Patents

Literature

59results about How to "Improve spot welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

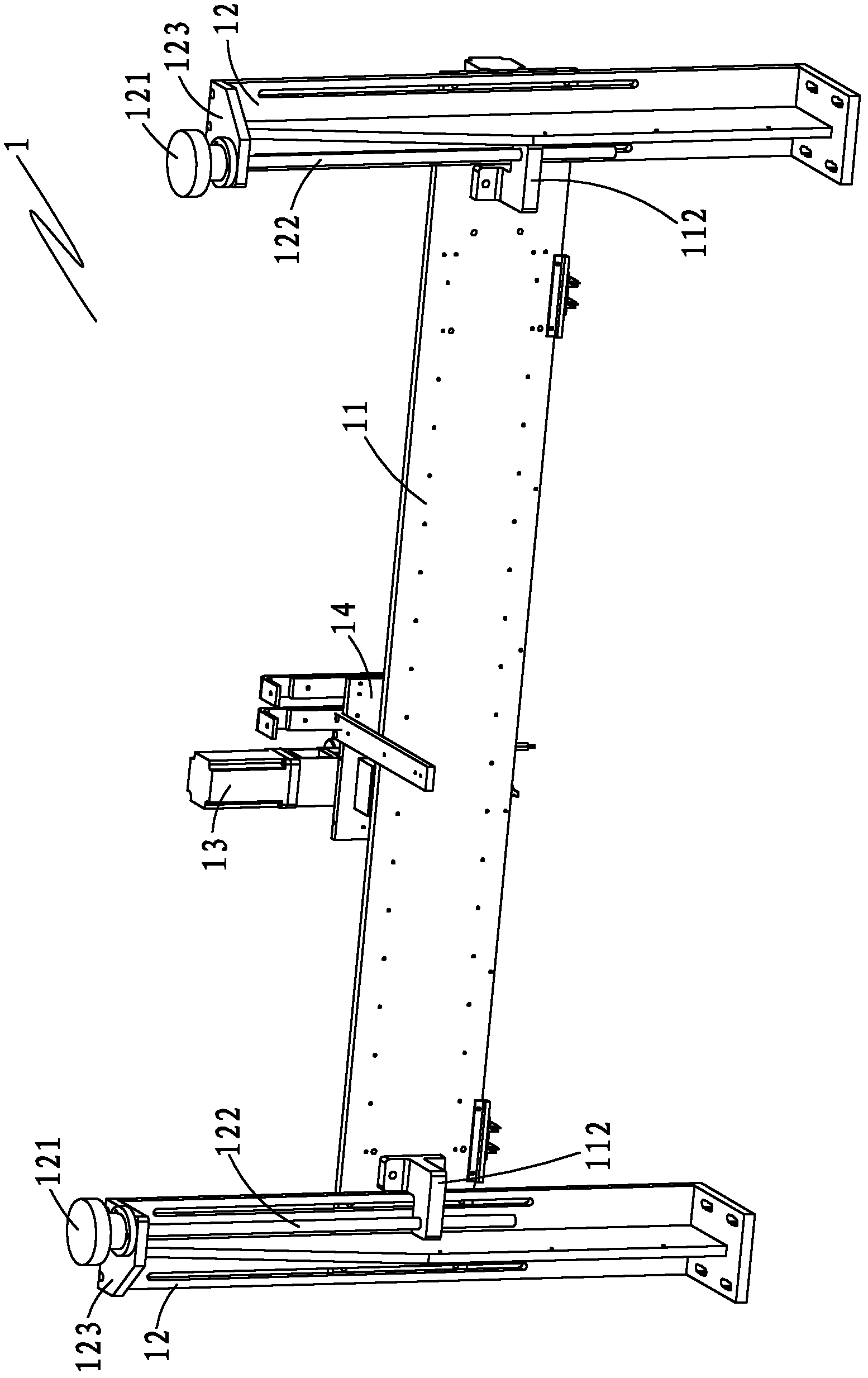

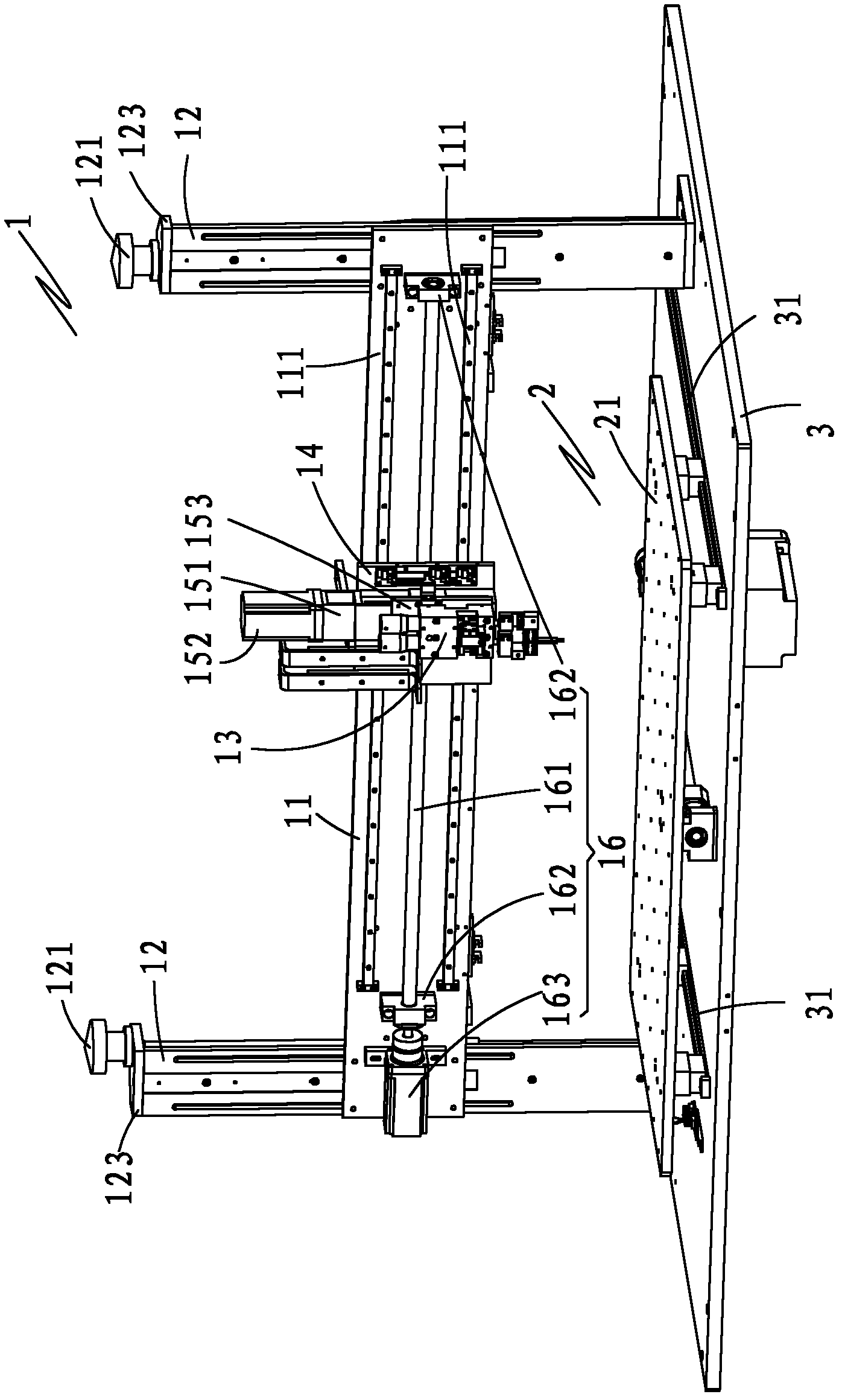

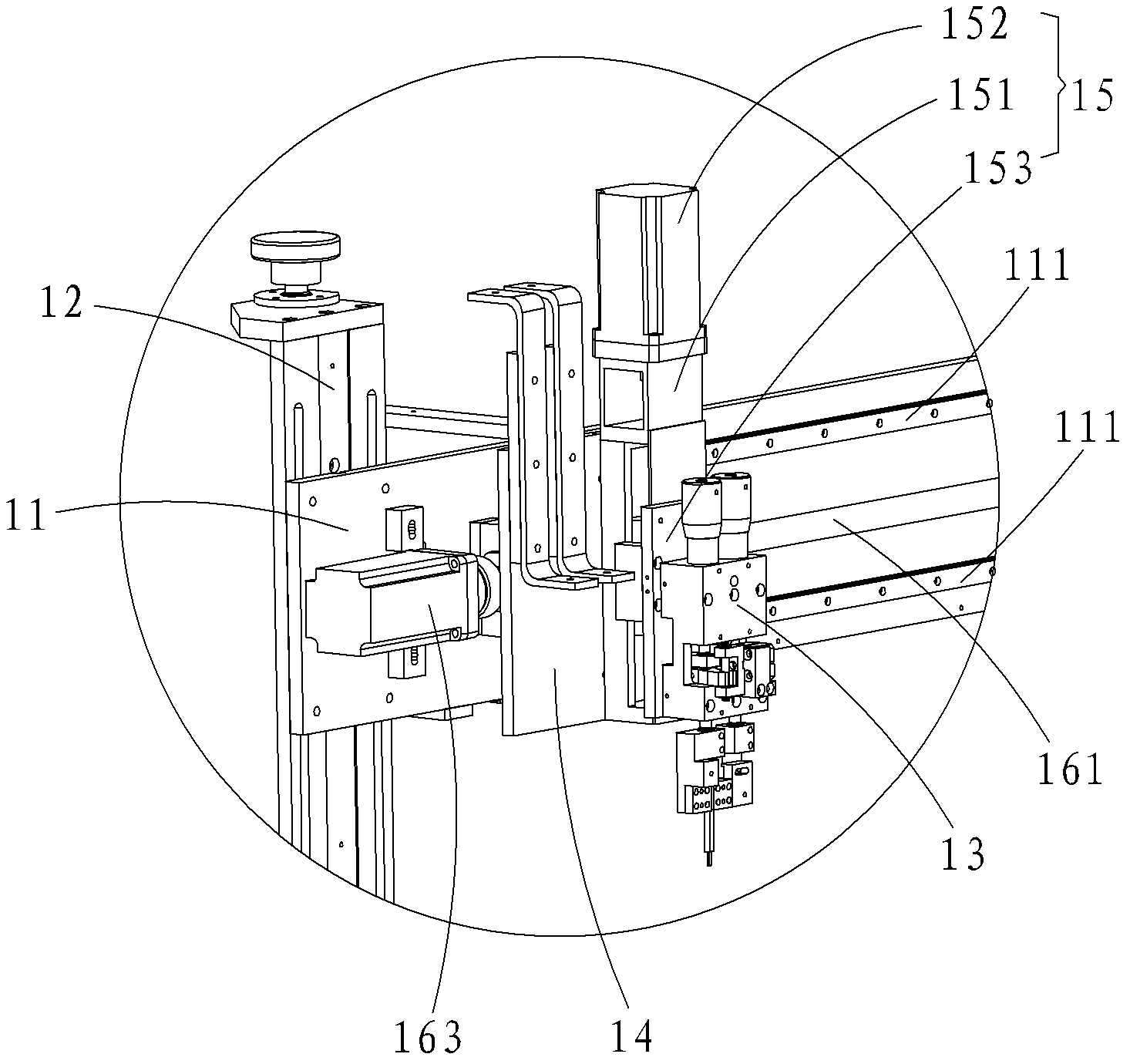

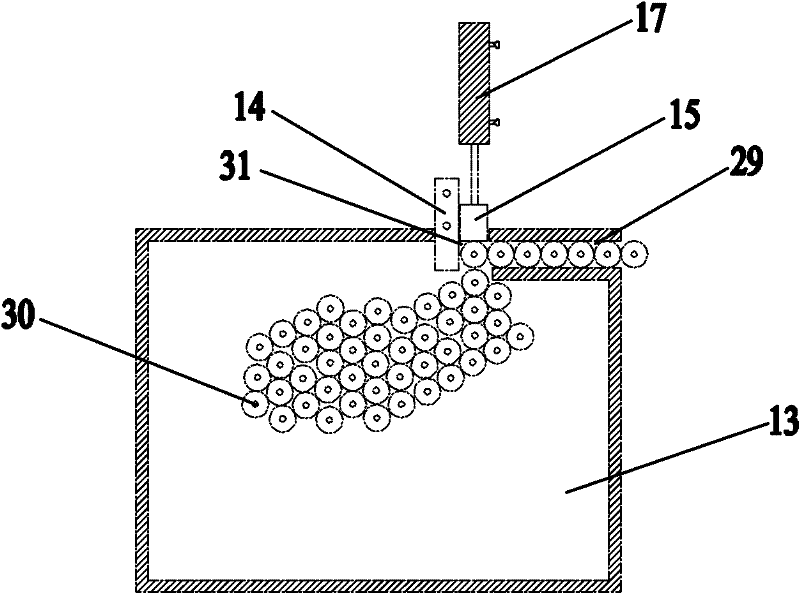

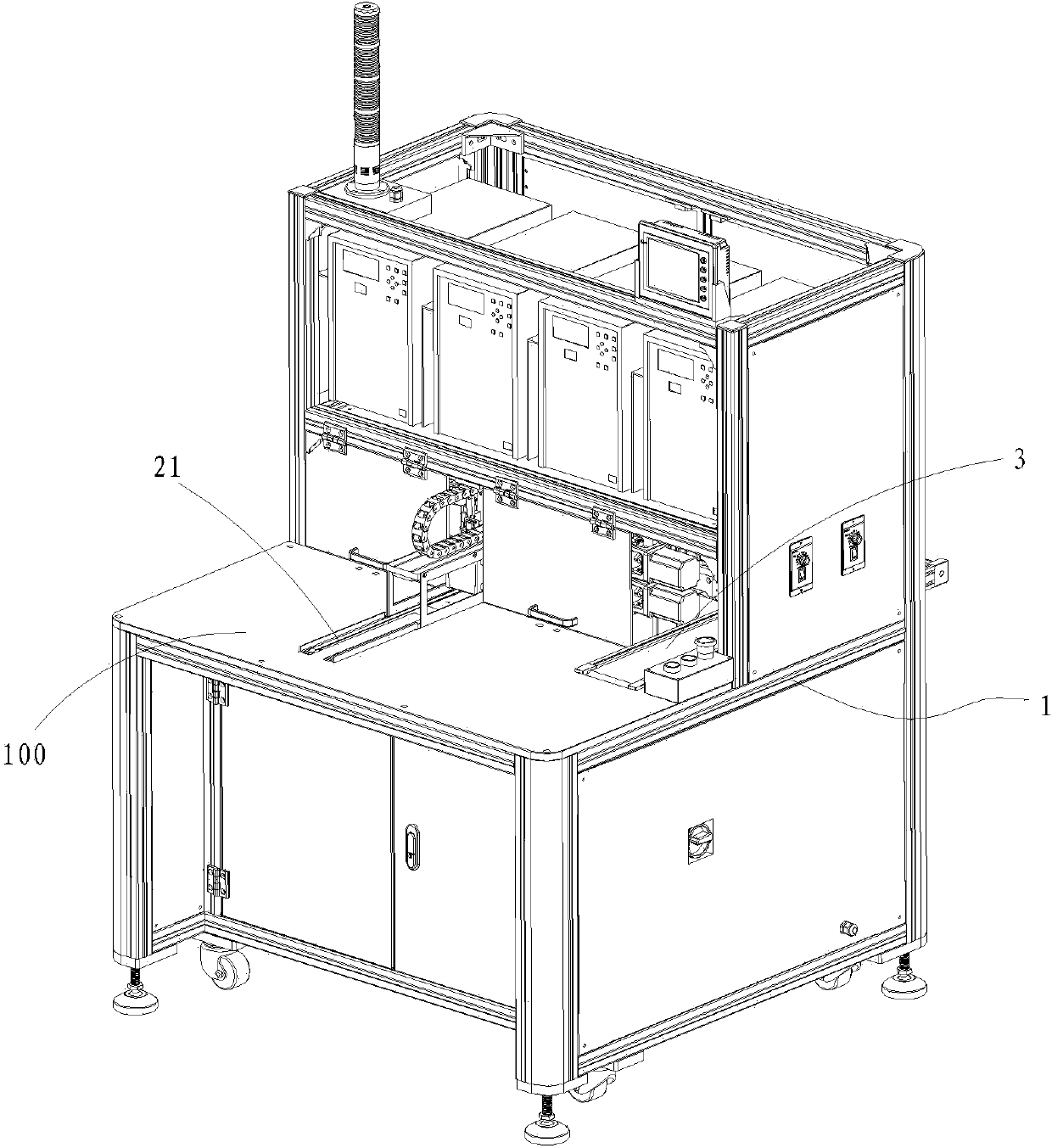

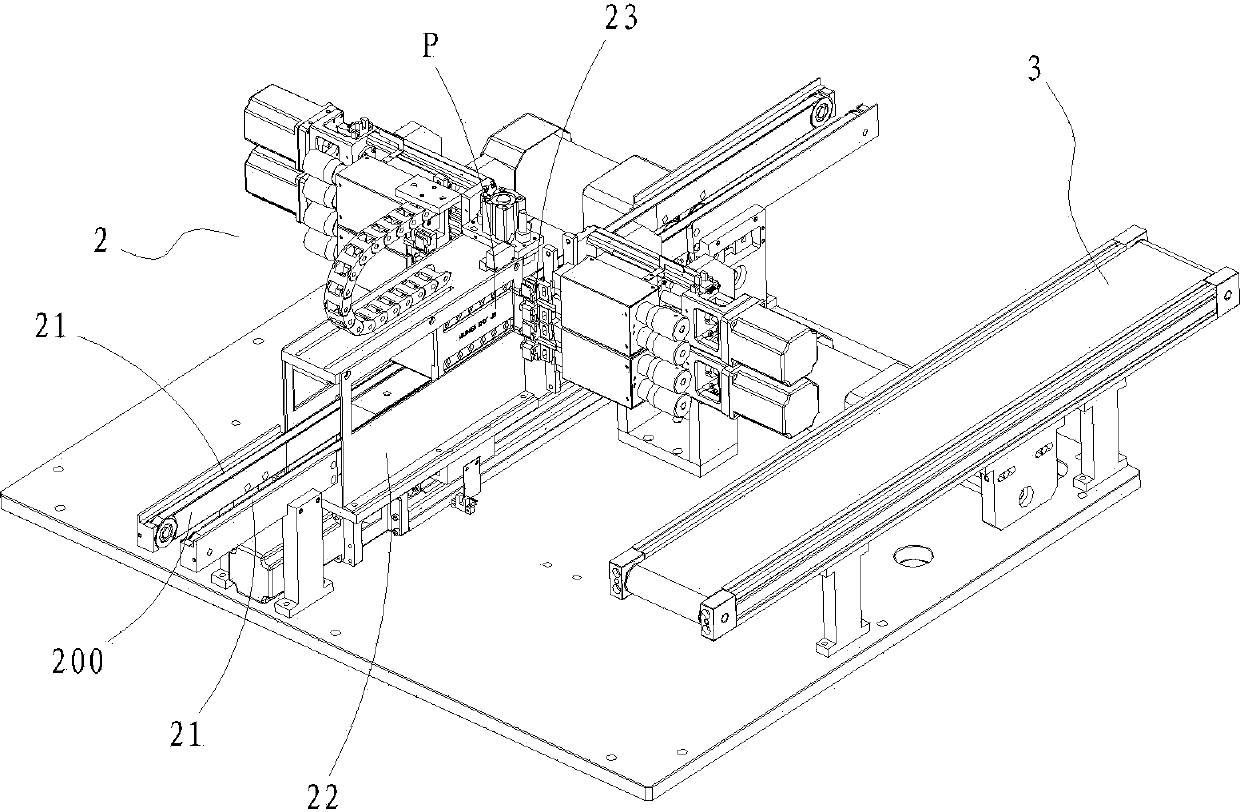

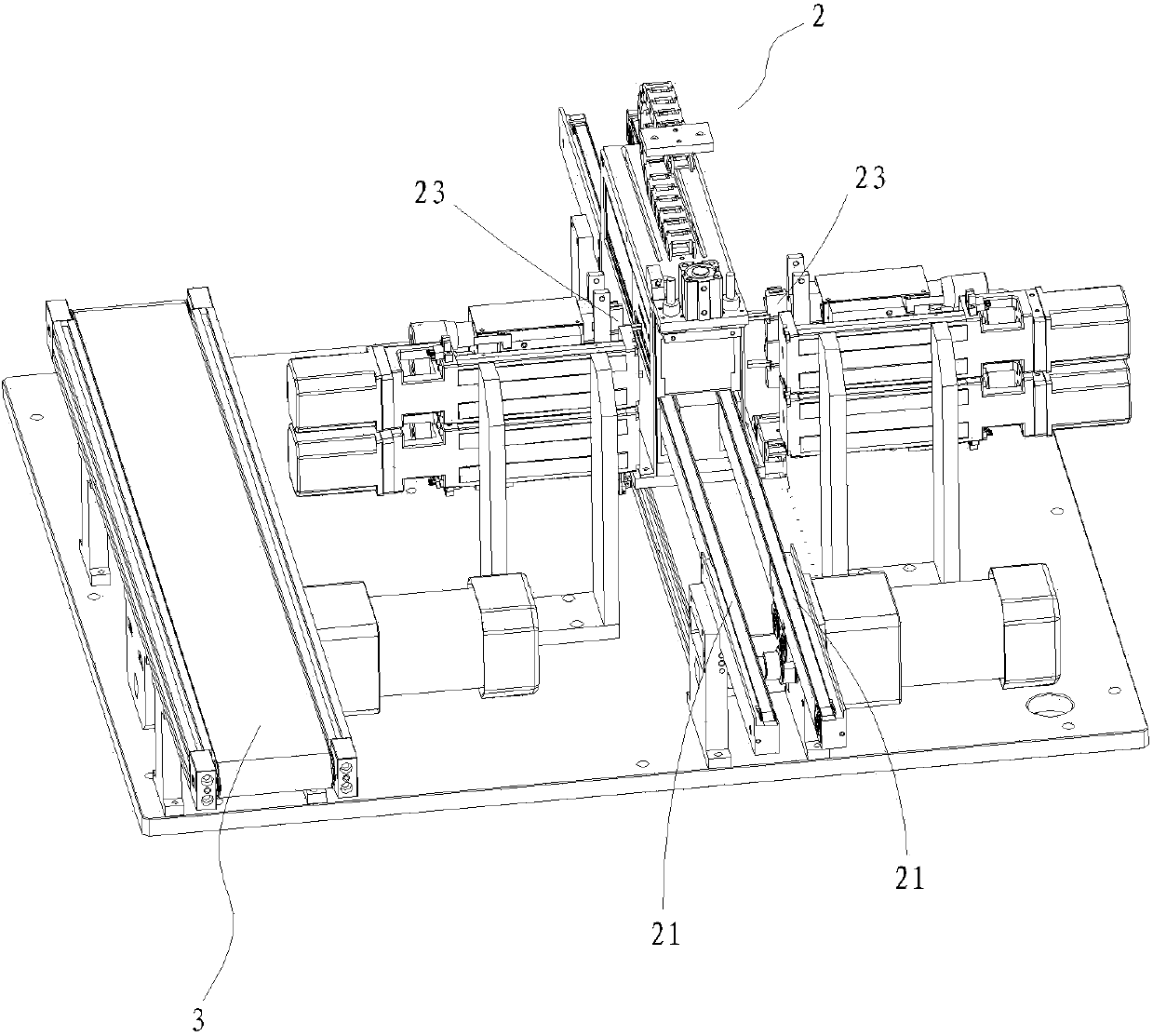

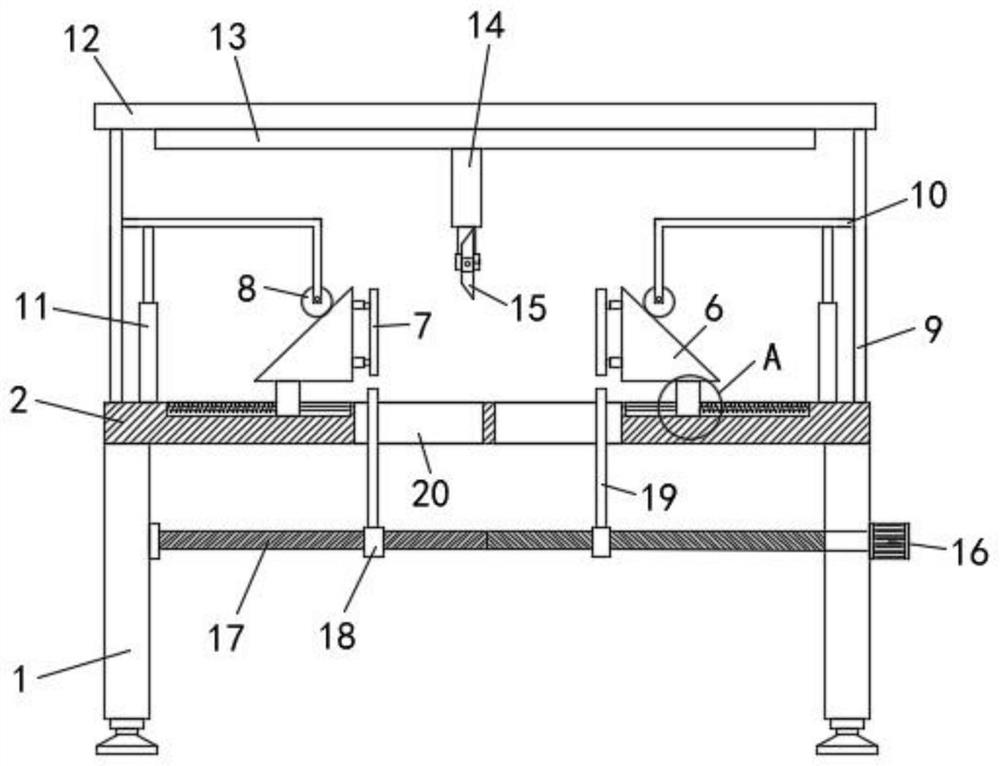

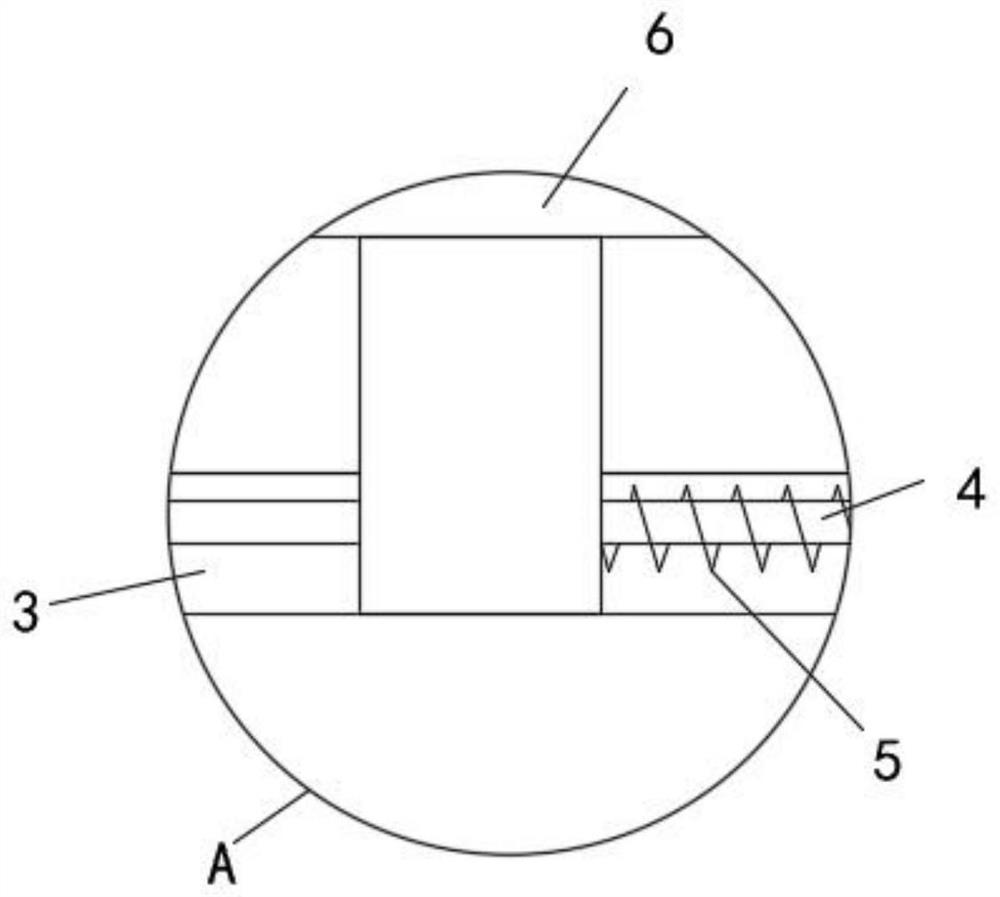

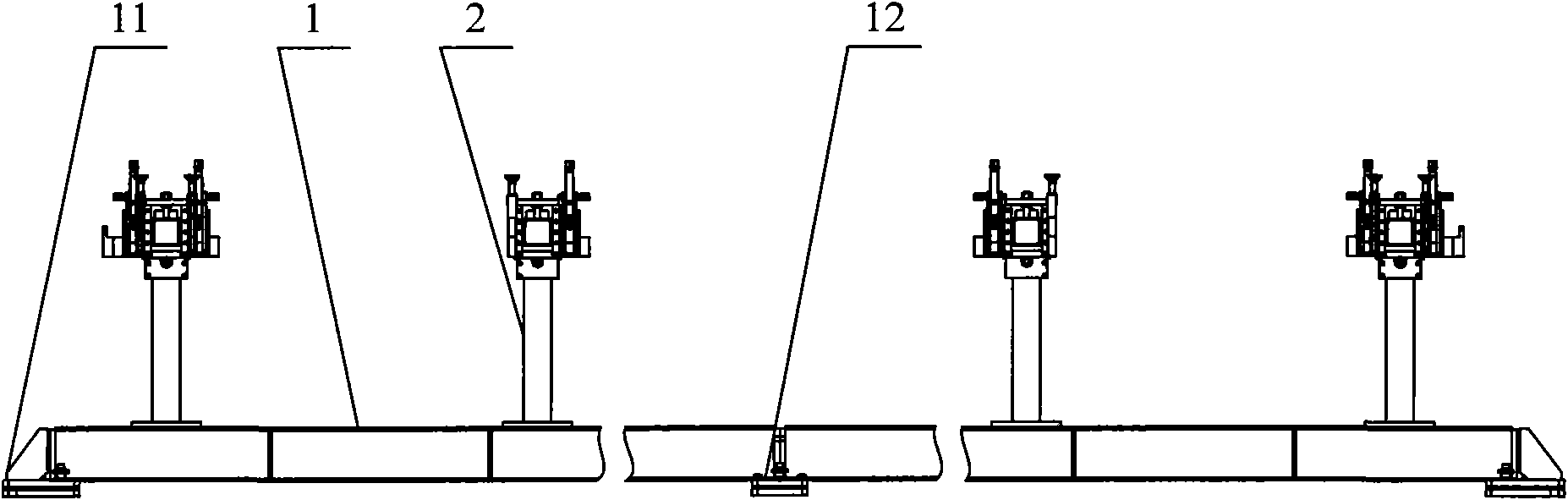

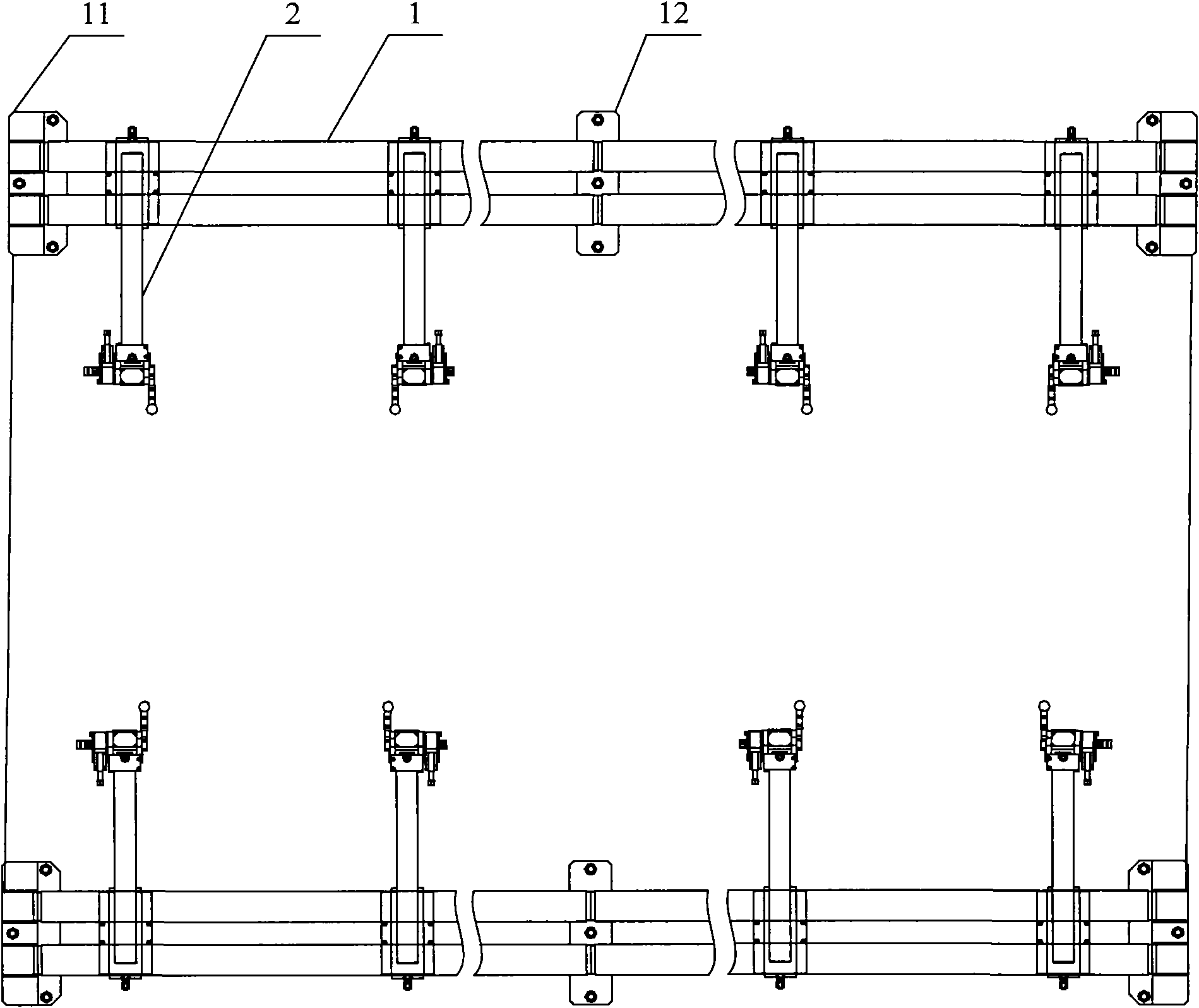

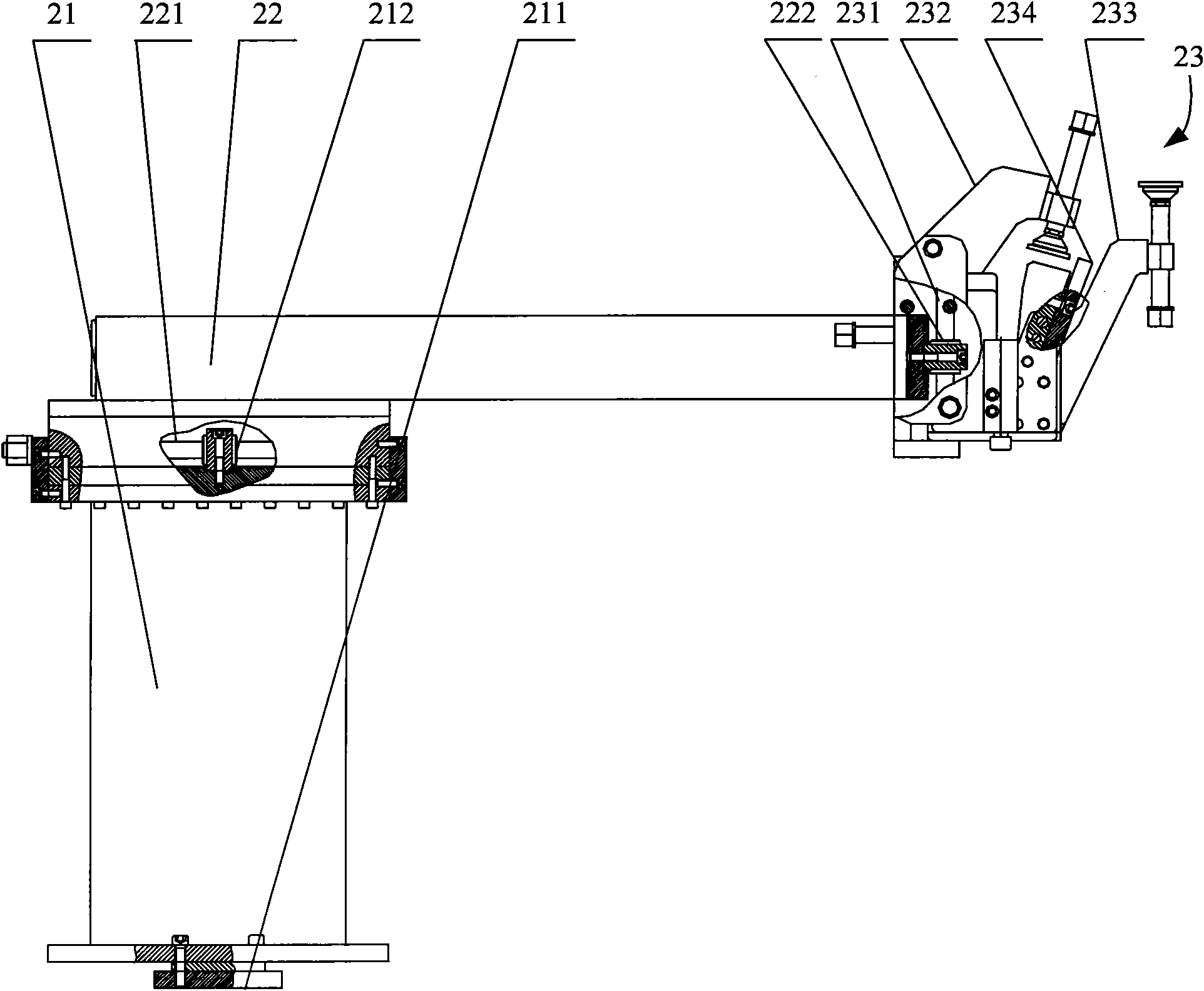

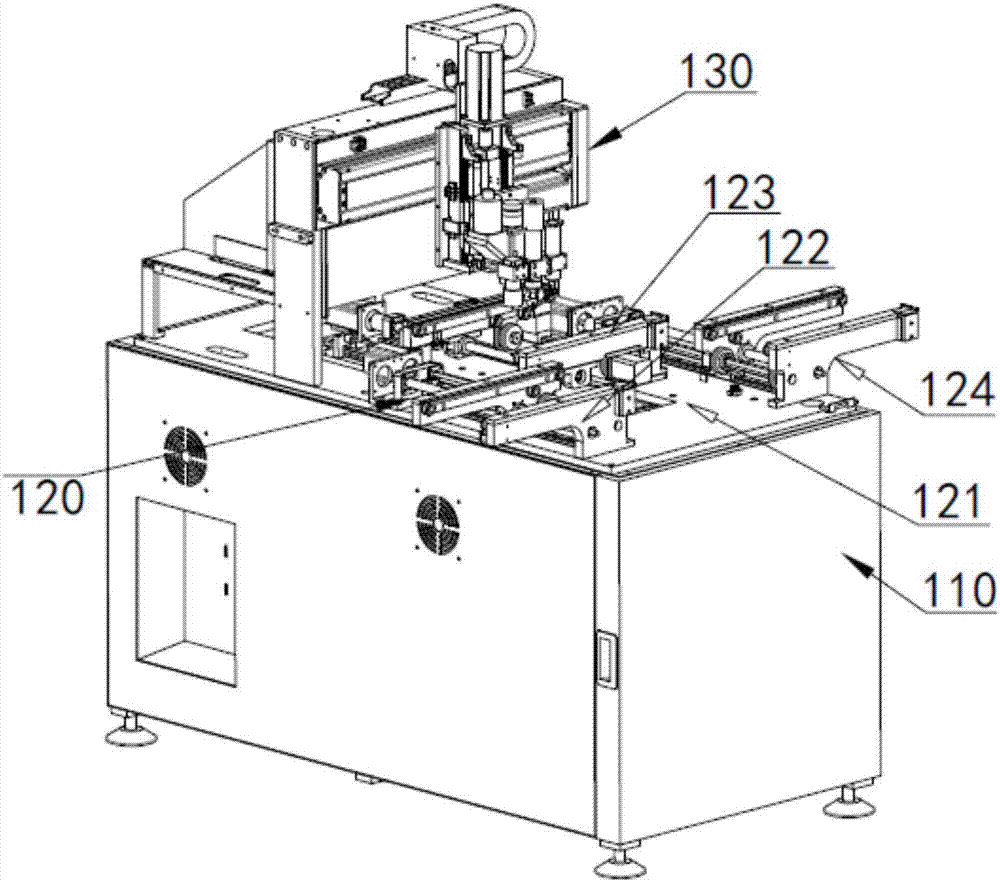

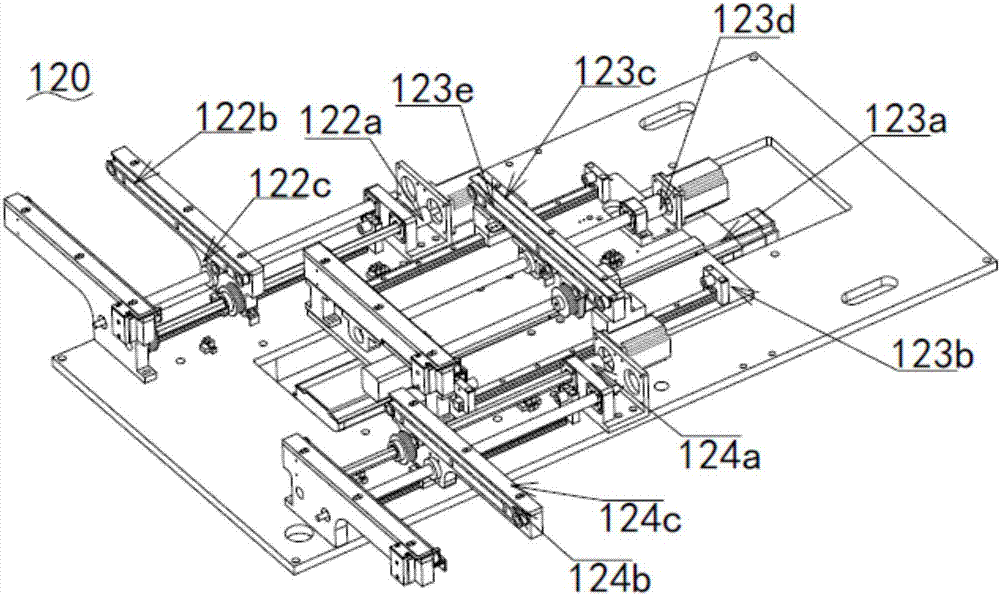

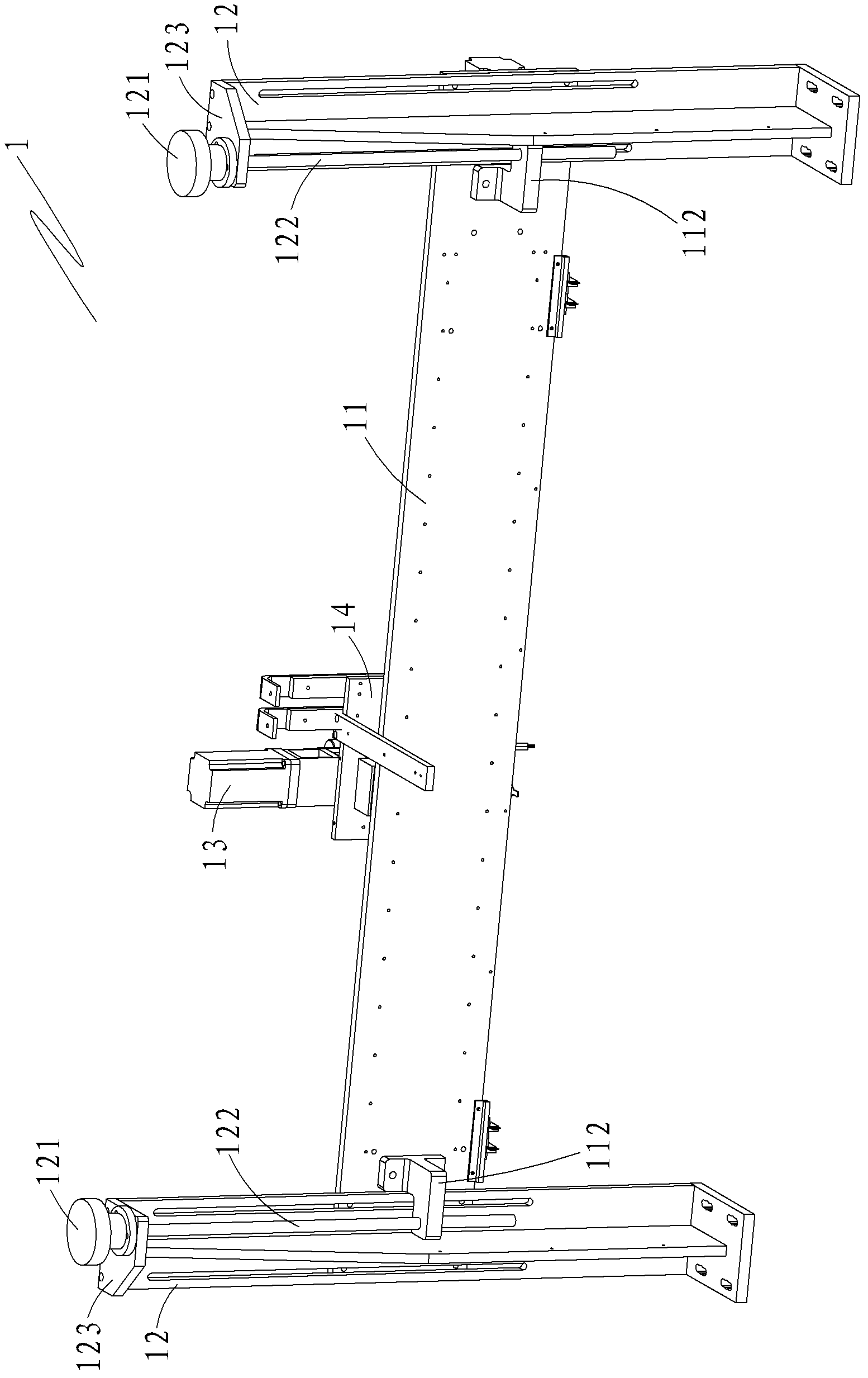

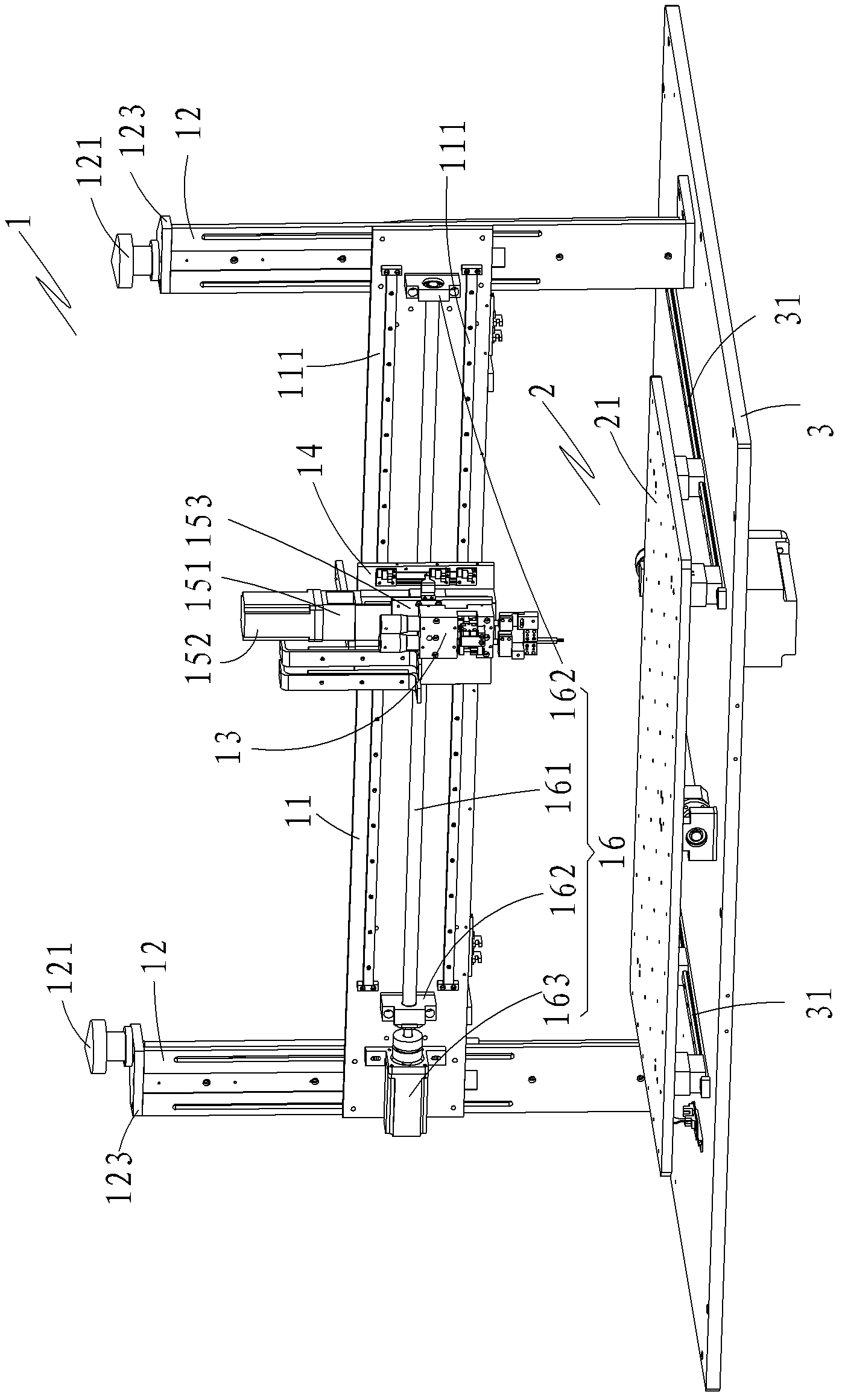

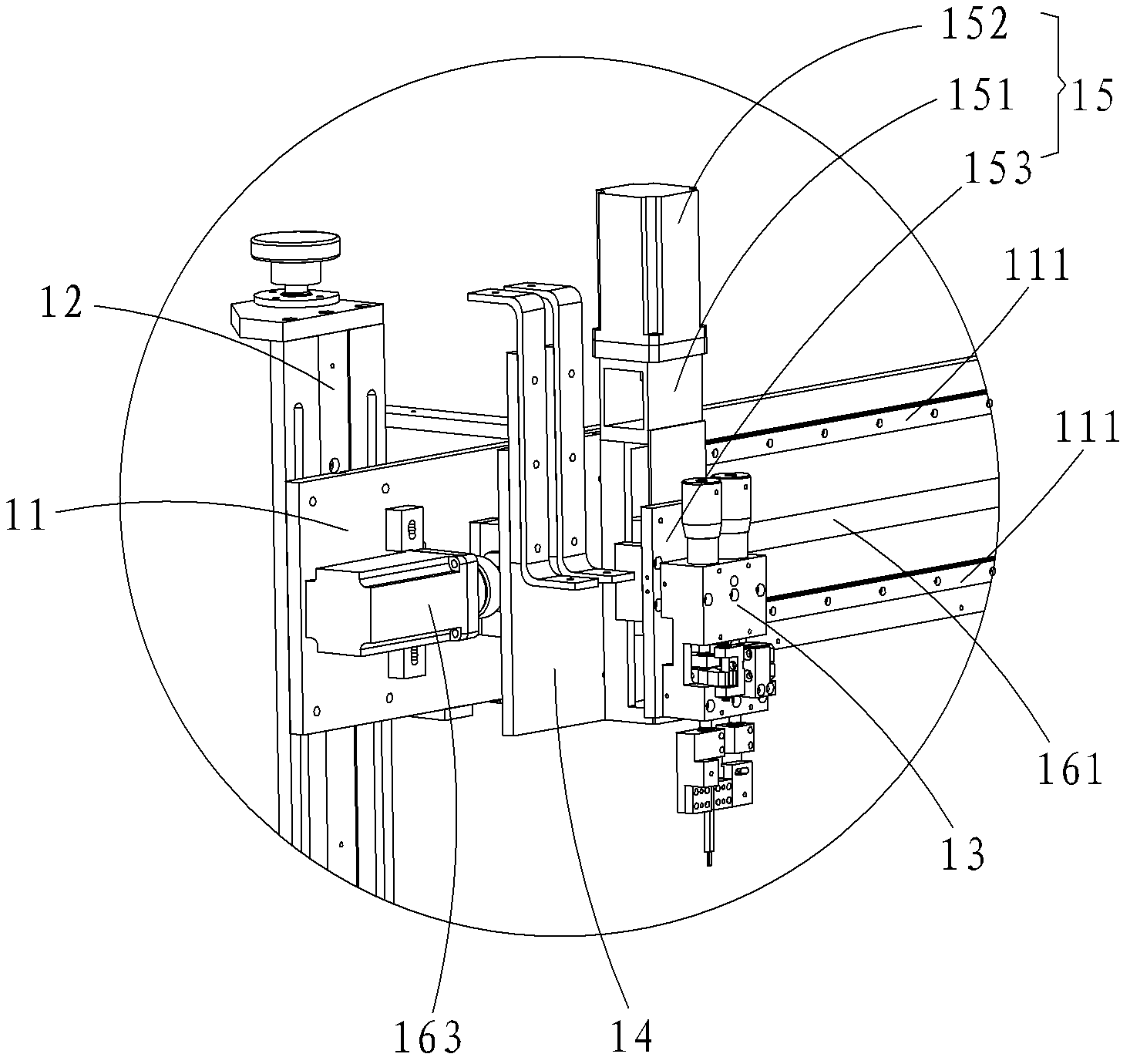

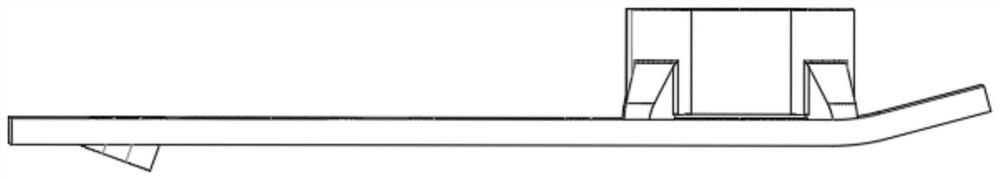

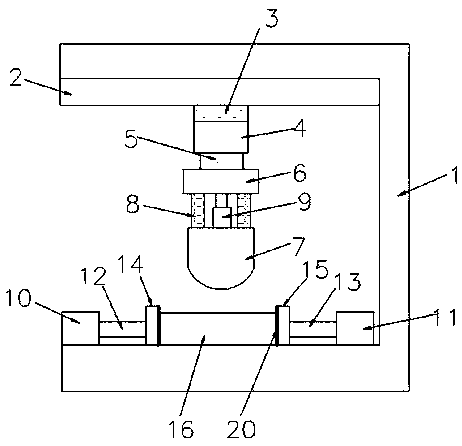

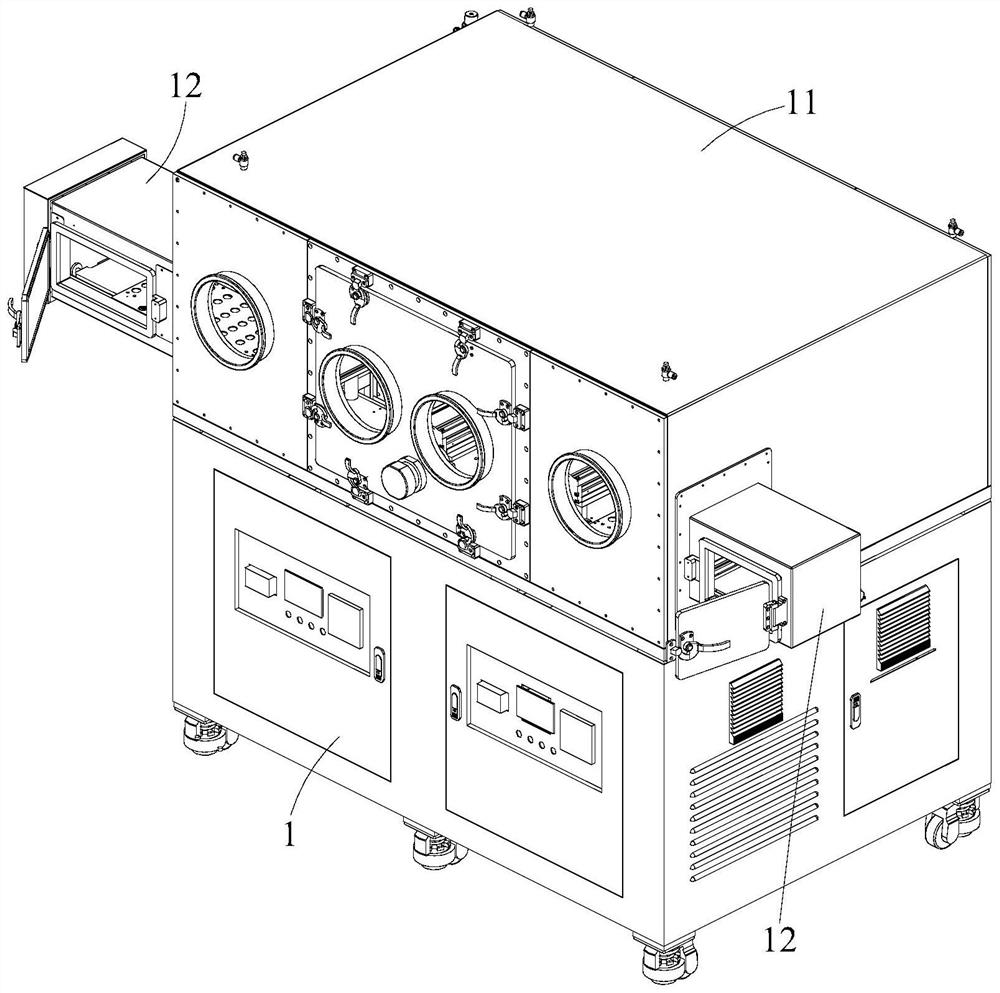

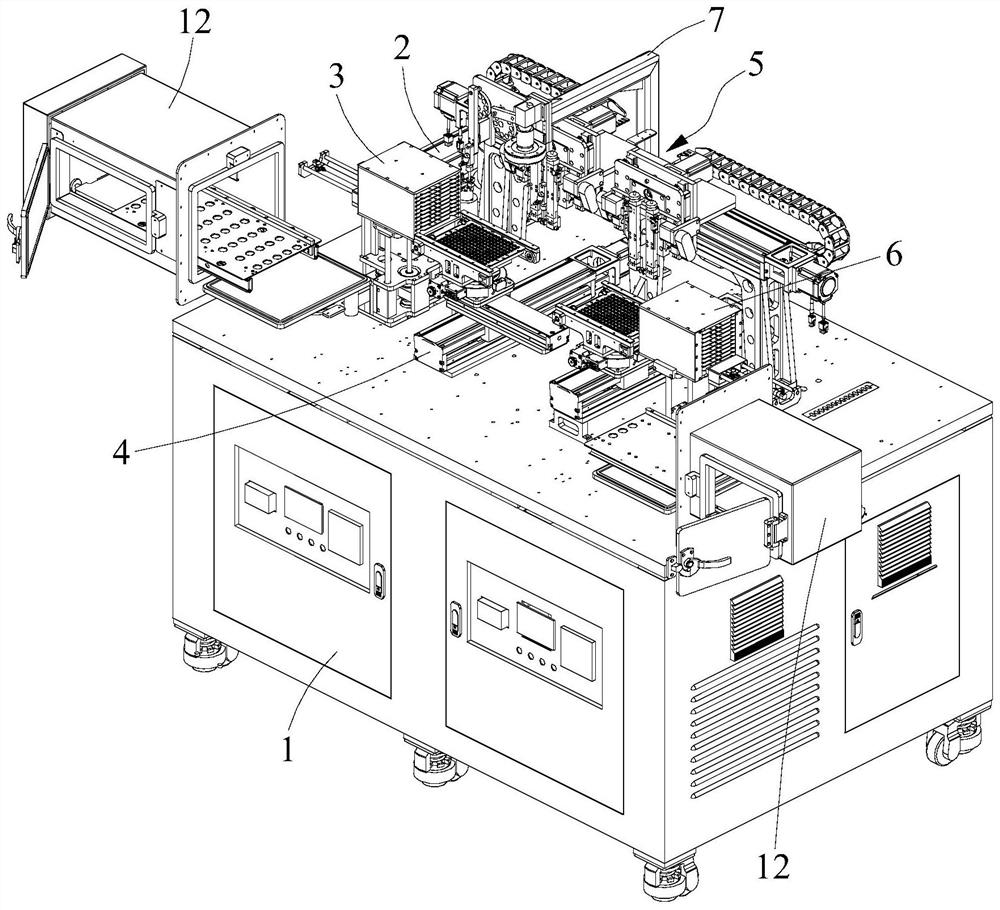

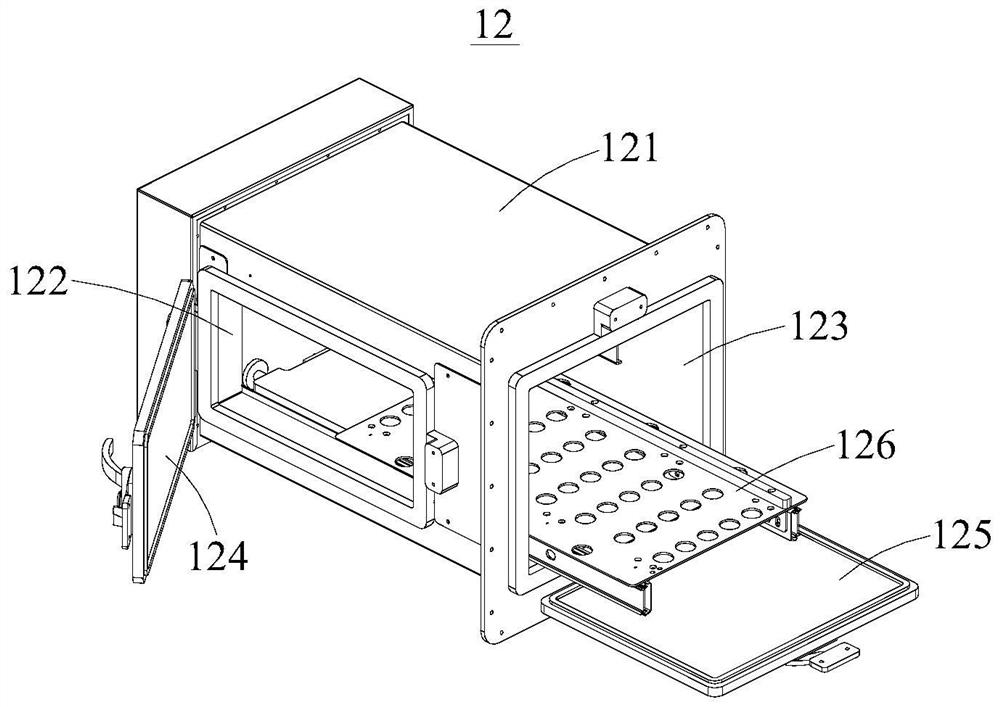

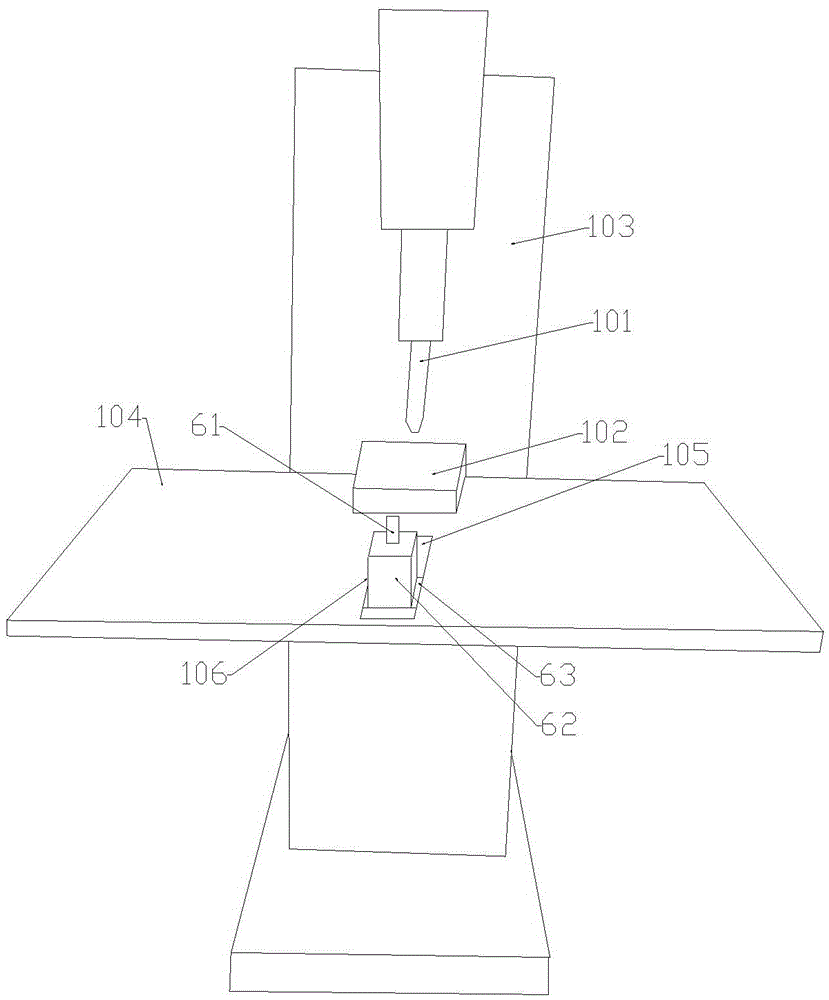

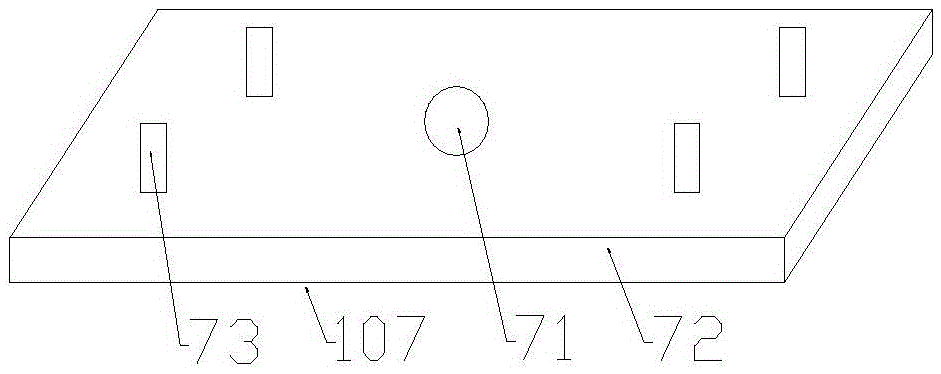

Gantry-type automatic spot welding system for battery pack

ActiveCN102554437AIncrease the number of installations andReduce manual labor intensityResistance welding apparatusProgrammable logic controllerMechanical engineering

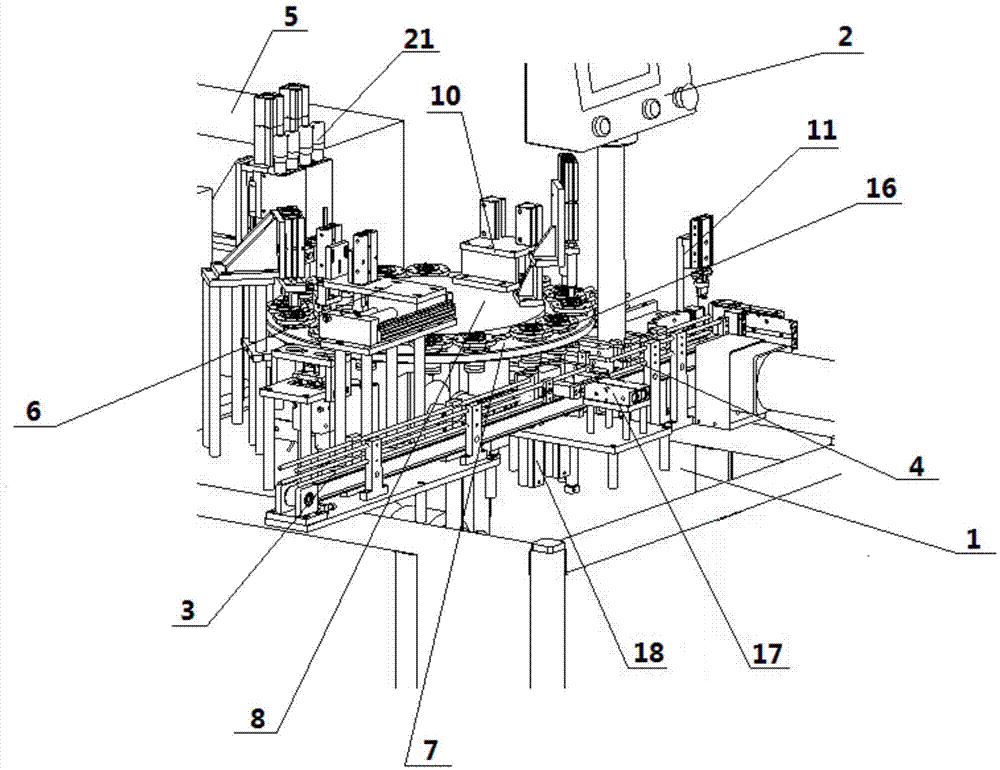

