Patents

Literature

39results about How to "Reduce defective welding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

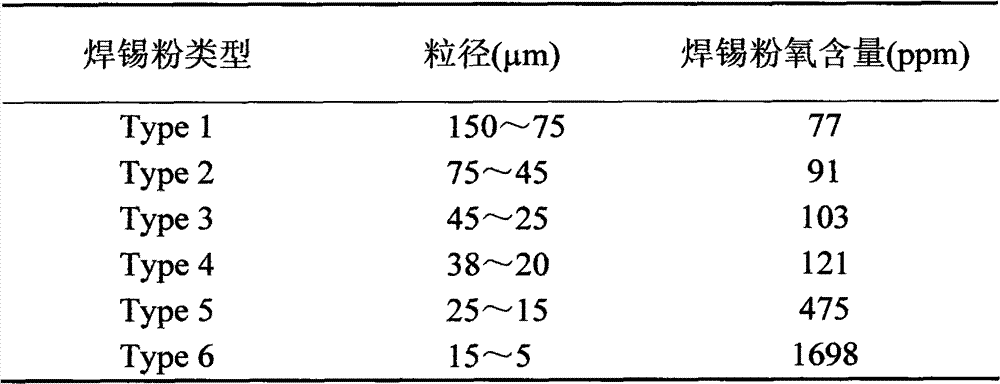

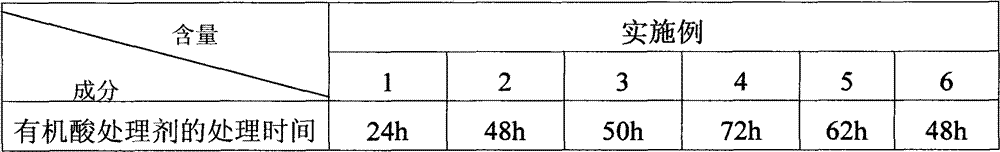

Surface treatment method for protecting superfine raw solder powder, and superfine powder solder paste prepared according to method

ActiveCN102785038AImprove qualityReduce defective welding rateWelding/cutting media/materialsSoldering mediaOrganic acidSurface finishing

The invention provides a surface treatment method for protecting superfine raw solder powder, a superfine powder solder paste prepared according to the method, and a preparation technology of the solder paste, and belongs to the technical field of welding materials. The surface treatment method comprises the following steps: a), preparing superfine raw solder powder; b), adopting an organic acid treating agent to treat oxide on the surface of superfine raw solder powder till the oxygen content of the superfine raw solder powder is lower than 150 ppm, so as to obtain a semi-finished product A;c), further treating the semi-finished product A with an anti-oxidant treating agent till a complex compound film is generated on the surface of the semi-finished product A, so as to obtain a semi-finished product B; and d), placing the semi-finished product B into a 30 to 40 DEG C oven for drying, and charging nitrogen during packing, so as to obtain the superfine solder powder. The superfine solder powder is compounded with scaling powder to form the superfine powder solder paste. According to the invention, the technical defects of more tin beads, poor wettability, narrow PCB printing interval, and high welding defective rate of the superfine powder solder paste in the prior art are overcome.

Owner:DONGGUAN YONGAN TECH

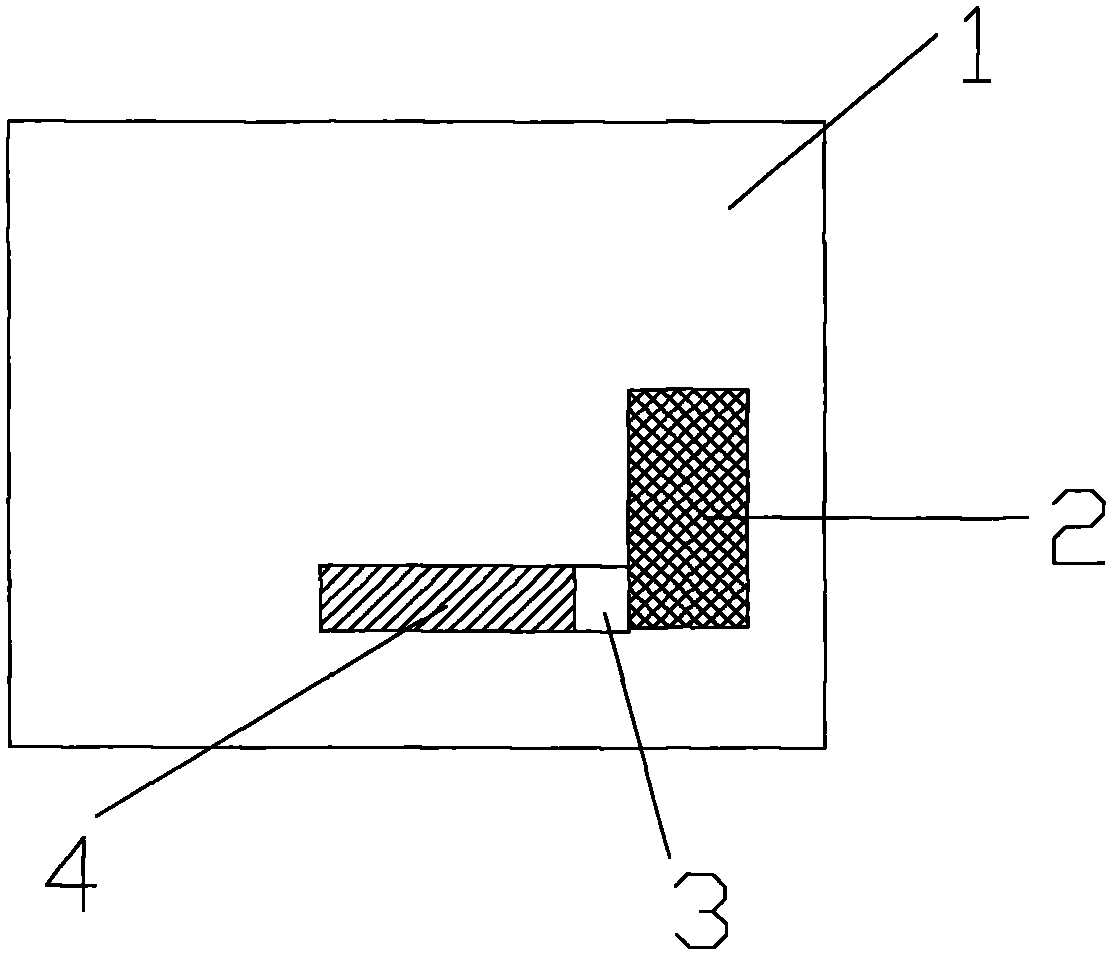

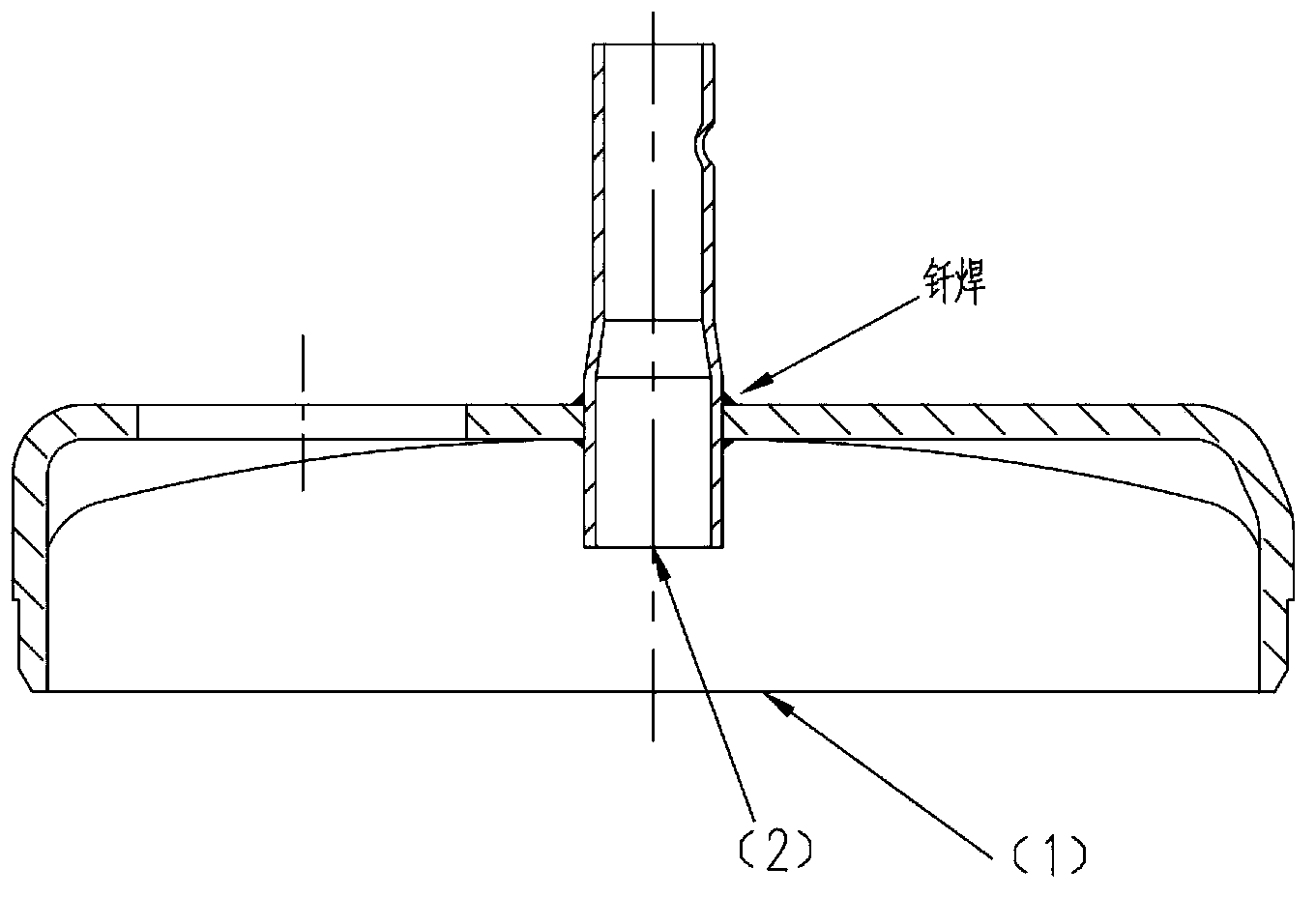

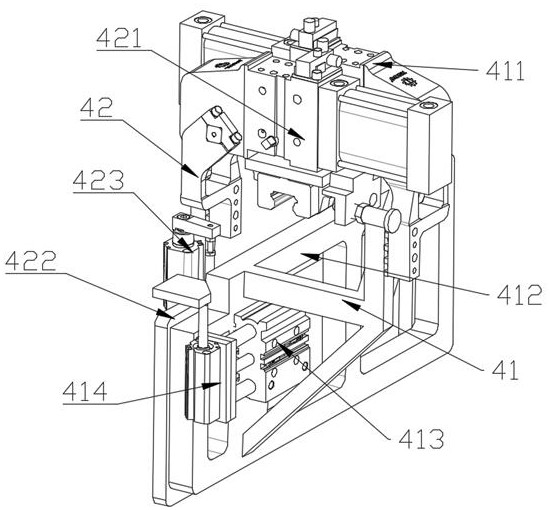

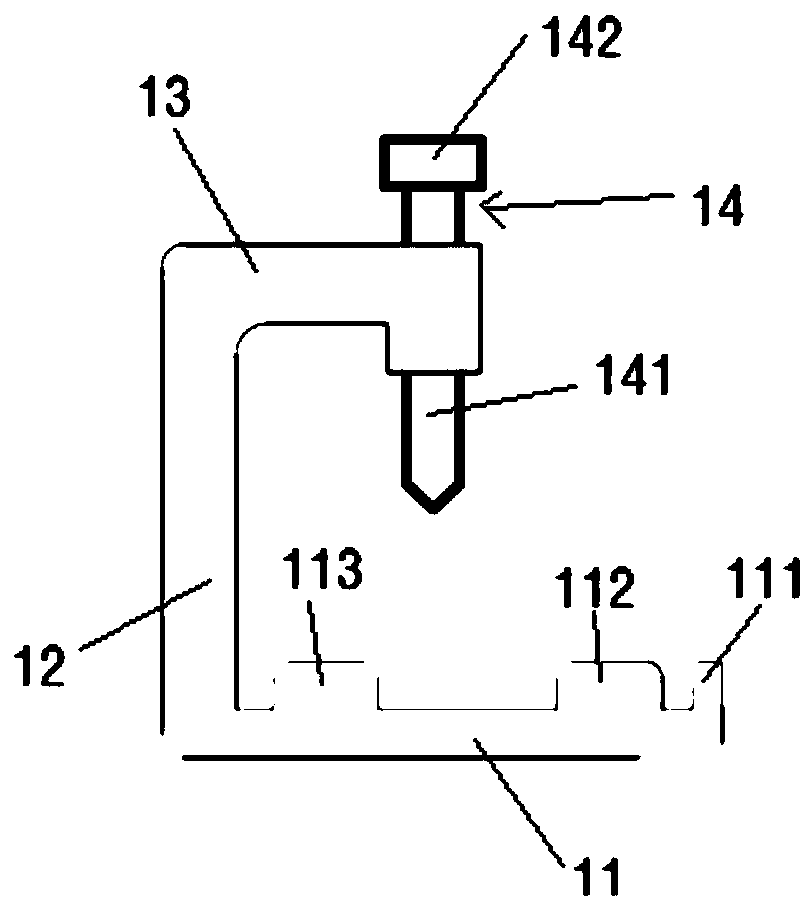

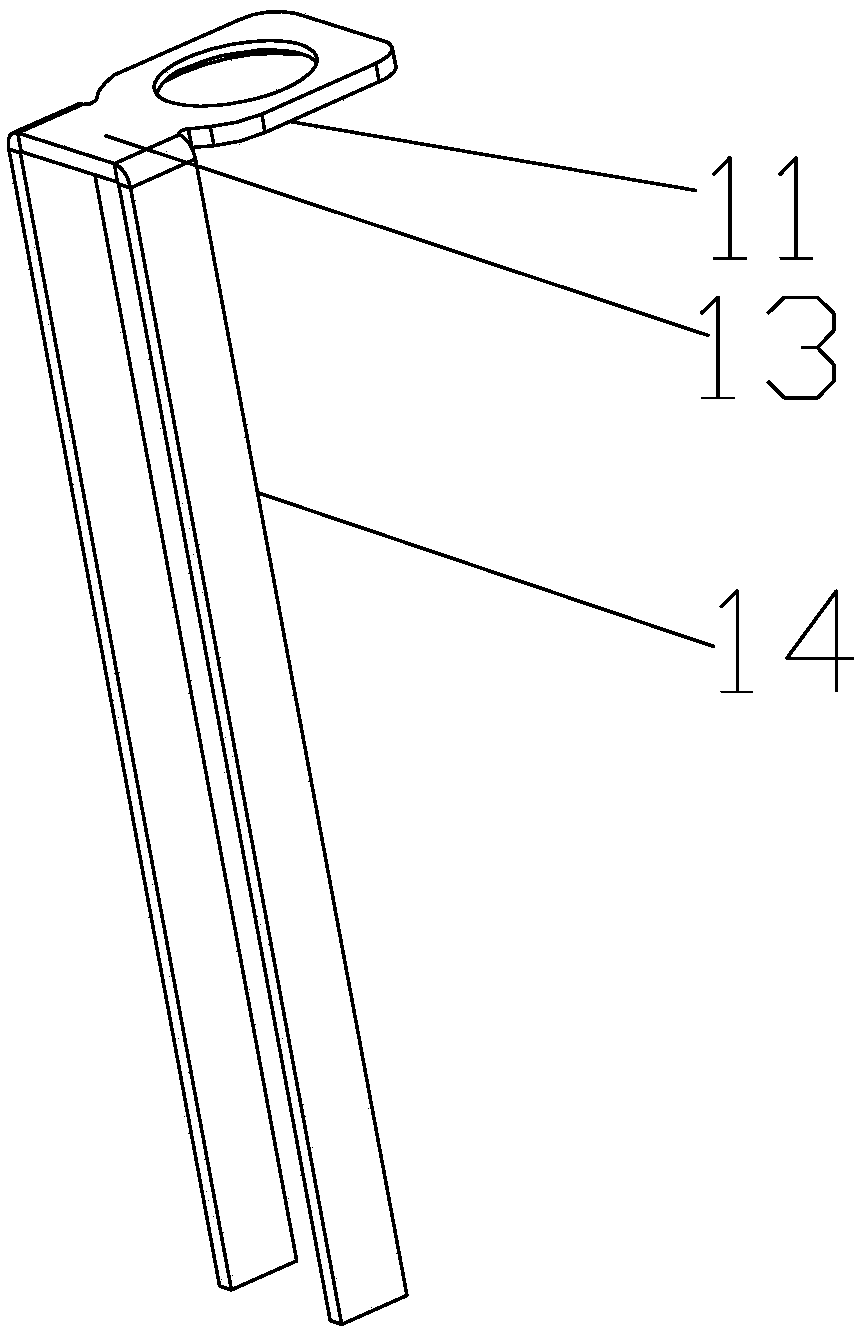

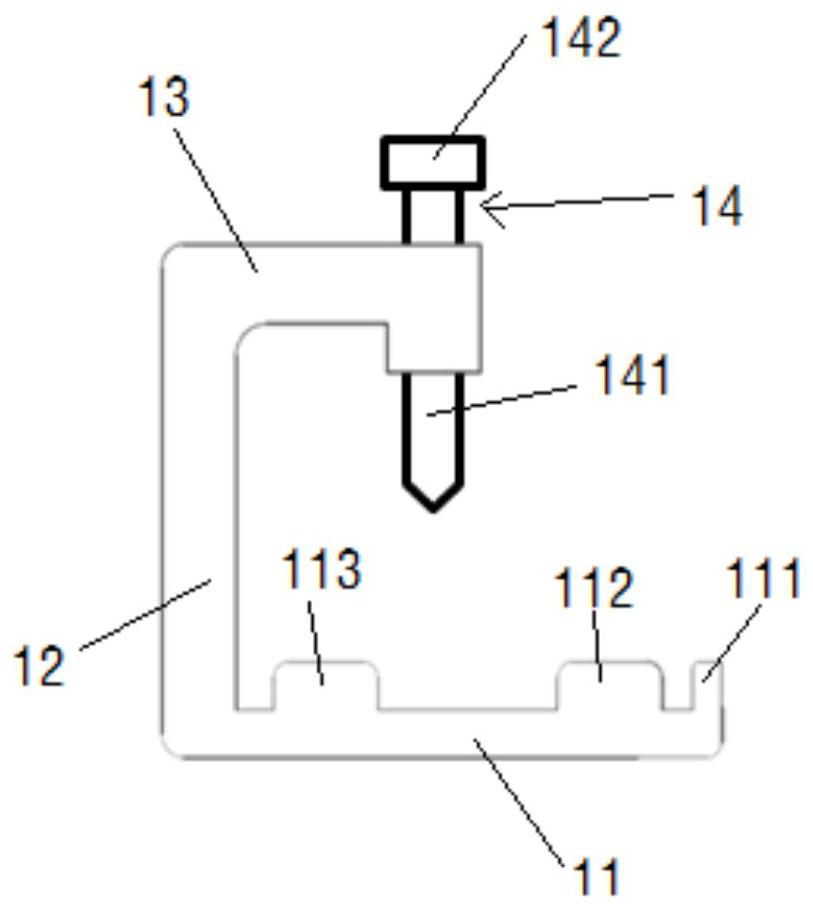

Spot soldering fixture and spot soldering process

InactiveCN102581458APrecise positioningHeight adjustableResistance welding apparatusEngineeringSoldering process

The invention belongs to the technical field of soldering, and particularly relates to a spot soldering fixture, which is used in a spot soldering process capable of avoiding pseudo soldering, false soldering and bursting, and is high in soldering efficiency. The spot soldering fixture comprises a fixture body, a cell storage area and a fuse storage area, and an avoidance hole is reserved between the cell storage area and the fuse storage area. Compared with the prior art, the spot soldering fixture has the advantages that a fuse and a metal strap can be effectively positioned, the height of a soldering pin can be adjusted, spot soldering quality can be improved, soldering reject ratio can be decreased, production efficiency can be improved, and cost can be saved. Besides, the invention further discloses the spot soldering process using the spot soldering fixture.

Owner:DONGGUAN NVT TECH

Combined lithium battery tab kneading method

InactiveCN110718665AReduce defective welding rateMake up for unevennessCell component detailsEngineeringMechanical engineering

The invention relates to a combined lithium battery tab kneading method, which comprises the following steps: a positive conductive tab is ultrasonically kneaded to a fixed depth, and a negative conductive tab is not kneaded; the positive conductive tab subjected to ultrasonic kneading is mechanically leveled to a depth required by the process, and the negative conductive tab is not leveled; the negative conductive tab is ultrasonically kneaded to a certain depth; and the negative conductive tab subjected to ultrasonic kneading is mechanically leveled to a depth required by the process. According to the invention, the lithium battery tabs are kneaded in a combined manner through ultrasonic kneading and then mechanical leveling, so that the situation in which the end faces of the battery tabs are uneven due to the adoption of ultrasonic kneading only is avoided, the flatness of the end faces of the battery tabs is improved, and the welding reject ratio of the lithium battery tabs is reduced.

Owner:国轩新能源(庐江)有限公司

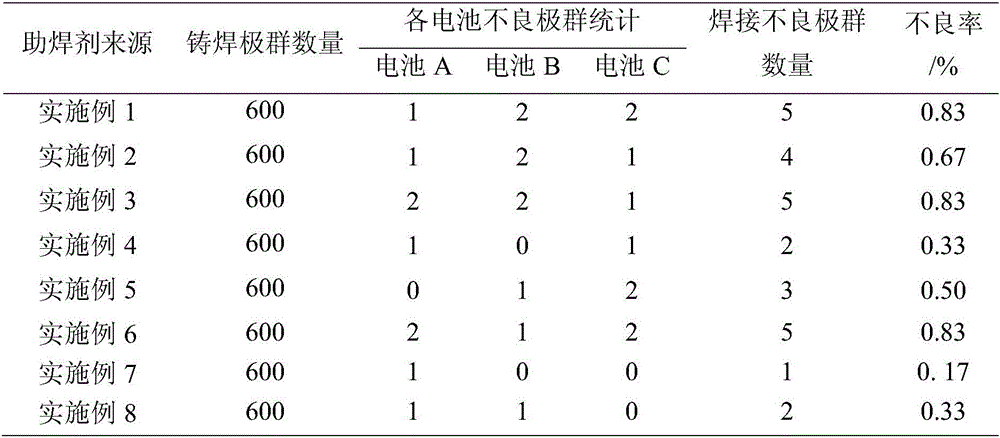

Lead acid battery flux and preparation method and application thereof

InactiveCN105945452AEfficient removalGood welding effectWelding/cutting media/materialsSoldering mediaAlcoholPhosphoric acid

The invention discloses a lead acid battery flux. The lead acid battery flux comprises the following components by mass percent: 5 to 20% of alcohol and 50 to 80% of phosphoric acid, and the balance being water. According to the lead acid battery flux, oxides on a tap can be effectively removed, the battery has a good busbar welding effect, the battery welding quality is improved, the defective problems of false welding, wrap welding and scaling of a product are improved, the welding defect rate is effectively decreased, residues after welding are less, the phenomenon that a battery is scrapped due to the situation that the flux adheres to a polar plate and a partition plate is eliminated, raw materials are convenient to obtain and prepare, and compared with a flux which can be purchased in the market, the flux has the advantage that the production cost is relatively low.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Solder composition and preparing method and application thereof

ActiveCN103506771AReduce manufacturing costGood brazing penetrationWelding/cutting media/materialsWelding/soldering/cutting articlesManganeseExhaust pipe

The invention discloses solder composition and a preparing method and application thereof. The solder composition comprises first metal and second metal. The first metal is at least one of copper, nickel and manganese. The second metal is at least one of zinc, silver, copper, nickel, manganese and chrome. The first metal and the second metal are different. The solder composition does not contain at least one of silicon and phosphorus. The solder composition can be effectively used for connecting objects made of different kinds of metal, and the solder composition is especially suitable for copper-steel brazing of an air sucking pipe and an exhaust pipe of a compressor. Compared with existing silver-based solder, the solder composition is low in production cost, compared with national standard copper zinc solder, the solder composition is good in brazing permeability, high in welding intensity, good in welding filling performance and reliability and strong in corrosion resistance, base metal in an application range is strong in adaptability, and welding reject ratio and airtight leakage rate are low.

