Spot welding system

A spot welding and plane technology, applied in welding equipment, gas flame welding equipment, applications, etc., can solve the problems of manual stacking of flanges and cooling chips, easy misplacement and leakage, etc., to improve spot welding efficiency and Spot welding quality, ensuring correctness, and overcoming the effect of easy misplacement and omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

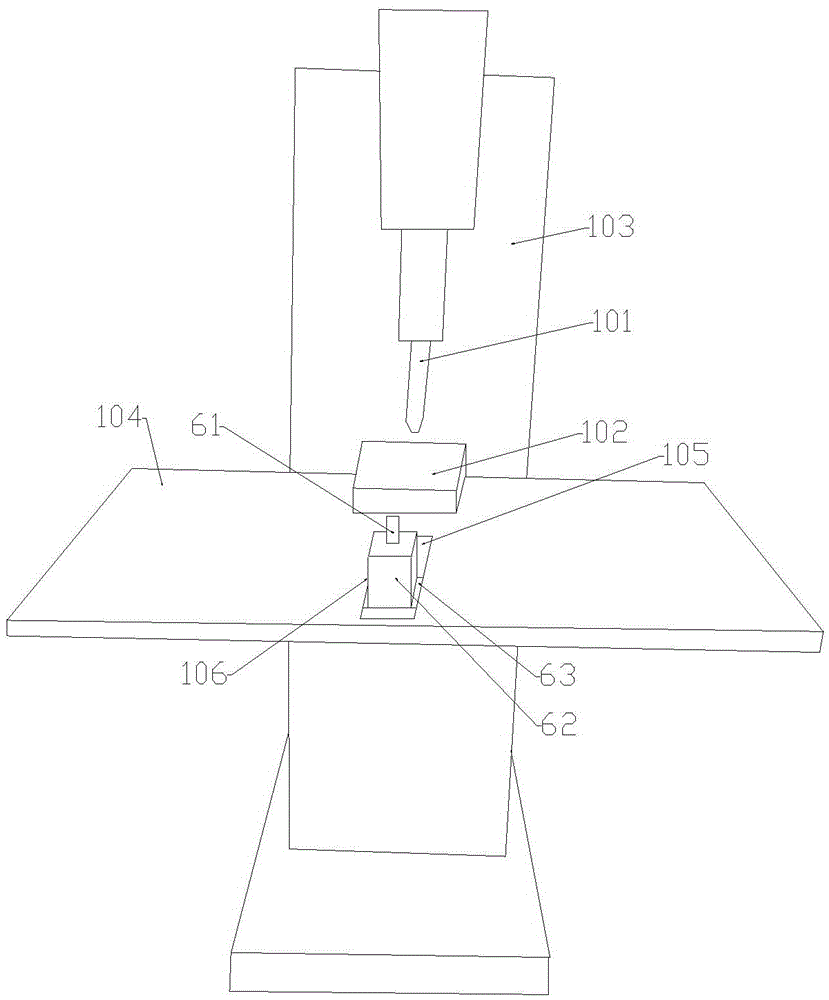

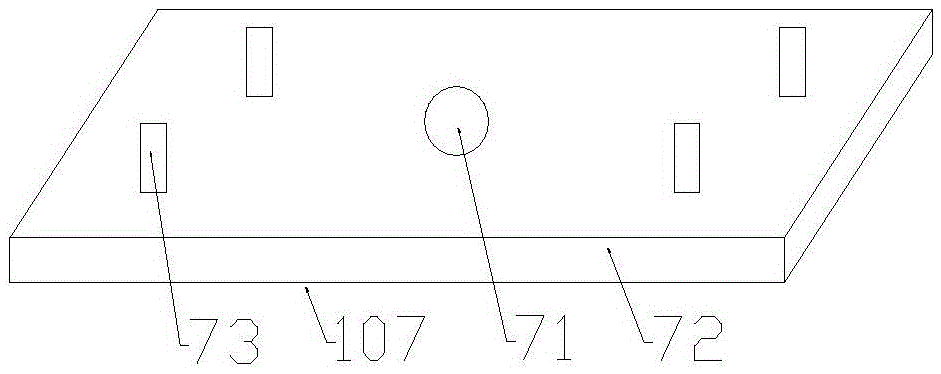

[0021] figure 1 It is a partial structural schematic diagram of the spot welding system provided by Embodiment 1 of the present invention; figure 2 It is a structural schematic diagram of the flange fixture in the spot welding system provided by Embodiment 1 of the present invention; as shown in the figure, the spot welding system provided by Embodiment 1 of the present invention includes: a spot welding head 101 and a spot welding base 102 Spot welding machine body 103, spot welding platform plate 104 is fixed on the spot welding machine body 103, is provided with chute 105 on the spot welding platform plate 104, is provided with the supporting mechanism 106 that is used to place flange tool fixture on the chute 105, supports The supporting rod 61 of the mechanism 106 is provided with a flange fixture 107, and the flange fixture 107 includes a flange fixture plate 72 with a through hole 71 in the middle and a flange fixed on the flange fixture plate 72. Lan positioning rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com