The invention provides a gantry-type automatic spot welding system for a battery pack, which comprises a spot welding device and a spot welding jig fixing device which are vertically arranged and are connected with a PLC (programmable logic controller) of the system. The spot welding device comprises a beam, a group of opposite vertical columns in parallel, a spot welding mechanism, an X-axis sliding table, a Y-axis movement mechanism and an X-axis movement mechanism, wherein the vertical columns are used for adjusting the height of the beam, the X-axis sliding table is used for fixing the spot welding mechanism, the Y-axis movement mechanism enables the spot welding mechanism to transversely move, and the X-axis movement mechanism enables the X-axis sliding table to transversely move. The spot welding jig fixing device comprises a spot welding jig platen and a clamping mechanism for clamping a spot welding jig, wherein the clamping mechanism is arranged on the spot welding jig platen and is perpendicular to the spot welding mechanism. By the aid of a gantry-type structure, clamping is performed once, cells are numerous, spot welding parameters are controllable, and the system is fast in running speed, high in spot welding efficiency, highly adaptable to the cells, accurate in positioning and fine in spot welding quality.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

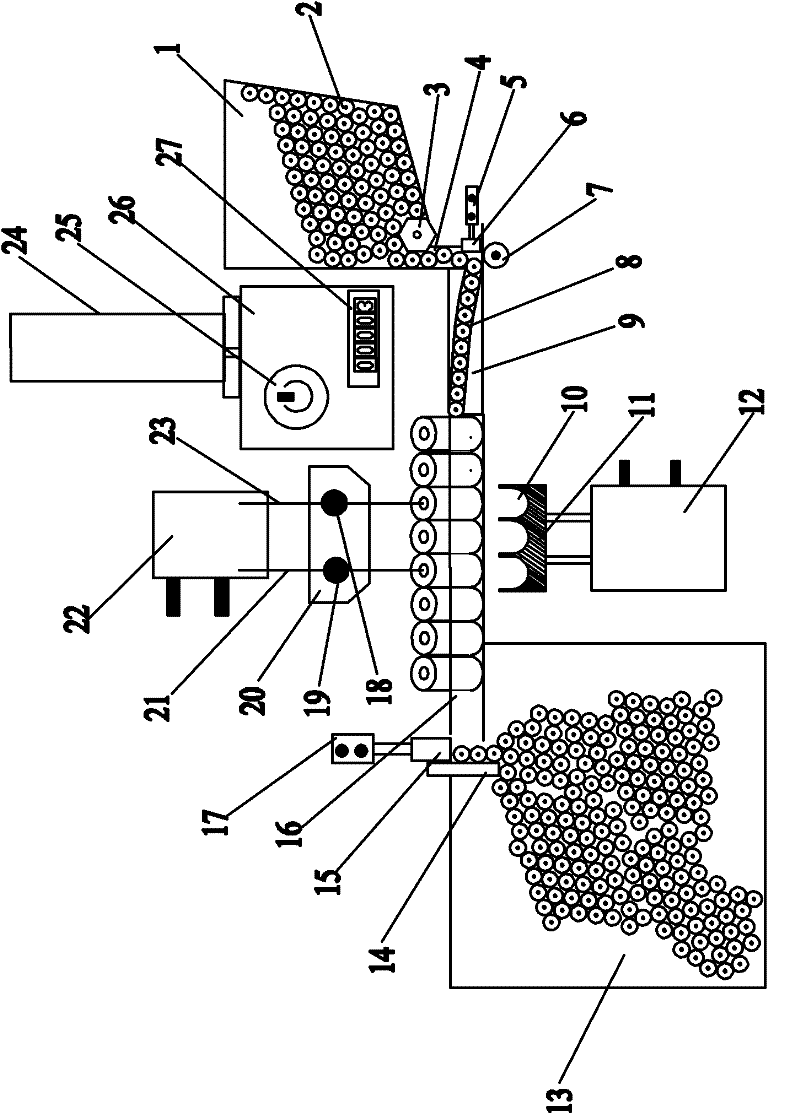

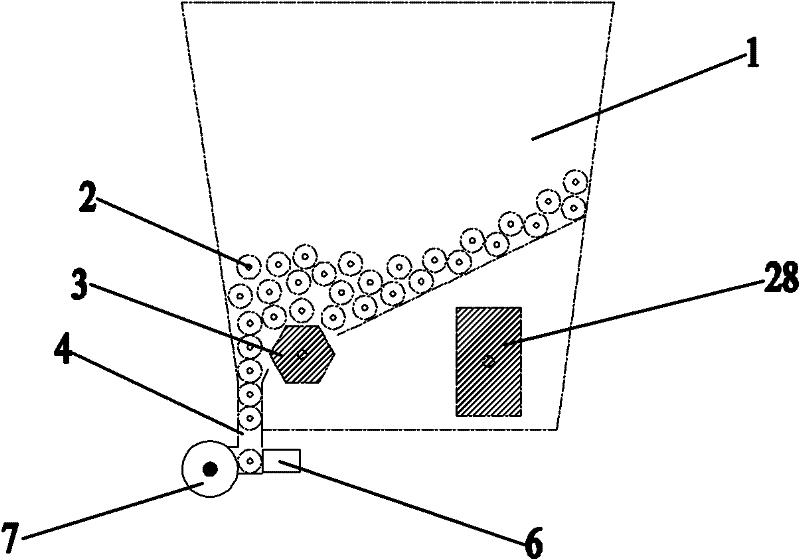

Full-automatic spot welding machine

InactiveCN101412147AImprove work efficiencyRealize fully automatic spot welding processingWelding/cutting auxillary devicesElectrode featuresSolderingSpot welding

The invention relates to the technical field of spot welding machine, in particular to a full automatic spot welding machine. The spot welding machine is provided with an upper electrode, a lower electrode, a soldering terminal conveying device, a soldering terminal conveying vibration disk, a workpiece conveying device and a workpiece conveying vibration disk, wherein the soldering terminal is conveyed in a welding terminal conveying groove of the welding terminal conveying device through the welding terminal conveying vibration disk; and the soldering terminal is pushed in a fixing hole of the lower electrode by a pushing cutter of the welding terminal conveying device, thereby completing the automatic conveying and positioning of the soldering terminal; besides, the workpiece conveying vibration disk conveys the workpiece in a work piece conveying groove of the workpiece conveying device, the workpiece conveying device clips the workpiece through a clipping cylinder, a rotary cylinder drives the clipping cylinder to rotate, and the workpiece is positioned on the upper part of the lower electrode, thereby completing the full automatic conveying and positioning of the workpiece; and at last, a working cylinder drives the upper electrode to descend to complete the automatic spot welding. The full automatic spot welding machine has the advantages of realizing the full automatic spot welding processing, improving the working efficiency, improving the spot welding quality and lowering the production cost.