Owner:GUANGDONG MEIZHI COMPRESSOR

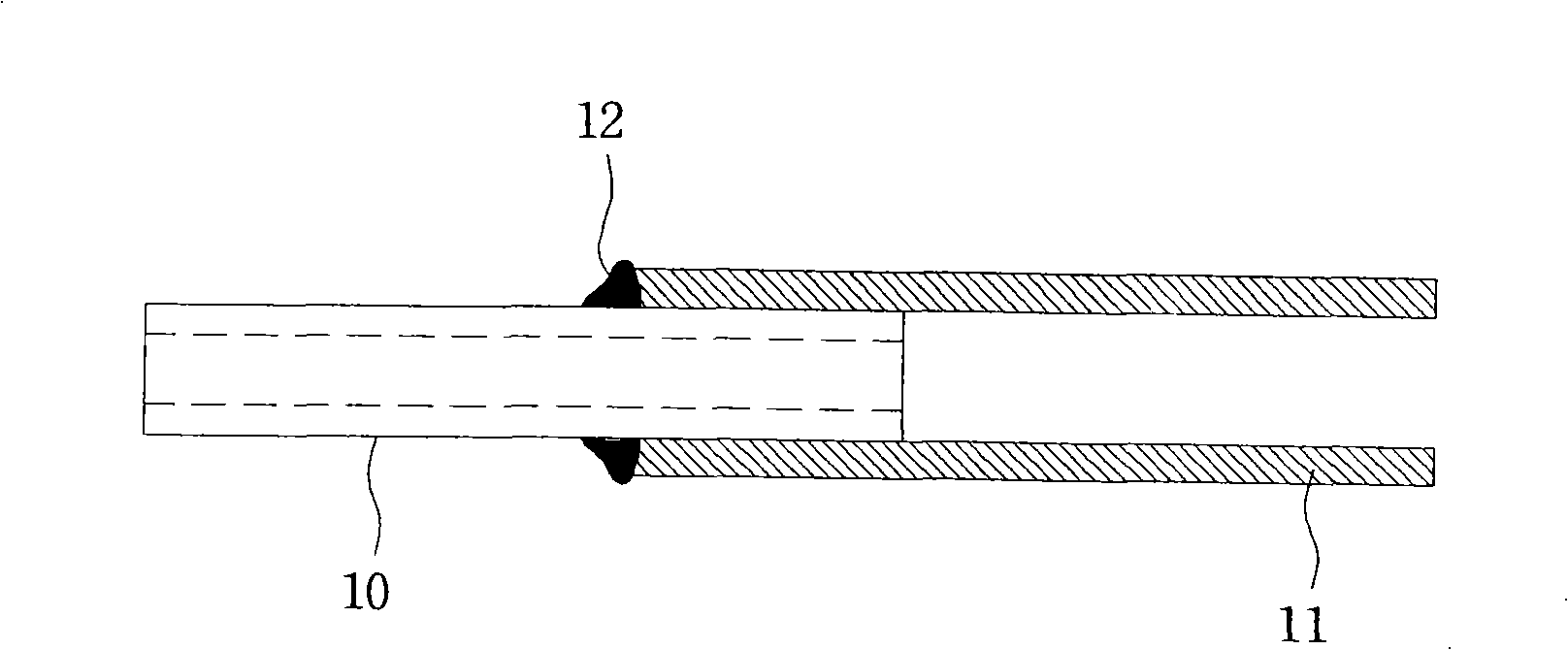

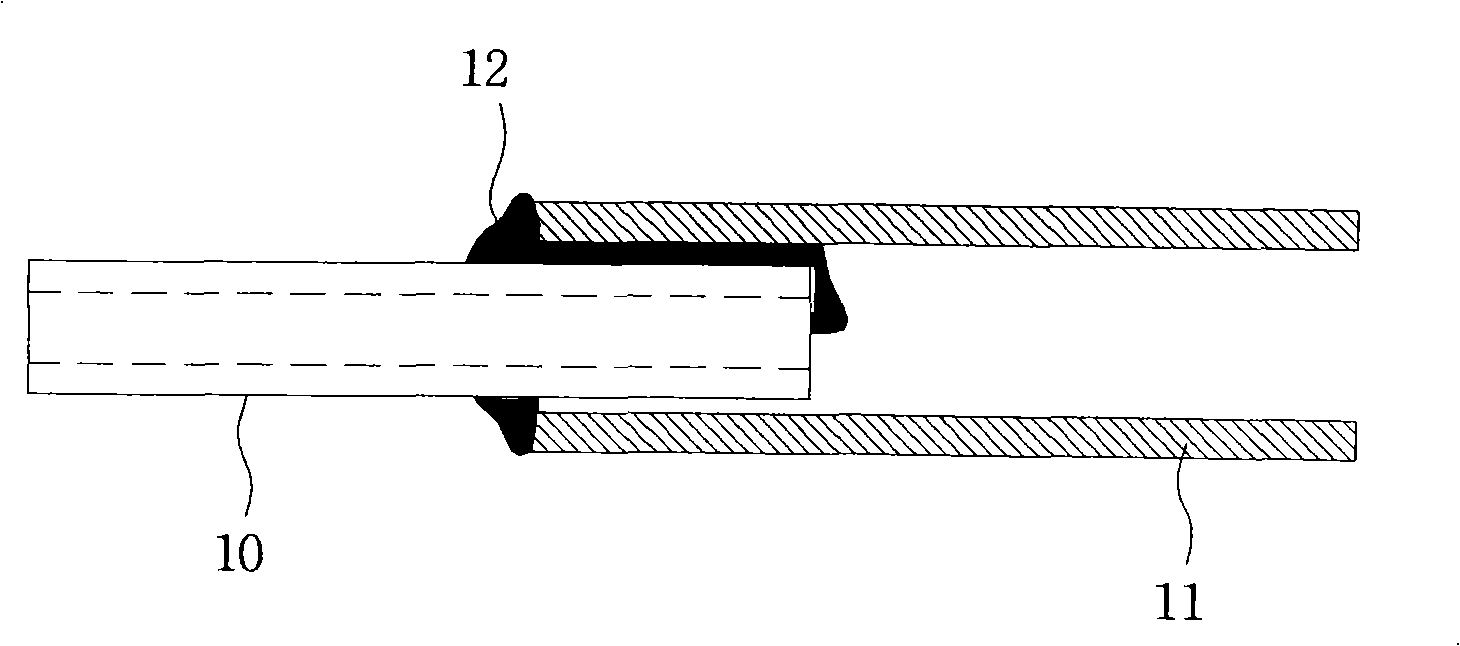

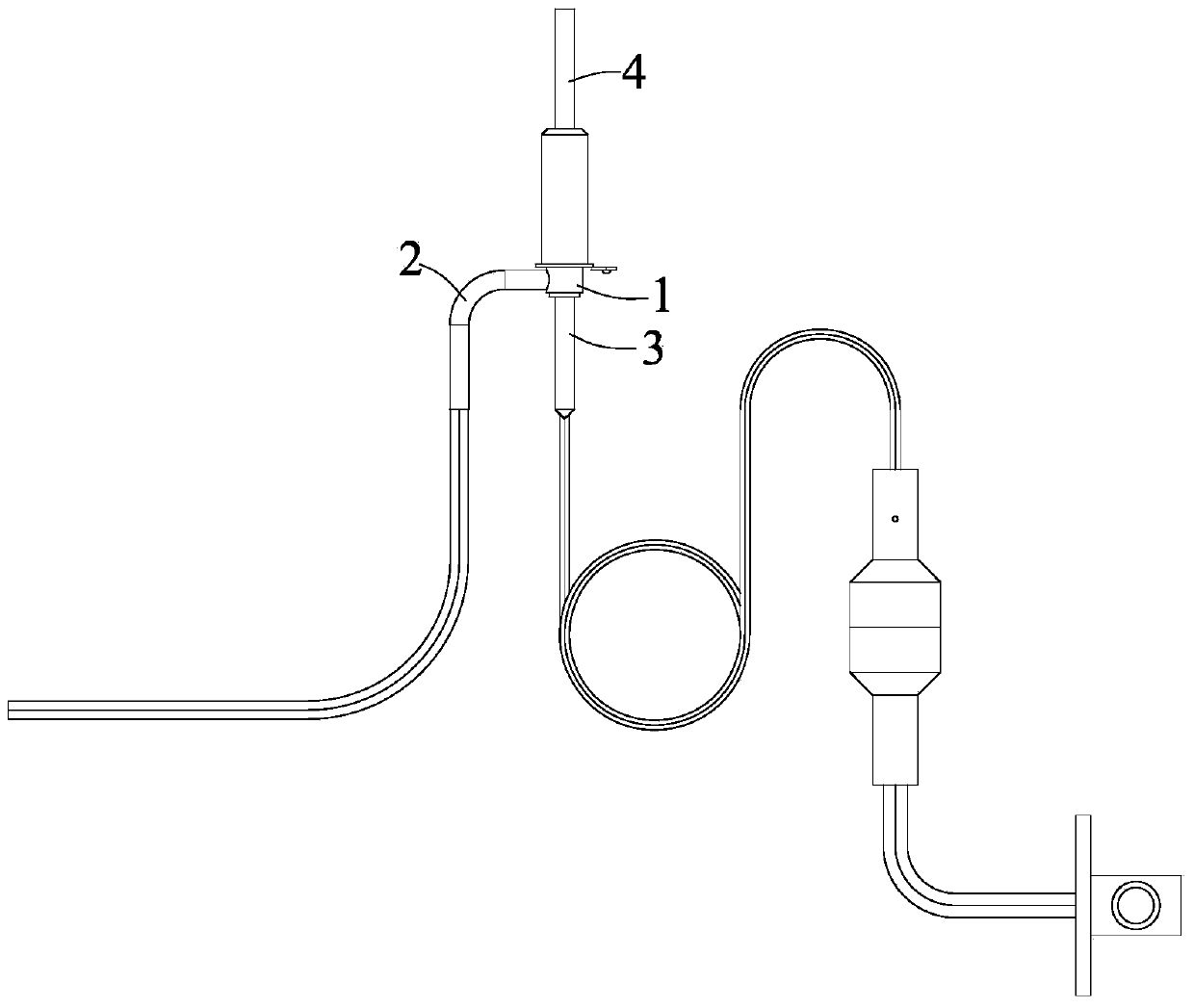

Copper tube connection device and method

InactiveCN101307848AAvoid cloggingPrevent leakagePipeline systemsWelding/soldering/cutting articlesHeating timeRefrigerant

The invention discloses a copper tube connecting apparatus for connecting a copper tube with another tube to facilitate welding operation in the refrigerating device. The new apparatus will reduce the poor welding rate so that it will effectively prevent clogging of the copper tubes and leaking the refrigerant. It also has merit to easily determine a suitable heating time while the copper tubes are welding. Thus, the rate of poor welding is reduced, as well as a method for connecting copper tubes by using the tube connecting apparatus.

Owner:忠州大学校产学协力团

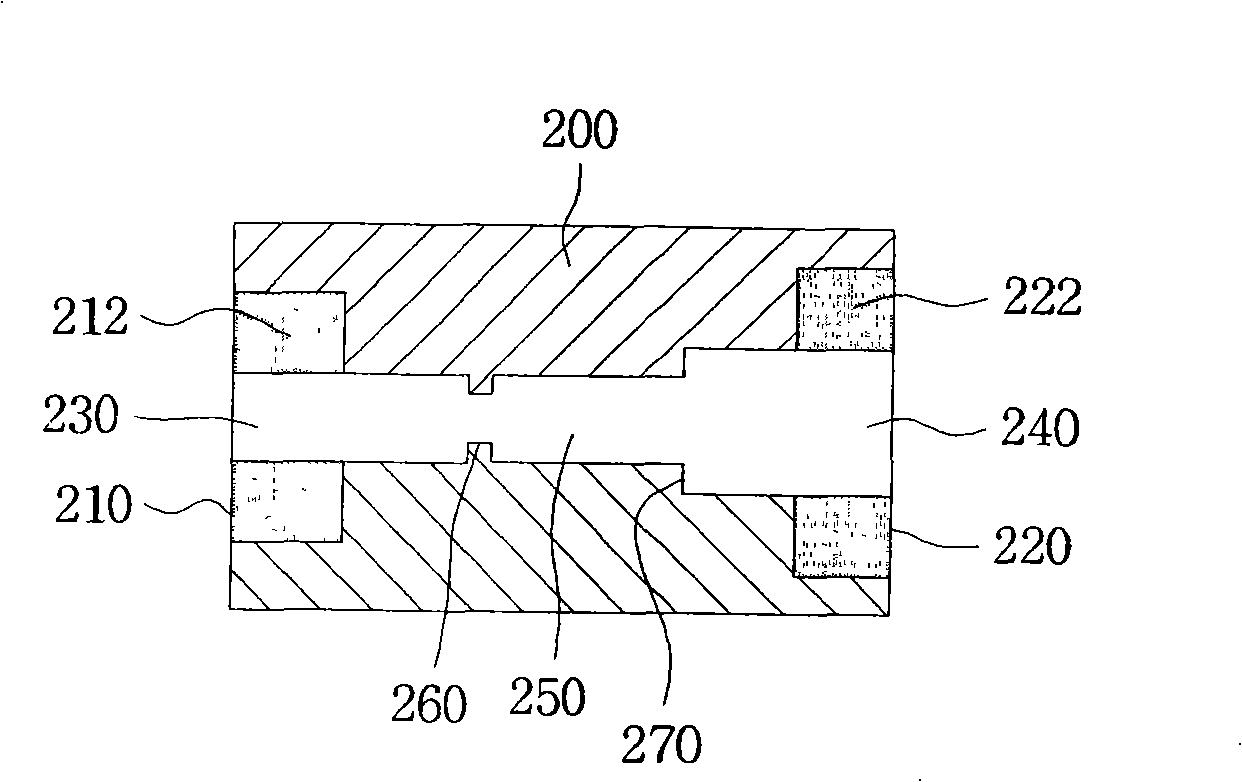

Welding structure and semiconductor part

InactiveCN108520866AImprove welding qualityPrevent inflowSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention provides a welding structure and a semiconductor part, and relates to the technical field of semiconductor equipment. The welding structure includes a cover plate and a bottom plate; thebottom plate has a first end face, grooves are arranged in the first end face, and two ends of the grooves penetrate through a side wall of the bottom plate, and the grooves and the first end face form openings; and the cover plate has a second end face, the first end face is arranged opposite to the second end face, the second end face is provided with bulges, the bulges can seal the openings, and a gap between the first end face and the second end face is provided for arrangement of a solder layer, and the cover plate and the bottom plate are welded through the solder layer. When the coverplate and bottom plate are welded, the solder layer is heated, pressure towards the bottom plate is applied to the cover plate , pressure towards the cover plate is applied to the bottom plate, sincethe bulges can seal the openings, the solder layer in the gap is prevented from flowing into the grooves, the solder between the cover plate and the bottom plate is prevented from being insufficient,the probability of poor welding is reduced, the blockage of a water channel or an air passage can also be prevented, and the welding quality of the welding structure is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

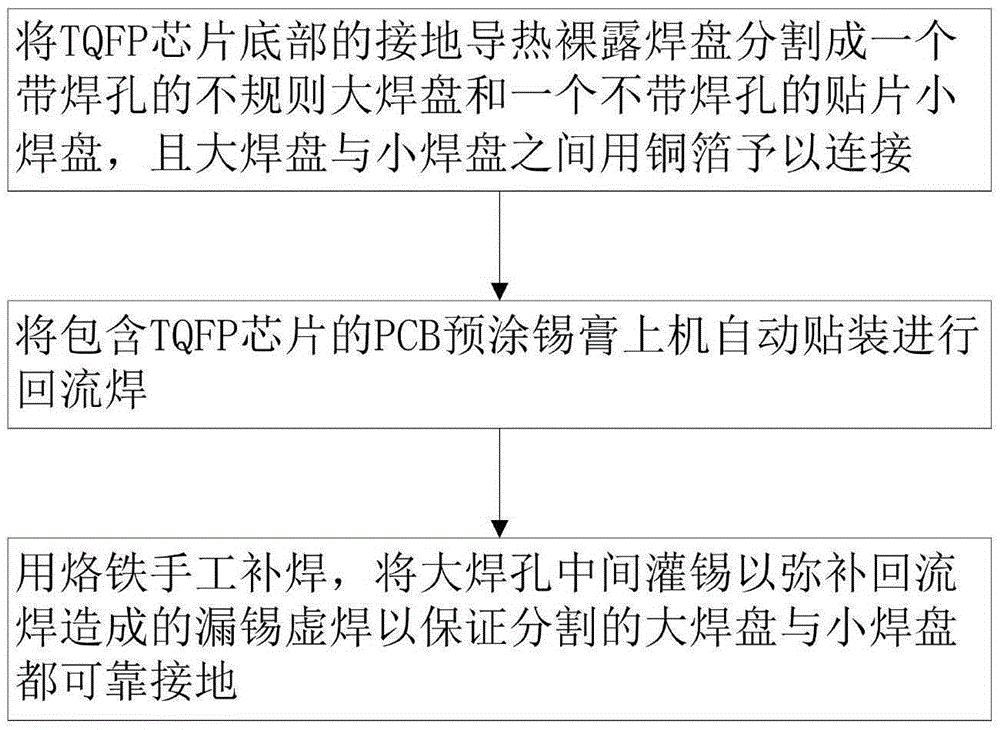

PCB packaging design and welding method of TQFP chip

InactiveCN105397221AReduce defective welding rateReduce manufacturing costSoldering apparatusMetal working apparatusHeat conductingCopper foil

The invention provides a PCB packaging design and welding method of a TQFP chip. The PCB packaging design and welding method comprises the steps of dividing a grounded heat conducting exposed welding plate at the bottom of the TQFP chip into a big irregular welding plate with a welding hole, and a small SMT welding plate without welding holes, and connecting the big welding plate and the small welding plate with copper foil; loading PCB pre-coating solder paste containing the TQFP chip for automatic sticking and mounting, and carrying out reflow soldering; and finally, manually repairing welding through using soldering iron, and filling the middle part of the large welding hole with tin to make up the tin leaking and insufficient solder caused by reflow soldering, so as to guarantee that the divided big welding plate and the small welding plate are reliably grounded. The welding fraction defective of the TQFP package chips, welded through the method, on a PCB, is obviously decreased, the production cost is reduced, and the product quality is improved.

