Automatic spot welding device for car body board

An automatic spot welding and sheet metal technology, applied in auxiliary devices, vehicle parts, welding equipment, etc., can solve the problems of large structure, complexity of welding tooling, and difficult to guarantee the quality of appearance in batches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

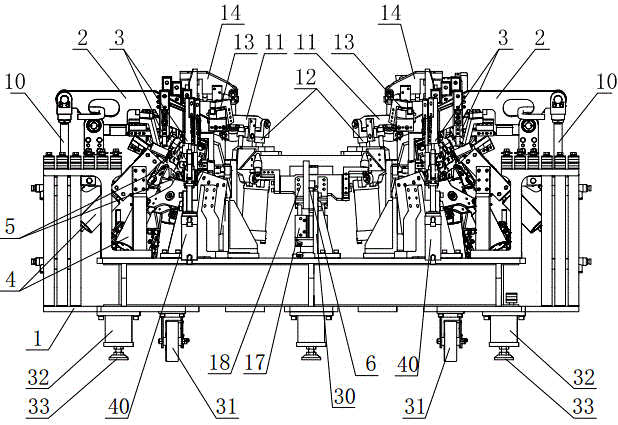

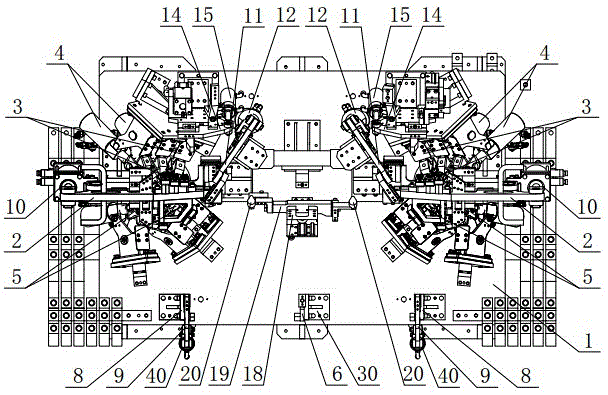

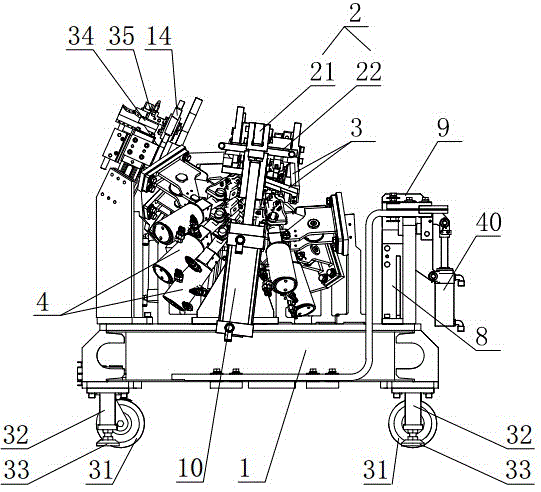

[0020] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides an embodiment of an automatic spot welding device for vehicle body panels. This embodiment is used for spot welding of car door panels. It includes a support frame 1, and the bottom of the support frame 1 is equipped with walking wheels 31. The bottom of support frame 1 is also equipped with the parking cylinder 32 that piston rod is arranged downwards, and the downward extension end of the piston rod of parking cylinder 32 is equipped with parking seat 33, and the front portion of support frame 1 is equipped with plate front end positioning mechanism and The clamping mechanism at the front part of the plate, the rear part of the support frame 1 is equipped with a side positioning rear clamping mechanism which is oppositely arranged and respectively carries out width positioning on both sides of the plate, that is to say, the side positioning rear clamping mechanism can The two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com