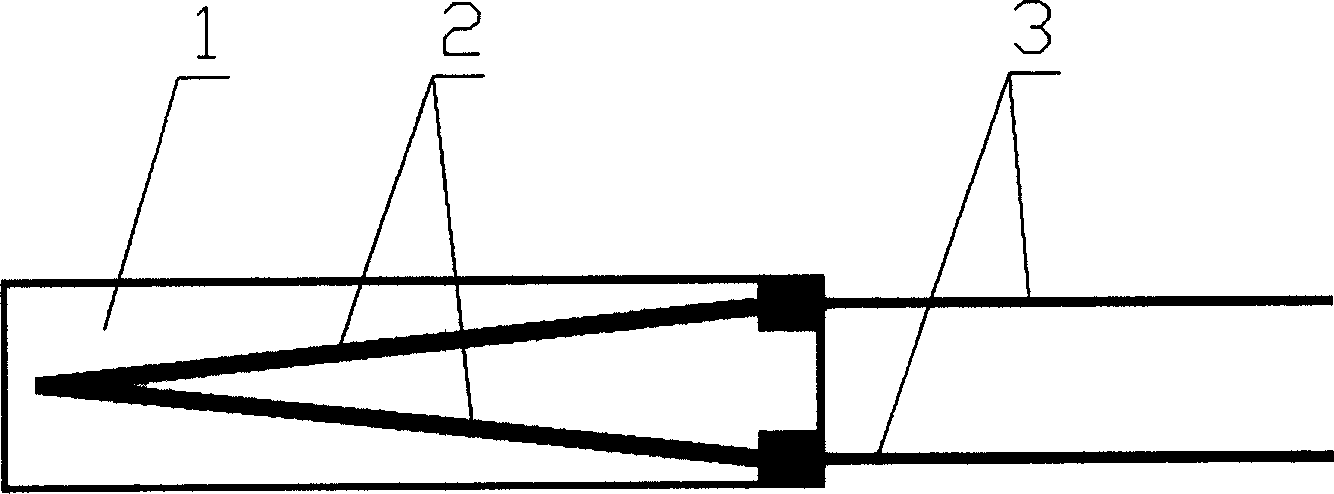

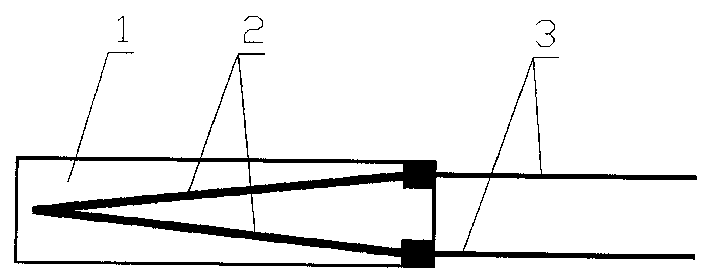

Thick-film thermocouple for quickly measuring temp of molten steel and its making method

A manufacturing method and technology of thermocouples, which are applied to thermoelectric devices, measure heat, and use electrical devices, etc., can solve the problems of high consumption of precious metal materials, low product reliability, and increased operation difficulty, and achieve the realization of mechanized operation, simple structure, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: make the positive pole of thick-film thermocouple with pure platinum slurry, make the negative pole of thick-film thermocouple with platinum-rhodium slurry containing 10.5% rhodium, and sinter into thick-film platinum at a temperature of 1200°C Rhodium thermocouple, its technical parameters are in full compliance with the temperature-thermoelectric potential characteristics of standard S-type industrial thermocouple (wire material).

Embodiment 2

[0035] Embodiment 2: make the positive pole of thick-film thermocouple with pure platinum slurry, make the negative pole of thick-film thermocouple with the platinum-rhodium slurry that contains rhodium content 13.7%, sinter at the temperature of 1250 ℃~1300 ℃ Thick-film platinum-rhodium thermocouple, its technical parameters are in full compliance with Pt-PtRh 13 Temperature-thermoelectric potential characteristics of industrial thermocouples (wires).

Embodiment 3

[0036] Embodiment 3: be that the positive electrode of thick-film thermocouple is made with the platinum-rhodium slurry that contains rhodium of 6%, be that the negative pole of thick-film thermocouple is made with the platinum-rhodium slurry that contains rhodium of 31%, at 1350 ℃~ Thick-film platinum-rhodium thermocouples are sintered at a temperature of 1400°C, and their technical parameters fully comply with the temperature-thermoelectric potential characteristics of standard B-type industrial thermocouples (wires).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com