Owner:长沙奥托自动化技术有限公司

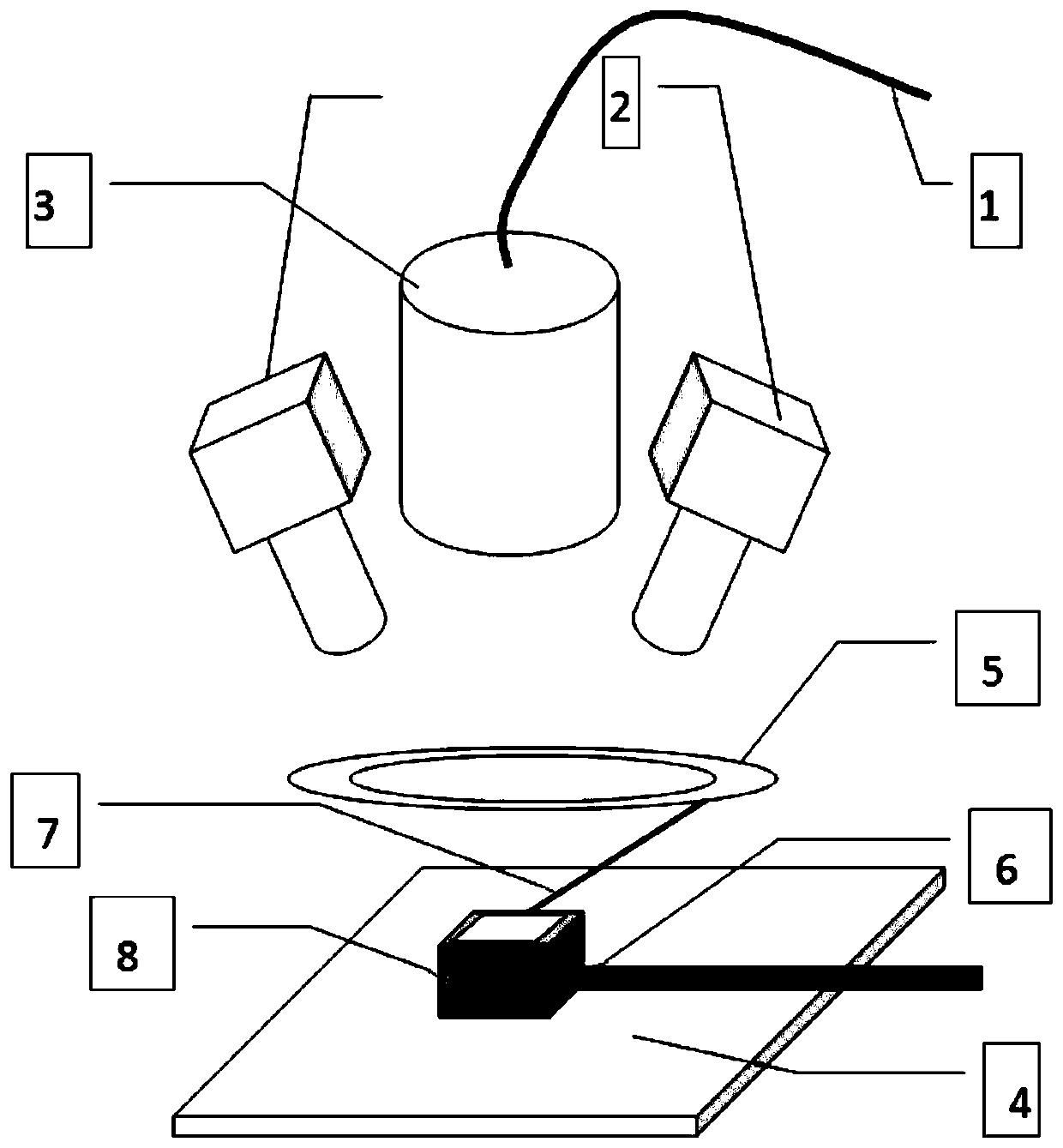

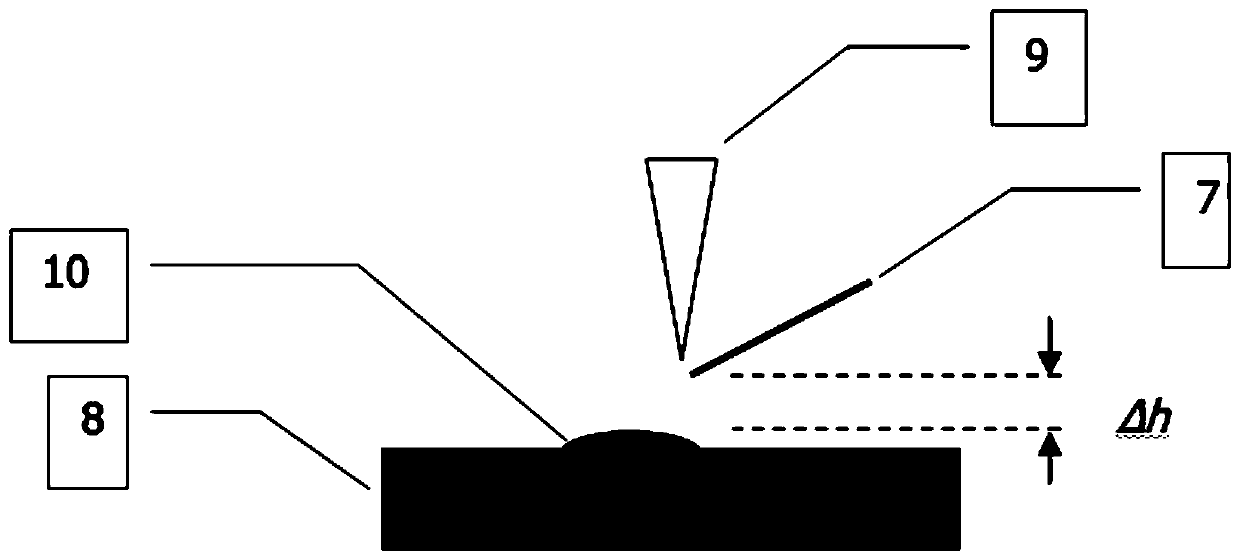

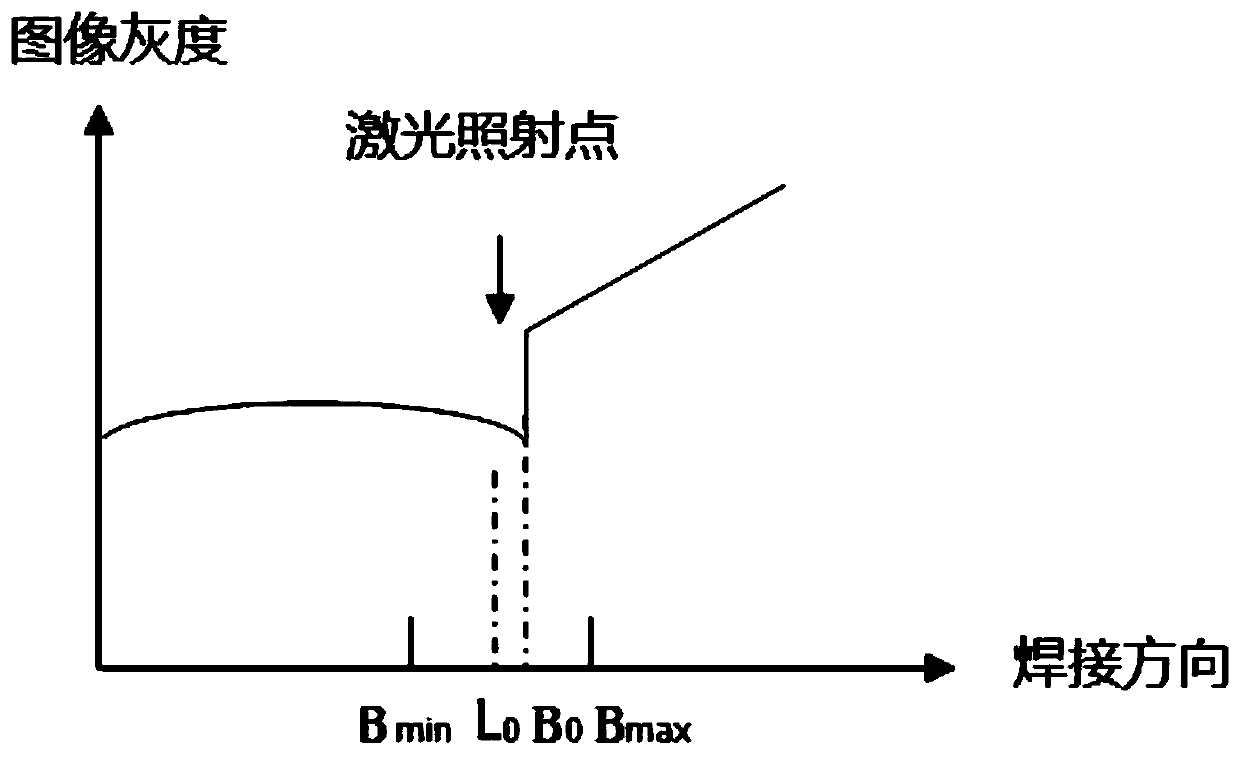

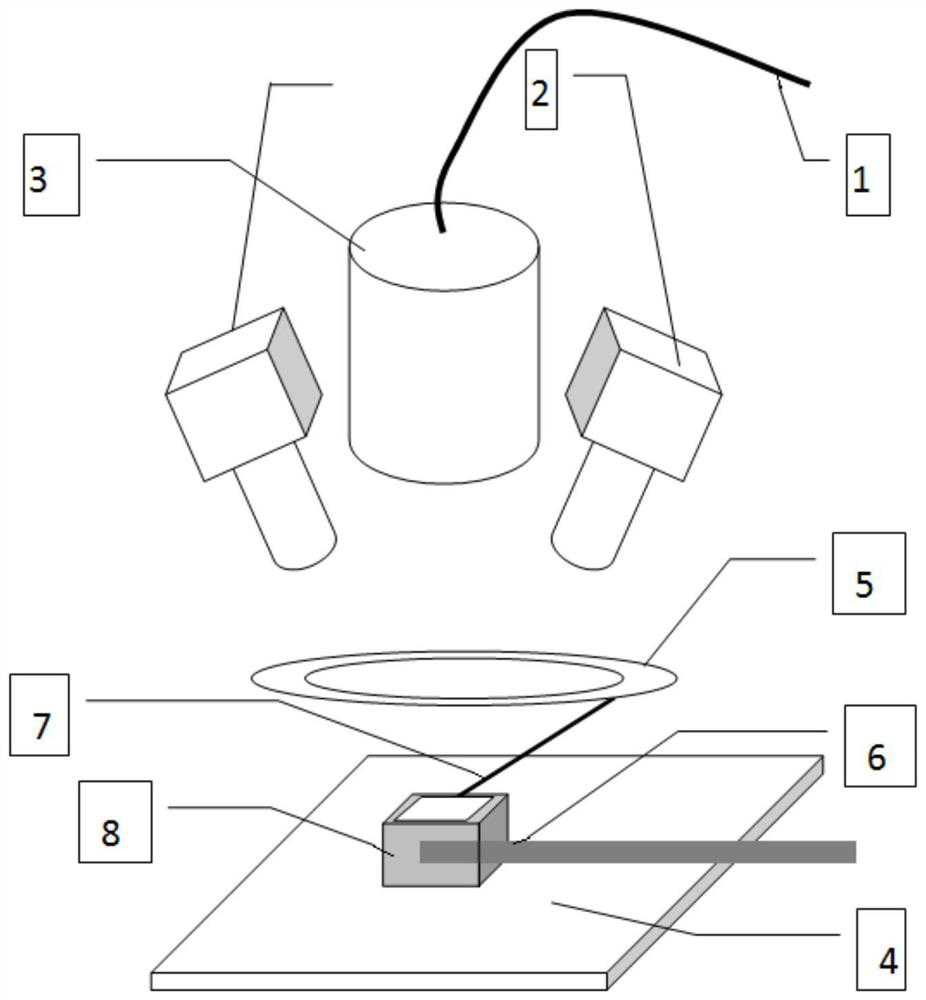

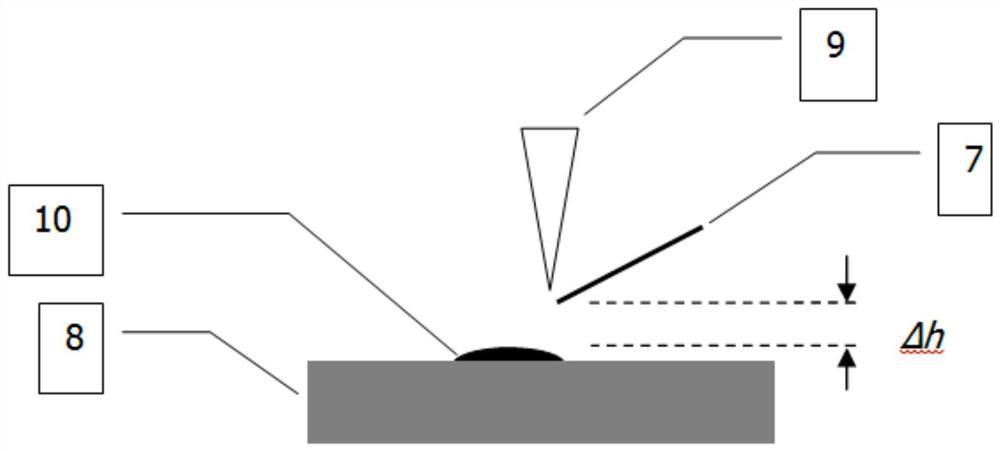

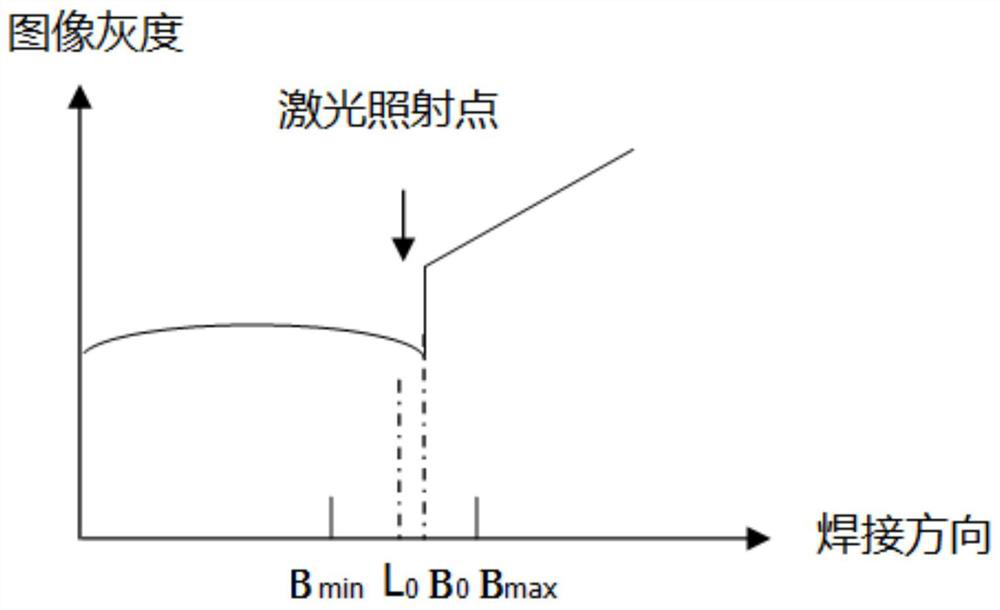

Connecting piece laser processing method based on binocular vision

ActiveCN110842316AOptimize welding trajectoryHigh speedHeating appliancesSoldering auxillary devicesLaser processingMechanical engineering

The invention provides a connecting piece laser processing method based on binocular vision, and relates to the technical field of conductive connection. The method is characterized in that in the connecting process of a conductive piece, the laser power is fed back in real time according to a gray scale step point formed in a depth image by a fusion point when brazing filler metal is fused; in the filling process, the welding speed is optimized according to the gray scale of the depth image; and the speed optimization method is characterized in that the welding motion speed is determined according to the gray scale of the image, the gray scale average value is taken as a base point, the speed is slowed down when being less than the value, and the speed is increased when being larger thanthe value. According to the method, welding track and speed planning is optimized according to the depth image, and the connecting processing efficiency of the conductive piece is improved.

Owner:WUHAN BESKYS TECH CO LTD

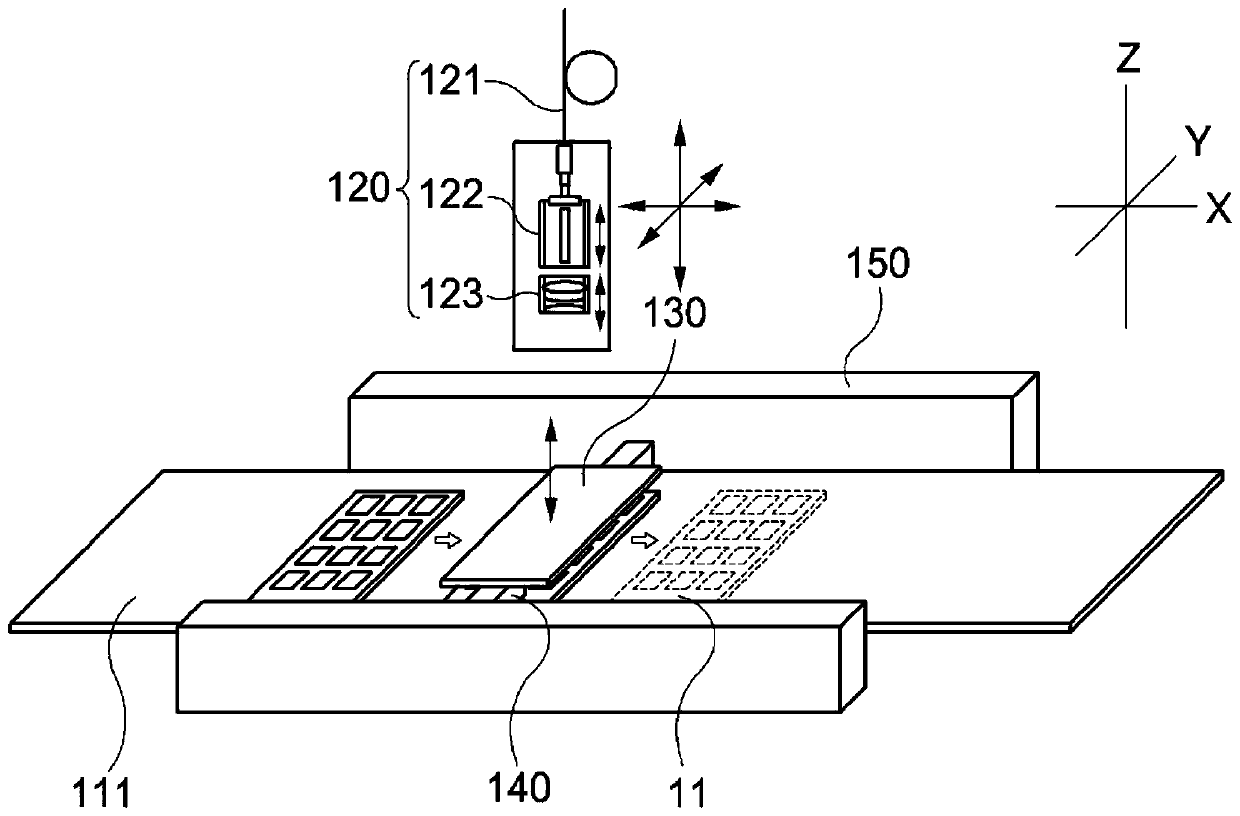

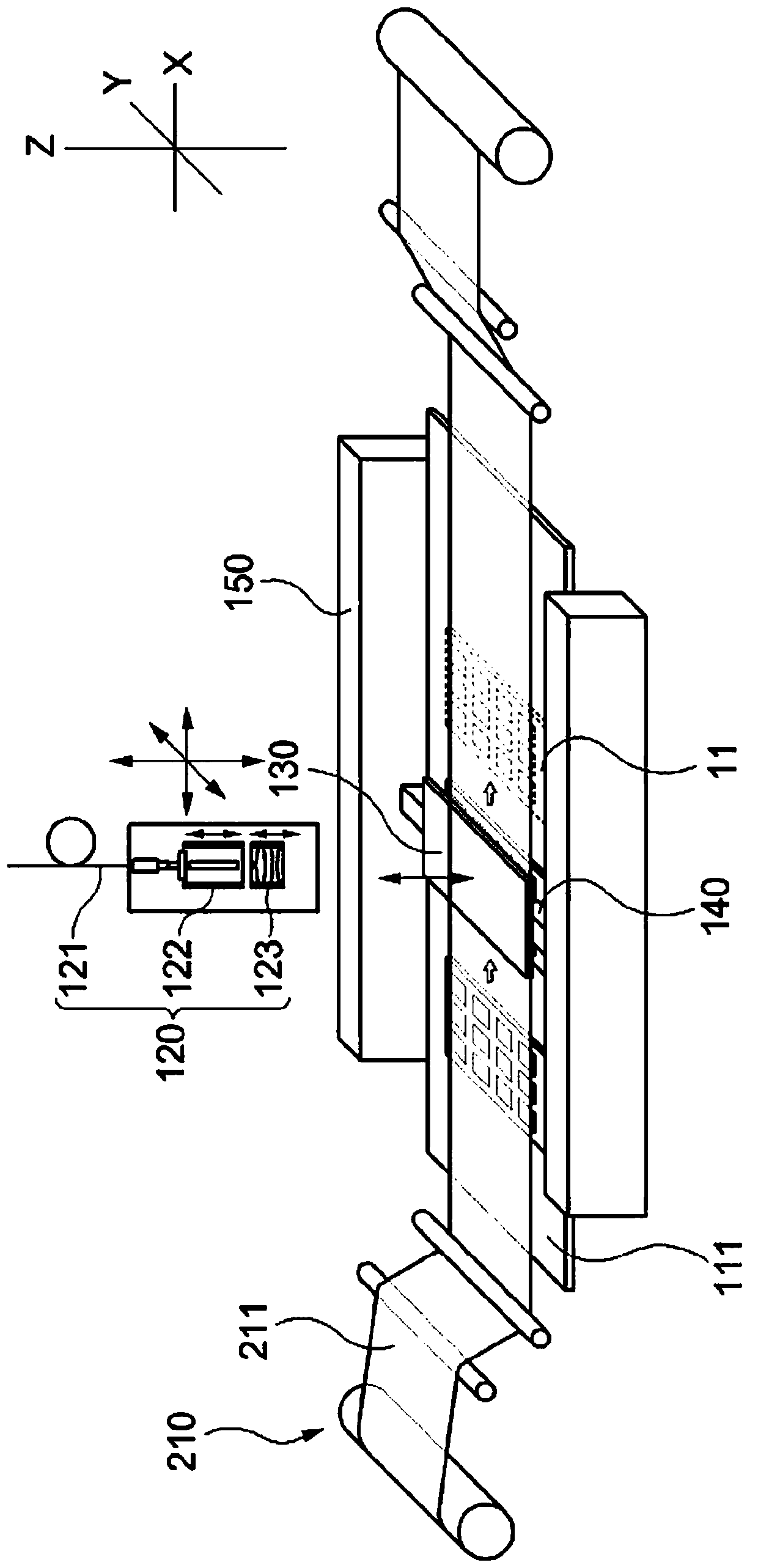

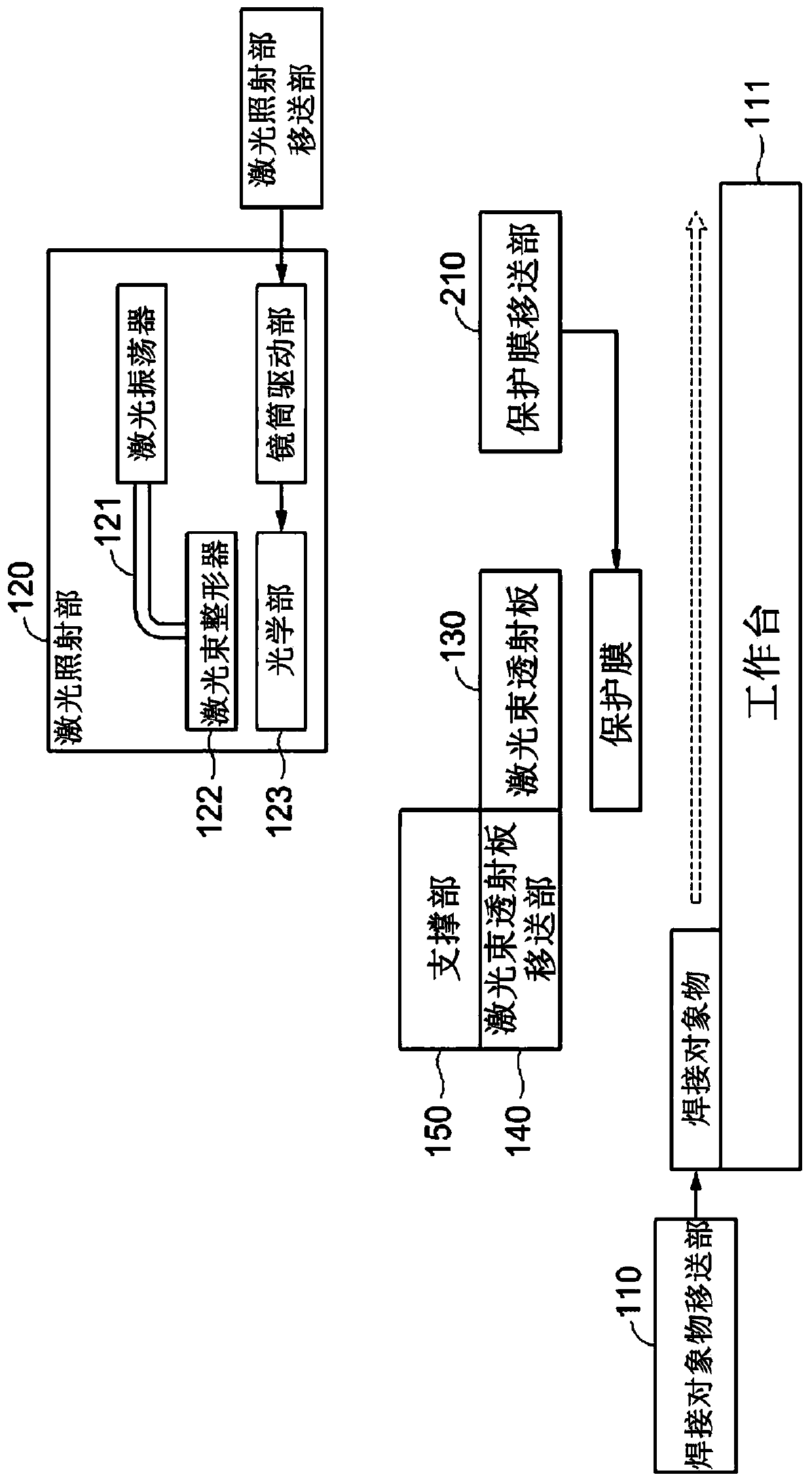

Laser reflow device

ActiveCN110326096AShorten takt timeAchieve high speedSoldering apparatusSemiconductor/solid-state device manufacturingEngineeringIrradiation laser

The present invention relates to a laser reflow device, which can implement shortening of a tact time for one object to be bonded and the acceleration of a bonding operation for all of the plurality of objects to be bonded and comprises: an object-to-be-bonded transferring part including a stage for supporting the object to be bonded, and transferring the object to be bonded; a laser emitting partfor converting a laser into a surface light source form and emitting the same to the object to be bonded, and a laser emitting part transferring part for moving the laser emitting part to an emissionposition or a standby position; and a beam-transmitting plate independently provided separately from the laser emitting part and allowing the laser having the surface light source form to pass therethrough, and a beam-transmitting plate transferring part for moving the beam-transmitting plate to an operation position or the standby position.

Owner:LASERSSEL CO LTD

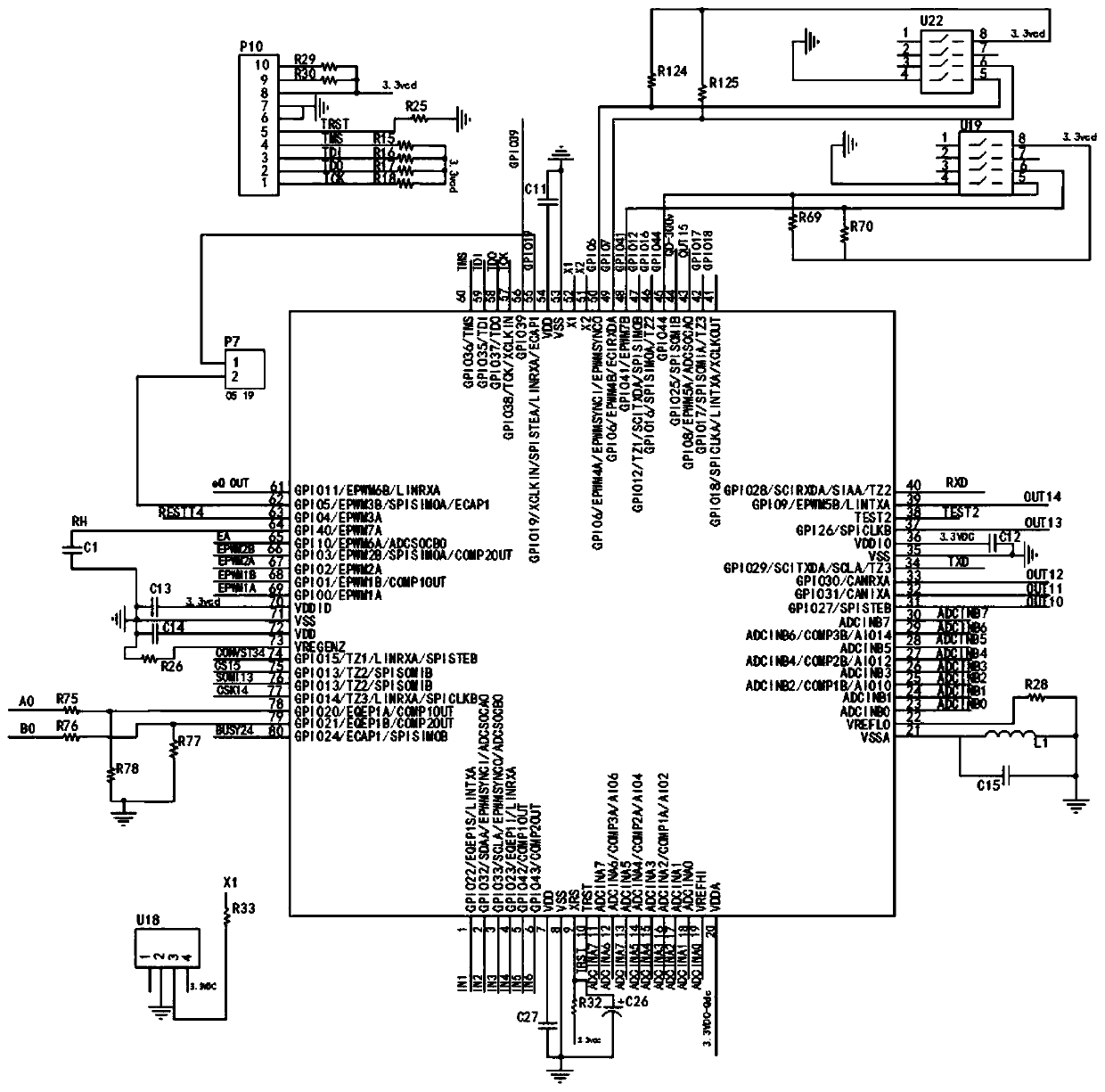

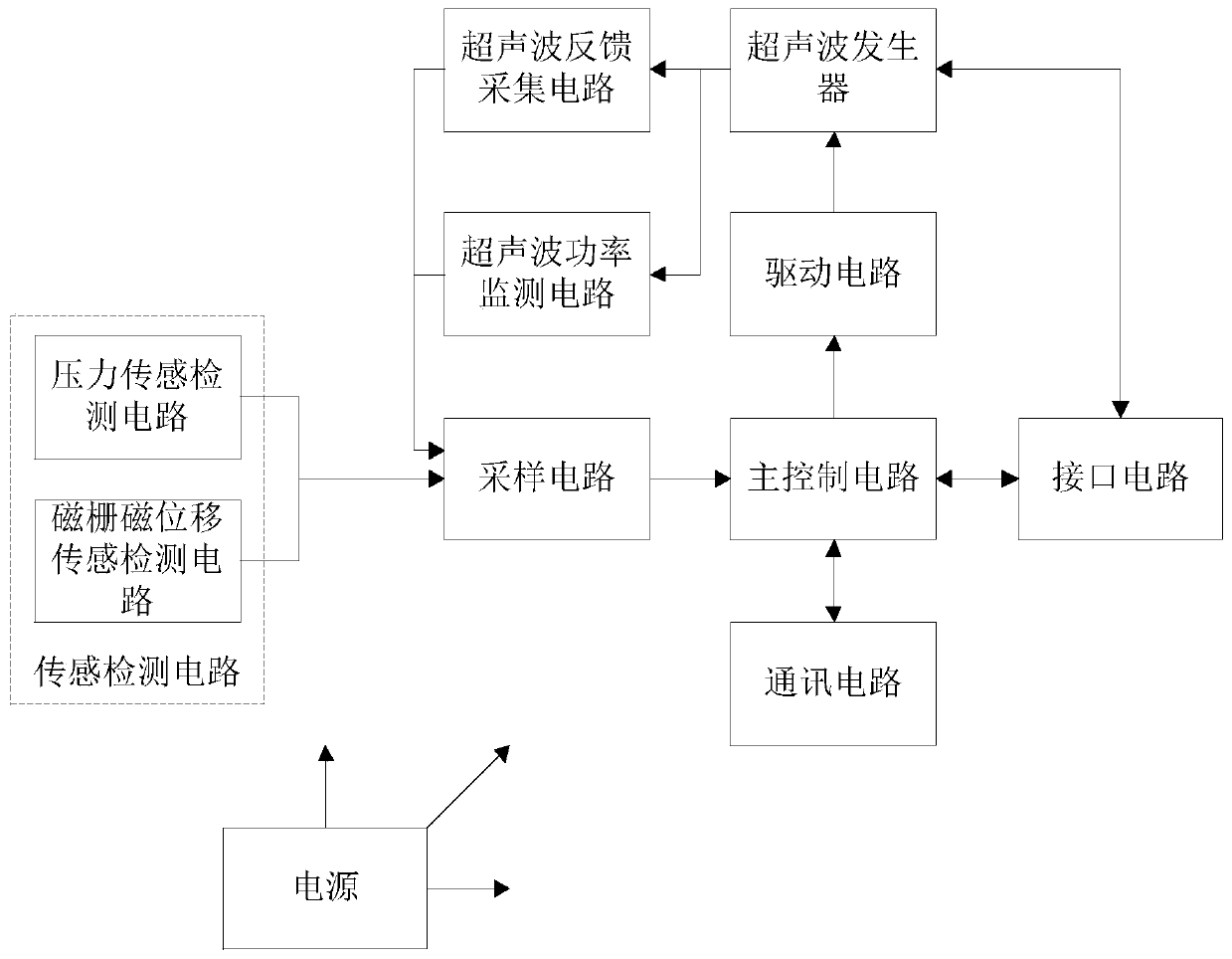

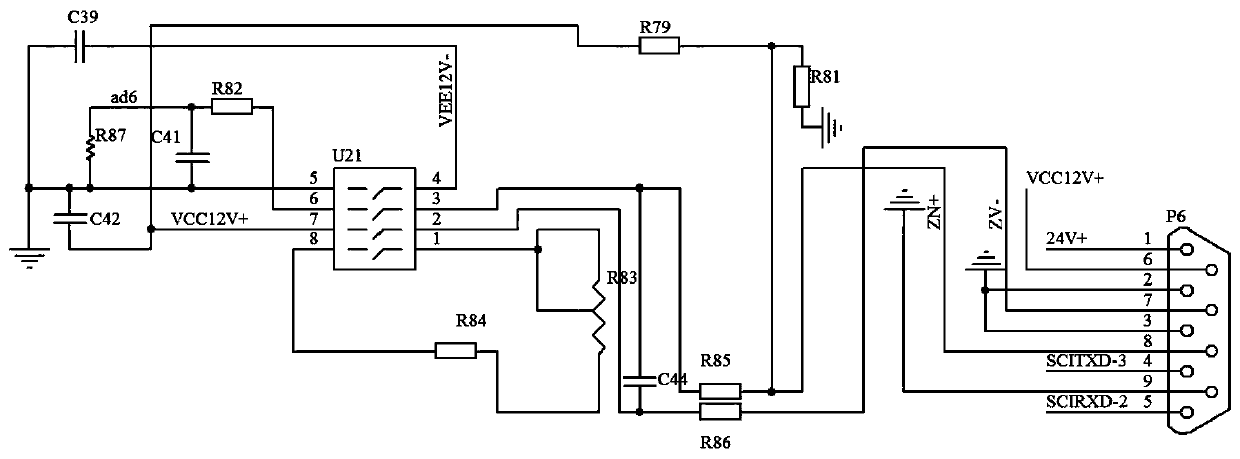

Ultrasonic control circuit triggered by position and pressure and welding method

PendingCN109702315AEnsure consistencyAvoid timeNon-electric welding apparatusEngineeringControl ultrasound

The invention relates to an ultrasonic control circuit triggered by position and pressure and a welding method. The ultrasonic control circuit includes a sensing detection circuit body, a sampling circuit body, a main control circuit body, an interface circuit body, a driving circuit body and a power supply, wherein the sensing detection circuit body is electrically connected with the sampling circuit body; the sampling circuit body, the interface circuit body and the driving circuit body are respectively electrically connected with the main control circuit body; and the driving circuit body is electrically connected with an ultrasonic generator. According to the ultrasonic control circuit, the displacement signal of the vibration group of the ultrasonic generator and the pressure signal between an ultrasonic welding head and a product to be welded are collected; the vibration is controlled to a preset amplitude before the ultrasonic welding head is in contact with the product to be welded; time is kept after the ultrasonic welding head is in contact with the product to be welded; the problem that in the welding process, the time occupied by the vibration of the ultrasonic weldinghead to a preset amplitude results in insufficient welding time or the waste of welding energy is avoided; the welding time or the welding energy is accurately controlled; the welding defect rate is greatly reduced; and the consistency of welding products is ensured.