Owner:东莞市中一合金科技有限公司

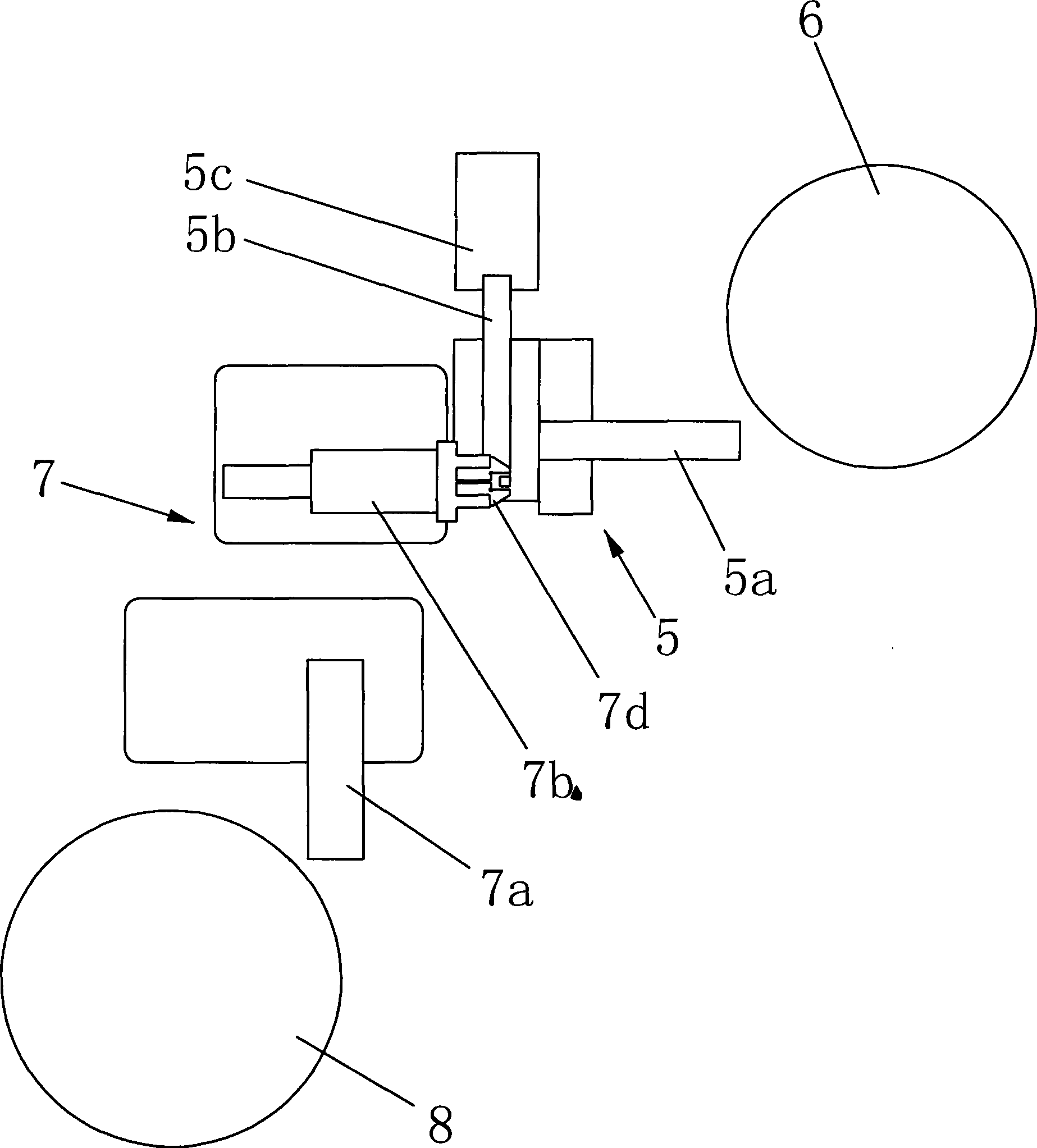

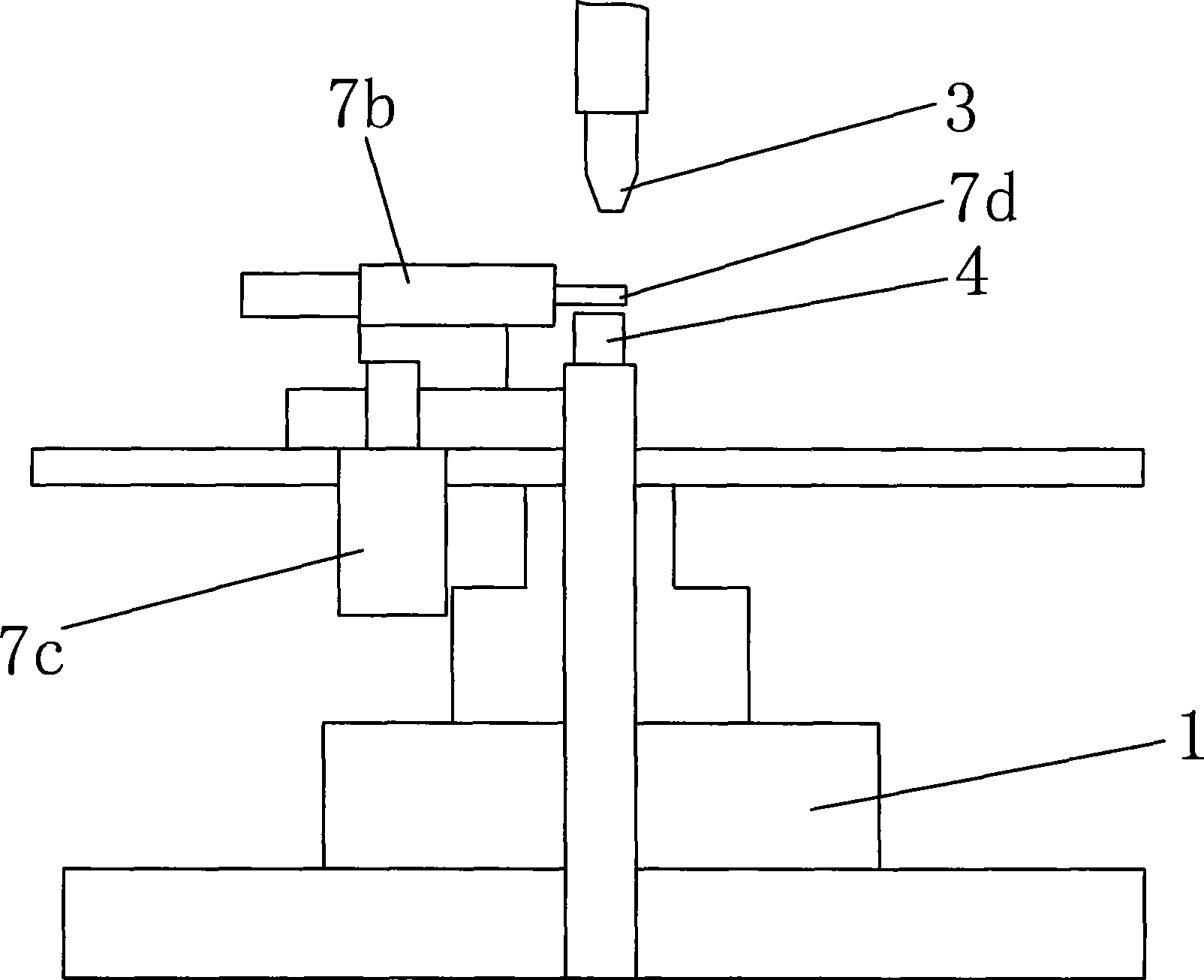

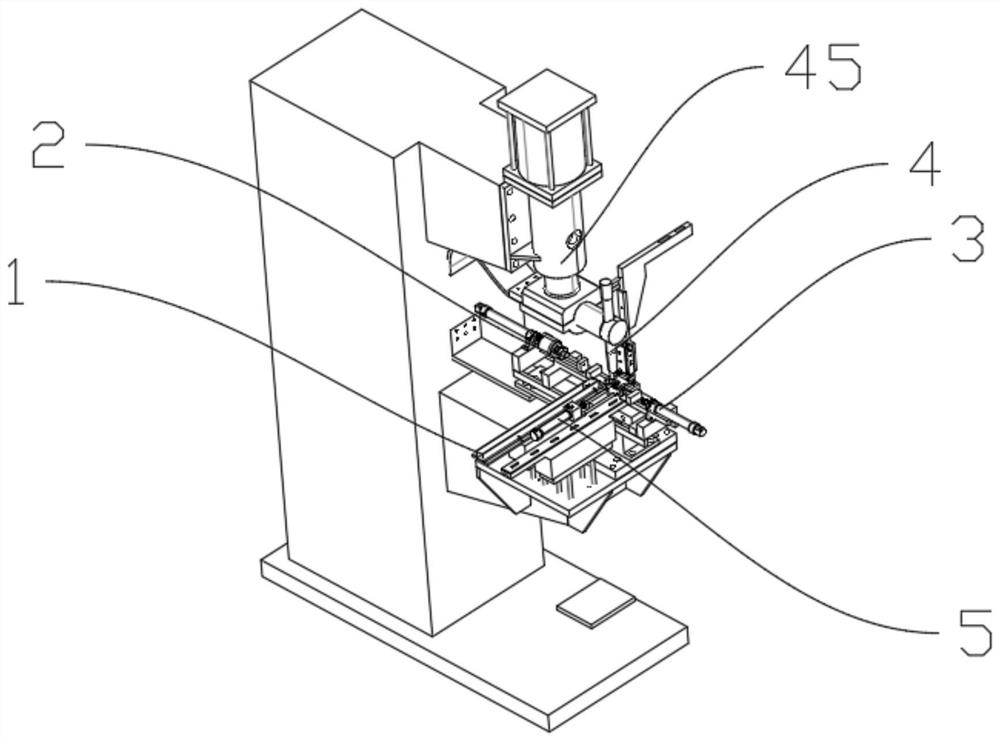

A double-needle automatic spot welding device

ActiveCN102294562AImprove spot welding qualityCompact structureFinal product manufactureWelding/cutting auxillary devicesElectrical batterySpot welding

The invention relates to a dual-needle automatic spot bottom welding device, which comprises a blanking hopper, wherein a spot-welding machine is arranged on one side of the blanking hopper; a battery discharging outlet is formed on the lower part of the blanking hopper; a shaft used for turning a battery is arranged above the place, corresponding to the battery discharging outlet, in the blanking hopper; a first battery pushing mechanism is arranged below the battery discharging outlet; the spot-welding machine comprises a first spot-welding needle and a second spot-welding needle; a welding supporting body is arranged below the first spot-welding needle and the second spot-welding needle; a battery turning mechanism is arranged between the welding supporting body and the first battery pushing mechanism; after the battery in the blanking hopper is turned through the battery turning mechanism, the end, to be welded, of the battery sliding into the welding supporting body, can be correspondingly matched with the first spot-welding needle and the second spot-welding needle; and the other end, correspondingly connected with the battery turning mechanism, of the welding supporting body is connected with a battery feeding inlet of a battery receiving hopper. The dual-needle automatic spot bottom welding device has the advantages that: the automation degree is high, the working efficiency is improved, the labour intensity is reduced, the spot-welding quality of the battery is improved, the application range is wide, and the device is safe and reliable.

