Machining method of aviation V-shaped groove hoop

A processing method and V-groove technology, applied in the processing field of clamps, to achieve the effect of overcoming large resistance, eliminating residual stress and improving spot welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

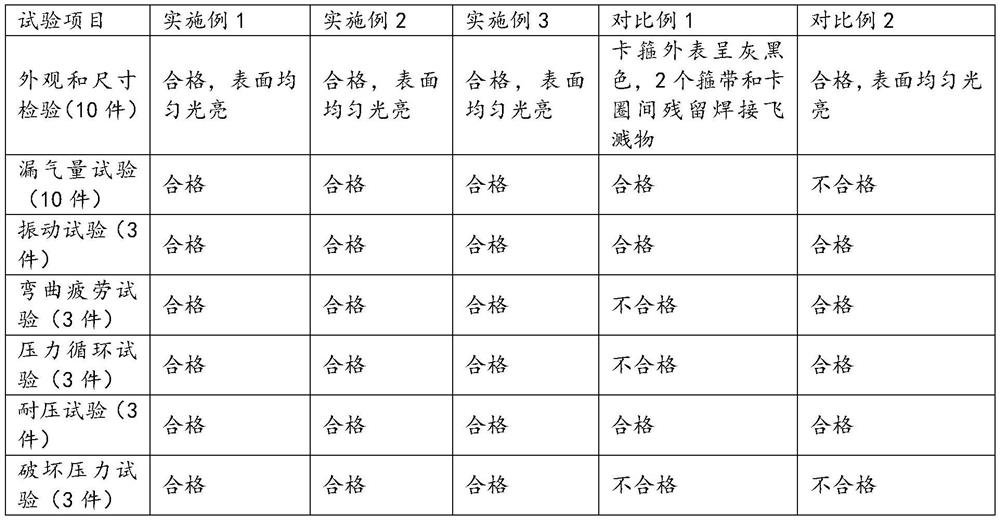

Examples

Embodiment 1

[0025] This embodiment provides an aviation V-groove clamp processing method, including the following steps:

[0026] S1, processing bands and collars;

[0027] The processing process of the hoop and collar is to cut the steel strip into strips, stamp it into shape, then carry out vacuum heat treatment, and finally carry out magnetic polishing;

[0028] Vacuum heat treatment process: in a vacuum heat treatment furnace, the temperature is raised to 900°C at a rate of 80°C / h, kept for 40min, and the vacuum coefficient is 6x10 -5 Pa; furnace-cooled to 720°C and held for 8 hours, then furnace-cooled to 580°C at a rate of 120°C / h and held for 20 hours, then furnace-cooled to 350°C, and then quickly cooled to room temperature with nitrogen gas.

[0029] The magnetic polishing process parameters are: the diameter of the magnetic needle is 0.2mm, the length of the magnetic needle is 2mm, the weight ratio of the magnetic needle to the band or collar is 1:1; the amount of polishing liq...

Embodiment 2

[0033] This embodiment provides an aviation V-groove clamp processing method, including the following steps:

[0034] S1, processing bands and collars;

[0035] The processing process of the hoop and collar is to cut the steel strip into strips, stamp it into shape, then carry out vacuum heat treatment, and finally carry out magnetic polishing;

[0036] Vacuum heat treatment process: in a vacuum heat treatment furnace, the temperature is raised to 900°C at a rate of 80°C / h, kept for 40min, and the vacuum coefficient is 6x10 -5 Pa; furnace-cooled to 720°C and held for 8 hours, then furnace-cooled to 580°C at a rate of 120°C / h and held for 20 hours, then furnace-cooled to 350°C, and then quickly cooled to room temperature with nitrogen gas.

[0037] The magnetic polishing process parameters are as follows: the diameter of the magnetic needle is 0.4mm, the length of the magnetic needle is 4mm, the weight ratio of the magnetic needle to the band or collar is 2:1; the amount of po...

Embodiment 3

[0041] This embodiment provides an aviation V-groove clamp processing method, including the following steps:

[0042] S1, processing bands and collars;

[0043] The processing process of the hoop and collar is to cut the steel strip into strips, stamp it into shape, then carry out vacuum heat treatment, and finally carry out magnetic polishing;

[0044] Vacuum heat treatment process: in a vacuum heat treatment furnace, the temperature is raised to 900°C at a rate of 80°C / h, kept for 40min, and the vacuum coefficient is 6x10 -5 Pa; furnace-cooled to 720°C and held for 8 hours, then furnace-cooled to 580°C at a rate of 120°C / h and held for 20 hours, then furnace-cooled to 350°C, and then quickly cooled to room temperature with nitrogen gas.

[0045] The magnetic polishing process parameters are: the diameter of the magnetic needle is 0.6 mm, the length of the magnetic needle is 3 mm, the weight ratio of the magnetic needle to the band or collar is 3:1; the amount of polishing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com