Owner:东莞市鸿振超声波设备有限公司

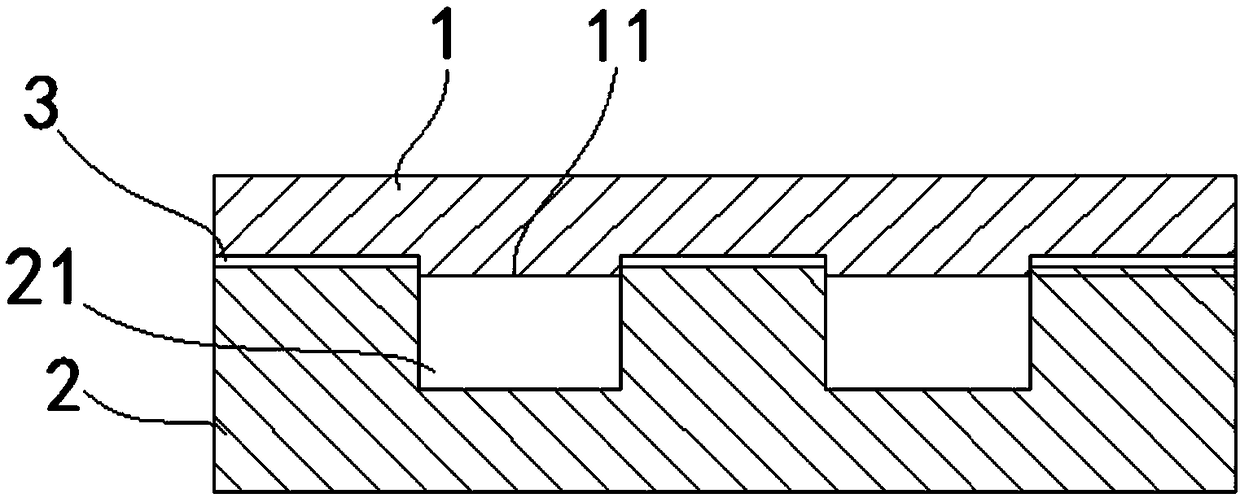

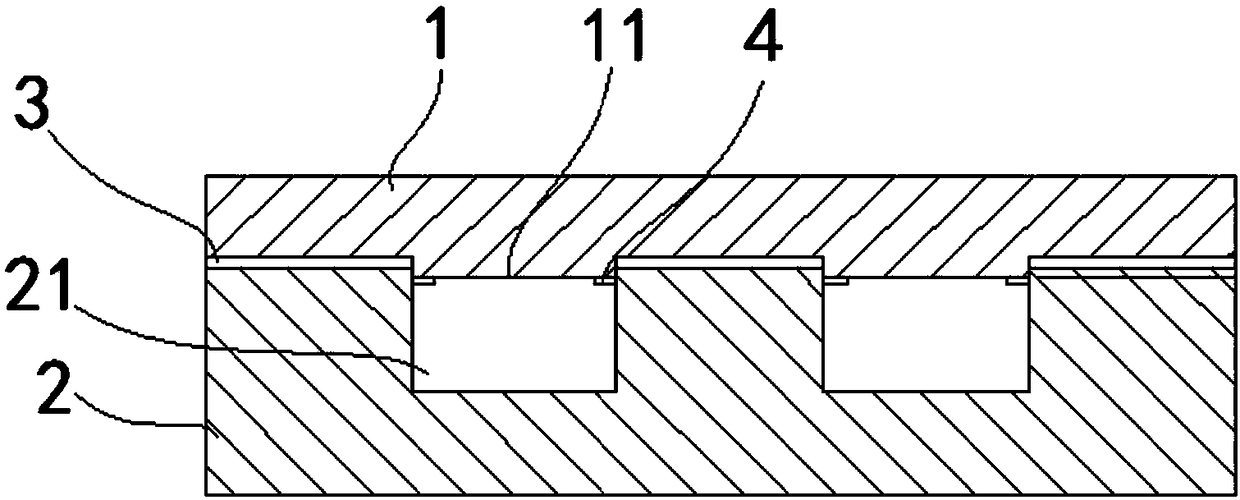

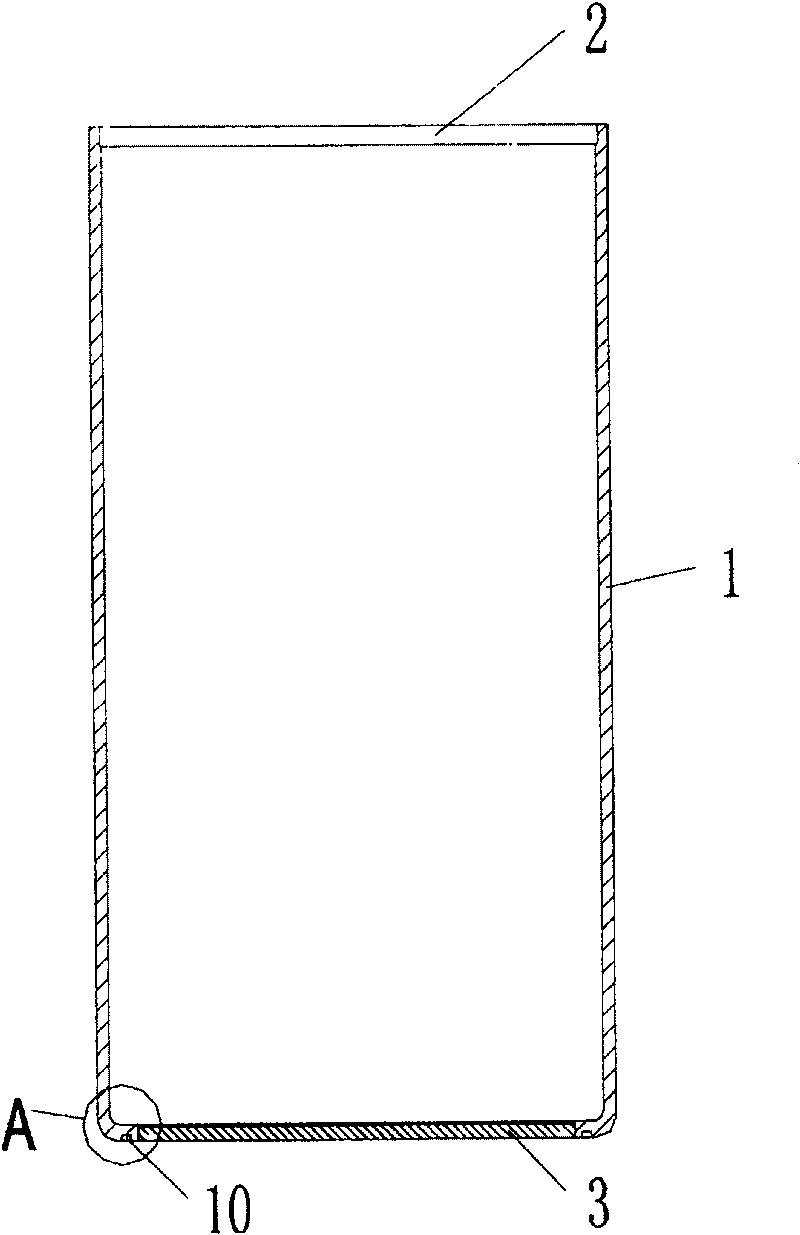

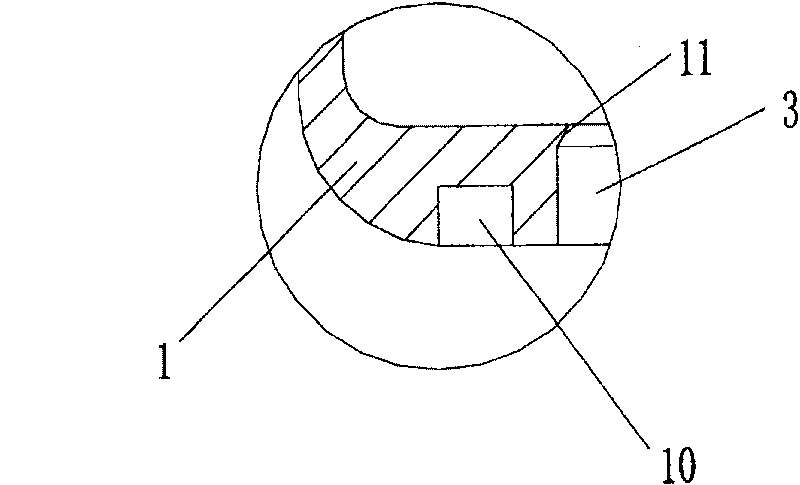

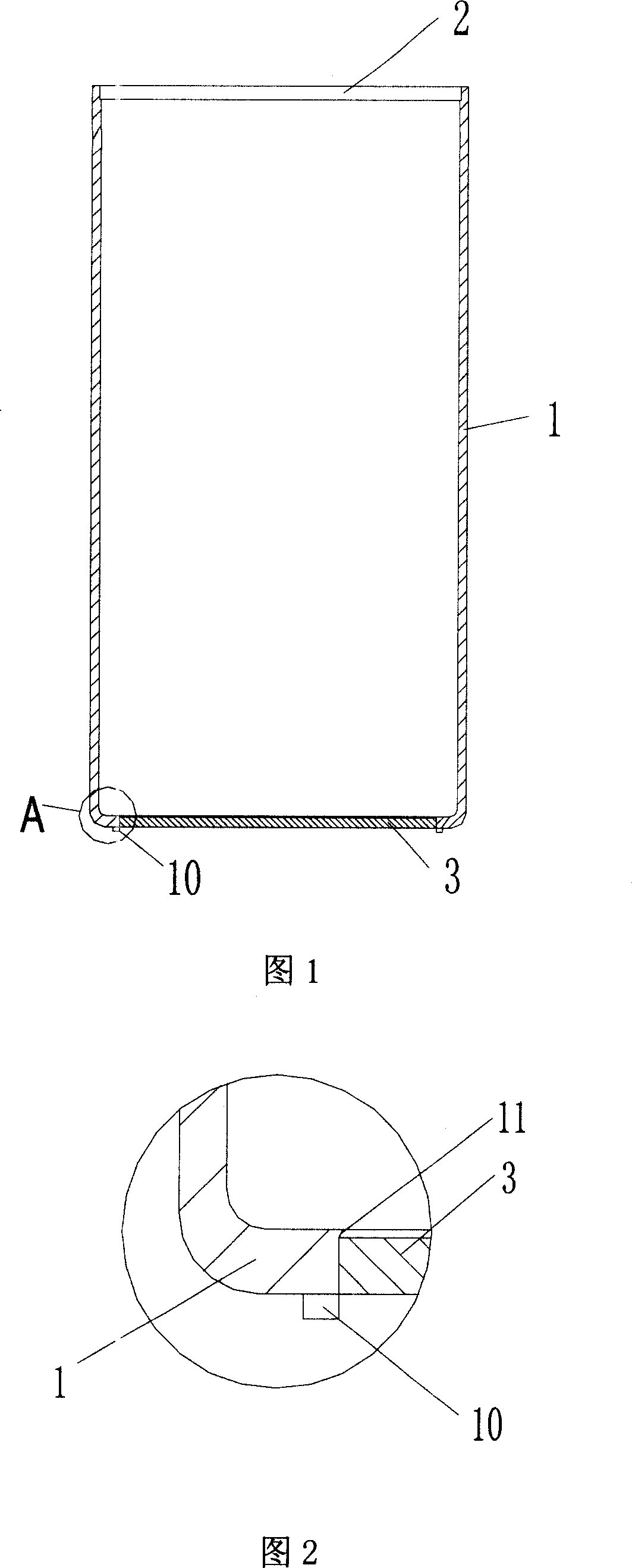

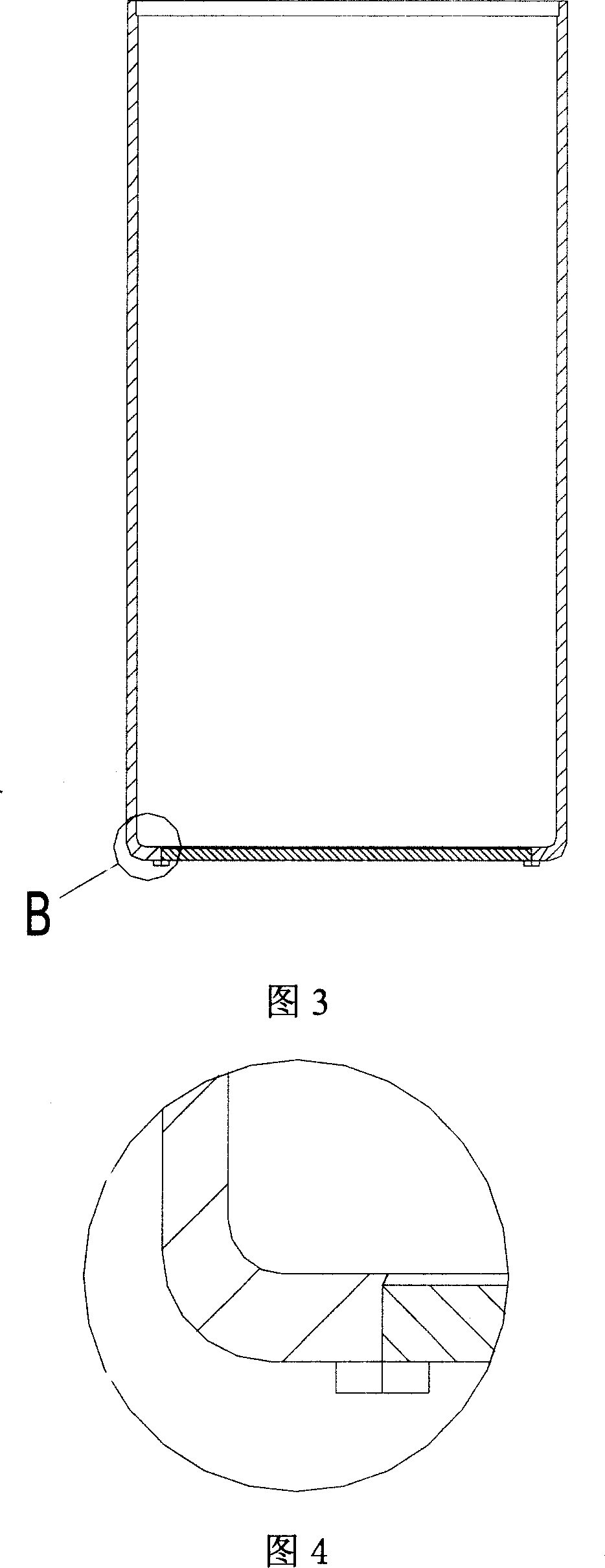

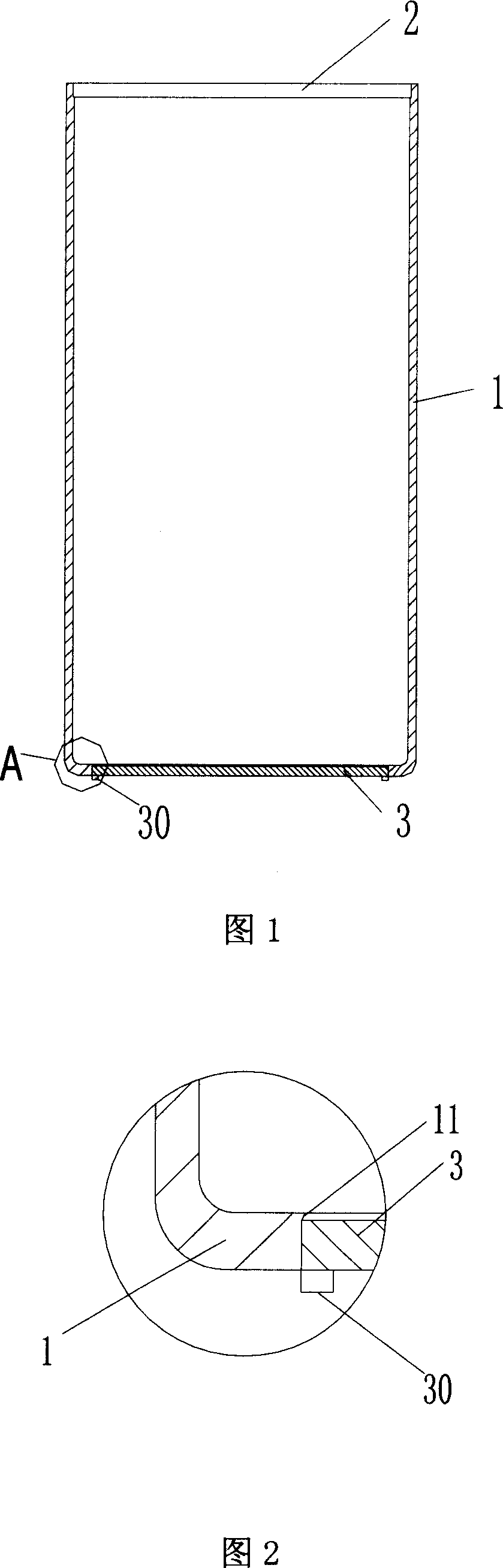

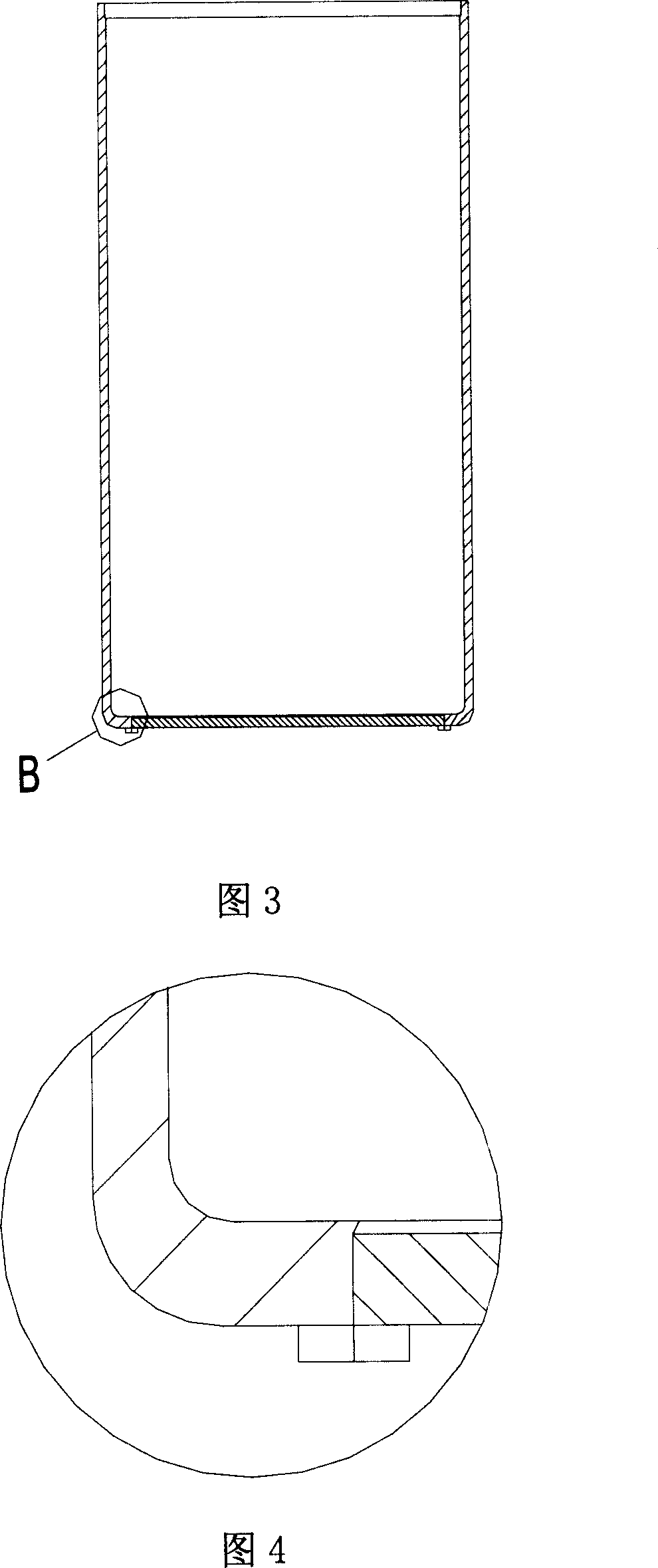

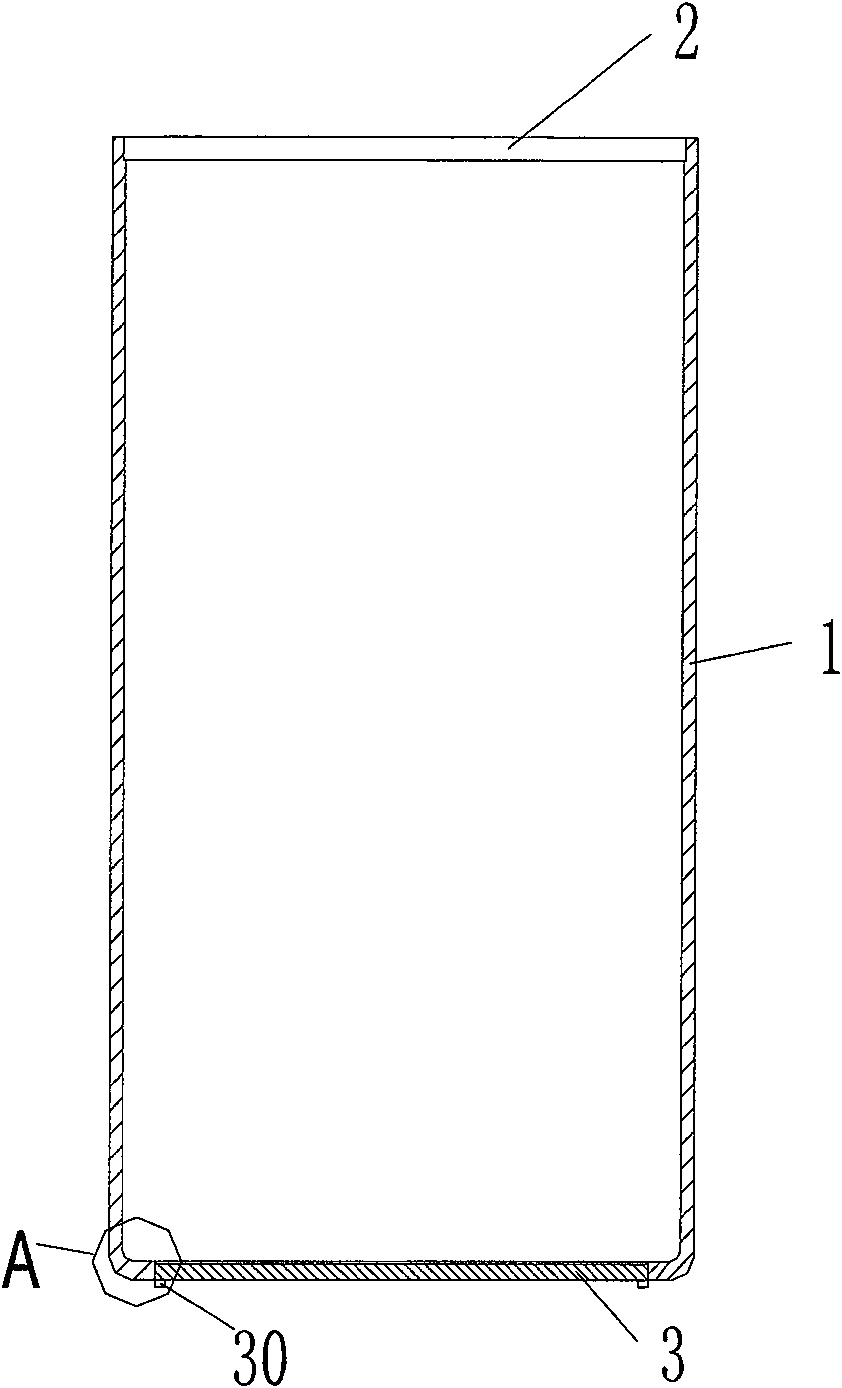

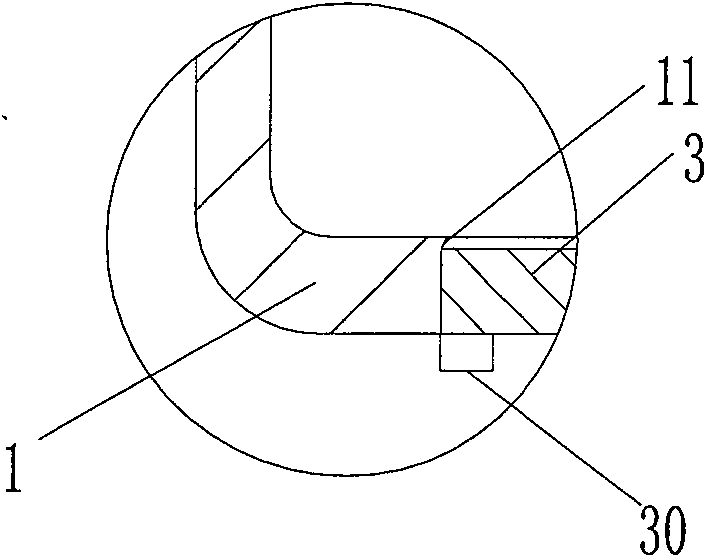

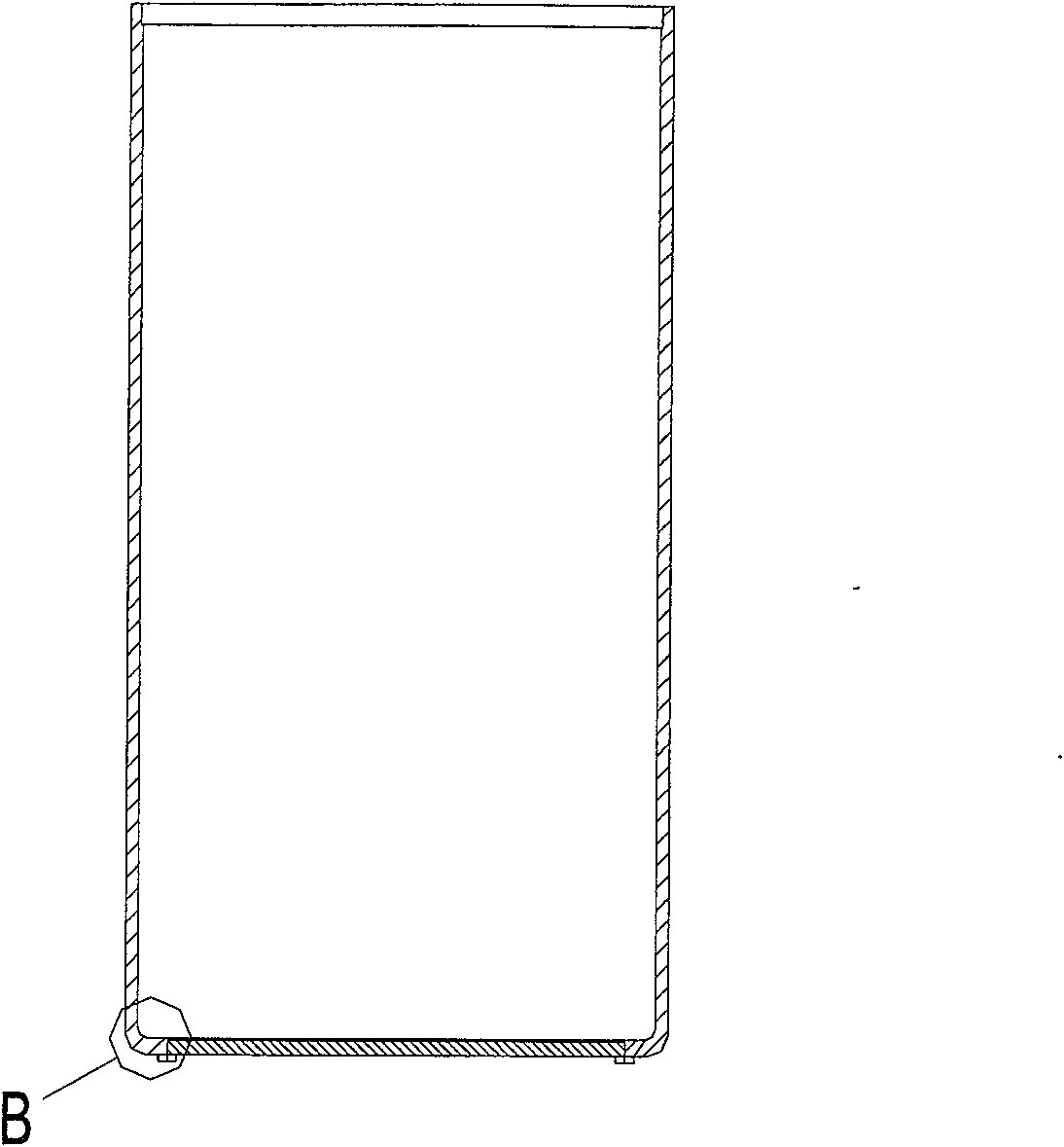

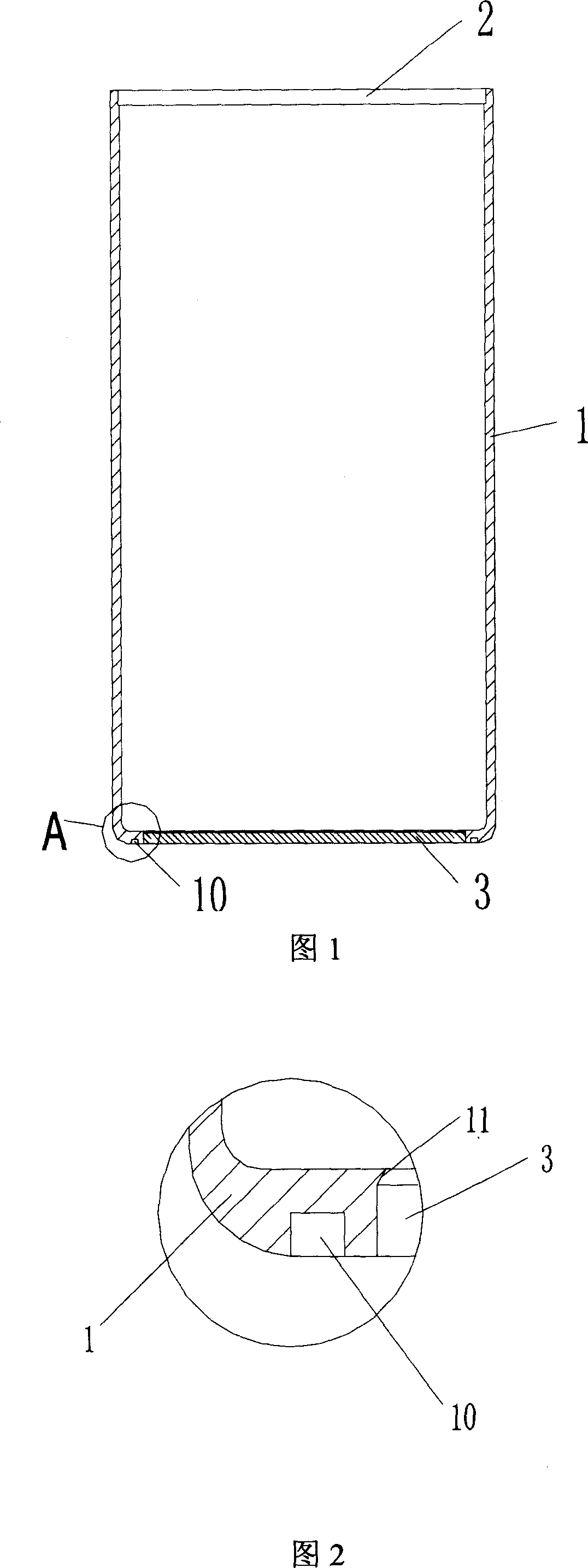

An electric core shell and electric core

ActiveCN101150177BInhibition lossReduce defective welding ratePrimary cellsSecondary cellsEngineeringCore shell

This invention discloses a shell of electric core and a core using it, in which, the shell includes a drum, a top cover plate and a bottom cover plate, and the drum is a drum with a bottom with a through hole and an paerture at the top, a groove along the circle is set on the bottom plate and a groove along the circle is set on the drum of the shell. Since the heat conductivity of air is much lower than that of metal, it can stop losing of heat at the welding place when welding by laser effectively by grooves along the circle directin on the drum bottom and on the bottom plate so as to deepenthe depth fusion under definite laser strength.

Owner:ZHENGZHOU BAK BATTERY CO LTD

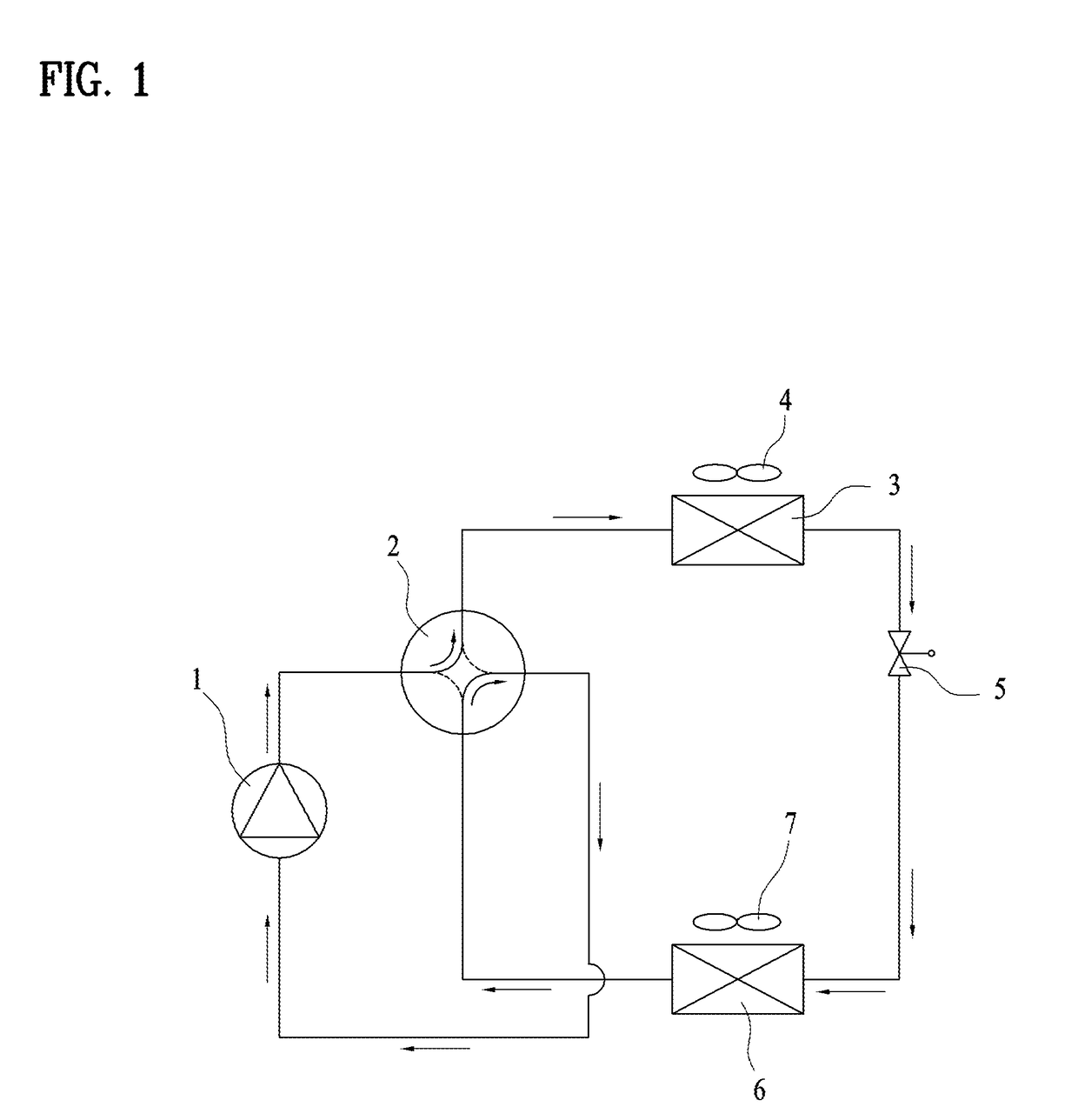

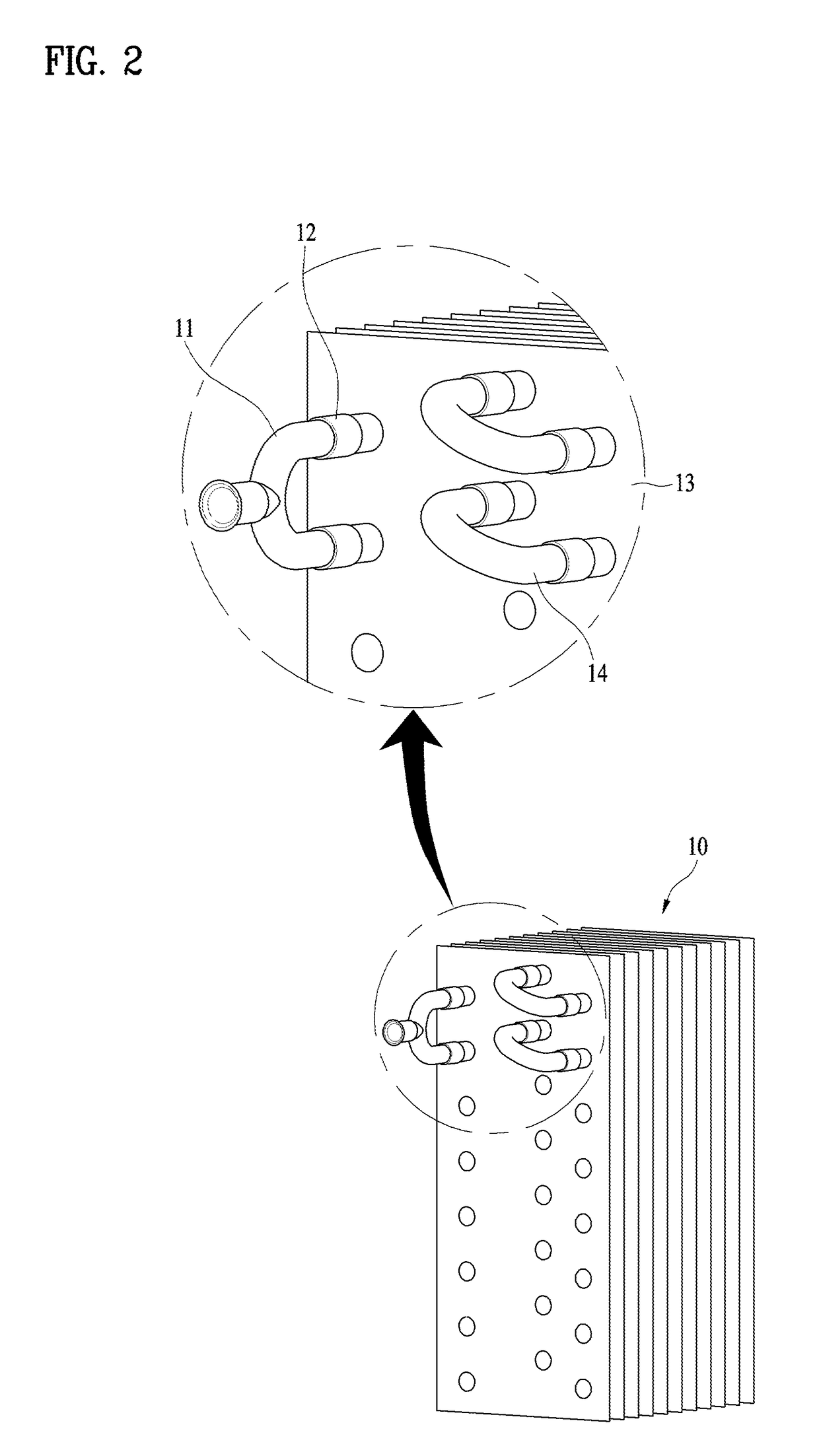

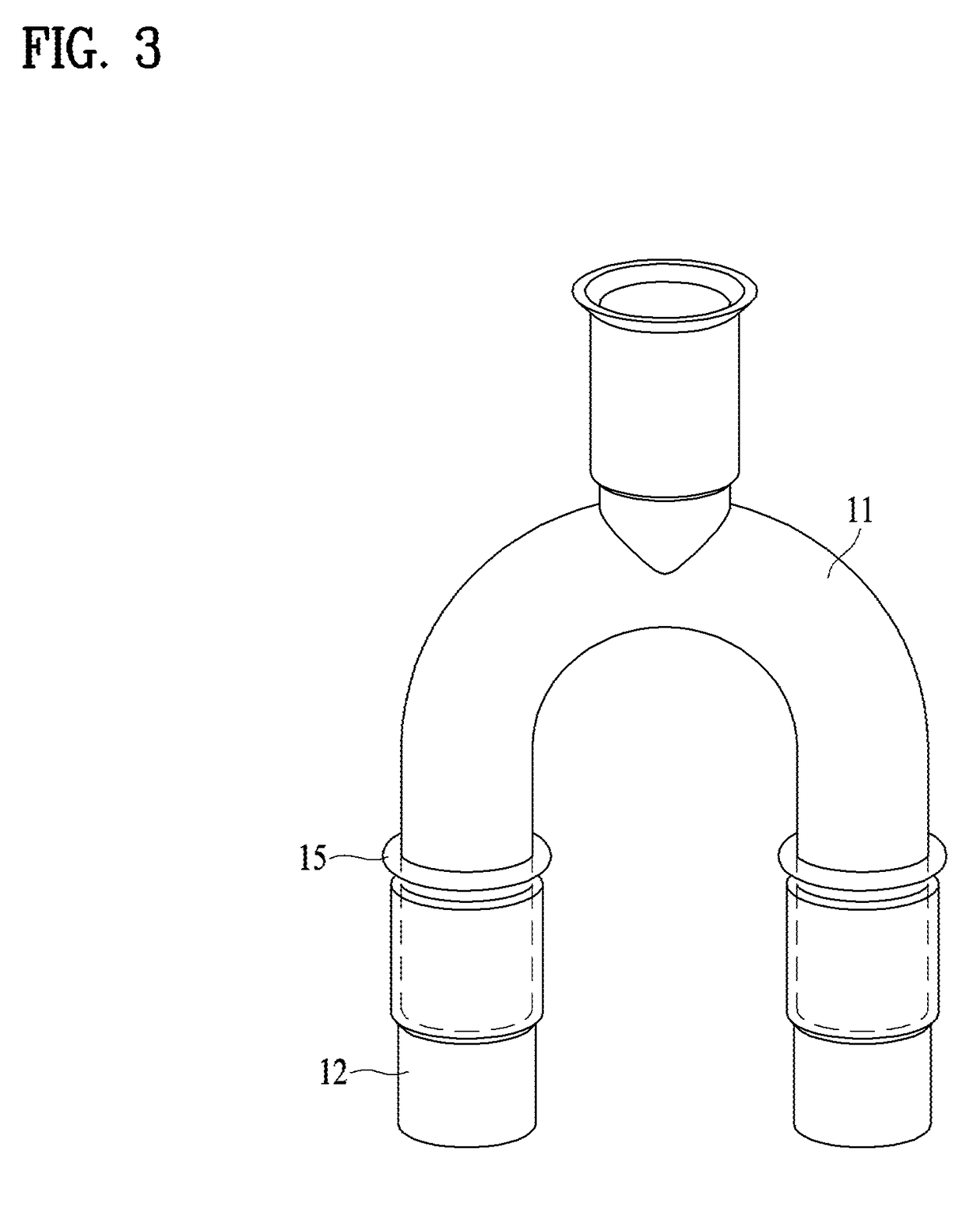

Air conditioner and method of manufacturing the same

ActiveUS20190017755A1Reduce defective welding rateEnhanced couplingSoldering apparatusStationary conduit assembliesPunchingEngineering

An air conditioner and a method of manufacturing the same are disclosed. The air conditioner includes an indoor heat exchanger and an outdoor heat exchanger, each including a plurality of refrigerant pipes and at least one connection pipe for interconnecting the refrigerant pipes, a welding hole formed in the connection pipe by punching, and a welding ring mounted over the welding hole, wherein portions of the refrigerant pipes are inserted into the connection pipe through inlet ends of the connection pipe, the welding hole is located between ends of the refrigerant pipes and the inlet ends of the connection pipe, and the connection pipe is bonded to the refrigerant pipes by heating at least one selected from between the refrigerant pipes and the welding ring.