Owner:无锡市明杨新能源股份有限公司

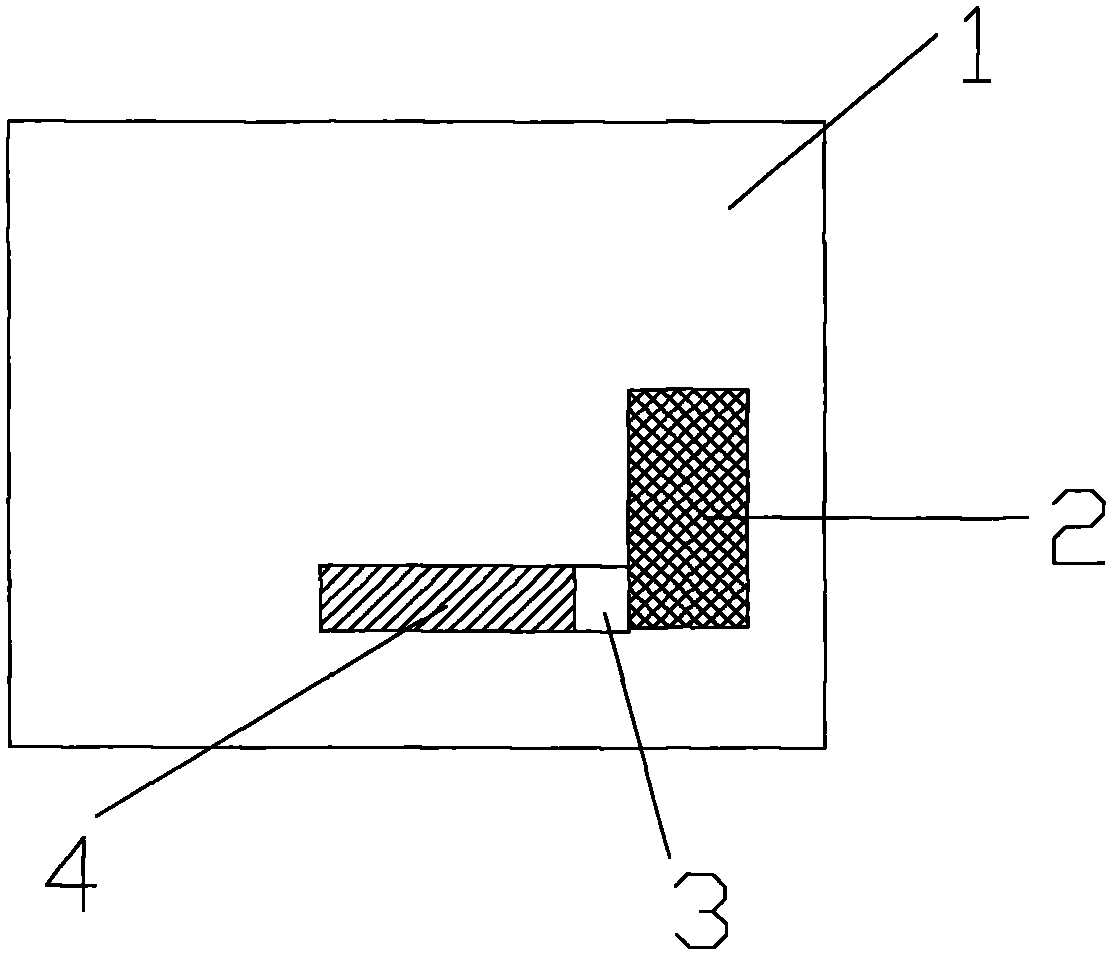

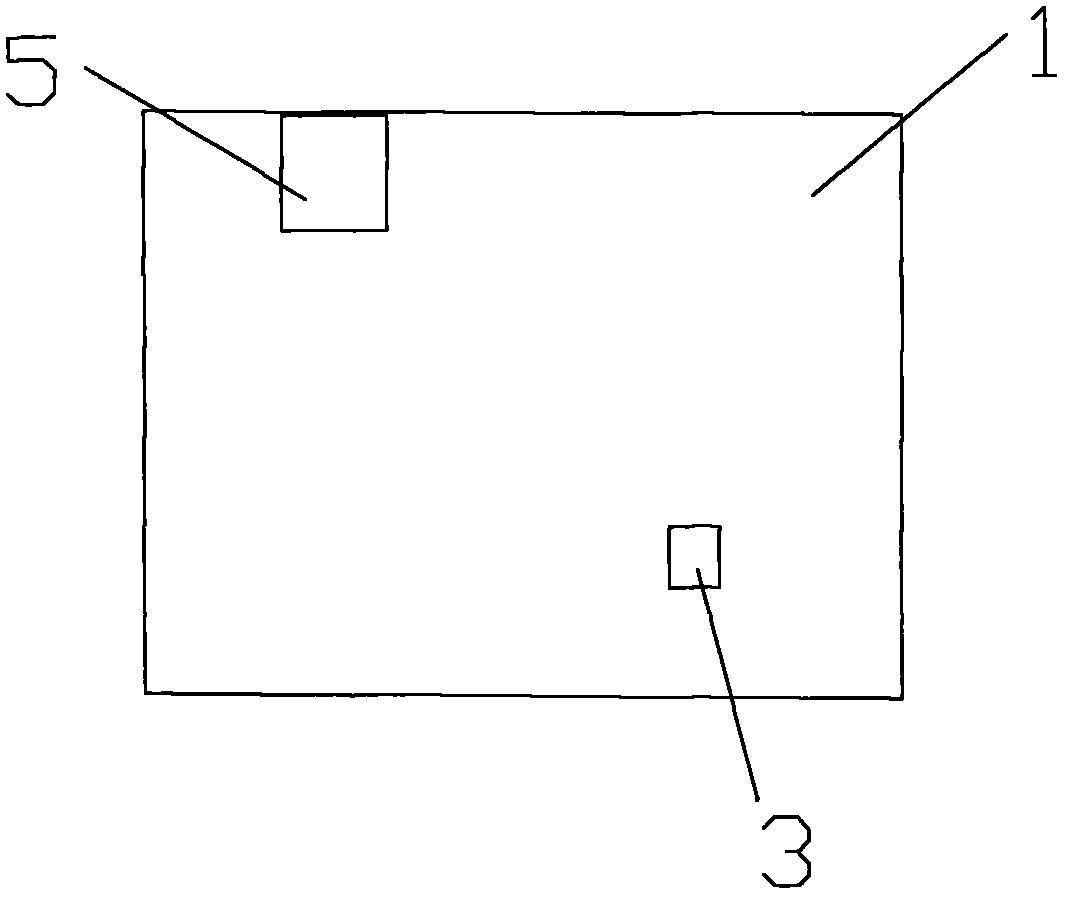

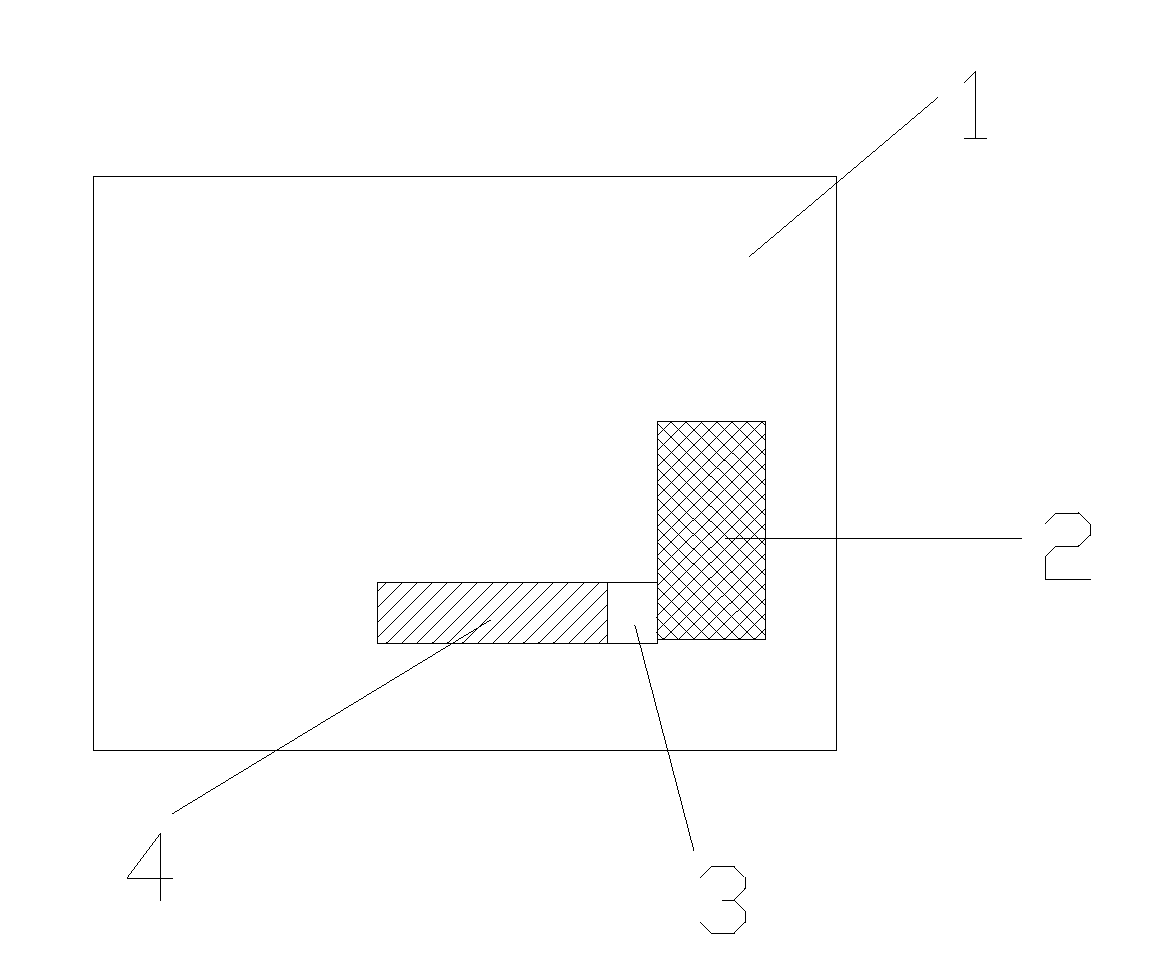

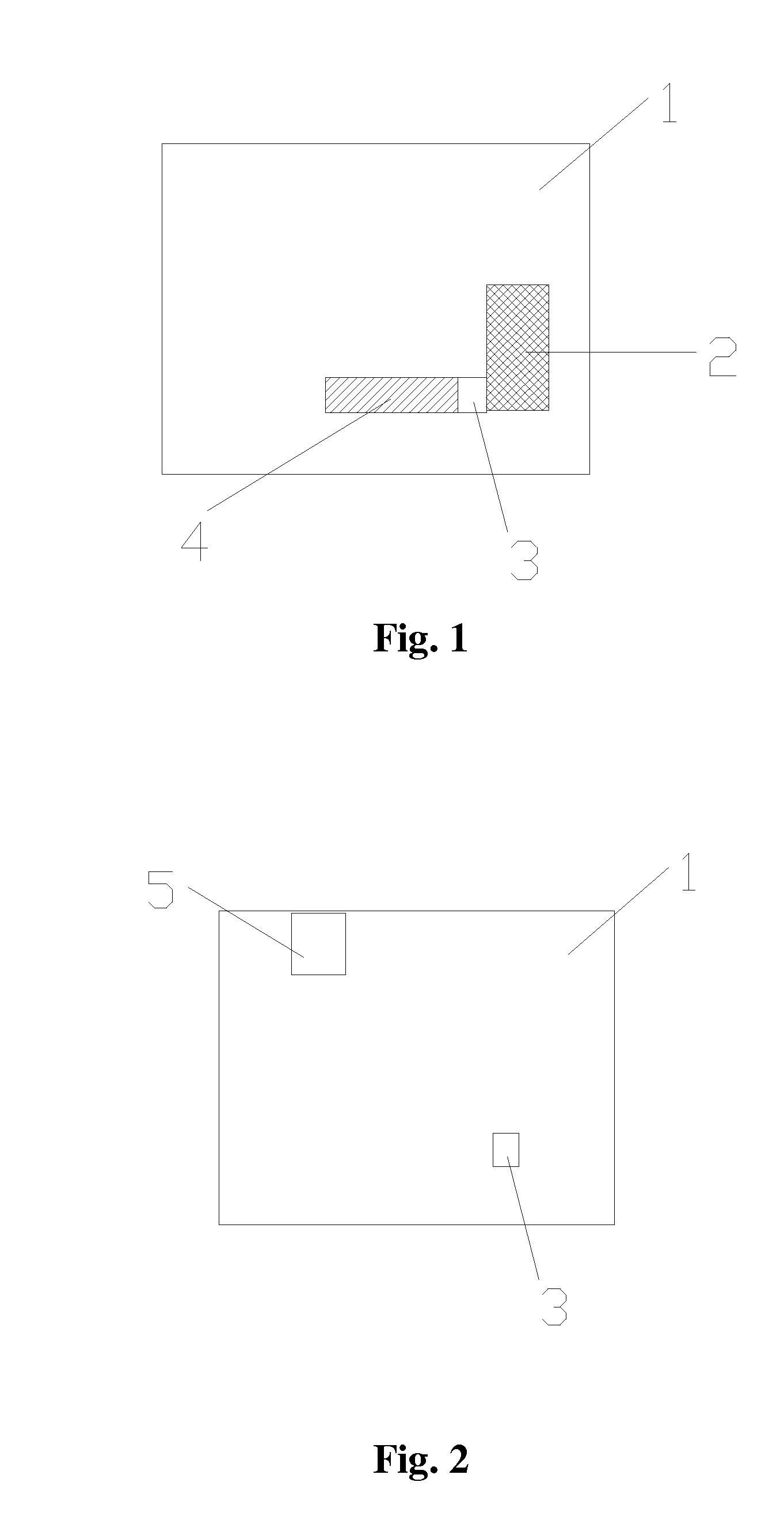

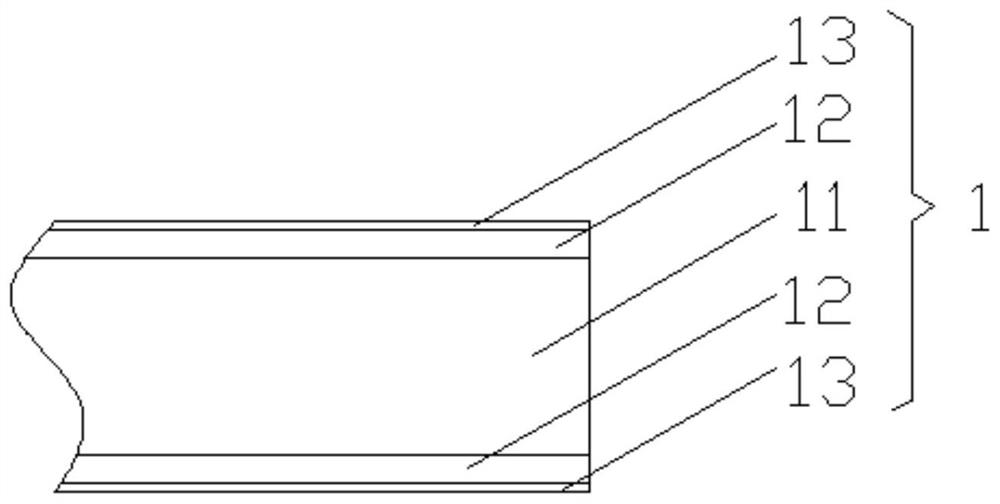

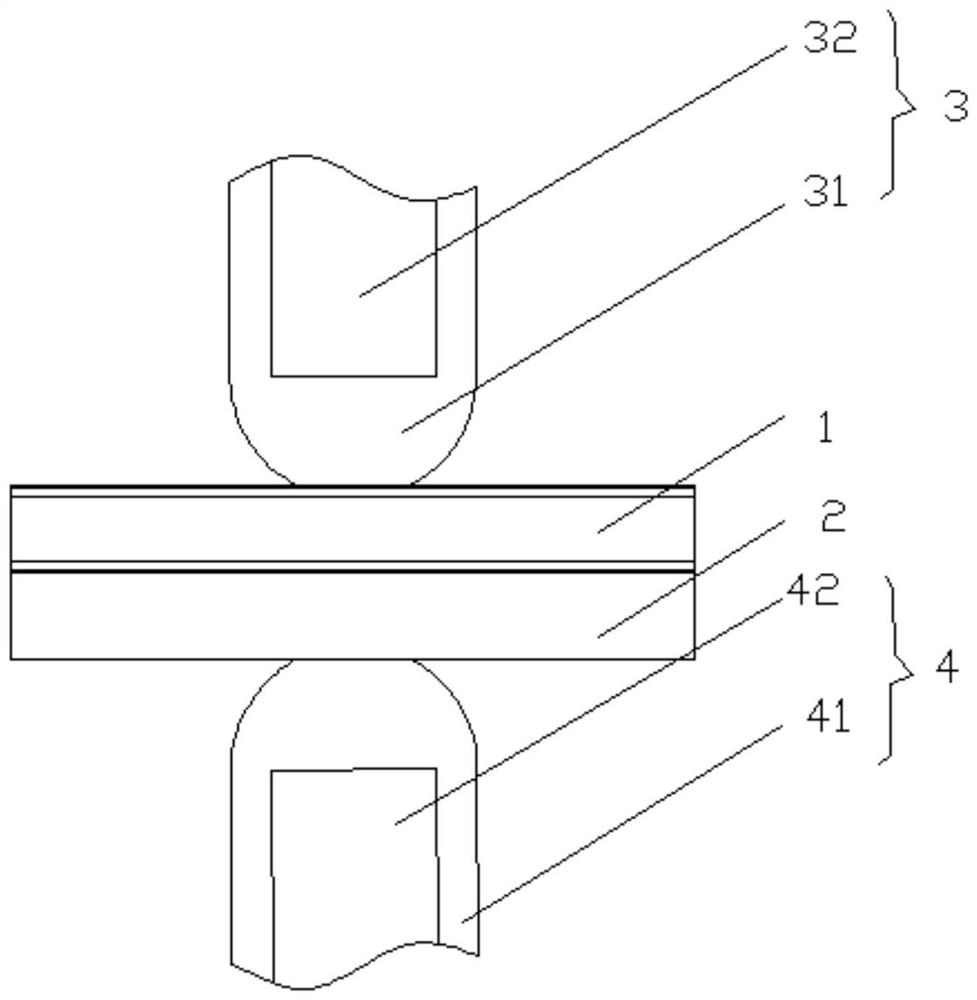

Spot soldering fixture and spot soldering process

InactiveCN102581458APrecise positioningHeight adjustableResistance welding apparatusEngineeringSoldering process

The invention belongs to the technical field of soldering, and particularly relates to a spot soldering fixture, which is used in a spot soldering process capable of avoiding pseudo soldering, false soldering and bursting, and is high in soldering efficiency. The spot soldering fixture comprises a fixture body, a cell storage area and a fuse storage area, and an avoidance hole is reserved between the cell storage area and the fuse storage area. Compared with the prior art, the spot soldering fixture has the advantages that a fuse and a metal strap can be effectively positioned, the height of a soldering pin can be adjusted, spot soldering quality can be improved, soldering reject ratio can be decreased, production efficiency can be improved, and cost can be saved. Besides, the invention further discloses the spot soldering process using the spot soldering fixture.

Owner:DONGGUAN NVT TECH

Spot welding machine for batteries

ActiveCN103418947AReasonable structureImprove spot welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a spot welding machine for batteries. The spot welding machine for the batteries comprises a rack, a spot welding device and a jig returning belt, wherein the spot welding device and the jig returning belt are arranged on the rack. The spot welding device comprises a conveying belt, a spot welding frame and a spot welding machine. The conveying belt is located in the middle of a worktable, passes through the spot welding frame and is used for conveying the batteries from front to back; welding heads of the spot welding machine are respectively located at both sides of the spot welding frame; a lead screw is driven by a motor to control the welding heads to horizontally move; when the batteries are conveyed to a spot welding station by the conveying belt, a spot welding operation can be performed. After all the batteries are welded, a tray assembly falls, and a jig falls to the conveying belt, and the conveying belt continues to move forward to convey the batteries; after the welded batteries are taken out by personnel in the rear of the rack, the jig is put to the jig returning belt to return to the worktable of the rack for cycle use. The spot welding machine for the batteries has the advantages that the structure is reasonable, the spot welding quality is high, the spot welding efficiency is high, and the like.

Owner:XIAMEN LIJU AUTOMATION TECH

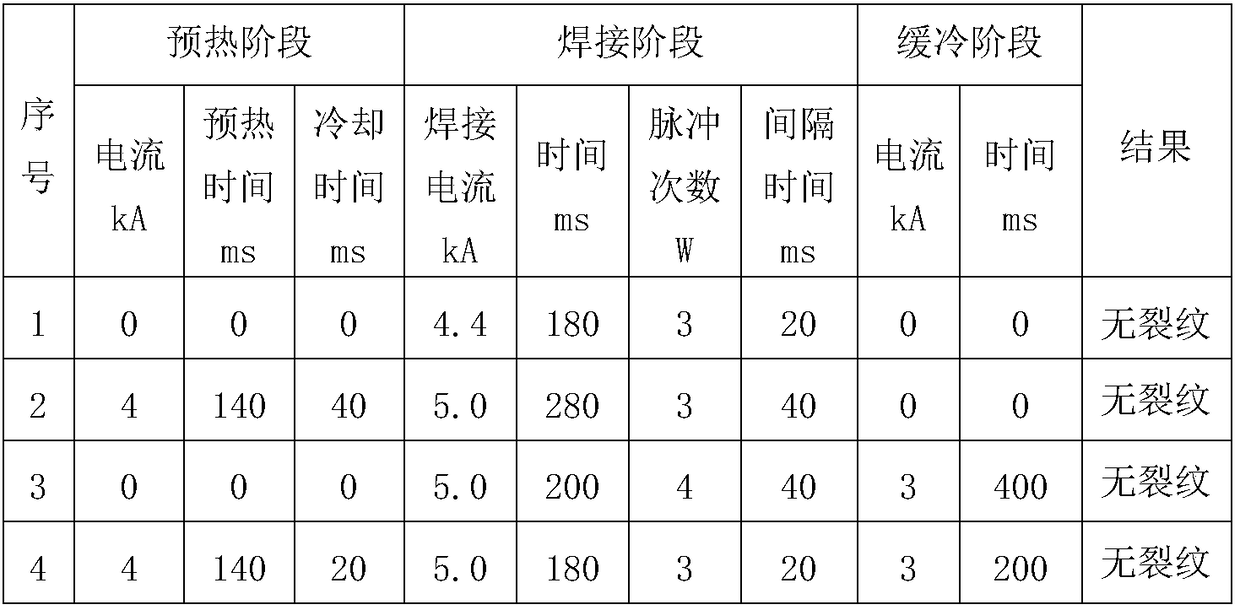

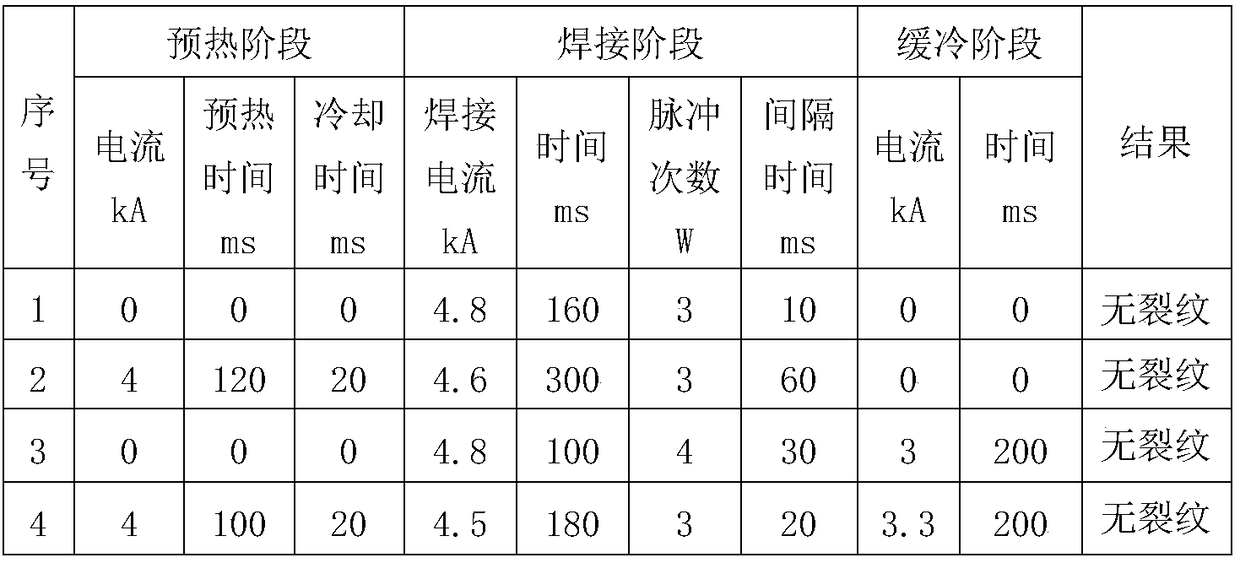

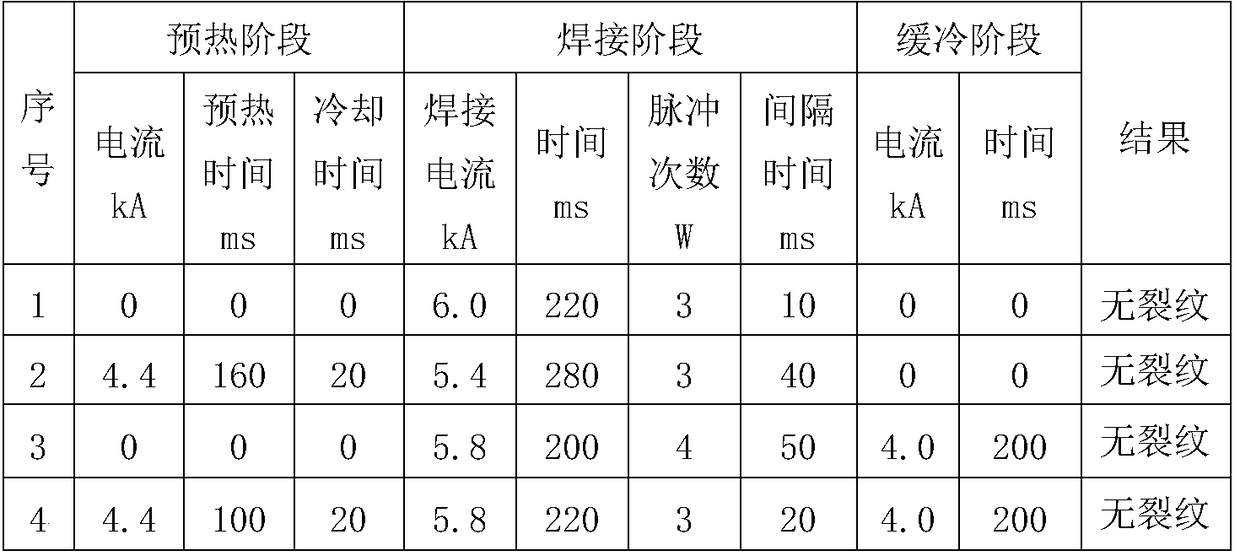

Spot welding process method for high carbon equivalent cold-rolling dual phase steel

InactiveCN109079304AImprove stress statusAvoid crackingResistance welding apparatusHigh carbonThree stage

The invention relates to a spot welding process method for high carbon equivalent cold-rolling dual phase steel. The cold-rolling dual phase steel has carbon equivalent Ceq greater than or equal to 0.5; the spot welding process comprises three stages, namely a preheating stage, a welding stage and a slow cooling stage, and at least comprises the welding stage; at the preheating stage, structure rigidity of a steel plate is eliminated to obtain uniform contact resistance; at the welding stage, a molten core is formed, and textures and stress of the molten core of the steel plate are improved byusing a multi-pulse process; at the slow cooling stage, the cooling speed of a molten core metal is reduced after the molten core is formed at a welding spot, and then various properties of the welding spot are improved. By adopting the spot welding process, texture constitution and stress states of a molten core part can be improved, the problem that cracks can be easily caused at a molten coreline part when spot welding is carried out on the cold-rolling dual phase steel of which the carbon equivalent Ceq is not smaller than 0.5, is solved, and the spot welding quality can be improved.

Owner:ANGANG STEEL CO LTD

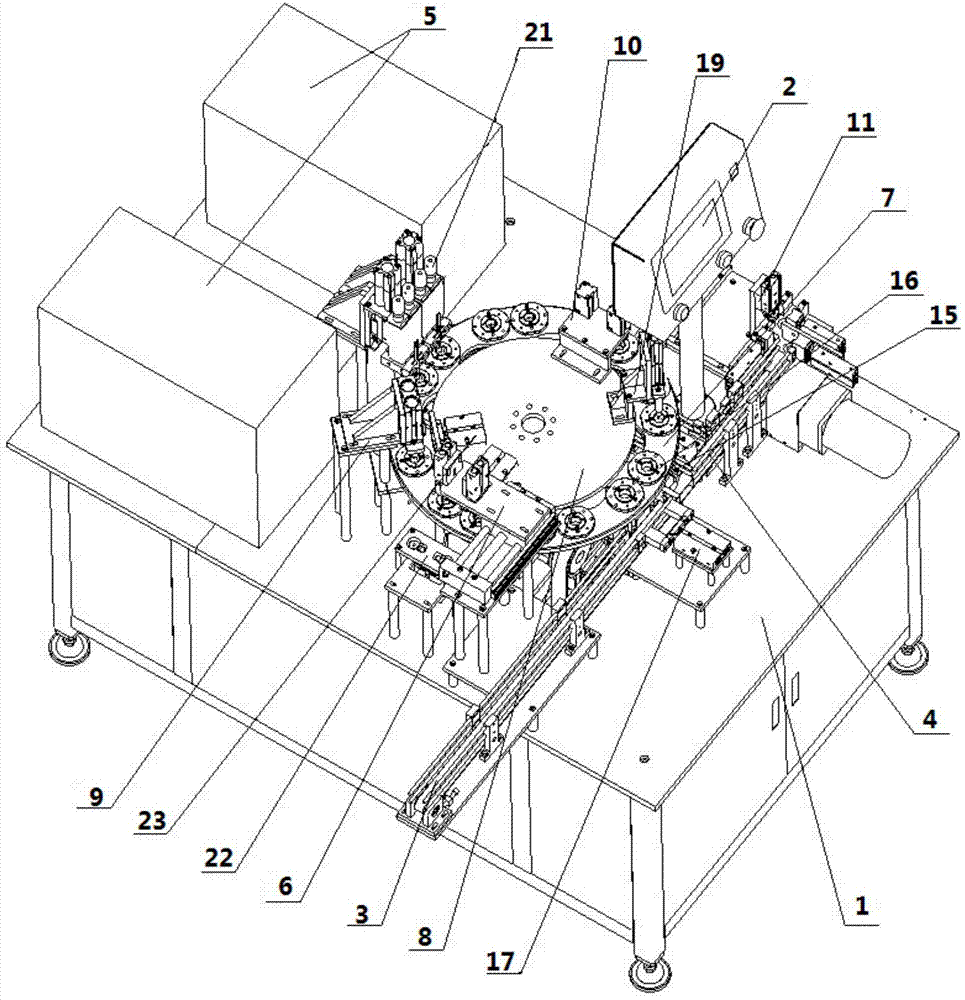

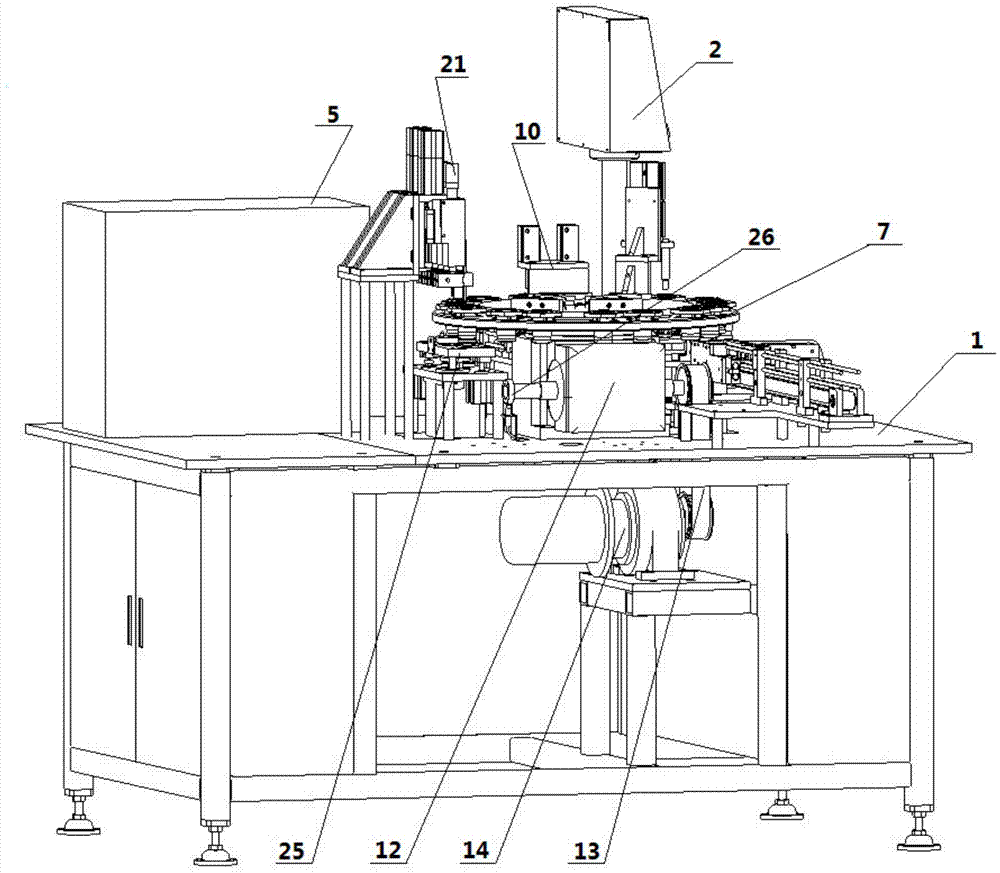

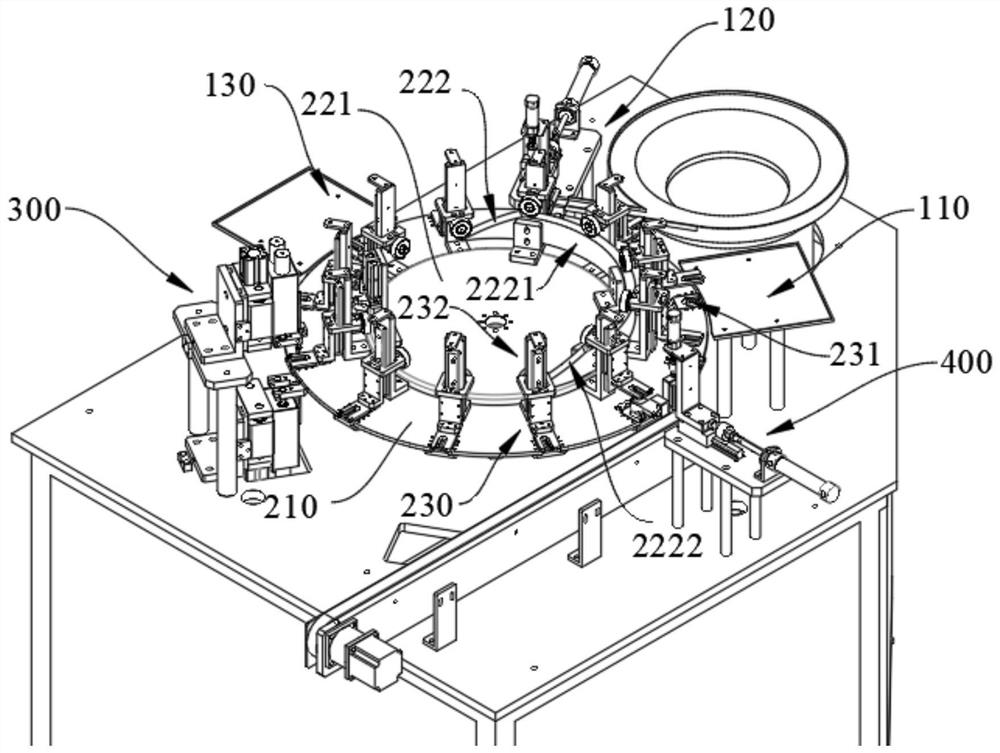

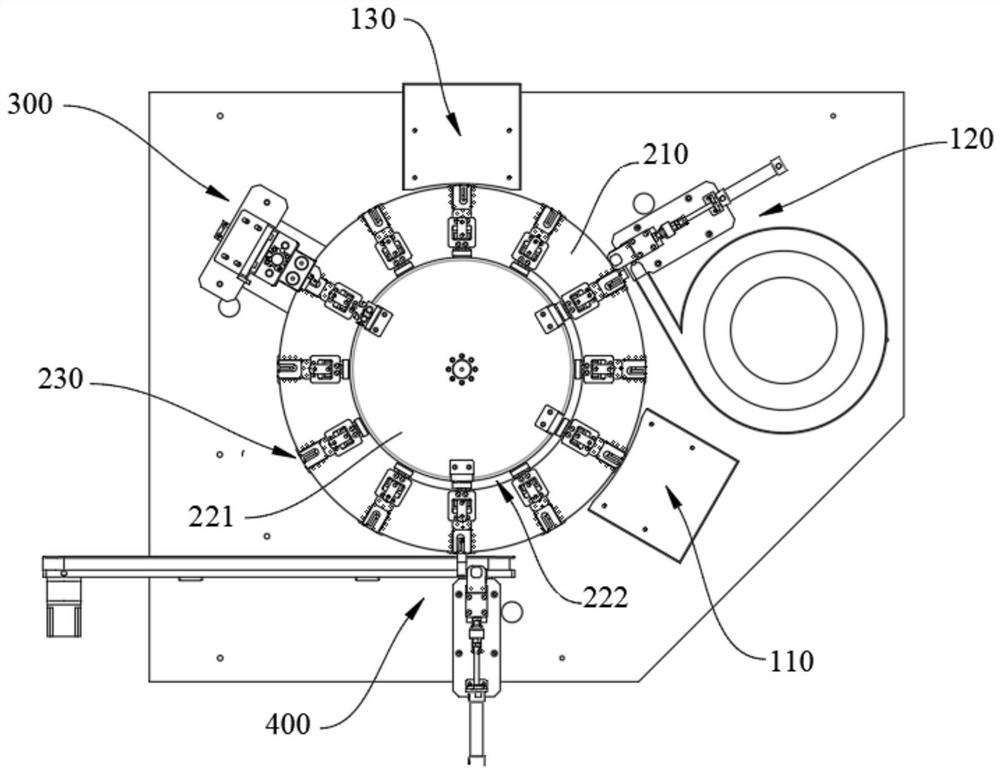

Automatic afflux disk all-in-one welding machine

ActiveCN104708219AImprove spot weld consistencyLower internal resistanceWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingComputer engineering

The invention provides an automatic afflux disk all-in-one welding machine comprising a machine frame platform, an operation and control panel, a feeding trough, a discharging trough and at least one spot welder and further comprises an afflux disk placing device, a round-ring-shaped rotating disk and a fixing disk arranged at the center of the rotating disk. The fixing disk and the rotating disk are both installed on a cam divider. The cam divider is provided with a sensor and installed on the machine frame platform. The cam divider is synchronous with a motor installed on the lower portion of the machine frame platform through a belt, multiple locating troughs are arranged on the periphery of the rotating disk, fixing dies are arranged in the locating troughs, the afflux disk placing device and the spot welders are sequentially installed on the periphery of the rotating disk, each spot welder is provided with at least one spot welding needle, a locating and rotating device is arranged below the rotating disk and is opposite to the spot welding needles, and an afflux disk bending device is arranged at the rear end of the afflux disk placing device. The automatic afflux disk all-in-one welding machine achieves automatic production and reduces labor cost.

