A preparation method of an electronic cigarette mesh heating body

A heating body and electronic cigarette technology, which is applied in the field of electronic cigarettes, can solve the problems of small heating area, difficult welding, and unsatisfactory e-liquid atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

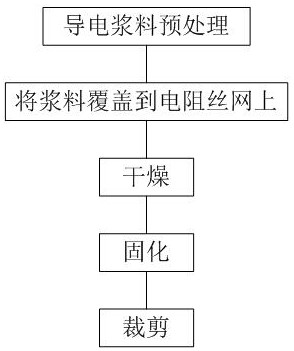

[0022] Example 1, figure 1 As shown, this embodiment is a method for preparing an electronic cigarette mesh heating body, which includes two major steps:

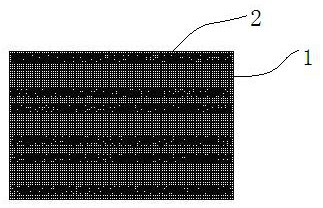

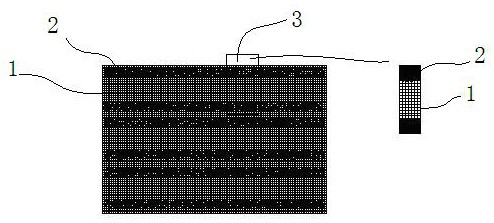

[0023] First use the resistance wire to weave into the step of the resistance wire mesh. In the present embodiment, the resistance wire mesh is a 400 mesh Fe-Cr-Al alloy mesh. In practice, the shape of the resistance wire mesh includes flat, curved, and arc-shaped , cylindrical, wavy at least one. In this embodiment, it is a square Fe—Cr—Al alloy mesh, which can be cut into N×M mesh heating bodies.

[0024] Then, prepare electrode on resistance screen; Wherein, prepare electrode on resistance screen is the focus of this embodiment, it is to adopt conductive paste to cover on resistance screen and form; comprise the following steps:

[0025] Step 1, the step of pretreatment of conductive paste; in this step, adjust the size of the slurry particles by stirring and grinding to ensure that the particles can pass through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com