Owner:LG ELECTRONICS INC

An electric core shell and electric core

ActiveCN101150176AInhibition lossReduce defective welding rateFinal product manufactureSmall-sized cells cases/jacketsEngineeringMetal

This invention discloses a shell of cores and a core using it, in which, the shell includes a drum and up-down cover plates, and the drum is one with a bottom and an aperture on the top and the bottom of which includes a through hole, a circle of convex stand set along the edge of the through hole is set on the bottom of the drum and a circle of convex stand set along the edge of the cover plate is set on the bottom cover plate of the drum. Since the heat conductivity of air is much lower than that of metal, it can stop losing of heat in laser welding effectively by setting a circle of convex stand along the edge of the through hole on the bottom and a convex stand on the bottom cover plate so as to deepen the depth of fusion under definite laser strength.

Owner:ZHENGZHOU BAK BATTERY CO LTD

An electric core shell and electric core

ActiveCN101150178AInhibition lossReduce defective welding rateFinal product manufactureOrganic electrolyte cellsEngineeringCore shell

This invention discloses a core shell including a drum and up and down cover plates, in which, said drum is a drum with bottom and an aperture at the top, the bottom is set with a through hole characterizing that a convex stand is set along the edge of the down cover plate and a convex stand is also set along the edge of the through hole on the bottom of the drum. This invention also discloses a core using the shell. Since the heat conductivity of air is much lower than that of metal, it can stop losing of heat in laser welding effectively by setting a circle of convex stand along the edge of the through hole on the bottom and a convex stand on the bottom cover plate so as to deepen the depth of fusion under definite laser strength.