Owner:YIYANG CORUN BATTERY

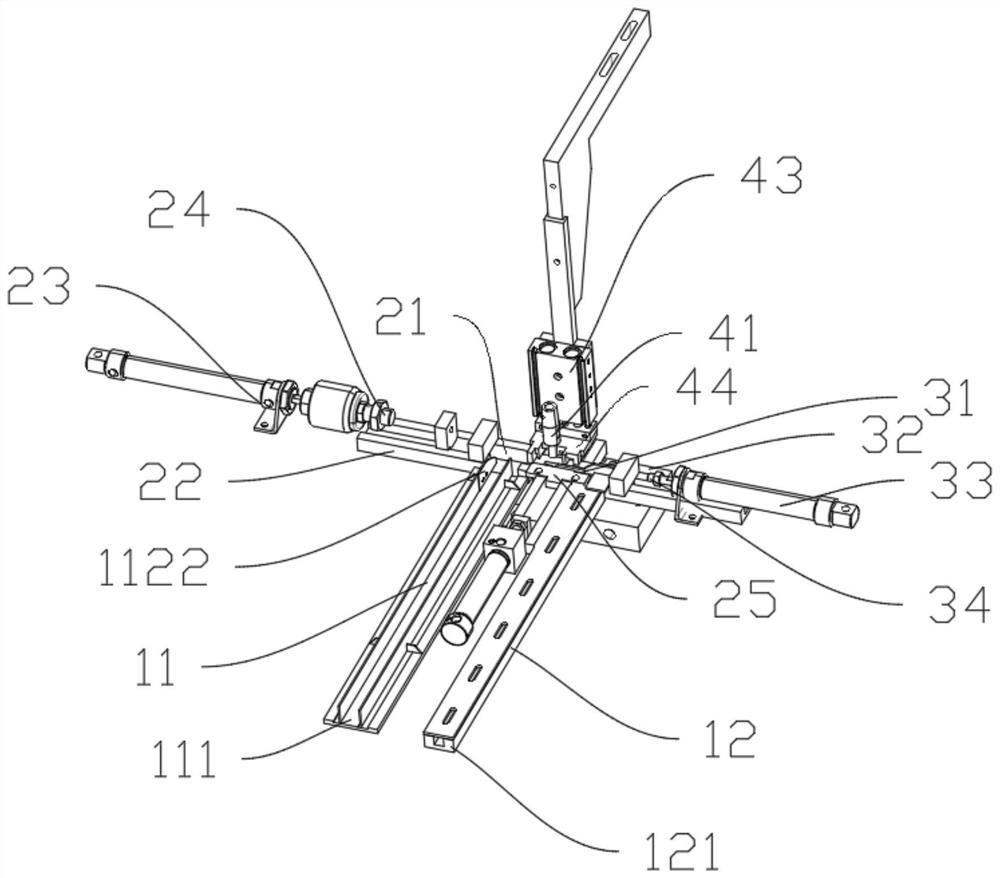

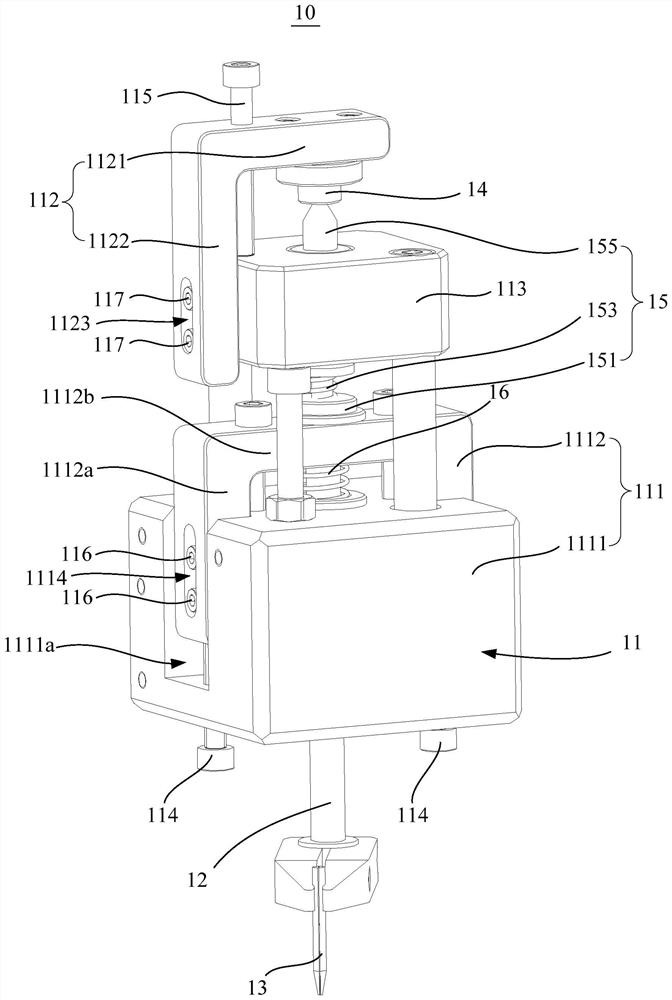

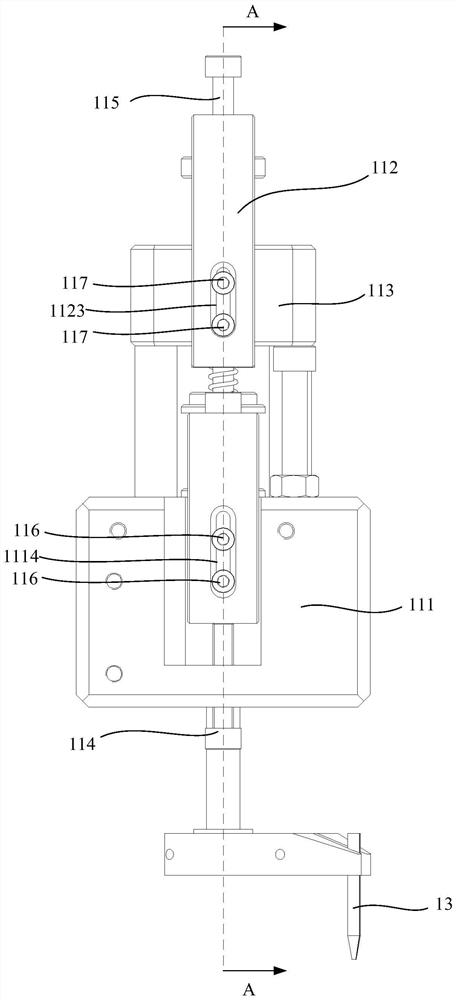

Four-needle point welding head device

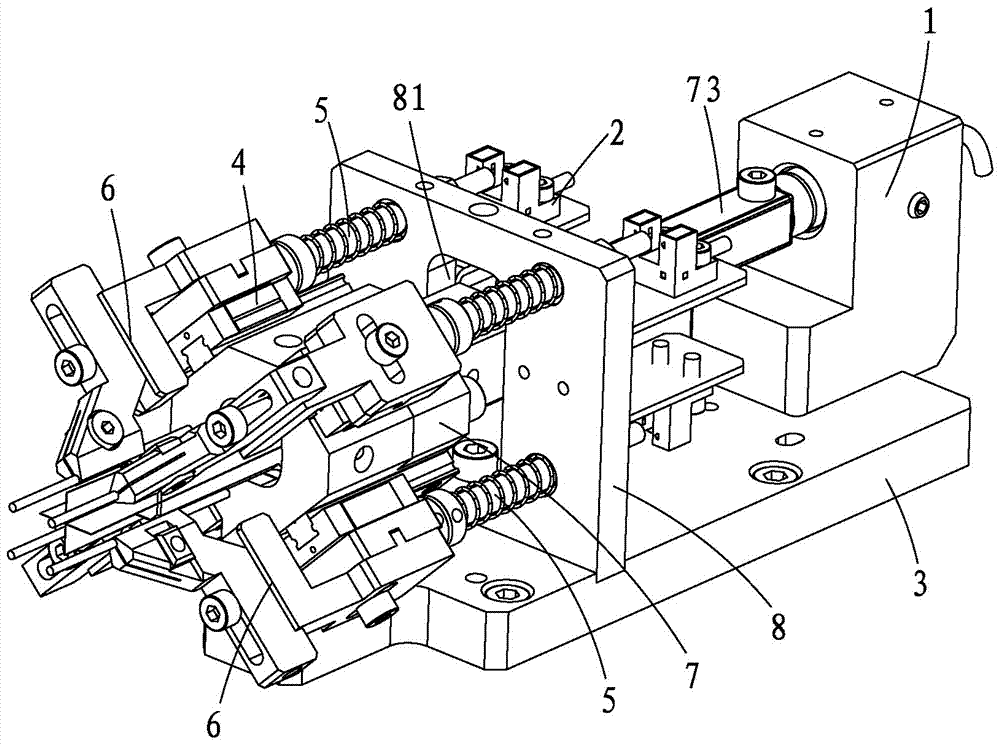

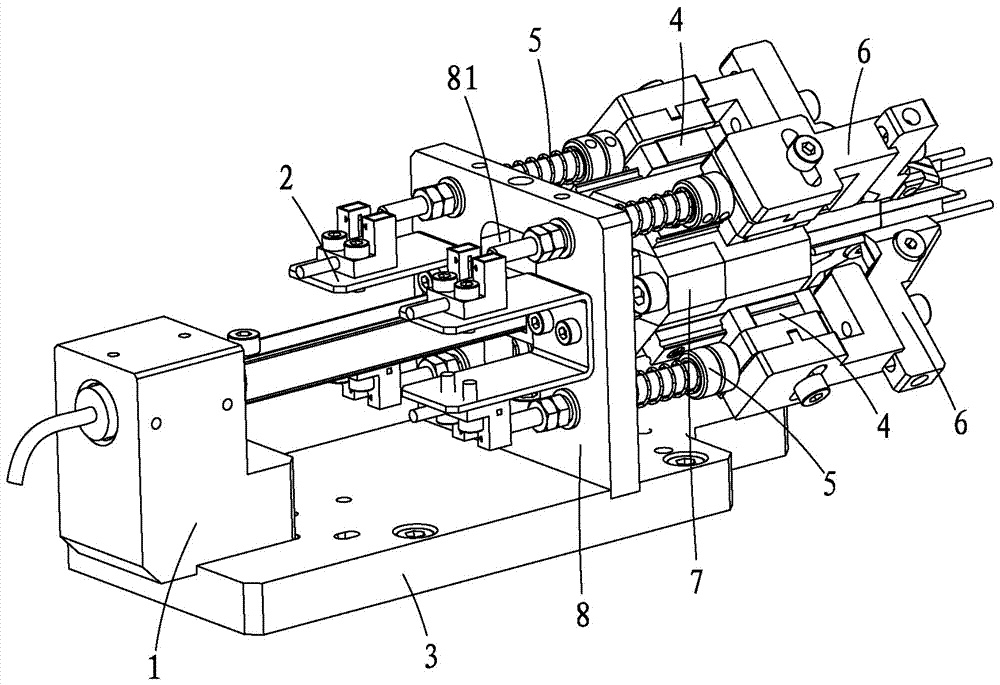

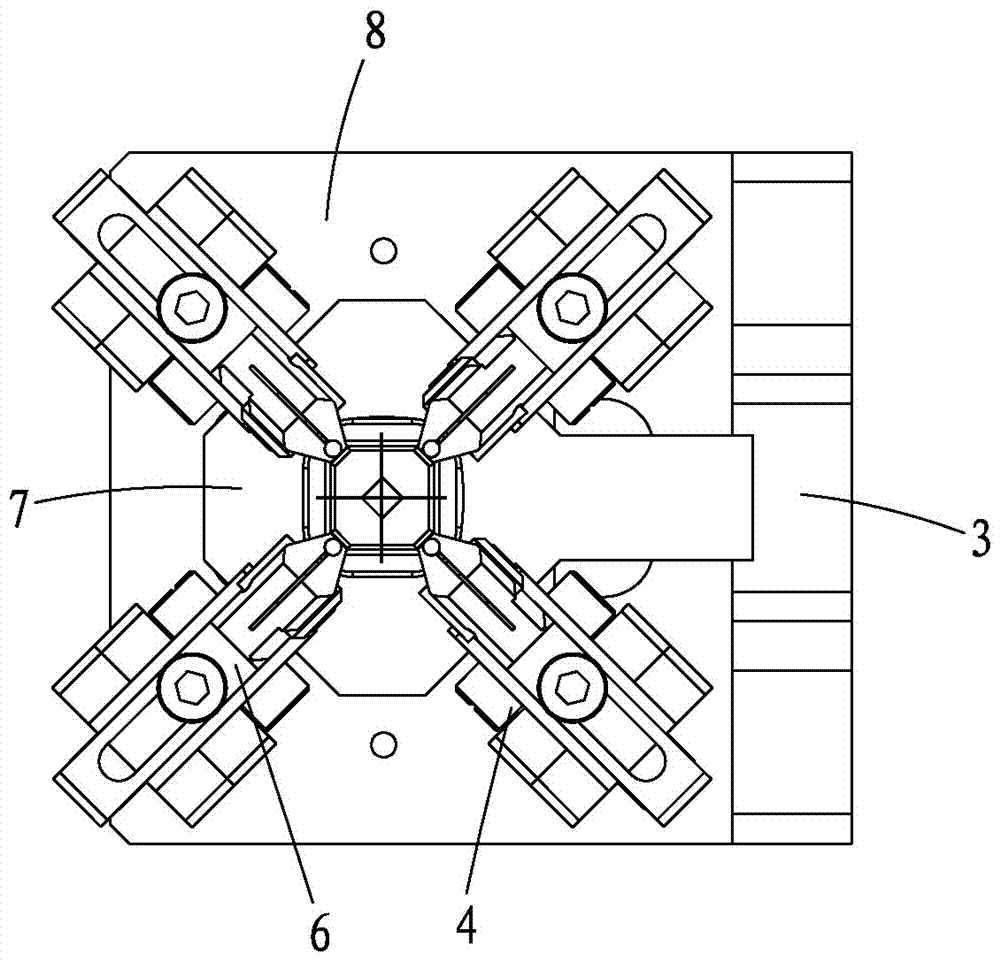

ActiveCN107150182AImprove spot welding precision and spot welding qualityIncrease the speed of needle adjustmentWelding/soldering/cutting articlesMetal working apparatusNeedle guideEngineering

The invention provides a four-needle point welding head device. The four-needle point welding head device comprises a laser alignment mechanism, a position induction mechanism, a fixed base, a welding needle guide mechanism, a pressure adjusting mechanism, a welding needle position adjusting mechanism and a rapid welding needle adjusting mechanism. The fixed base is provided with a point welding head vertical plate with an open hole. The rapid welding needle adjusting mechanism is arranged at the front end of the point welding head vertical plate and provided with a guide through hole. The position induction mechanism is arranged at the back end of the point welding head vertical plate. The laser alignment mechanism is arranged on the fixed base. The welding needle position adjusting mechanism is movably connected with the welding needle guide mechanism. The welding needle guide mechanism is slidably arranged on the rapid welding needle adjusting mechanism. The front end of the pressure adjusting mechanism is fixed to the welding needle guide mechanism, and the tail end of the pressure adjusting mechanism extends to the front end of the position induction mechanism. The four-needle point welding head device has the advantages that the welding efficiency of a welding point can be improved through the point welding head device; the welding quality of the welding point is ensured; and meanwhile, the needle adjusting speed can be greatly increased.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Spot Welding Clamp and A Spot Welding Process

InactiveUS20130186867A1High efficiencyImprove efficiencyElectrode supporting devicesResistance welding apparatusProduction rateWelding defect

The invention belongs to the technical field of welding, and in particular relates to a spot welding clamp which avoids rosin joint, false welding and fire blasting and is used in spot welding process with high efficiency. The spot welding clamp comprises a clamp body, an electric core holding area and a fuse holding area, wherein the electric core holding area and the fuse holding area are arranged on the clamp body. A clearance is arranged between the electric core holding area and the fuse holding area. Compared with the prior art, the spot welding clamp can well position a fuse and a metal strip and adjust the height of a welding pin, thus improving spot welding quality, lowering welding defect rate, improving productivity and reducing cost. In addition, the invention also discloses a spot welding process using the spot welding clamp.

Owner:DONGGUAN NVT TECH

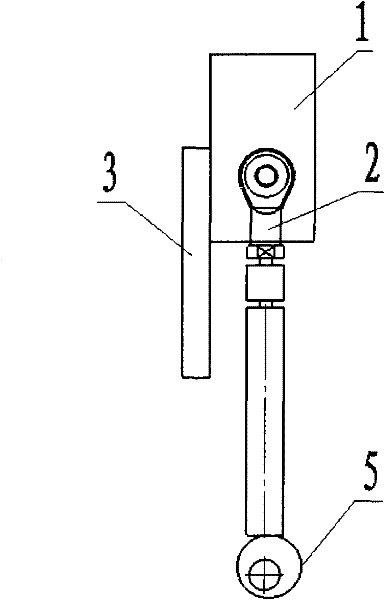

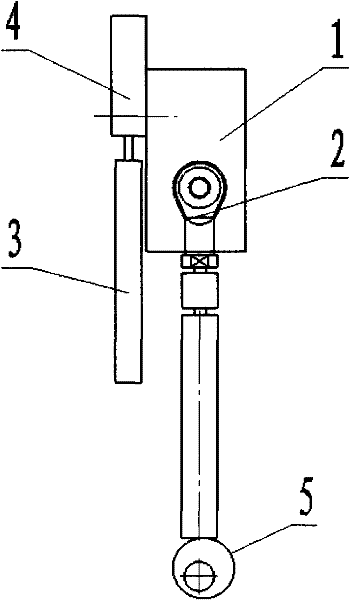

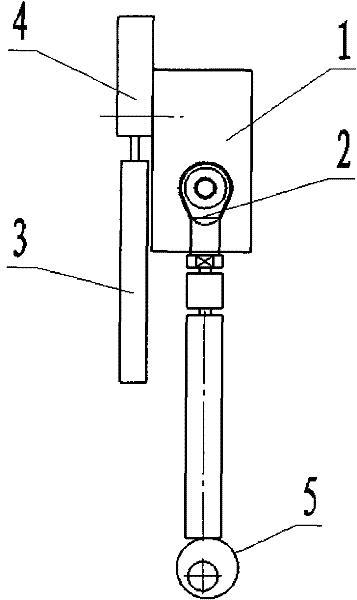

Welding head acceleration device for spot-welding package machine

InactiveCN102248272AFast spot weldingImprove equipment productivity and spot welding qualityResistance welding apparatusEngineeringCam

The invention relates to an accelerated spot-welding package machine and in particular relates to a welding head acceleration device for improving the spot-welding quality and increasing the spot-welding speed. The welding head acceleration device comprises a draw bar fixing block, a draw bar, a welding head mechanism, a cylinder and a cam, wherein the cylinder is arranged at a welding head, the cylinder is fixed on the draw bar fixing block, and the welding head mechanism and the cylinder are connected with each other. The cylinder pushes the welding head to move rapidly, and the cylinder is matched with the draw bar and works together with the cam, so as to achieve the acceleration purpose. The pressure and stroke of the cylinder are stable during motion, the spot-welding quality is improved, the problem of slow speed of the welding head is solved, the equipment production efficiency is increased, and the designed purpose is achieved.

Owner:YANTAI LIKAI ELECTRONICS TECH

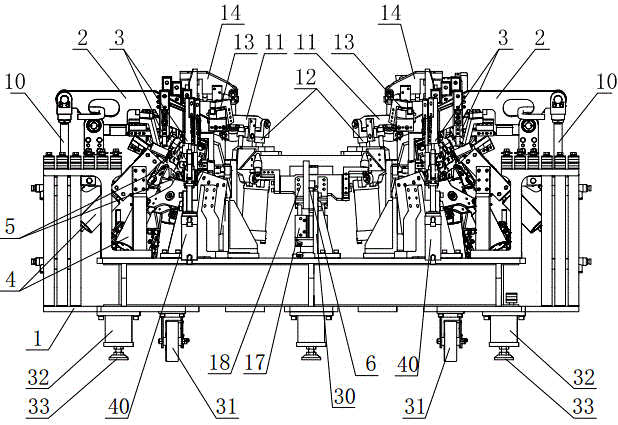

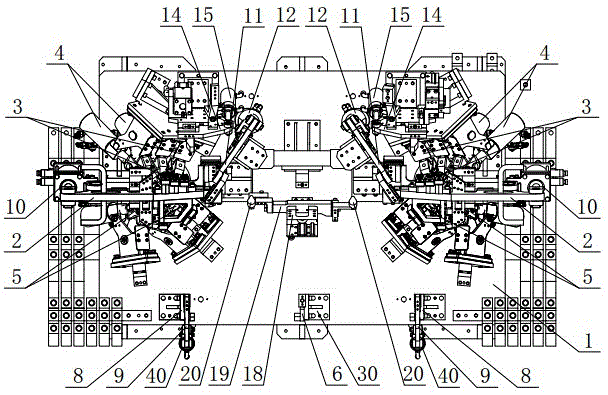

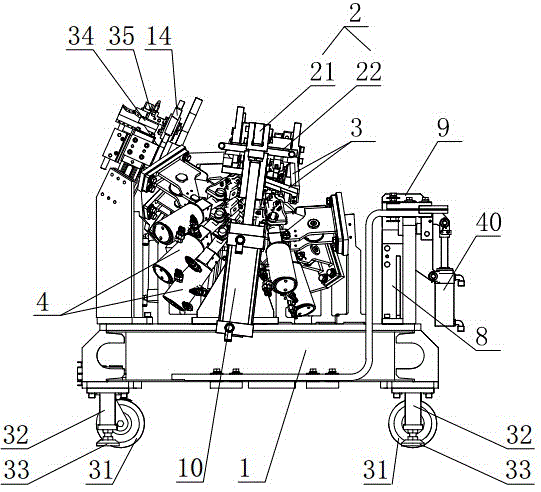

Automatic spot welding device for car body board

ActiveCN105537830AImprove spot welding qualityImprove bulk body appearanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses an automatic spot welding device for a car body board, comprising a support frame, wherein a board front end positioning mechanism and a board front part clamping mechanism are arranged at the front part of the support frame, lateral positioning and rear clamping mechanisms which are oppositely arranged and are respectively used for carrying out width positioning on two lateral parts of the board are arranged at the rear part of the support frame, upper electrode stands driven to swing up and down by an upper electrode power mechanism are arranged on the support frame, a plurality of upper electrodes connected with a main welding machine are respectively arranged on the upper electrode stands, a plurality of lower electrode driving cylinders which are located below the upper electrodes and are arranged corresponding to the upper electrodes in position are arranged on the support frame, lower electrodes which are connected with the main welding machine and matched with the upper electrodes to carry out spot welding are arranged on the lower electrode driving cylinders, and a middle positioning and tightening mechanism which can prop against a board is arranged in the middle of the support frame. According to the invention, the car body board can be clamped, automatic spot welding can be carried out on the car body board, and the device has the advantages of being high in spot welding quality and improving the appearances of large-batch car bodies.

