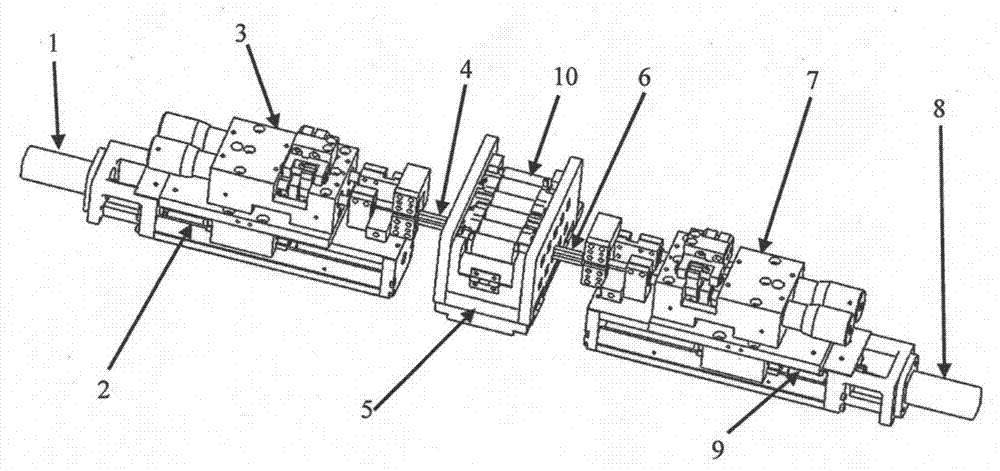

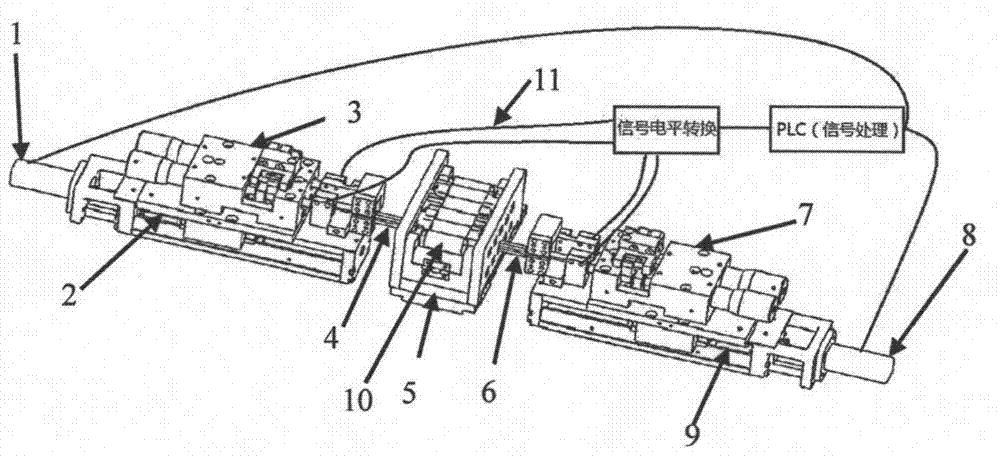

Double-sided automatic spot welding machine control device and method

A control device and automatic spot welding technology, which is applied in the direction of welding power supply, manufacturing tools, welding equipment, etc., can solve problems affecting spot welding quality, cell movement, and compacting cells, so as to improve spot welding efficiency and prevent misalignment , Improve the effect of spot welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

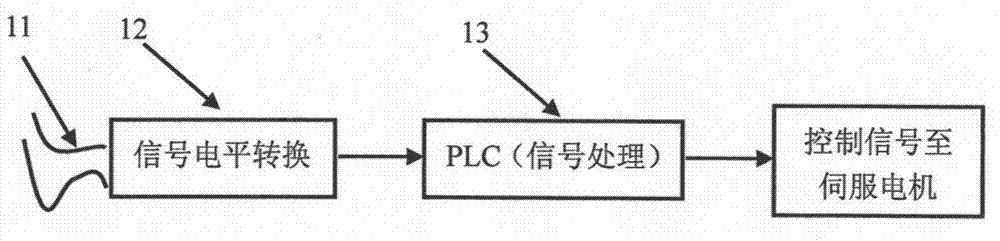

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0020] The movement of the cell and the dislocation of the nickel sheet are due to the different distances between the surface of the electrode holders on both sides and the surface of the cell. When the motor speed is the same, the time to reach the surface of the cell is different. Controlling the motor speed so that the electrode rods reach the motor at the same time requires many trials and is imprecise. The control mode of the automatic spot welding machine is position control mode, spot welding position, standby position, etc., so set a position that touches the surface of the cell, and before reaching the spot welding position, the two electrode rods can reach the surface of the cell at the same time . After the electrode rods on both sides are in contact with the battery cell, and then press the battery cell, the battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com