Owner:ZHENGZHOU BAK BATTERY CO LTD

An electric core shell and electric core

ActiveCN100590907CInhibition lossReduce defective welding rateFinal product manufactureOrganic electrolyte cellsEngineeringCore shell

Owner:ZHENGZHOU BAK BATTERY CO LTD

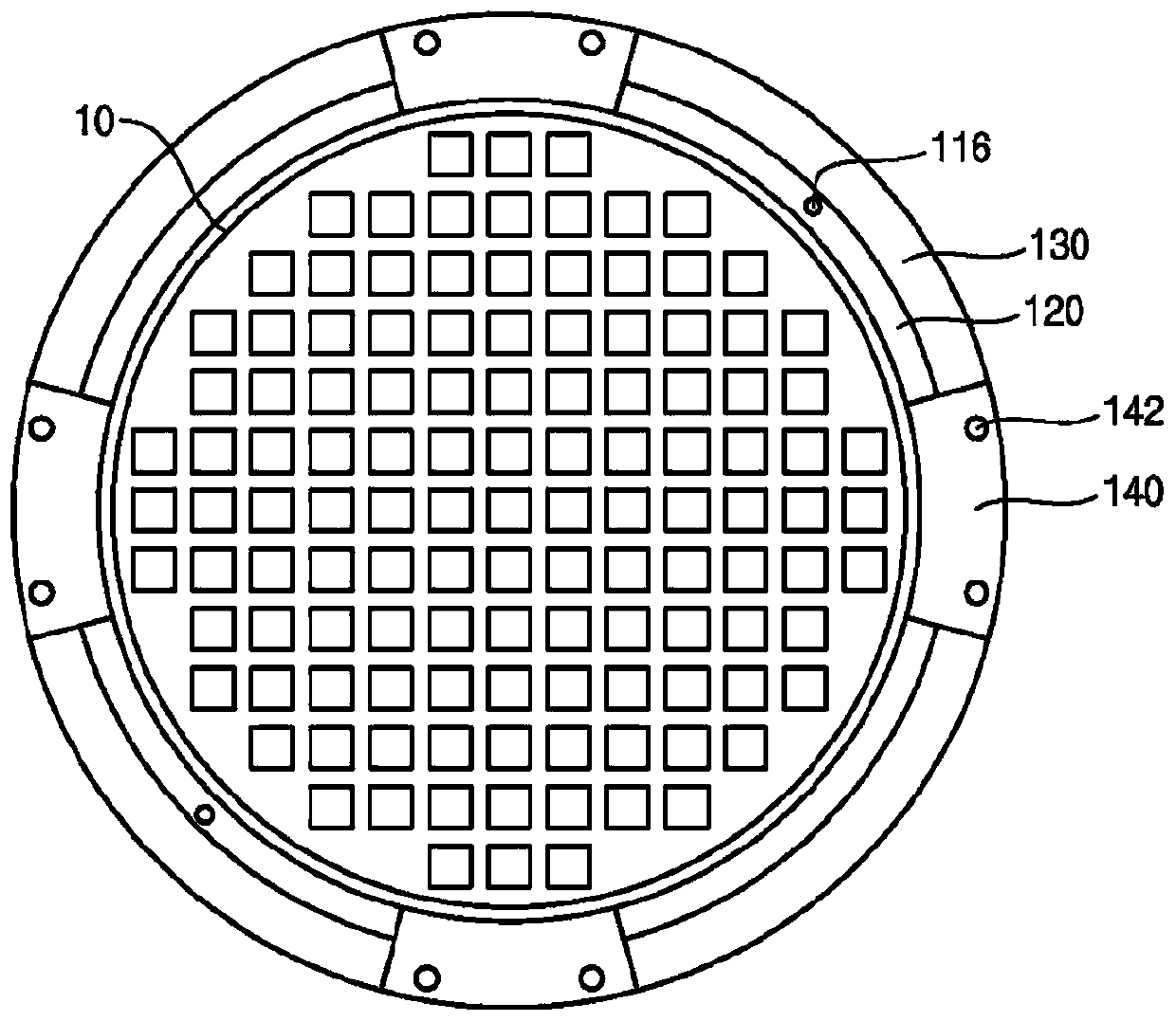

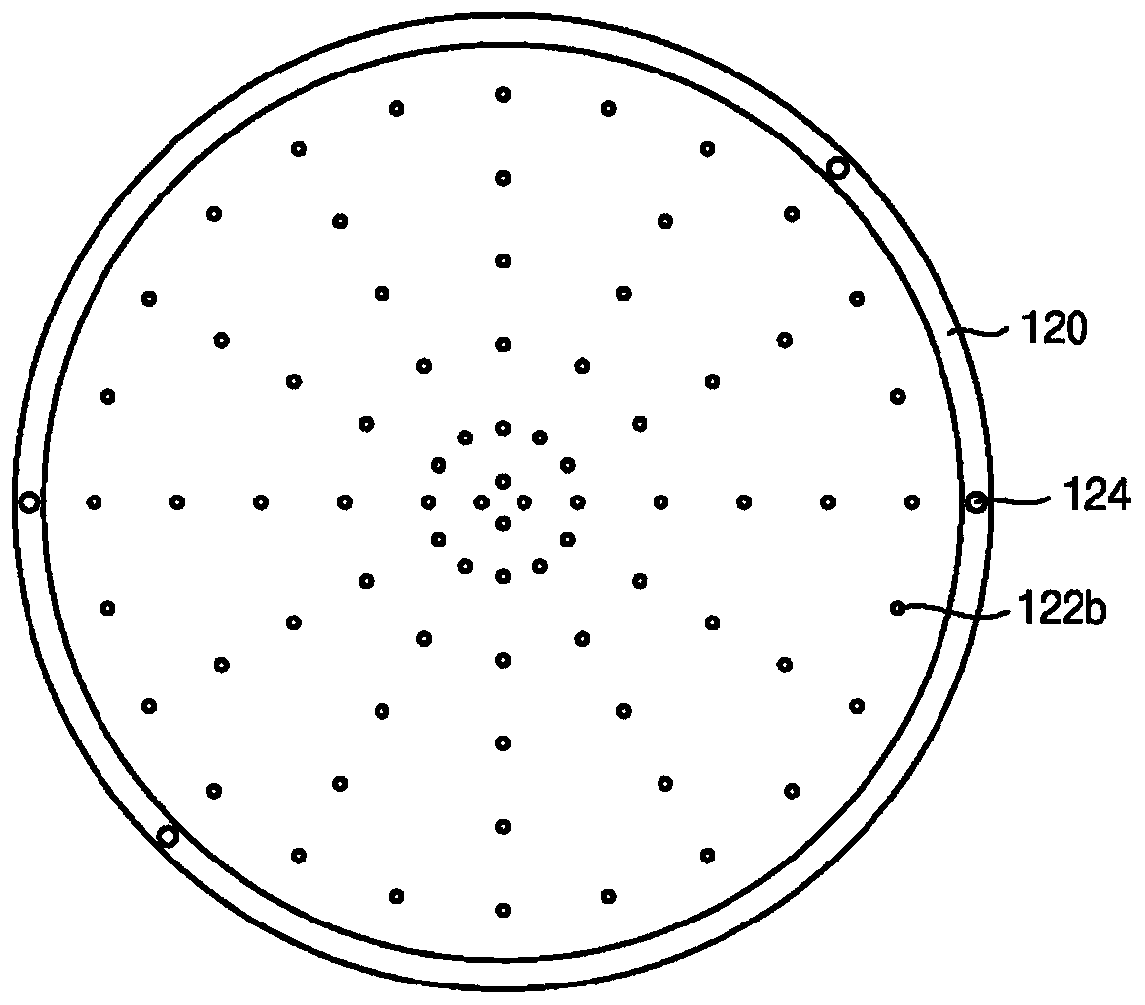

Chuck plate, chuck structure having chuck plate, and bonding device having chuck structure

PendingCN111344855AReduce defective welding ratePrevent crushingSemiconductor/solid-state device manufacturingPhysicsEngineering

A chuck plate of a chuck structure is placed on a heating plate, supports a wafer on the upper surface thereof, transfers, to the wafer, heat generated by the heating plate such that the wafer is heated, and can have: vacuum holes penetrating the top and the bottom thereof in order to adsorb the wafer by vacuum force; and a vacuum groove, which is provided on the lower surface thereof such that the chuck plate is vacuum-adsorbed to the heating plate, and forms a space by being limited by the upper surface of the heating plate.

Owner:MICOCERAMICS LTD

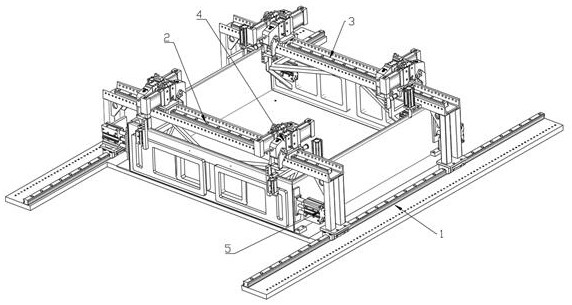

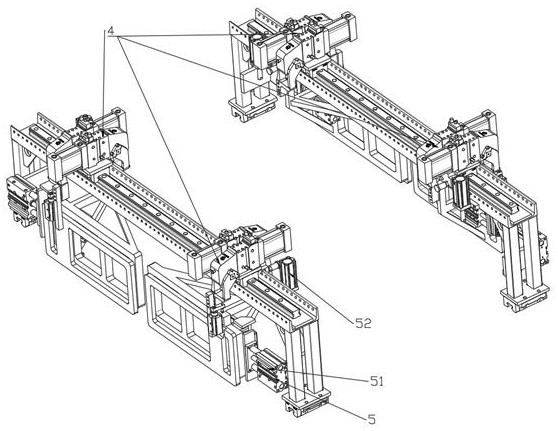

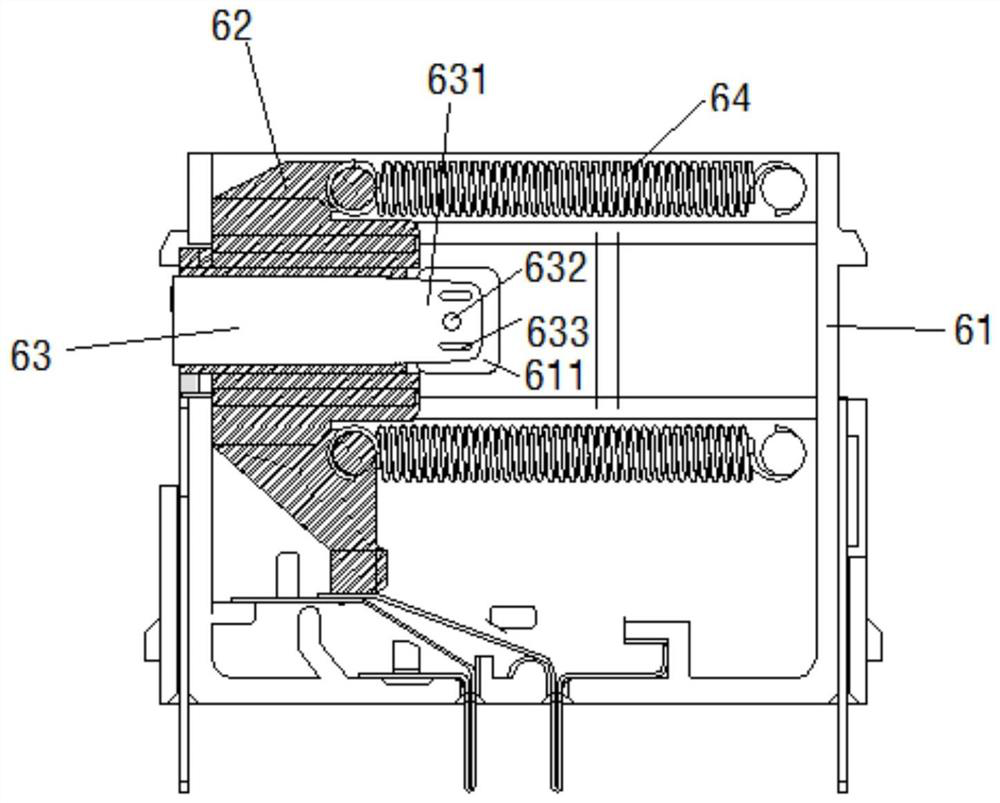

Clamping equipment for LED display screen box body welding

InactiveCN112719746AStable clampingAvoid offsetWelding/cutting auxillary devicesAuxillary welding devicesLED displayEngineering

The invention discloses a clamping device for LED display screen box body welding. The clamping device comprises a tool flat plate table, a first portal frame, a second portal frame, clamping mechanisms and pushing mechanisms; the first portal frame and the second portal frame are arranged on the tool flat plate table in parallel; the bottom of the first portal frame and the bottom of the second portal frame are both glidingly connected to the tool flat plate table; the clamping mechanisms are evenly distributed on the first portal frame and the second portal frame; the pushing mechanisms are arranged on the inner sides of stand columns and cross beams of the first portal frame and the second portal frame correspondingly; the clamping mechanisms are used for firmly and stably clamping to-be-welded box bodies; and the pushing mechanisms are used for tightly pushing the to-be-welded box bodies to prevent the to-be-welded box bodies from moving. According to the clamping device, welding position deviation caused by clamping can be effectively avoided, clamping is stable, the welding efficiency is high, the welding quality is firm, the welding reject ratio is greatly reduced, the production benefit is effectively improved, and the good market application value is achieved.

Owner:SHENZHEN BAKO OPTOELECTRONICS CO LTD

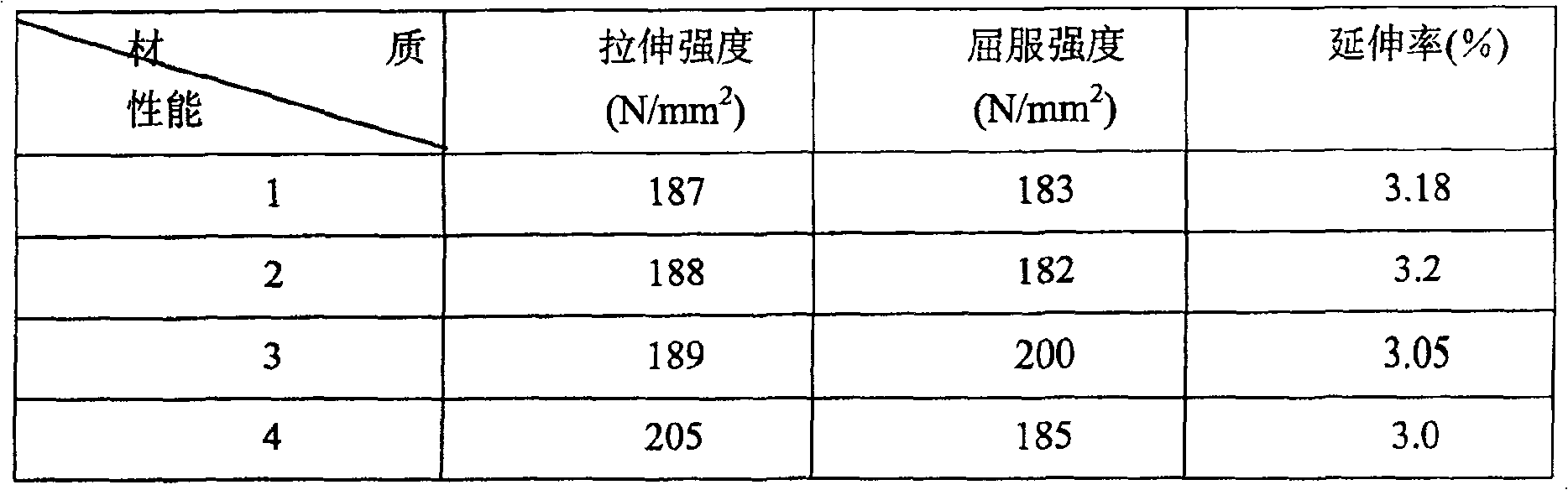

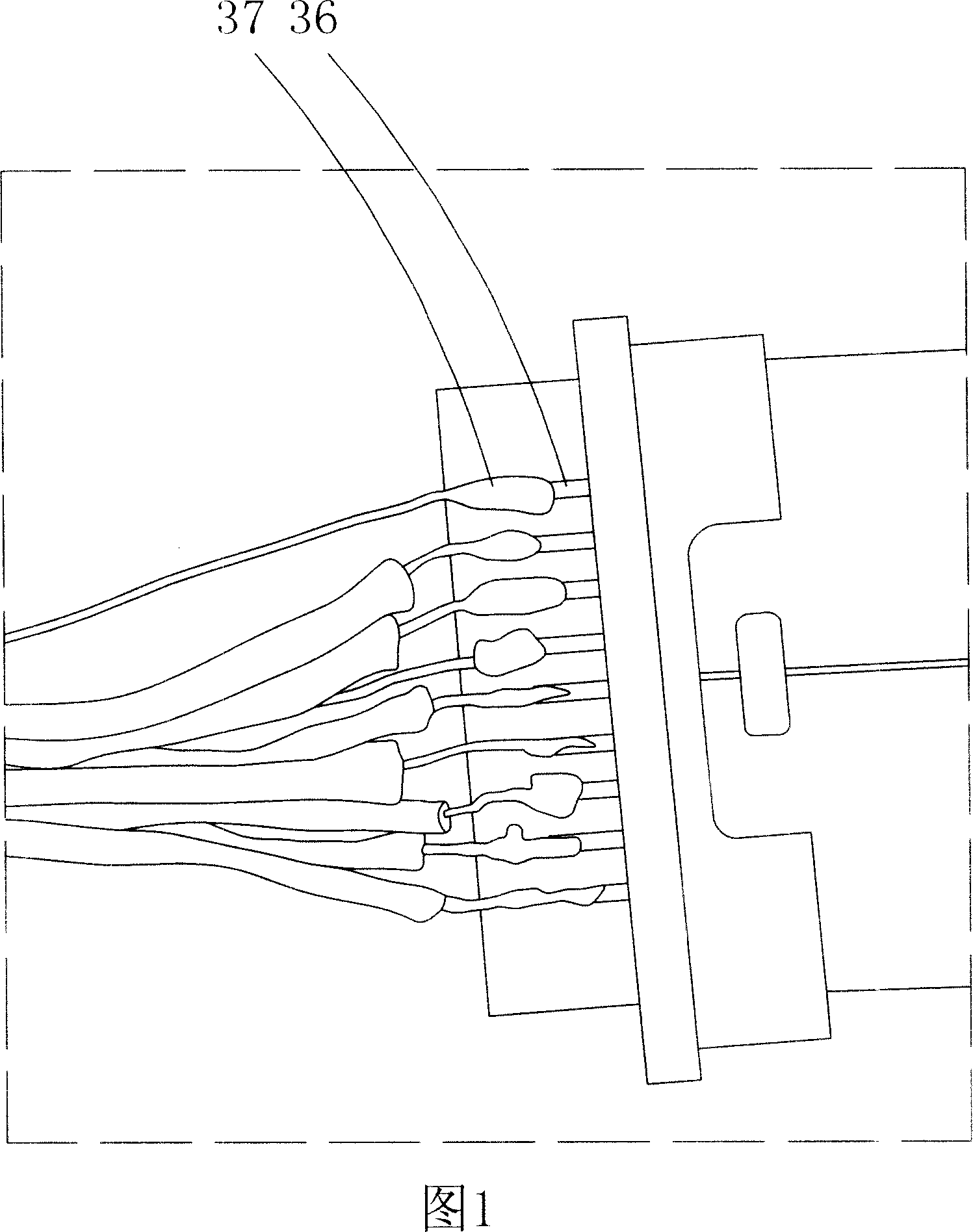

Aluminum alloy for preparing battery shell

ActiveCN100590214CImprove surface strengthIncrease design capacityCell component detailsTitaniumCopper

The invention relates to an aluminum alloy for manufacturing cell shell, which is composed of the following components in weight percentage: 0.1%<Si<0.3%, 0.2%<Fe<0.55%, 0.12%<Cu<1.0%, 0.25%< Mg<0.6%,0.5%<Mn<2%, 0.05%<Zr<0.3% and 0.05<=Ti<=0.1, and other elements are 0.05% at most for each and 0.15% at most for all and the rest element is aluminum. The invention provides an aluminum alloy for manufacturing cell shell with high tensile strength, high yield strength and low elongation percentage.