Owner:MH ROBOT & AUTOMATION

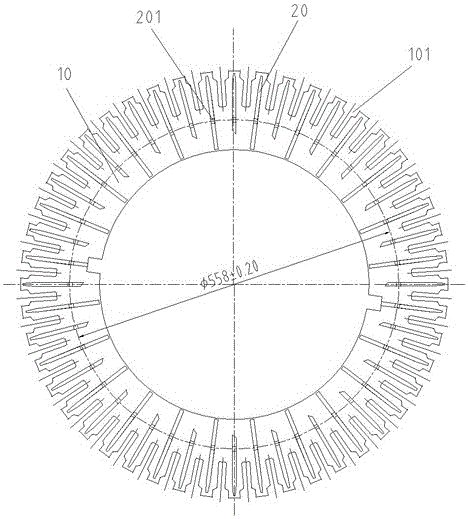

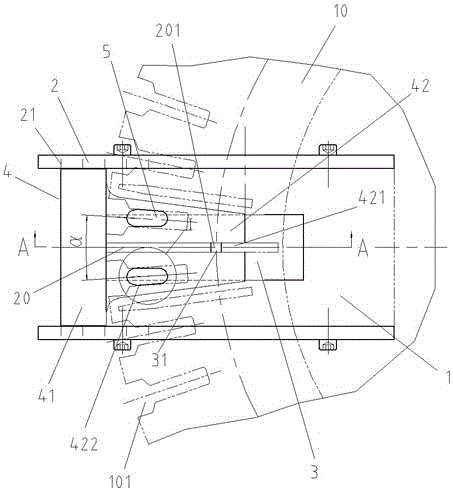

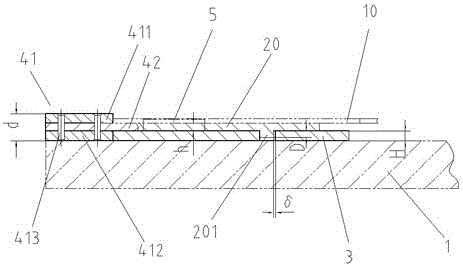

Point welding fixture for rotor ventilating slot piece and ventilating slot strip and using method of point welding fixture

ActiveCN106670706ASolve precise positioningImprove product qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a point welding fixture for a rotor ventilating slot piece and a ventilating slot strip. The point welding fixture comprises a point welding machine copper bottom plate, a pair of moving guide rails, a copper base plate, a rotor ventilating slot piece positioning component and two positioning blocks. A positioning groove is formed in the longitudinal center of a ventilating slot strip positioning plate. The two ends of a rear positioning plate are movably connected with the inner sides of the pair of moving guide rails. Positioning block grooves are formed in the two sides of the positioning groove correspondingly. The bottom surfaces of the positioning blocks are supported on the upper side face of the point welding machine copper bottom plate. The copper base plate is located between the rotor ventilating slot piece positioning component and the point welding machine copper bottom plate. A using method of the point welding fixture comprises the following steps that a boss of the ventilating slot strip is downwards embedded into the positioning groove, two adjacent notches of the rotor ventilating slot piece are embedded into the two positioning blocks, the rotor ventilating slot piece and the ventilating slot strip are pressed downwards and point-welded through a point welding head, and the rotor ventilating slot piece positioning component and the rotor ventilating slot piece on the rotor ventilating slot piece positioning component are pushed to complete point welding point by point. By adoption of the point welding fixture for the rotor ventilating slot piece and the ventilating slot strip and the using method of the point welding fixture, the manufacturing quality of the rotor ventilating slot piece is improved, the manufacturing cost is reduced, and the working efficiency is improved.

Owner:ZHENJIANG ZHONGCHUAN XIANDAI GENERATING EQUIP CO LTD

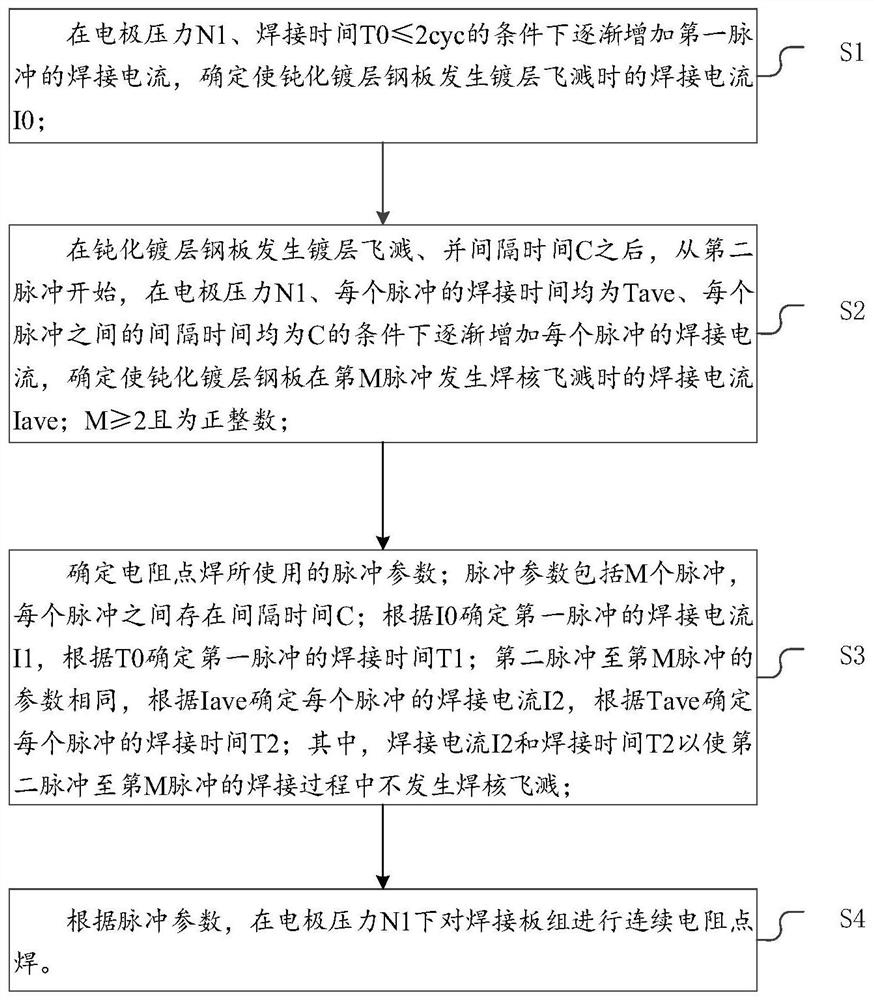

Resistance spot welding method for passivated coated steel plate

ActiveCN111673250AReduce adhesionExtend your lifeWelding electric suppliesElectrical resistance and conductanceMetallurgy

The invention discloses a resistance spot welding method for a passivated coated steel plate, and the method is applied to a welded plate group. The resistance spot welding method for the passivated coated steel plate comprises the following steps of determining the welding current I0 when coating splashing occurs on the passivated coated steel plate under the conditions of the electrode pressureof N1 and the welding time T0 less than or equal to 2 cyc; after a time interval C, from a second pulse, determining the welding current Iave when weld nugget splashing occurs on the passivated coatedsteel plate at the M-th pulse under the actions that the welding time of each pulse is Tave and the time interval between every two pulses is C; determining a pulse parameter used by resistance spotwelding, wherein the time interval between every two pulses is C; determining the welding current I1 of the first pulse according to I0; and determining the welding current I2 from the second pulse tothe M-th pulse according to the Iave, wherein the weld nugget splashing does not occur in a welding process from the second pulse to the M-th pulse. The method can reduce electrode adhesion, prolongthe service life of an electrode and improve the stability of the welding process.

Owner:SHOUGANG CORPORATION

Spot welding tool for hose support assembly

InactiveCN112372200APrecise positioningPrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesElectric machinerySlide plate

The invention discloses a spot welding tool for a hose support assembly. The spot welding tool comprises two oppositely-arranged supporting seats; a positioning table is fixed to the top ends of the two supporting seats; positioning grooves are formed in the two sides of the top of the positioning table; transverse rods are assembled on the two sides of the inner walls of the positioning grooves;the outer parts of the transverse rods are sleeved with reset springs; one end of each reset spring is fixedly matched with an extrusion plate; upper clamping plates are elastically connected to the sides, close to each other, of the two extrusion plates; extrusion wheels are arranged on the sides, away from each other, of the two extrusion plates in a contact mode; L-shaped plates are assembled on the extrusion wheels; sliding plates are fixed to the two sides of the top of the positioning table; first push rod motors are connected between the positioning table and the L-shaped plates; and electric sliding table sets are assembled at the tops of the two sliding plates. The situation that the welding quality is affected due to the fact that a hose support inclines and slides in the spot welding process is prevented, welding can be smoothly conducted, the spot welding quality of the hose support is improved, operation is easy, the practicability is high, and the spot welding tool is suitable for popularization.

Owner:十堰昌旺工贸有限公司

Spot or projection welding method using potential difference between positive and negative electrodes

InactiveCN105436682ASolve the problem of easy virtual weldingStrong penetrating powerResistance welding apparatusTransformerPotential difference

The invention provides a spot or projection welding method using the potential difference between positive and negative electrodes. Two layers of welding boards are clamped between two electrode arms. When the two layers of welding boards are unequal-thickness boards different in thickness, the electrode arm on the thin-board side is connected with the positive electrode of a transformer, and the electrode arm on the thick-board side is connected with the negative electrode of the transformer. When a robot is used for spot welding, the static electrode arm is connected with the negative electrode of the transformer, and the movable electrode arm is connected with the positive electrode of the transformer. During projection welding, the two layers of welding boards are a stamping part and a standard part respectively, the electrode arm on the stamping-part side is connected with the positive electrode of the transformer, and the electrode arm on the standard-part side is connected with the negative electrode of the transformer. Polarity characteristics of medium-frequency direct-current equipment are fully used, and the problem that pseudo soldering is likely to occur during spot welding of the unequal-thickness boards is solved; meanwhile, the depth of fusion of a welding core can be increased during projection welding.

Owner:SHANGHAI TRACTOR & INTERNAL COMBUSTION ENGINE

Ceiling welding tool and ceiling welding process

InactiveCN102019498AImprove spot welding qualitySimple structureResistance welding apparatusSpot weldingCantilever

The invention discloses a ceiling welding tool and a ceiling welding process. The ceiling welding tool comprises two symmetrically arranged supporting platforms, a plurality of tool fixtures are arranged at intervals on each supporting platform, the tool fixtures are slidably arranged on the supporting platforms and are used for fixing upper cantilever beams while installing a ceiling. The ceiling welding tool provided by the invention has simple structure, is convenient to realize and can effectively reduce tool expense. Meanwhile, the ceiling welding tool provided by the invention can be used for carrying out double-side single-spot welding on the ceiling and can effectively improve the welding quality of the ceiling.

Owner:CRRC DALIAN CO LTD

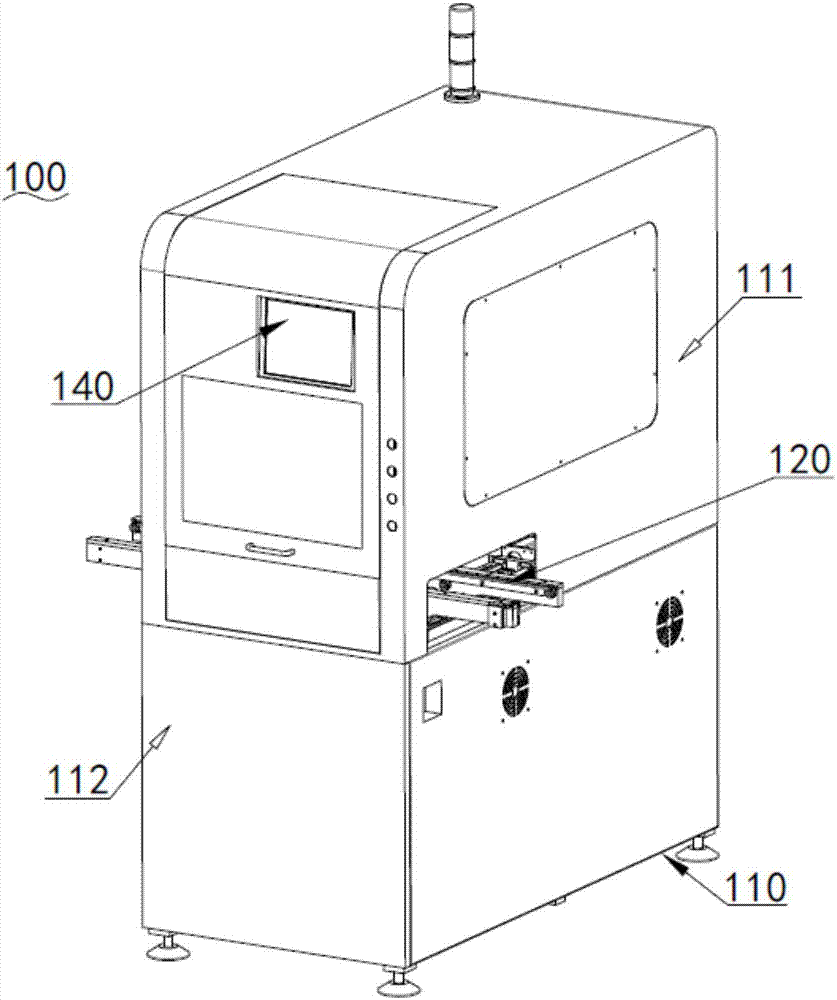

Automatic online tin paste dispensing equipment and working method thereof

PendingCN107088689AEasy to transportPlay a dynamic effectMetal working apparatusSoldering auxillary devicesEngineeringSpot welding

The invention relates to the technical field of tin dispensing equipment, in particular to automatic online tin paste dispensing equipment and a working method thereof. The automatic online tin paste dispensing equipment comprises a rack, a workbench, a tin dispensing device and a control device. The rack comprises an upper rack body and a lower rack body. The upper rack body is installed on the lower rack body and covers the workbench and the tin dispensing device. The control device is electrically connected to the workbench and the tin dispensing device. The workbench comprises an installation plate, a feeding assembly, a fixing assembly and a discharging assembly. The tin dispensing device comprises a supporting frame, a driving sliding platform, a detection assembly, a tin smearing assembly and a tin welding assembly. The automatic online tin paste dispensing equipment is high in working efficiency and automation degree and good in spot welding effect. The working method of the automatic online tin paste dispensing equipment comprises the steps that a program is written in the control device at first; a plate is fixed to the workbench, detected through the detection assembly, and smeared with tin paste through the tin smearing assembly; spot welding is conducted in the position where the tin paste is smeared through the tin welding assembly; and after spot welding is completed, the plate is detected again through the detection assembly. The working method is high in tin dispensing quality, automation degree and working efficiency.

Owner:VECTRON TECH ELECTRONICS EQUIP

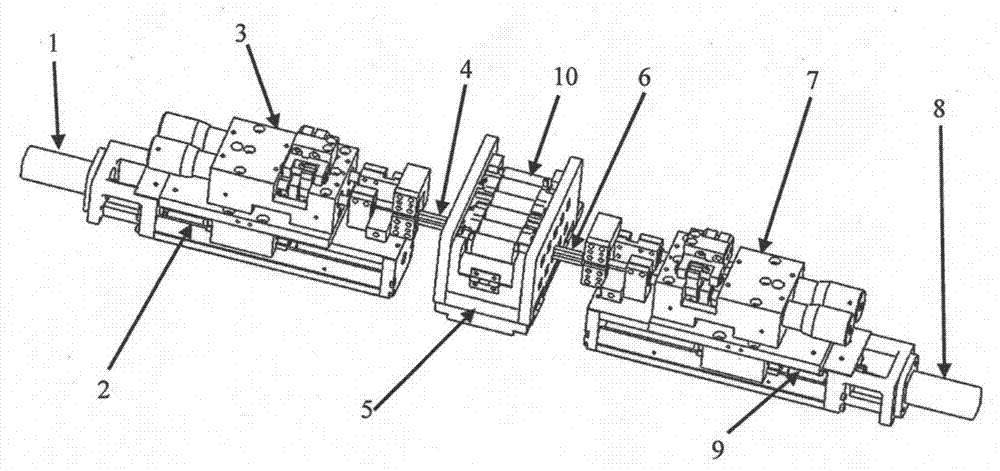

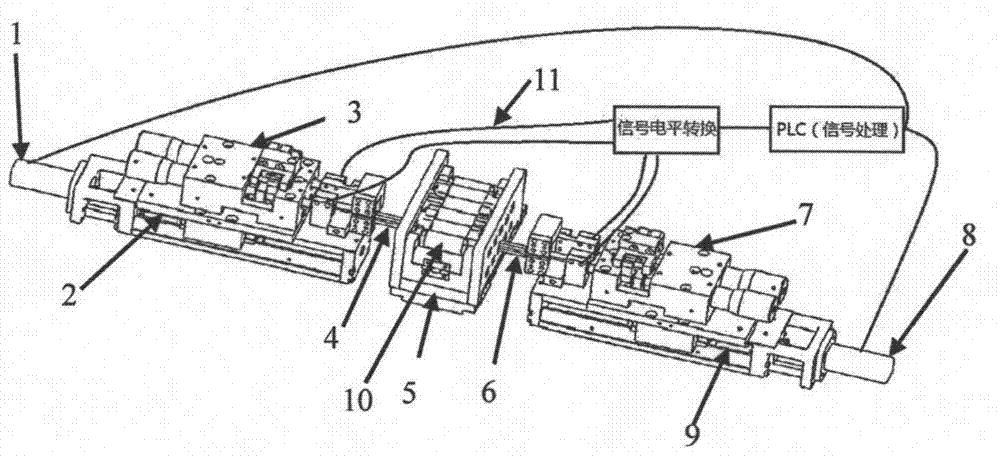

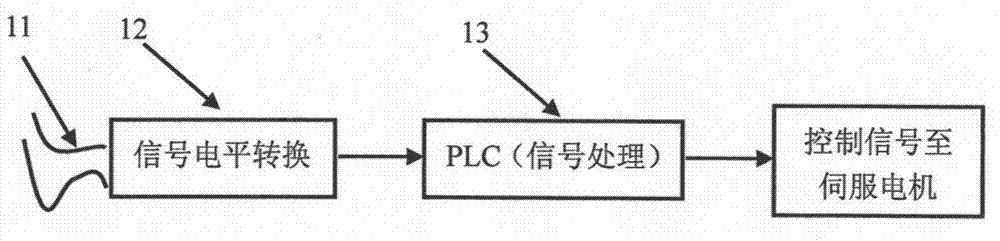

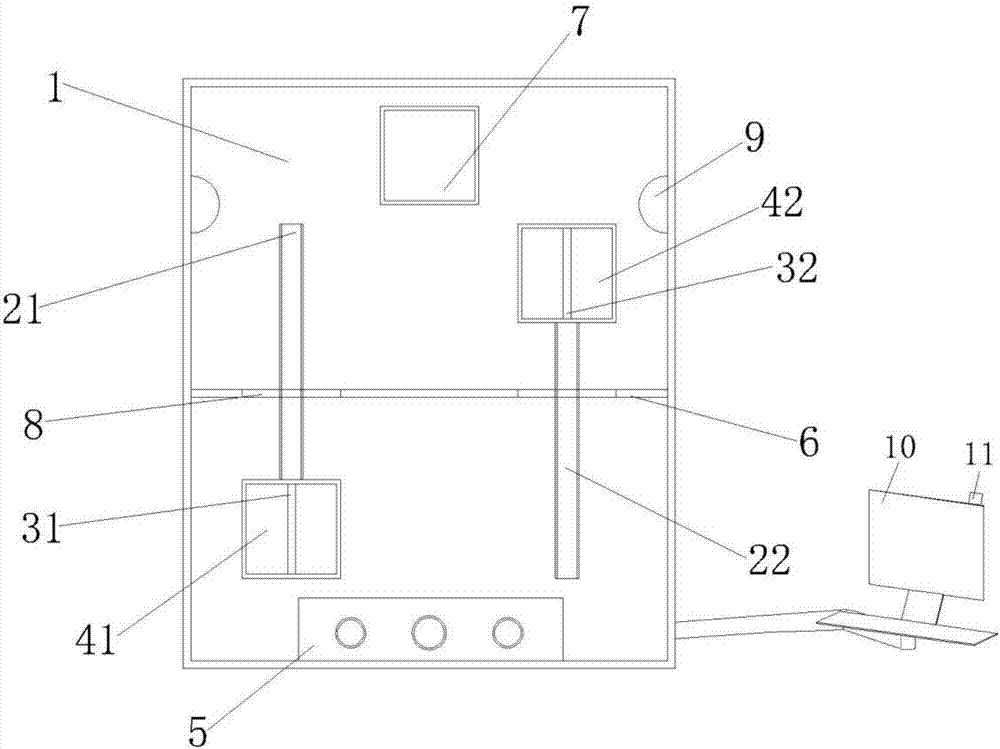

Double-sided automatic spot welding machine control device and method

ActiveCN104493352ANo movementNot misplacedWelding electric supplyMetal working apparatusMachine controlProgrammable logic controller

The invention provides a double-sided automatic spot welding machine control device. A double-sided automatic spot welding machine comprises a left screw rod, a right screw rod and a jig used for assembling a cell. A left servo motor and a right servo motor are connected with the left and right screw rods respectively, a left spot welding head and a right spot welding head are connected on the left and right screw rods respectively, a left electrode bar and a right electrode bar are arranged on the left and right spot welding heads respectively, a level conversion device is connected with a PLC (programmable logic controller), the left and right spot welding heads are both connected with the level conversion device, and the PLC is further connected with the left and right servo motors; a contact position is arranged on the surface of the cell. The invention further provides a double-sided automatic spot welding machine control method. After the spot welding heads on both sides reach the contact position, the electrode bars on two sides contact with the cell, and then the spot welding heads reach the spot welding position, so that the cell cannot move and a nickel plate cannot be misplaced. By the device, spot welding quality is improved, the servo motors can be set to be in full speed operation during movement before contact with the cell due to the contact position, and thus spot welding efficiency is improved as well.

Owner:上海电动工具研究所(集团)有限公司

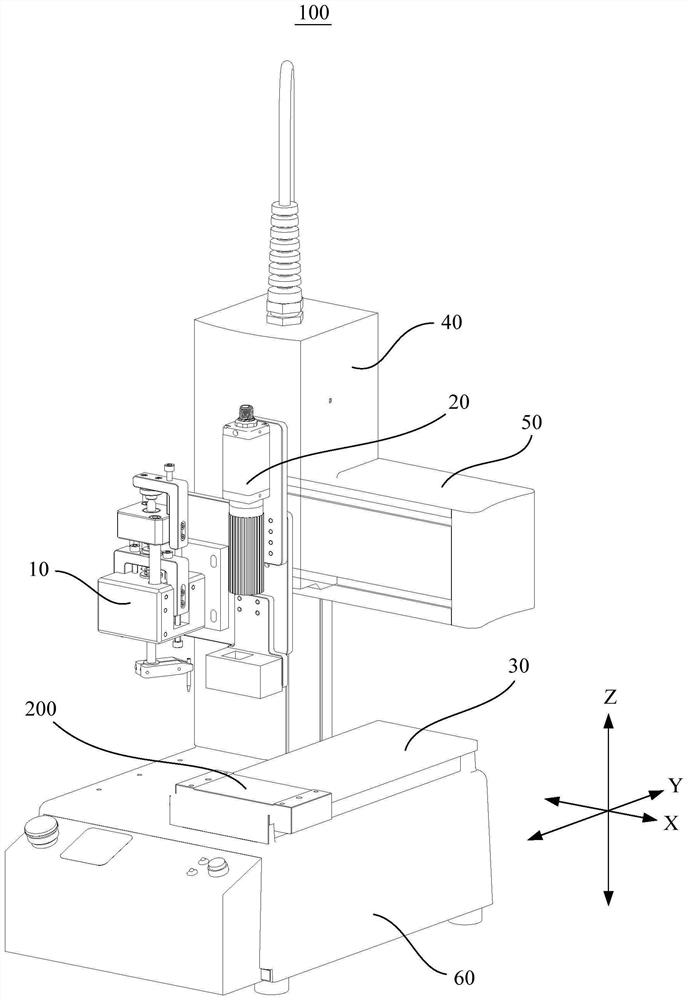

Gantry-type automatic spot welding system for battery pack

ActiveCN102554437BImprove adaptabilityReduce labor intensityResistance welding apparatusProgrammable logic controllerEngineering

The invention provides a gantry-type automatic spot welding system for a battery pack, which comprises a spot welding device and a spot welding jig fixing device which are vertically arranged and are connected with a PLC (programmable logic controller) of the system. The spot welding device comprises a beam, a group of opposite vertical columns in parallel, a spot welding mechanism, an X-axis sliding table, a Y-axis movement mechanism and an X-axis movement mechanism, wherein the vertical columns are used for adjusting the height of the beam, the X-axis sliding table is used for fixing the spot welding mechanism, the Y-axis movement mechanism enables the spot welding mechanism to transversely move, and the X-axis movement mechanism enables the X-axis sliding table to transversely move. The spot welding jig fixing device comprises a spot welding jig platen and a clamping mechanism for clamping a spot welding jig, wherein the clamping mechanism is arranged on the spot welding jig platen and is perpendicular to the spot welding mechanism. By the aid of a gantry-type structure, clamping is performed once, cells are numerous, spot welding parameters are controllable, and the system is fast in running speed, high in spot welding efficiency, highly adaptable to the cells, accurate in positioning and fine in spot welding quality.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Automatic spot welding working platform for clamping piece nuts

ActiveCN112475575AAutomate replenishmentRealize automatic processingResistance welding apparatusEngineeringSpot welding

The invention discloses an automatic spot welding working platform for clamping piece nuts. The automatic spot welding working platform comprises a feeding assembly, a clamping piece pushing-in assembly, a nut pushing-in assembly, a spot welding assembly and a pushing assembly, wherein the clamping piece pushing-in assembly and the nut pushing-in assembly are arranged on the same straight line andconnected with the feeding assembly at the same time, the spot welding assembly is arranged above the center of the connecting line of the clamping piece pushing-in assembly and the nut pushing-in assembly, the pushing assembly is arranged above the connecting line of the clamping piece pushing-in assembly and the nut pushing-in assembly; a clamping piece pushing air cylinder drives a clamping piece pushing block to push clamping pieces fed into a clamping piece guide groove by the feeding assembly to the position below the spot welding assembly, and a nut pushing air cylinder drives a nut pushing block to push nuts fed into a nut guide groove by the feeding assembly to the position below the spot welding assembly to be subjected to spot welding with the clamping pieces. According to theautomatic spot welding working platform, the clamping pieces and the nuts can be automatically supplemented, automatic spot welding of the clamping pieces and the nuts can be achieved, the spot welding strength of the clamping piece nuts after spot welding is high, the spot welding quality is good, and the rejection rate is low.