Owner:ZHENGZHOU BAK BATTERY CO LTD

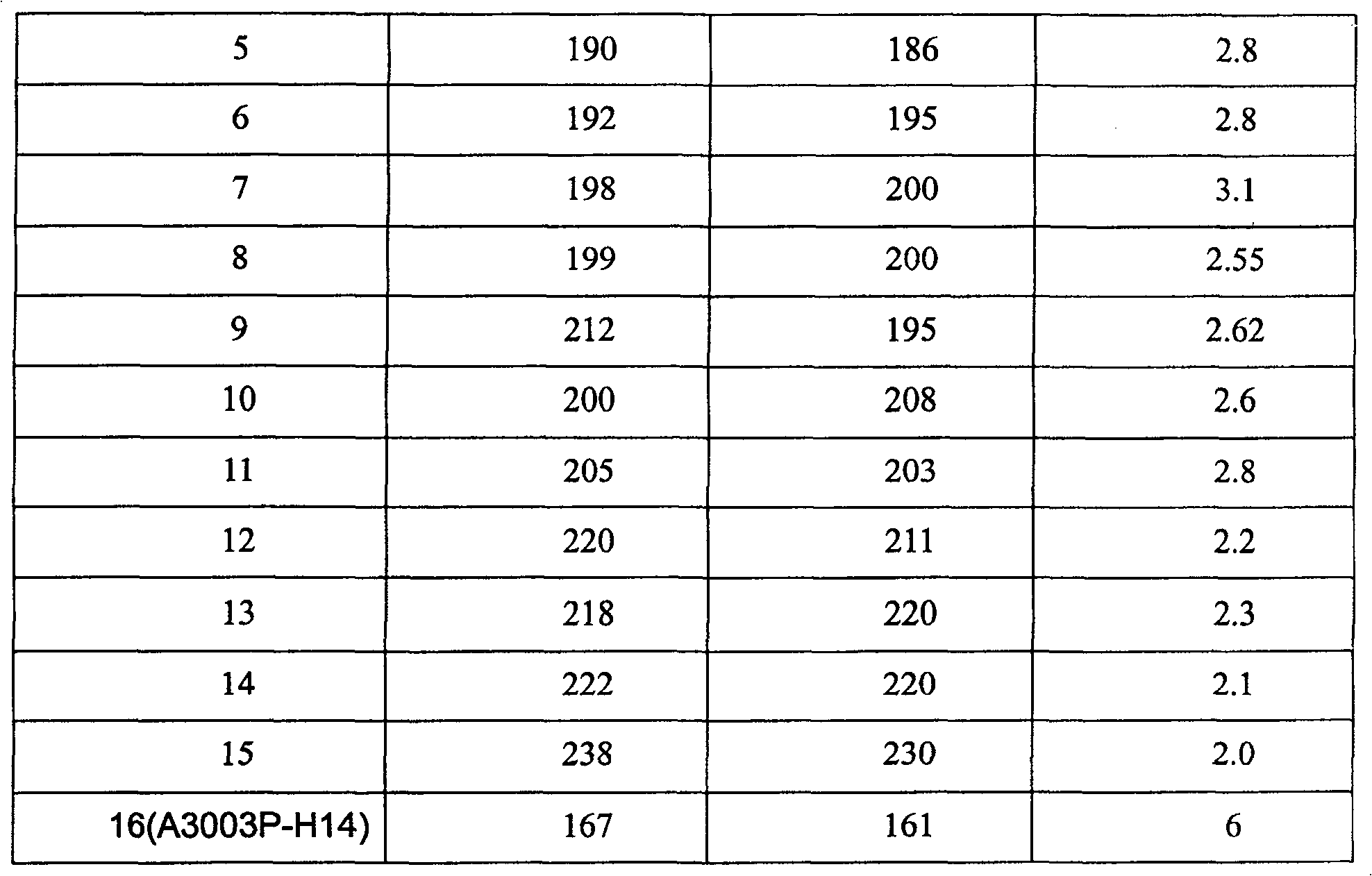

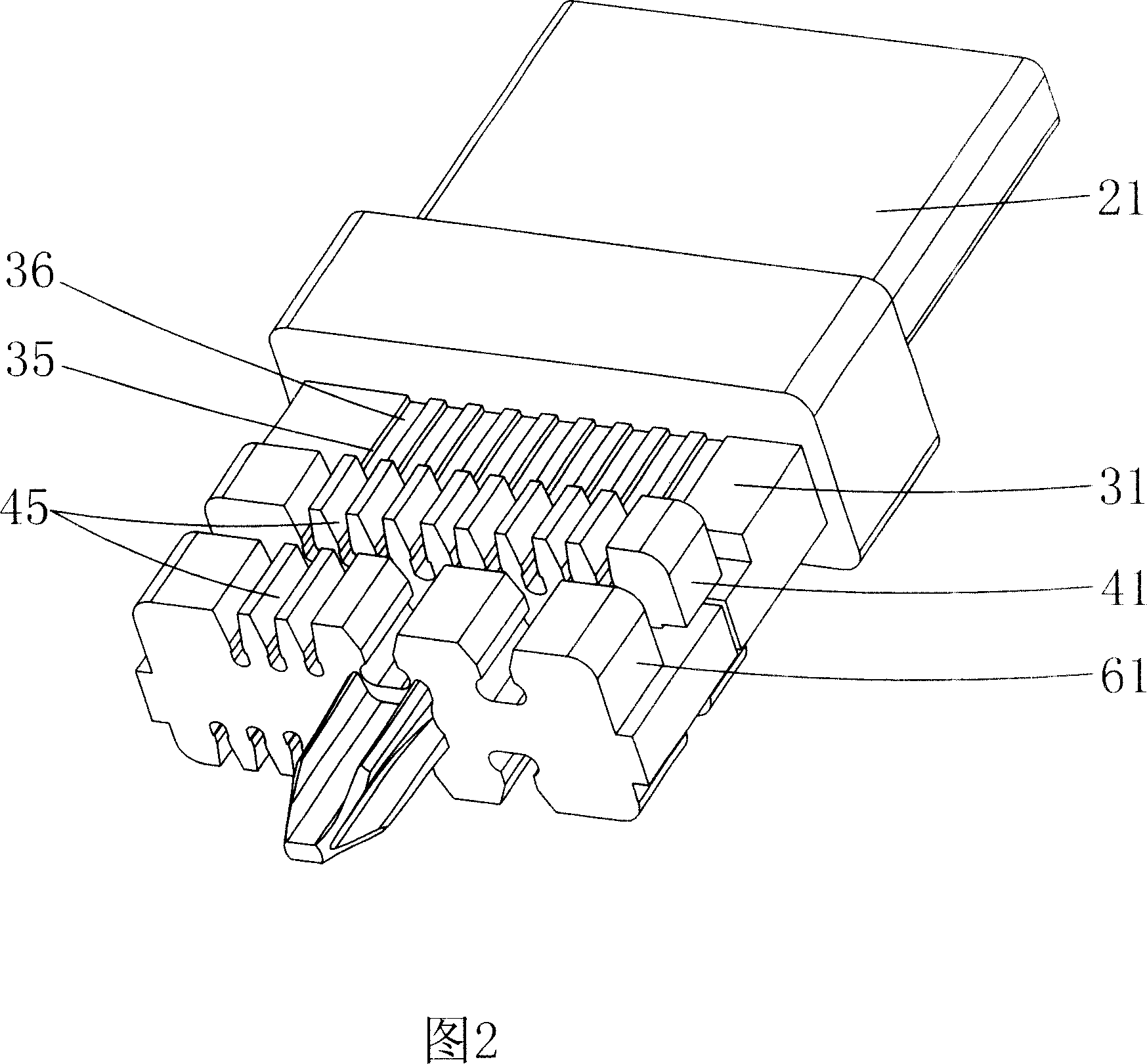

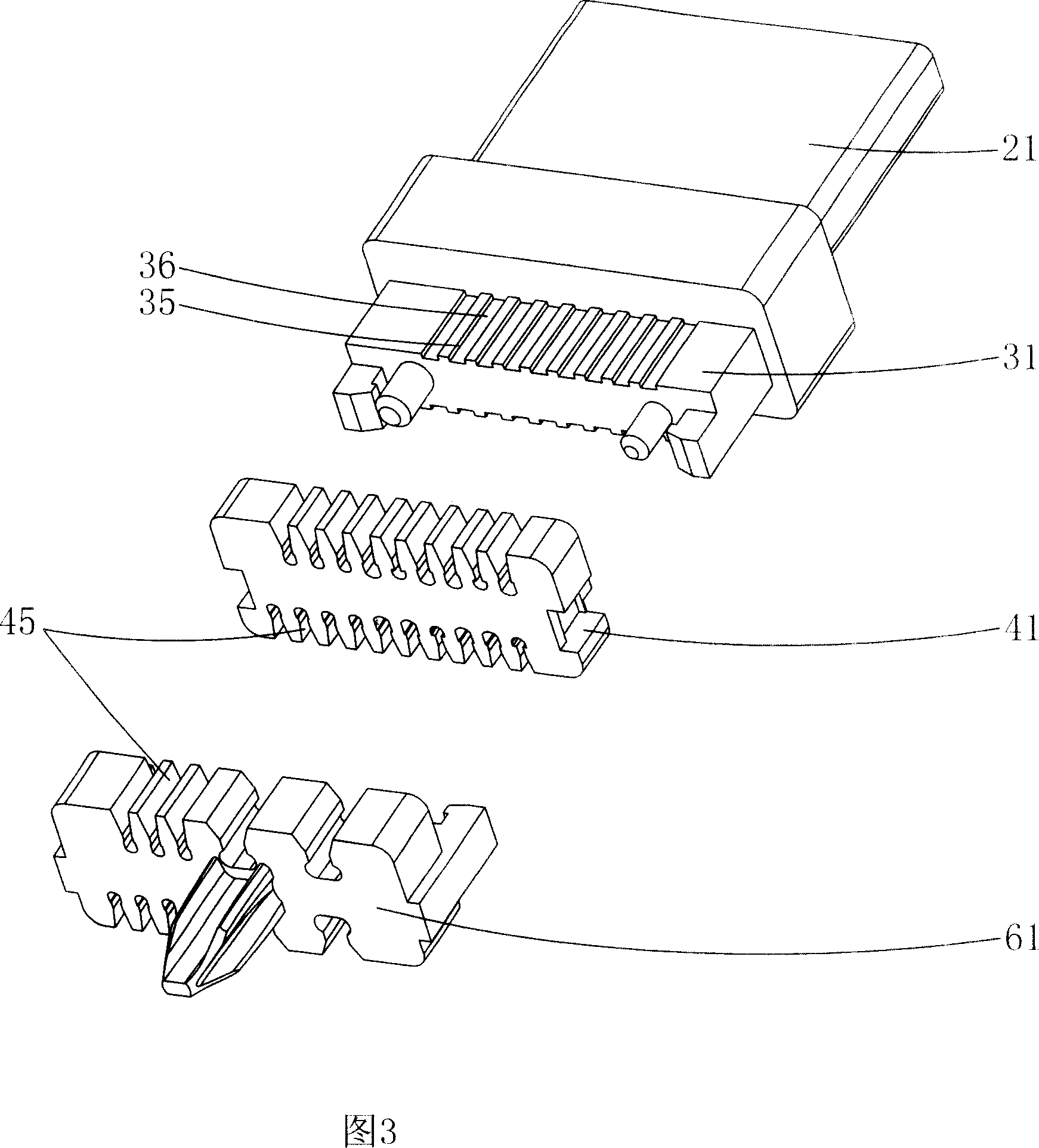

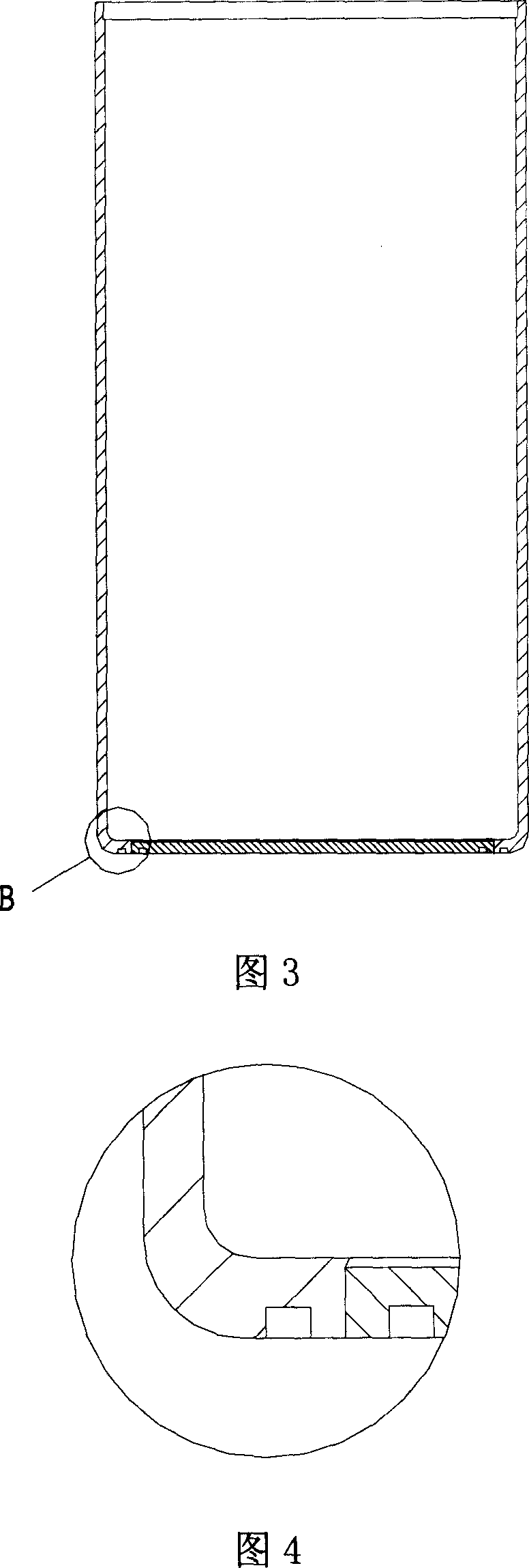

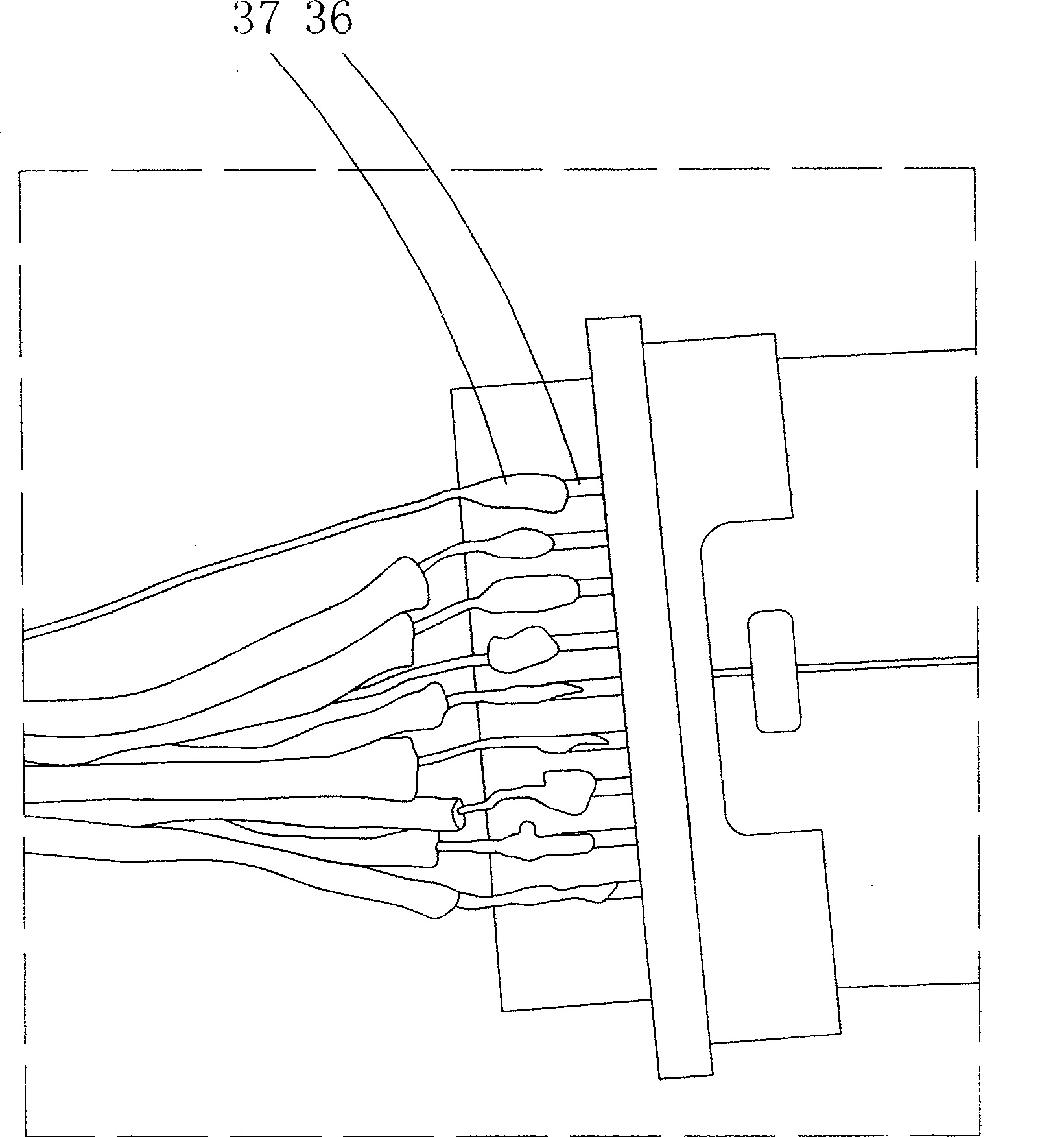

Processing technology for high-resolution digital interface

InactiveCN1976421AOrderly rowsAvoid mutual interferenceTelevision system detailsColor television detailsDigital interfaceEngineering

A manufacturing process of high definition digital interface includes assembling wire rubber plug, rubber plug in stab mode, medium rubber plug and automatic welding unit on said digital interface; pressing each core wire into grooves of wire rubber plug and rubber plug in stab mode, brushing tin solder on core wires and clamping them on automatic welder for carrying out automatic welding, shining light on core wire and terminal wiring end by welder to weld core wire on terminal wiring end by melting tin solder with heating for finalizing said welding at only one time.

Owner:许庆仁

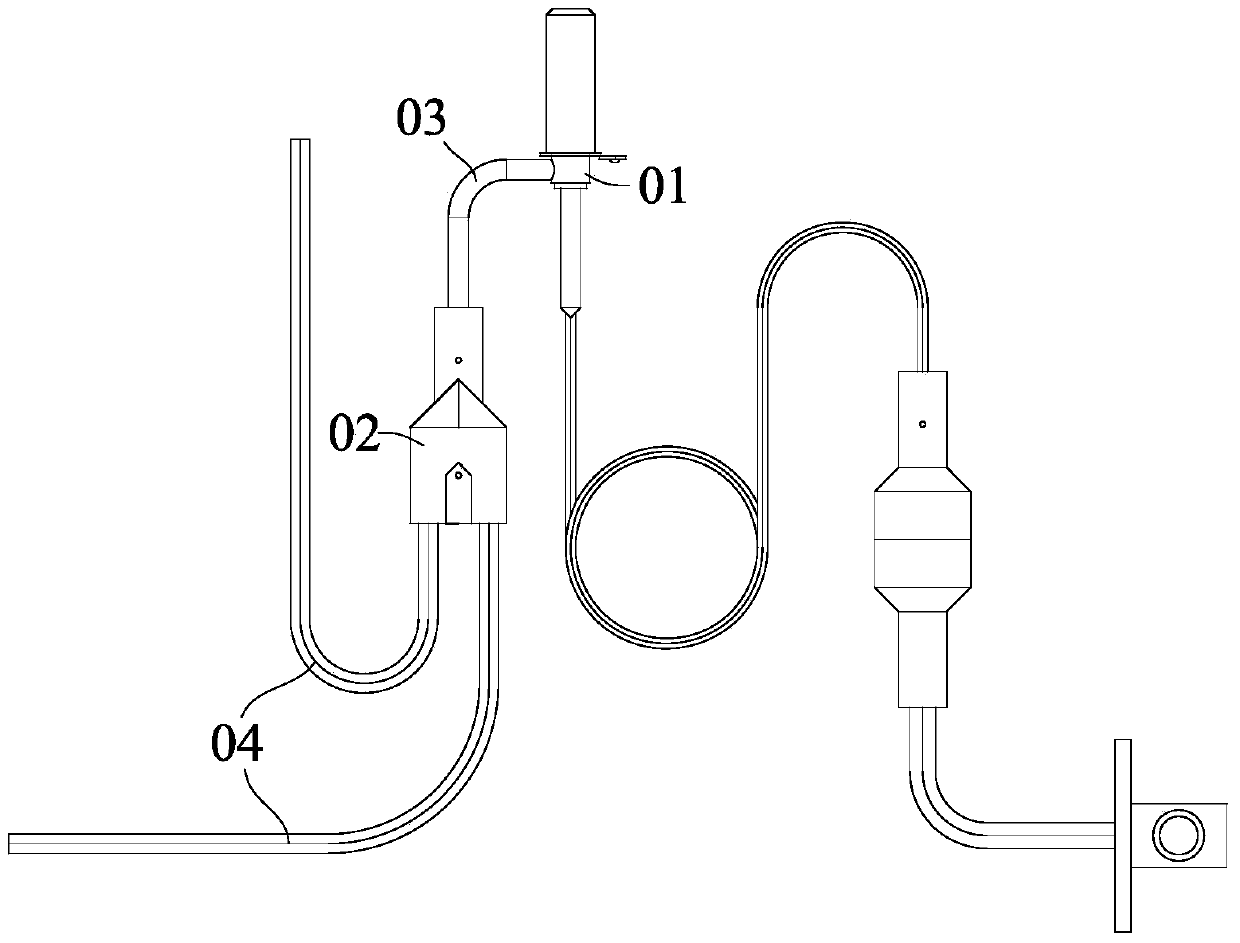

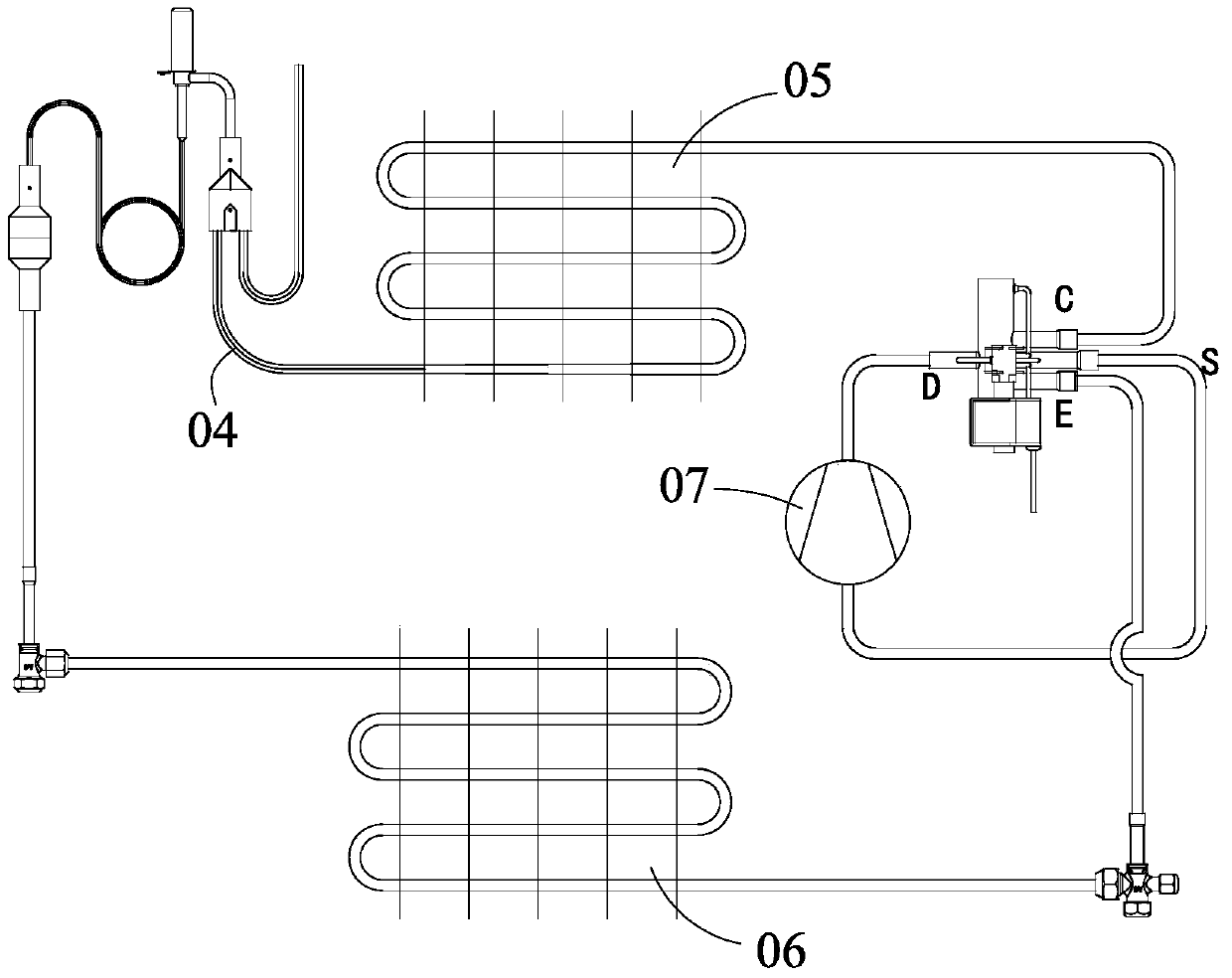

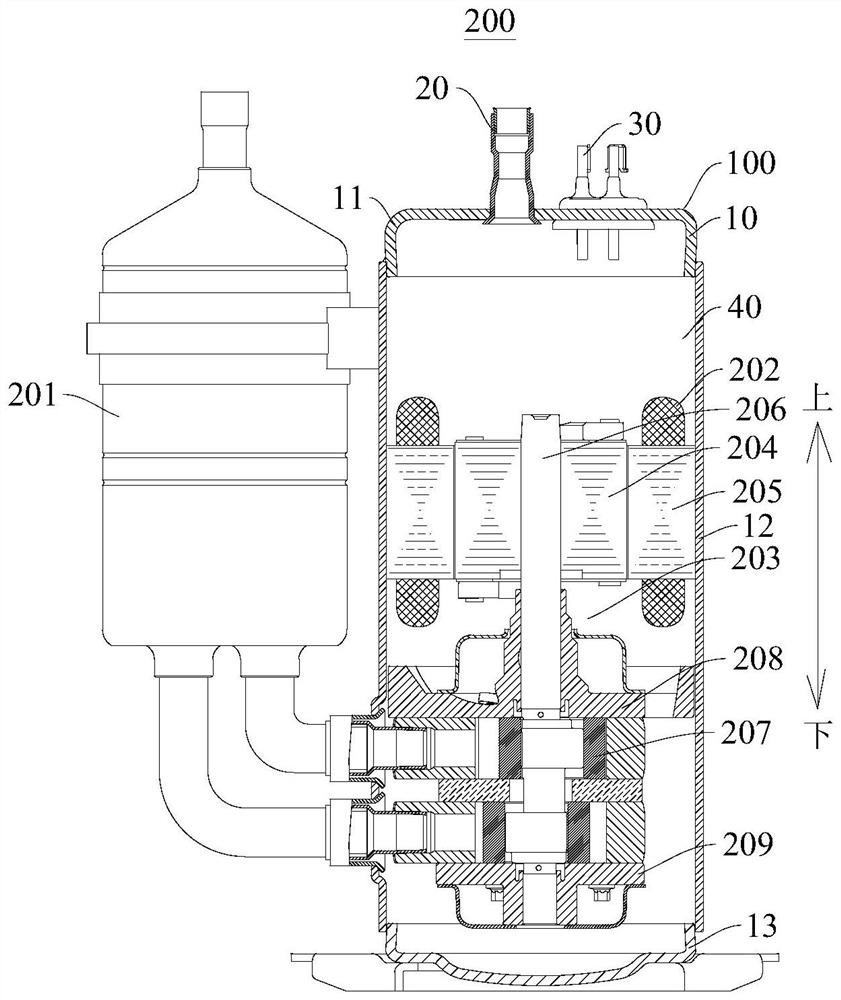

Electronic expansion valve for air-conditioning system and its air-conditioning system

ActiveCN105588378BLow costReduce defective welding rateMechanical apparatusEfficient regulation technologiesIceboxProcess engineering

The invention discloses an electronic expansion valve for an air-conditioning system and its air-conditioning system, which belongs to the technical field of refrigeration and solves the technical problems of the existing air-conditioning and refrigeration systems such as high production cost and complicated process. The electronic expansion valve of the present invention includes a valve body with an inner cavity , the valve body is connected with an inlet pipe and an outlet pipe, and the valve body is also connected with a refrigerant charging pipe communicating with the inner cavity. Embodiments of the present invention use expansion valves, usually electronic expansion valves used in air conditioning systems such as air conditioners and refrigerators.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

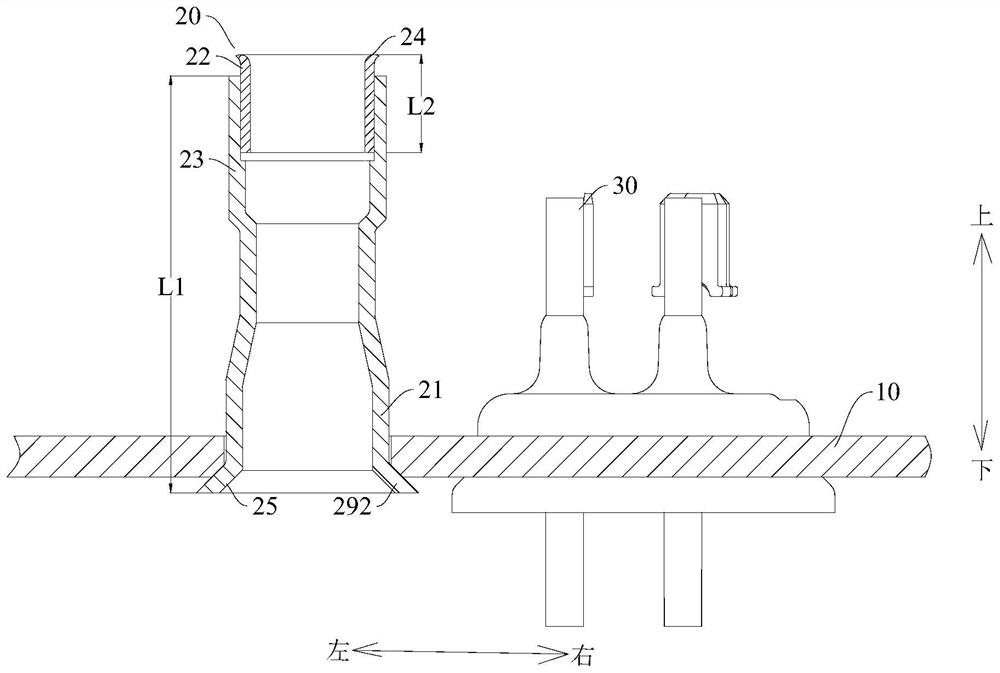

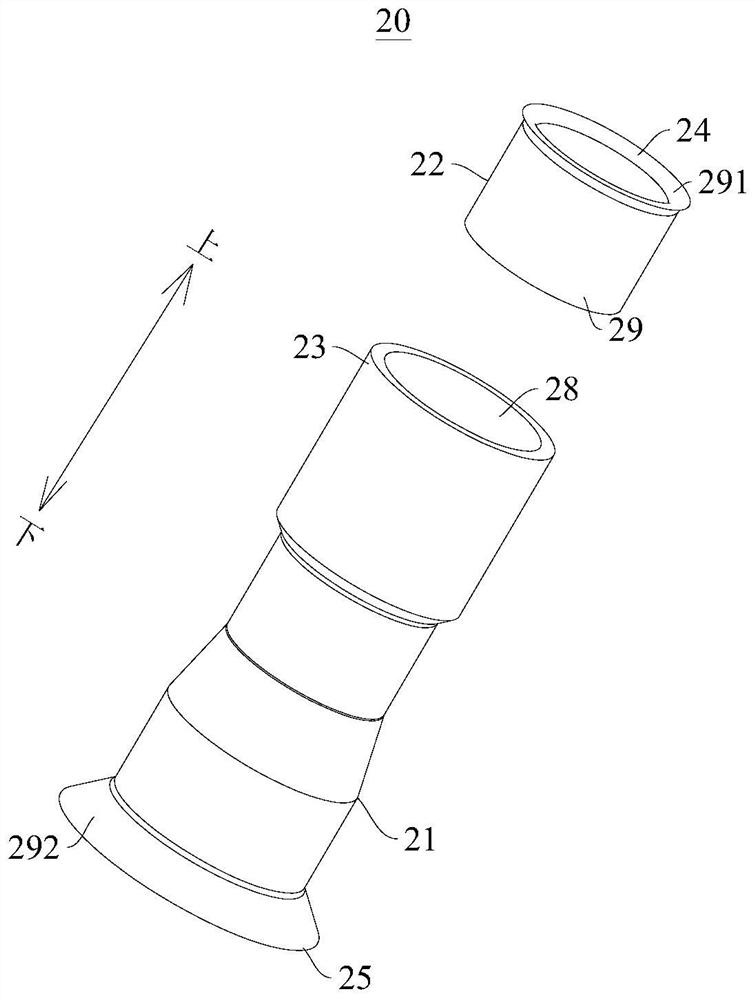

Shell for compressor and compressor

PendingCN114251267AIncrease productivityReduce manufacturing costRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectrical resistance and conductanceEngineering

The invention discloses a shell used for a compressor and the compressor. The shell used for the compressor comprises a shell body and a shell cover, the exhaust pipe assembly is fixed to the shell body and comprises a first pipe part and a second pipe part, the first pipe part is fixed to the shell body in a welded mode, the first pipe part is provided with an outer section part extending out of the shell body, the outer section part is fixed to the second pipe part in a welded mode, and the first pipe part and the shell body are made of iron. And the material of the second pipe part comprises copper. Therefore, the outer section part and the second pipe part are welded and fixed, and the outer section part and the shell body can be welded by adopting an electric resistance welding process, so that the production efficiency of the compressor can be improved, the welding reject ratio can be reduced, the use of brazing silver solder can be reduced, the production cost of the compressor can be reduced, and the production efficiency of the compressor can be improved. And the first pipe part is made of iron, so that the use of copper materials can be reduced, and the production cost of the compressor can be further reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