Owner:四川省彭山宏源机电科技开发有限公司

Spot welding equipment for machining metallic material and with monitoring function

InactiveCN107363378AMoves smoothly back and forthStable and reliable speed controlWelding protection meansCcd cameraManipulator

The invention discloses spot welding equipment for machining a metallic material and with a monitoring function, and relates to the technical field of automatic equipment. A first automatic clamping mechanism slides back and forth on a first guide rail through a first sliding rod arranged at the bottom. A second automatic clamping mechanism slides back and forth on a second guide rail through a second sliding rod arranged at the bottom. A sealing mechanism is arranged in the center of a machine body, and the left side and the right side of the sealing mechanism are provided with through holes. An electric control panel and a spot welding manipulator are arranged at the two ends of the machine body correspondingly. The machine body is connected with a displayer through a telescopic rod. An automatic warning device is arranged at the top of the displayer. CCD cameras connected with the displayer are arranged on the surfaces of the parts, on the two sides of the spot welding manipulator, of the machine body. Through the spot welding equipment, the spot welding efficiency and quality of metallic workpieces are greatly improved, harm of arc light and smoke to operators is reduced, the equipment is safe and environmentally friendly, operators can operate the equipment easily, working noise is low, and long-time efficient and stable spot welding operation is ensured.

Owner:SUZHOU CONYET AUTOMATION TECH

Spot-welder head and spot-welding device

InactiveCN111745335AAccurate spot weldingPressure real-time detectionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a spot-welder head and a spot-welding device applying the spot-welder head. The spot-welder head comprises a pedestal, a slide bar, a spot-welding head, a pressure sensor and atransmission mechanism, wherein the pedestal is provided with a first mounting part and a second mounting part, and the first mounting part is provided with a first mounting hole; the slide bar penetrates the first mounting hole and can move in a reciprocating manner along the axis direction of the first mounting hole; the spot-welding head is connected to the end part of the slide bar and is located below the first mounting part; the pressure sensor is mounted on the second mounting part; the transmission mechanism is located between the first mounting part and the second mounting part, theend part, deviated from the spot-welding head, of the slide bar is connected to the transmission mechanism, the transmission mechanism is stopped by the first mounting part, and the end, deviated fromthe slide bar, of the transmission mechanism is in contact with the pressure sensor, and the transmission mechanism is in elastic contact with the pressure sensor; and the center lines of the slide bar, the pressure sensor and the transmission mechanism are located on a same straight line. According to the technical scheme, the spot-welding efficiency can be improved and the rate of finished products is improved.

Owner:GEER TECH CO LTD

Working method of high-efficiency spot welding equipment for metal material machining

InactiveCN107234374AEnsure health and safetyShorten the timeWelding/cutting auxillary devicesAuxillary welding devicesMaterials processingSpot welding

The invention discloses a working method of high-efficiency spot welding equipment for metal material processing, and relates to the technical field of automation equipment; At the same time, the second automatic clamping mechanism starts to slide on the second guide rail through the second slide bar after clamping the workpiece to be processed; after the spot welding is completed, the first automatic clamping mechanism starts to slide downward, and the second automatic clamping mechanism The clamping mechanism starts to slide upwards, and when the second automatic clamping mechanism slides to the top, the spot welding manipulator moves to the right to start welding the workpiece to be processed, and at the same time, the first automatic clamping mechanism performs discharging work; the working method of the present invention It greatly improves the spot welding efficiency and quality of metal workpieces, reduces the damage to the staff caused by arc light and smoke, and ensures that the spot welding work can be carried out efficiently and stably for a long time.

Owner:太仓市华天冲压五金制品厂

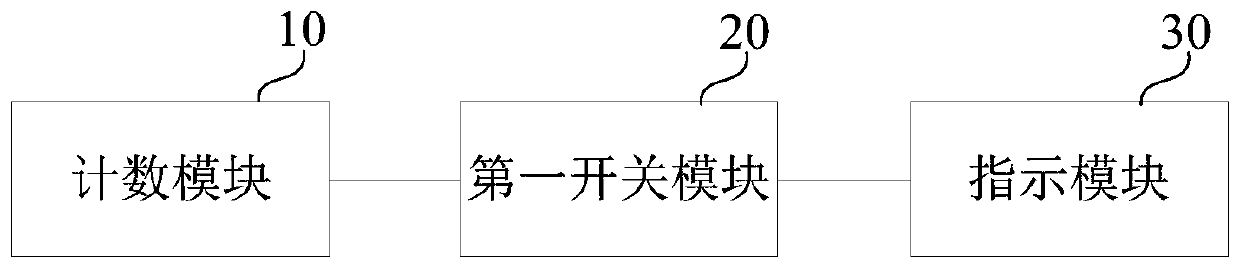

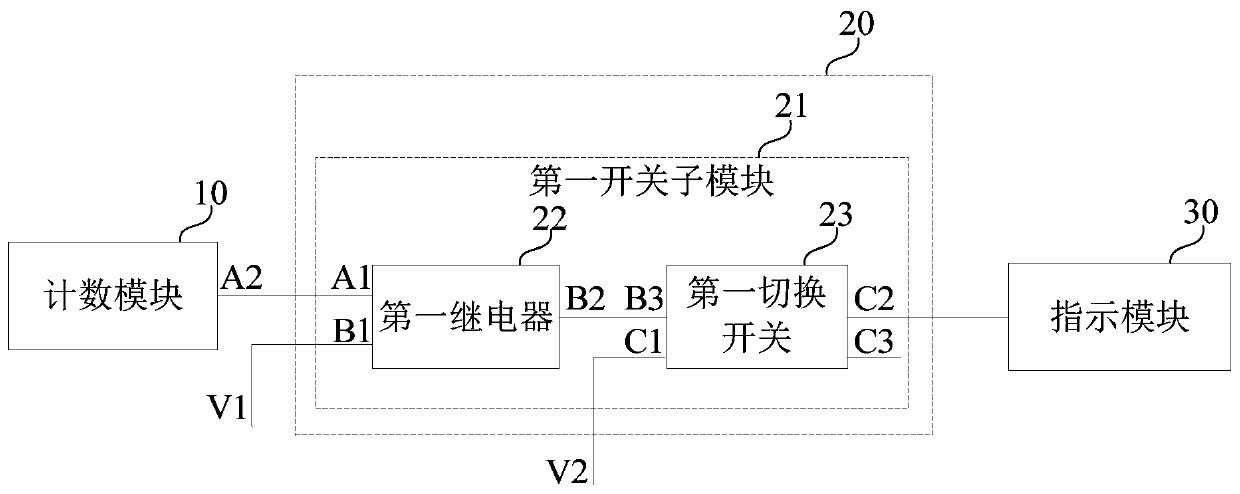

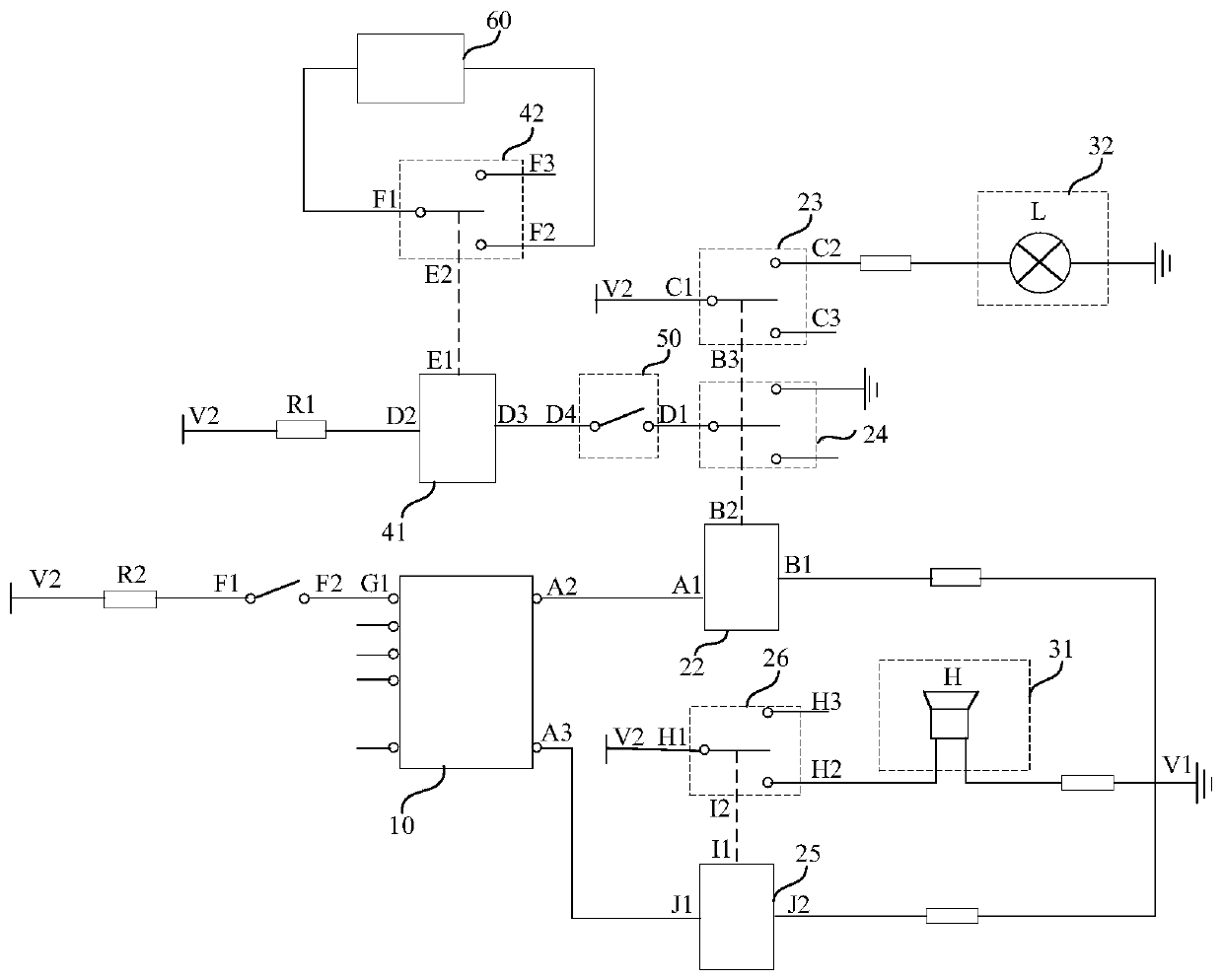

Spot welder monitoring system and spot welding equipment

PendingCN110614466AImprove reliabilityImprove spot welding qualityWelding/cutting auxillary devicesAuxillary welding devicesControl signalMonitoring system

An embodiment of the present invention discloses a spot welder monitoring system and spot welding equipment. The system includes a counting module, wherein the counting module is used for monitoring the spot welding number of at least one spot welder and generating monitoring signals of the corresponding spot welder; a first switch module for adjusting output indication control signals according to received corresponding monitoring signals; and at least one indication module for adjusting its own indication state according to received corresponding indication control signals. The spot welder monitoring system and the spot welding equipment provided by the embodiment of the present invention are beneficial to effectively improve the spot welding quality and spot welding reliability of the spot welder.

Owner:GREE ELECTRICAL APPLIANCE WUHU +1

Efficiency workpiece point welding machine

InactiveCN109551093APlay a buffer rolePlay a guiding roleResistance welding apparatusEngineeringMechanical engineering

The invention discloses an efficiency workpiece point welding machine. The efficiency workpiece point welding machine comprises a u-shaped bracket. A transverse sliding rail is fixedly mounted on theinner side of the upper end of the u-shaped bracket. A first sliding block is mounted in the transverse sliding rail. The first sliding block is mounted at the upper end of a longitudinal sliding rail. A second sliding block is mounted in the longitudinal sliding rail. A welding head mounting seat is mounted on the second sliding block. A welding head is mounted below the welding head mounting seat. Two sets of buffer springs are arranged between the upper end of the welding head and the lower end of the welding head mounting seat. A guide assembly is mounted between the two sets of buffer springs. A workpiece placing mechanism is mounted on the inner side of the u-shaped bracket. The physical design is novel. A workpiece can be welded transversely and longitudinally. The workpiece placingmechanism is arranged to clamp workpieces of different sizes. It is unnecessary to replace the whole placing mechanism, and therefore the point welding efficiency can be improved.

Owner:马鞍山迪斯福工业设计有限公司

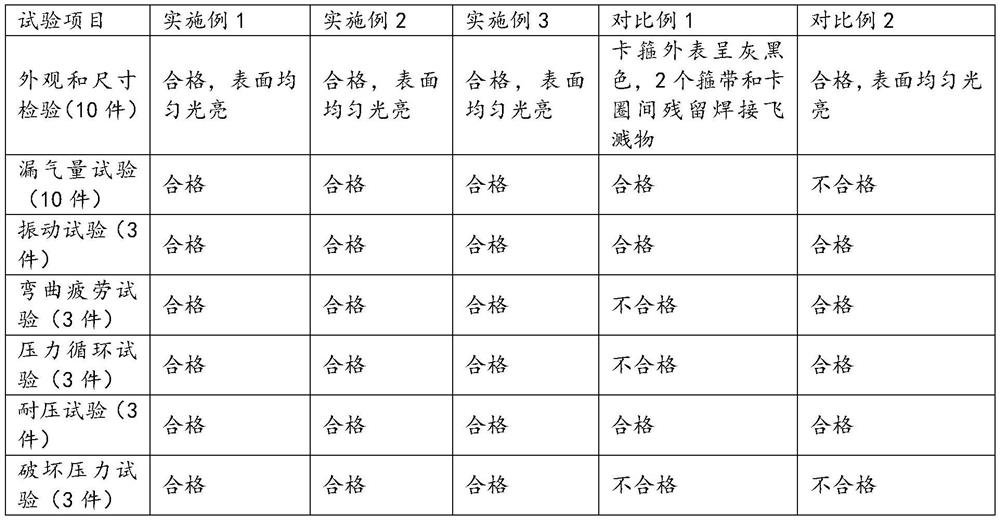

Machining method of aviation V-shaped groove hoop

The invention relates to a machining method of an aviation V-shaped groove hoop. The machining method comprises the following steps that a strap and a clamping ring are machined; the machining processof the strap and the clamping ring comprises the steps that a steel belt is punched and formed after being cut into strips, then vacuum heat treatment is conducted, and finally magnetic polishing isconducted; a bolt, a sleeve pipe, a gasket and a nut are machined; and the machined strap, clamping ring, bolt, sleeve pipe, gasket and nut are assembled, and spot welding is adopted for connection ofthe strap and the clamping ring. Compared with a common machining method of an aviation V-shaped groove hoop, the method combining vacuum heat treatment and magnetic polishing is adopted, residual stress generated in the forming process of the strap and the clamping ring can be effectively eliminated, oxidation films on the surface of the strap and the surface of the clamping ring are removed, the quality defects of large basic resistance of subsequent spot welding, serious splashing of a molten pool and the like caused by the oxidation films on the surfaces are overcome, the spot welding quality is improved, and then the reliability of the V-shaped hoop is improved.

Owner:湖北超卓航空技术有限公司

Welding equipment

PendingCN114789311AImprove spot welding qualityImprove production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention provides welding equipment which comprises a rack, a material supply assembly, a feeding assembly, a welding platform, a material moving and welding assembly and a discharging assembly, and the material moving and welding assembly comprises a supporting frame, a material moving module and two welding units. Double spot welding of pre-spot welding and spot welding can be achieved through the two welding units, and the spot welding quality is high; a second to-be-welded part can be automatically transferred to the welding platform through the feeding assembly; the material moving and welding assembly can automatically transfer the first to-be-welded part conveyed by the material supply assembly to the second to-be-welded part on the welding platform and can fixedly weld the first to-be-welded part and the second to-be-welded part. The discharging assembly can automatically transfer the welded parts on the welding platform to the next station after welding is completed. Therefore, automatic feeding of the second to-be-welded part can be achieved through the feeding assembly, automatic discharging of the weldment can be achieved through the discharging assembly, and the welding equipment is beneficial to improving the preparation efficiency of the weldment and reducing the labor cost through integrated design.

Owner:北科(深圳)机电科技有限公司

Spot welding system

ActiveCN105458447ARapid positioningSolve deviationHeat exchange apparatusMetal working apparatusEngineeringSpot welding

The invention discloses a spot welding system, and belongs to the field of machining devices of coolers. According to the spot welding system, a spot welding platform board is ingeniously designed, a sliding supporting mechanism is designed on the spot welding platform board, and meanwhile, a flange tool clamp for stacking flanges is designed and mounted on the supporting mechanism, so that the problems that in the prior art, when spot welding work is done, repeated manual flange stacking and chip cooling are needed, and therefore wrong placing and leaked placing are prone to happening are solved. Furthermore, correctness of spot welding is ensured, the clamping procedure is simplified, and the spot welding efficiency and the spot welding quality are improved.

Owner:JIANGSU PEACE POWER MACHINERY

Spot welding device

PendingCN112676687AImprove spot welding qualityReduce manual operationsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention provides a spot welding device. The spot welding device comprises a feeding mechanism, a conveying mechanism, a spot welding mechanism and a discharging mechanism. The feeding mechanism, the spot welding mechanism and the discharging mechanism are arranged on the periphery of the conveying mechanism in the rotating direction of the conveying mechanism in sequence; and the conveying mechanism comprises a lifting structure, a rotating disc and a soldering terminal clamp on the rotating disc. The lifting structure is fixedly arranged on the inner side of the rotating disc; the lifting structure comprises a bottom plate and a rail which is arranged on the bottom plate; and the rotating disc rotates around the bottom plate. The soldering terminal clamp comprises a first clamp body and a second clamp body which cooperate with each other; the first clamp body is installed on the side, close to the outer edge, on the rotating disc; the second clamp body is installed on the side, close to the inner edge, on the rotating disc; and the second clamp body moves up and down along the rail so as to be used for opening and closing between the second clamp body and the first clamp body. By means of the spot welding device, a lot of manual operation is reduced, the production efficiency is improved, the spot welding quality is greatly improved.

Owner:YICHANG LIJIA TECH

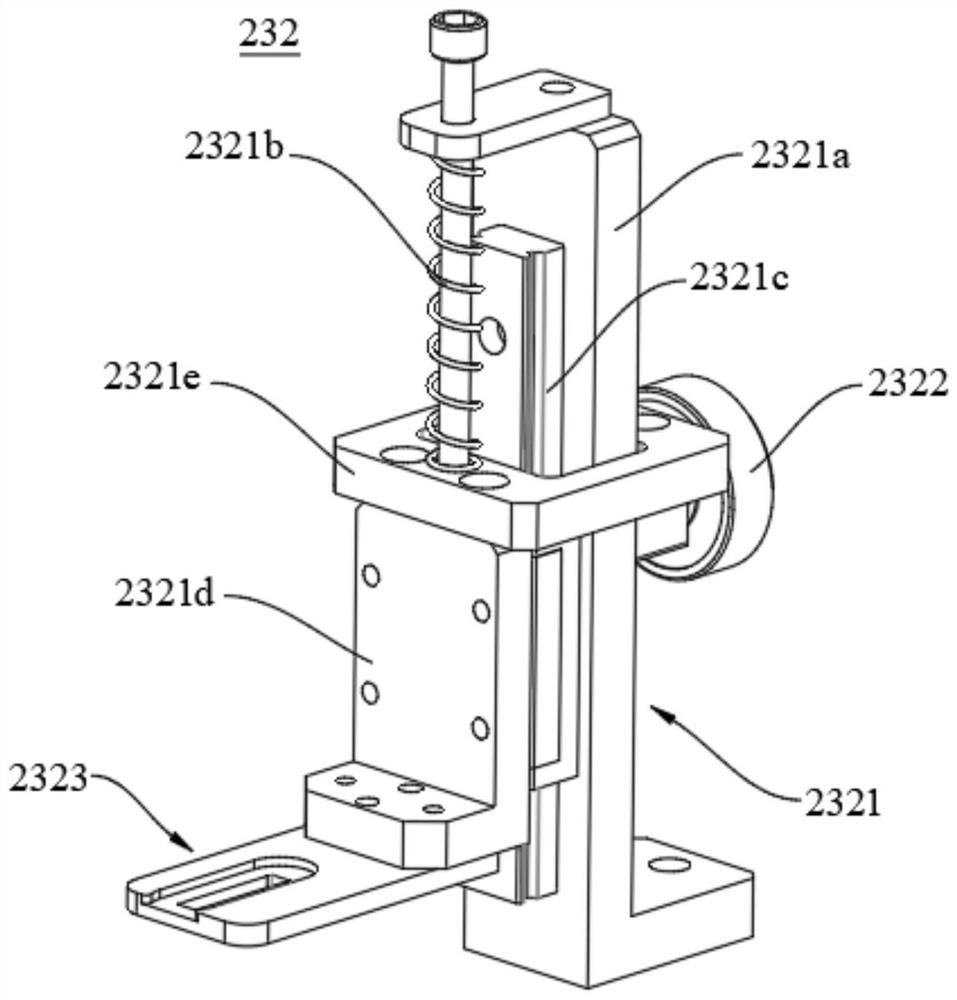

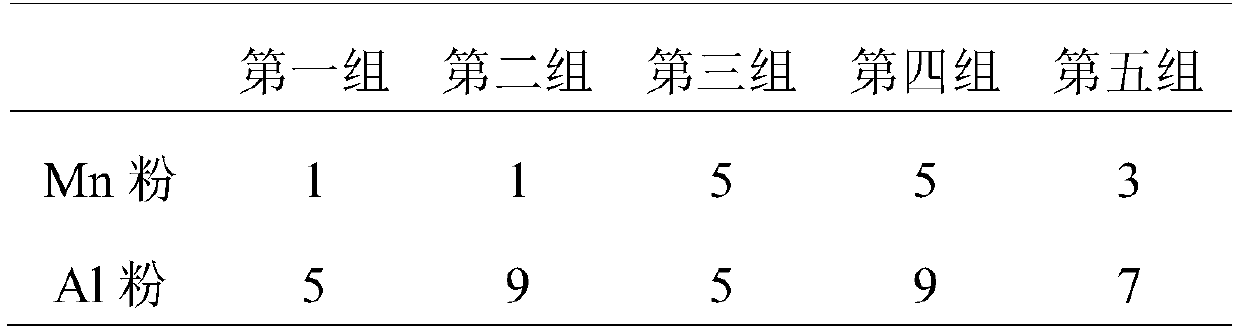

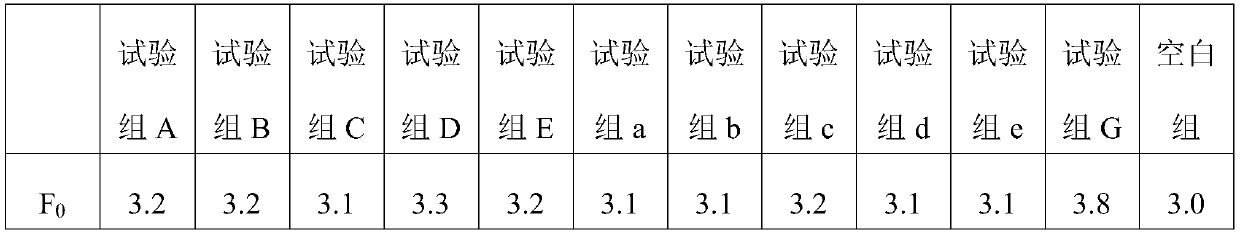

Microalloying improves the quality of mg-fe spot welding of dissimilar metals

ActiveCN107138841BIncrease nugget sizeImprove shear resistanceResistance welding apparatusAlloyViscosity

The invention discloses a technology for improving the dissimilar metal Mg-Fe spot welding quality through microalloying. The technology comprises the steps that firstly, Mn powder, Al powder and a volatile solvent serve as raw materials to prepare an alloy pulp cluster; secondly, when the alloy pulp cluster has proper viscosity, the alloy pulp cluster is scraped to the lap joint connector position of a to-be-welded Mg material and a to-be-welded Fe material, and accordingly the to-be-welded materials are subjected to pretreatment; and thirdly, a lap joint connector of the Mg material and the Fe material is subjected to spot welding. Adoption of the technology for improving the dissimilar metal Mg-Fe spot welding quality through microalloying has the obvious beneficial effects that the size of molten cores between the dissimilar metal Mg and Fe after spot welding is increased, distribution of the molten cores between Mg and Fe is uniform and symmetric, the anti-shearing performance between the dissimilar metal Mg and Fe after spot welding is obviously improved, and the spot welding quality between the dissimilar metal Mg and Fe is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com