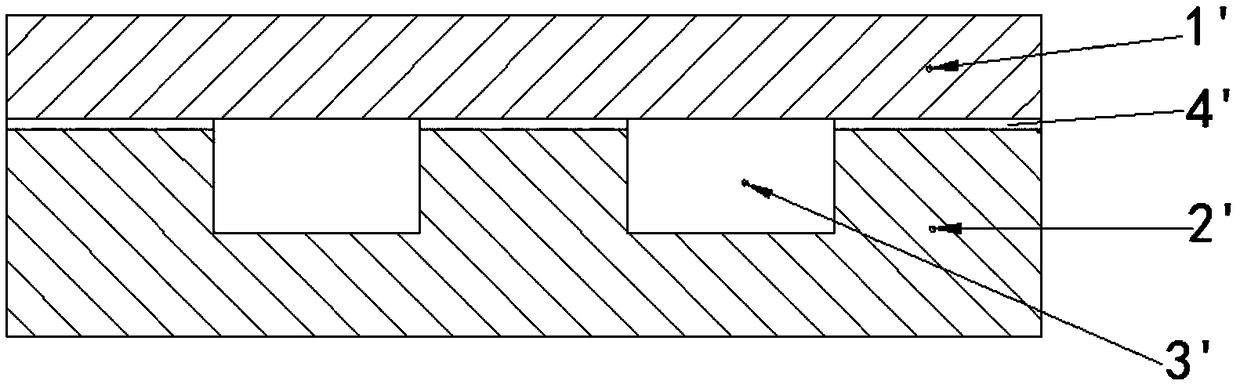

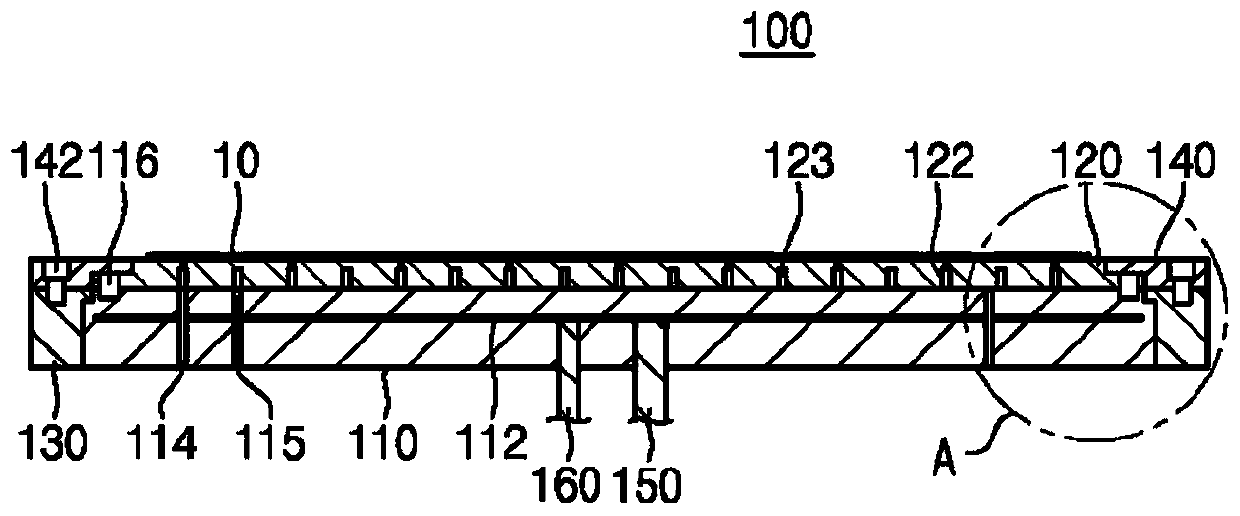

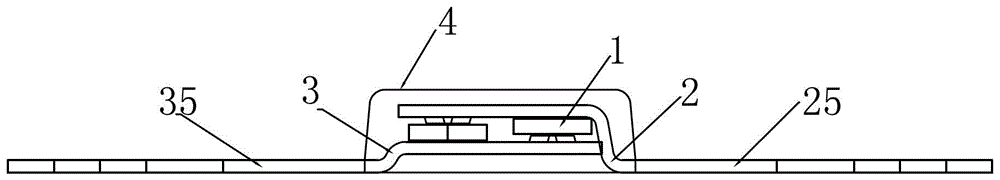

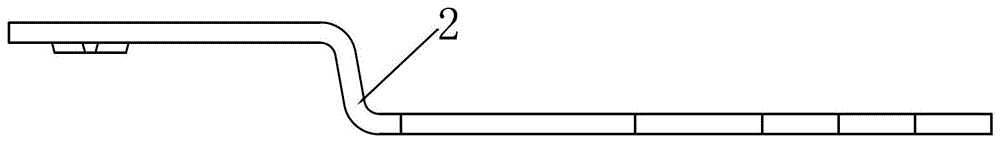

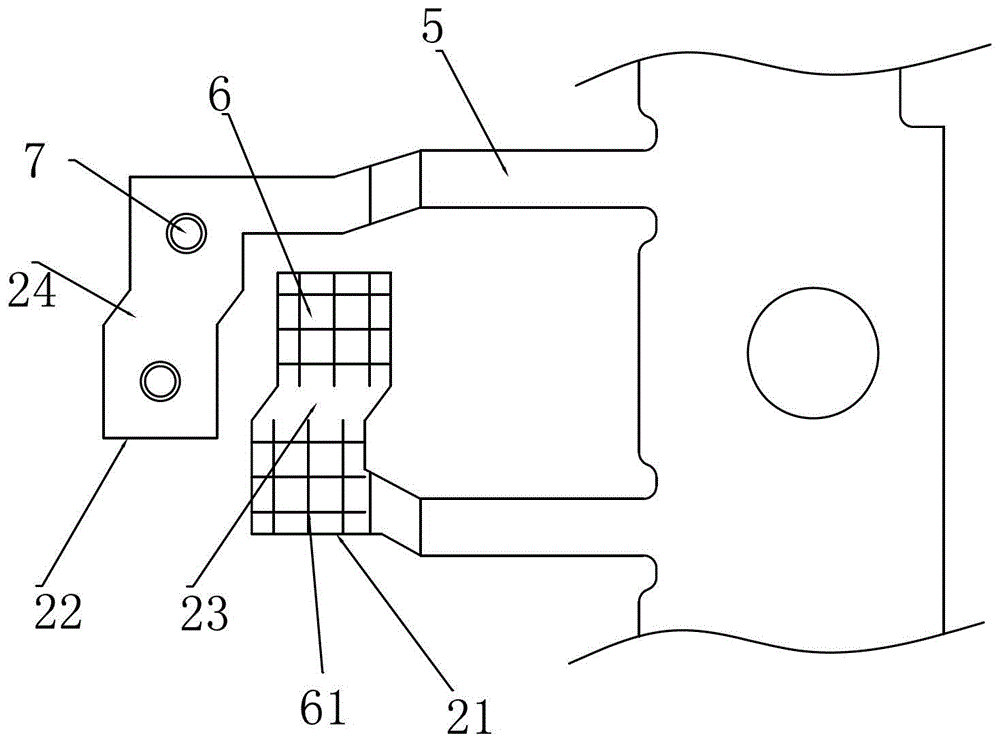

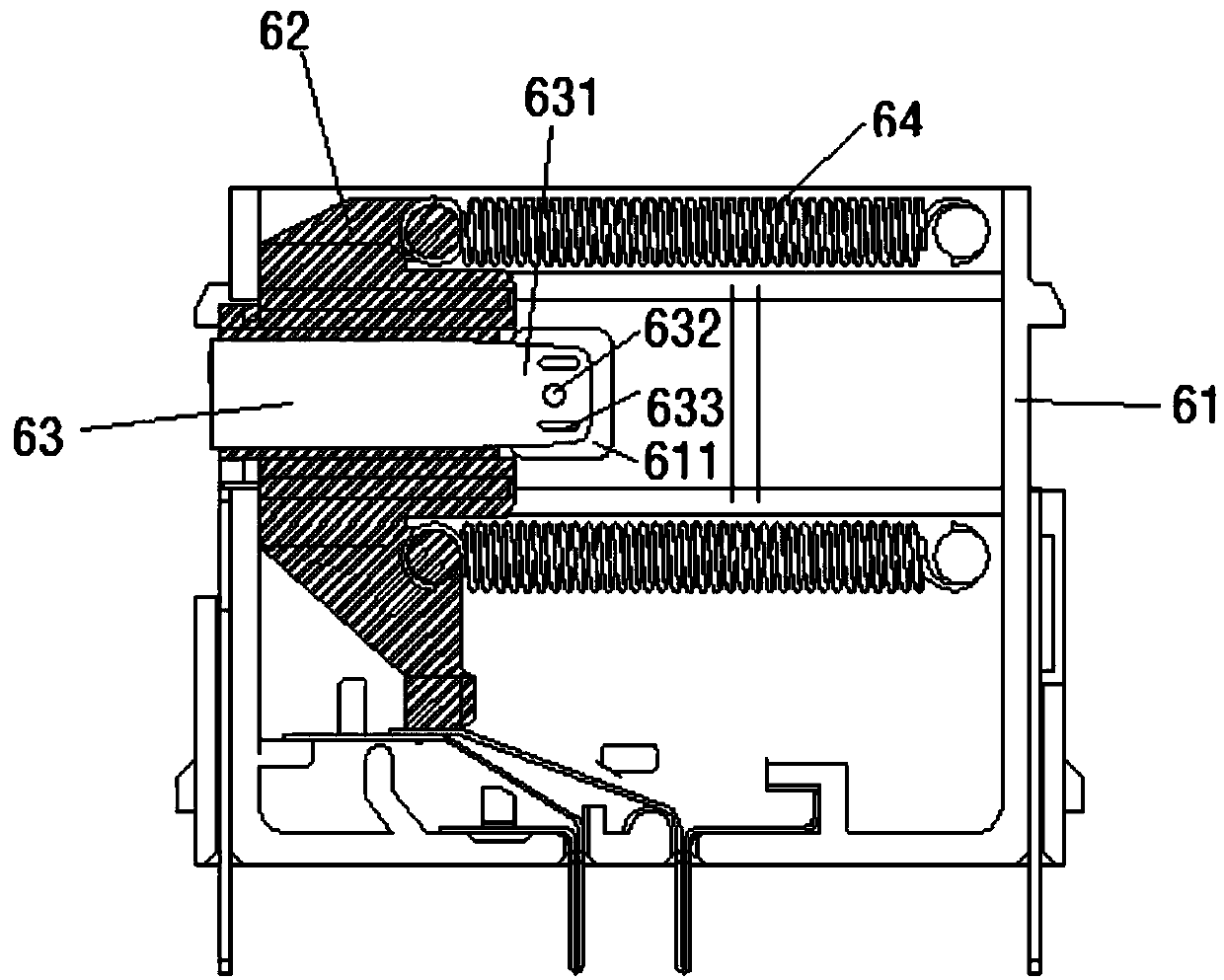

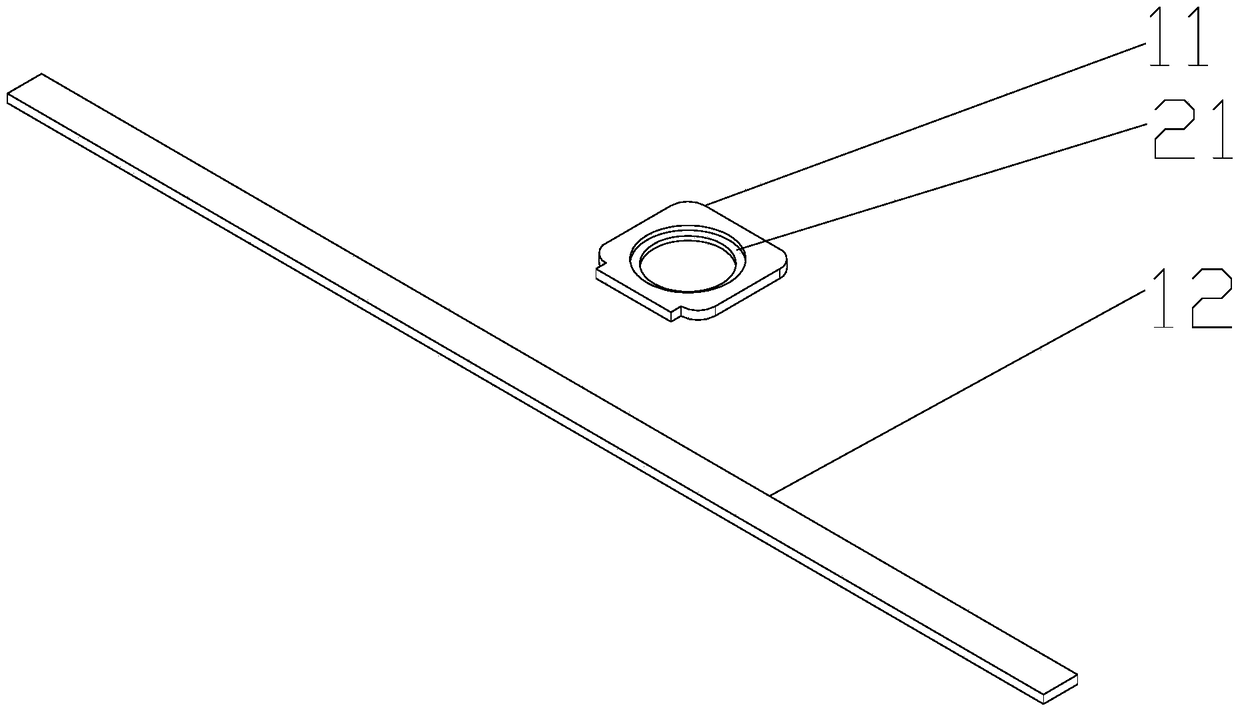

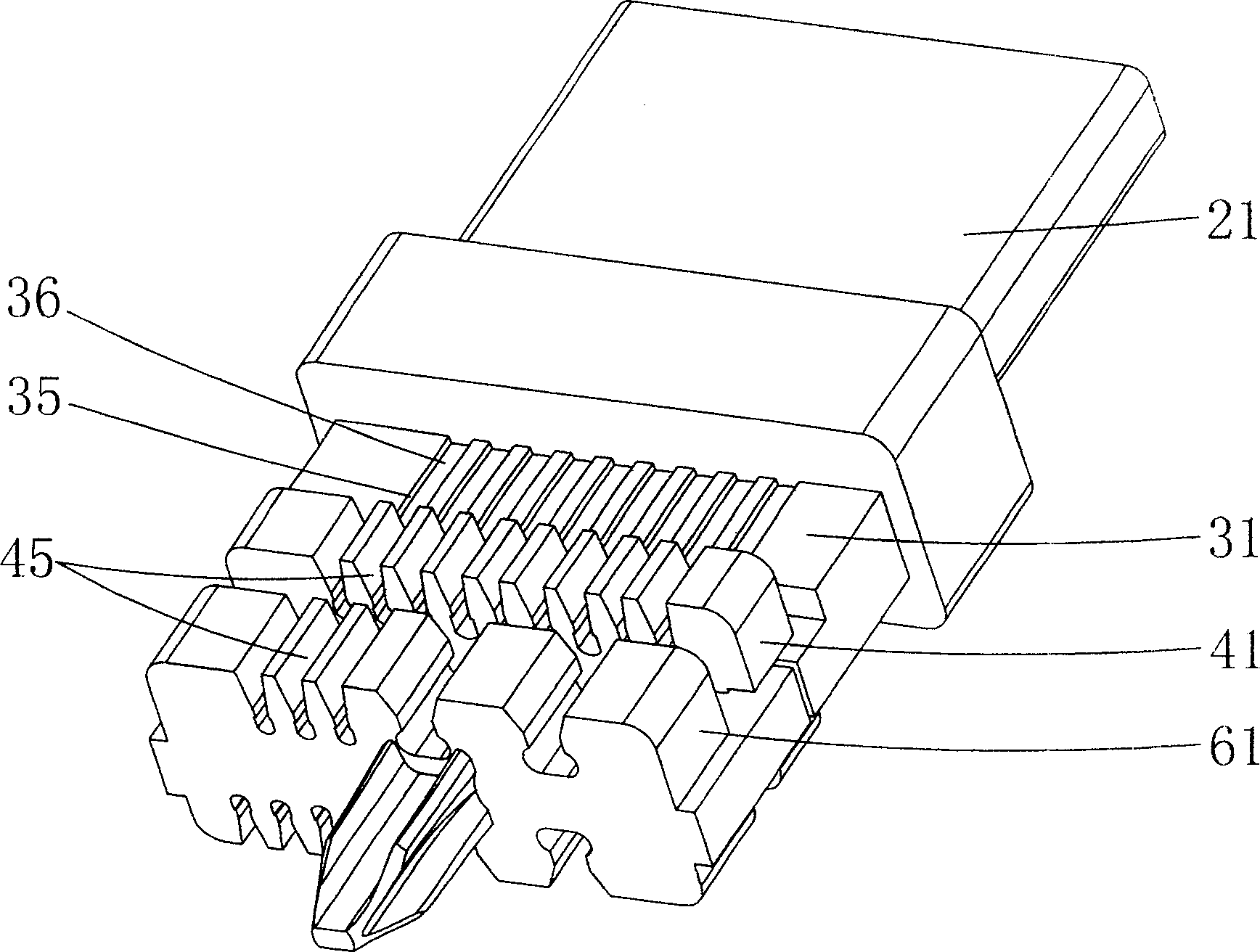

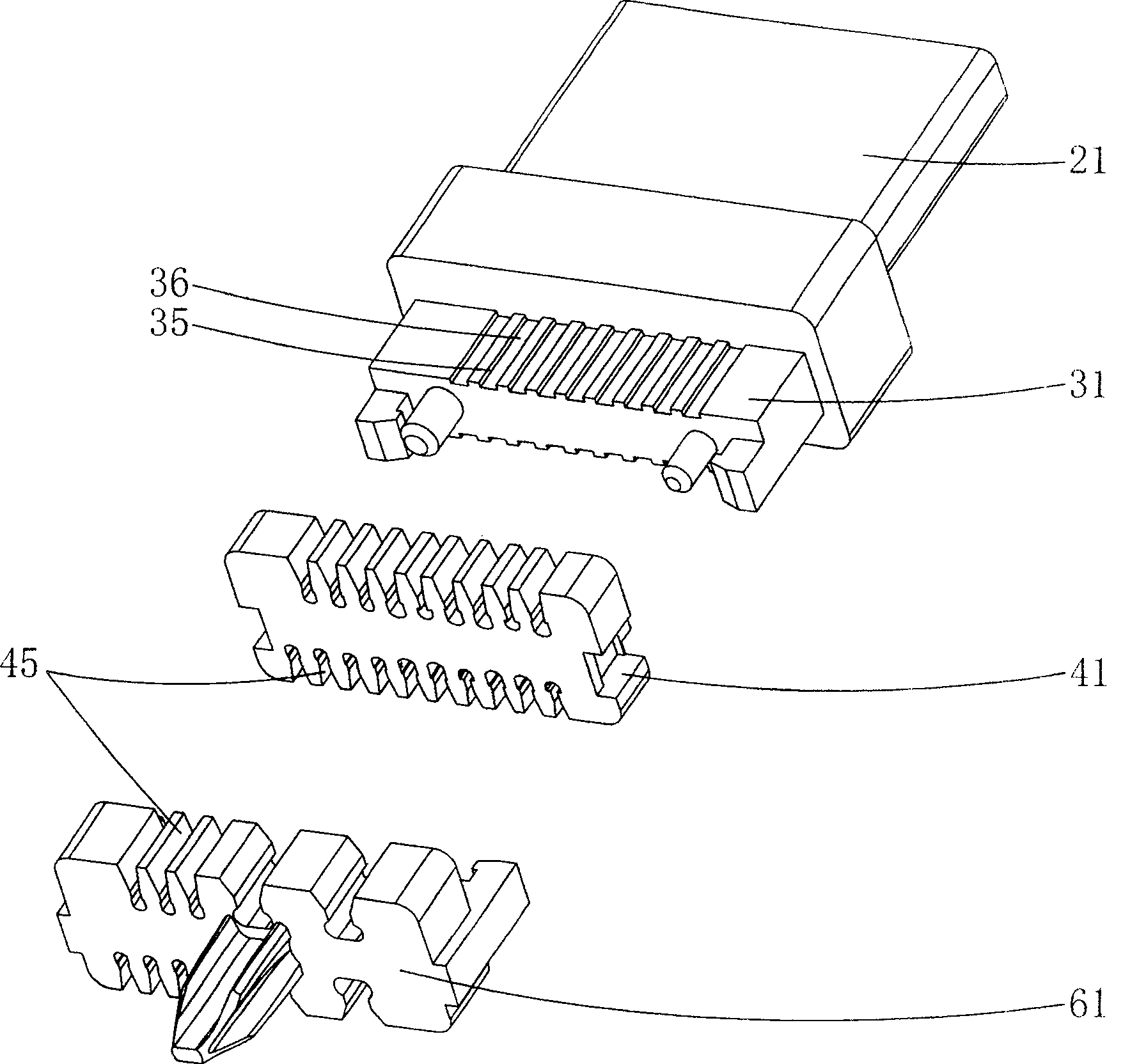

A miniature ultra-thin unidirectional rectifier bridge device and its processing technology

ActiveCN104124222BEasy to weldReduce defective welding rateSemiconductor/solid-state device detailsSolid-state devicesEngineeringMachining process

The invention discloses a miniature ultrathin unidirectional rectifier bridge device which comprises four rectification chips for forming a rectifier bridge circuit, an upper sheet unit, a lower sheet unit and a packaging body. The rectification chips are arranged between the upper sheet unit and the lower sheet unit. The upper sheet unit is arranged opposite to the lower sheet unit, and the cross section of the upper sheet unit and the lower sheet unit is Z-shaped. The upper sheet unit and the lower sheet unit both comprises two leading-out terminals, the lower surfaces of which share the same plane with the bottom surface of the packaging body. The upper sheet unit and the lower sheet unit are both provided with a flat welding pad and a projection welding pad with bumps. Warps for promoting the upper sheet unit and the lower sheet unit to be combined with the rectification chips are arranged on the flat welding pad. By the miniature ultrathin unidirectional rectifier bridge device and its processing technology, through the arrangement of the warps on the flat welding pad and by man-made creation of sheet atoms for crystal orientation layout, sheets are welded with the chips more perfectly during the welding process due to crystal orientation effect of the two materials. Thus, welding reject rate is reduced, product reliability is raised, cost is decreased, and resources are saved.

Owner:颖拓萃半导体(南通)有限公司

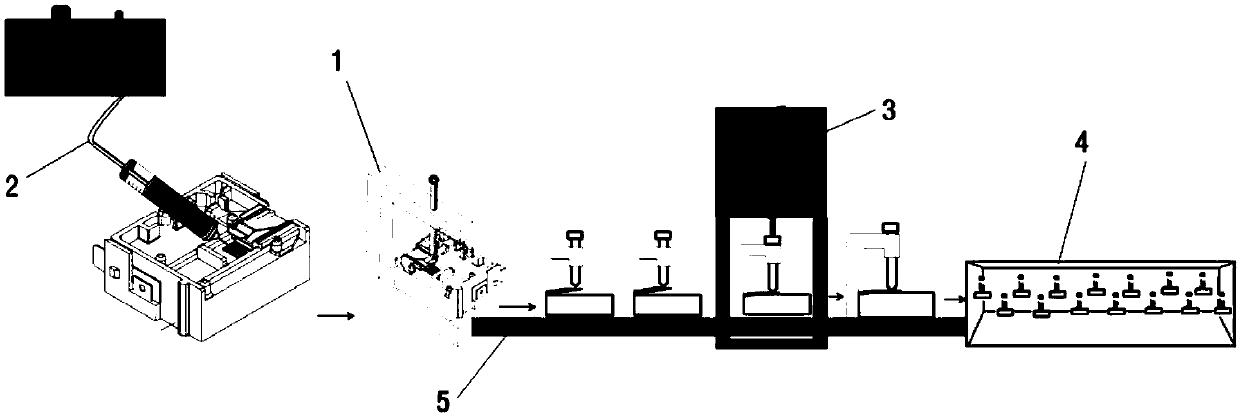

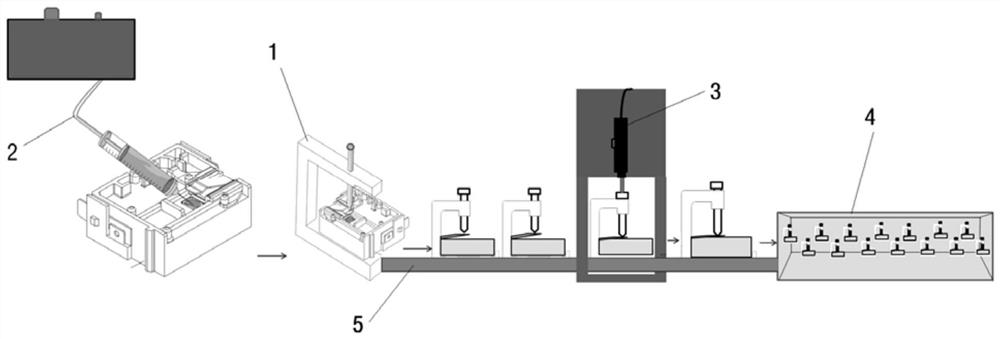

Welding method and system for electrode plate of surge protector

ActiveCN111375858AQualified solder jointsReduce defective welding rateSolder feeding devicesSoldering auxillary devicesSolder pasteSurge protector

The invention relates to a welding method and system for an electrode plate of a surge protector. The welding method provided by the invention comprises the steps that the surge protector to be weldedis provided, wherein the surge protector comprises a housing, a sliding block and the electrode plate, the sliding block is arranged between the housing and the electrode plate, the electrode plate comprises a welding end, and a bonding pad area used for welding the electrode plate is arranged on the housing; solder paste is injected into the bonding pad area, the welding end is attached to the solder paste, and a first workpiece is obtained; the first workpiece is obtained, the distance between the welding end and the bonding pad area is adjusted and fixed, the thickness of the solder pasteis smaller than or equal to the distance between the sliding block and the bonding pad area, the space between the welding end and the bonding pad area is filled with the solder paste, part of the solder paste is extruded to the edge of the outer side of the welding end, and a second workpiece is obtained; and the second workpiece is obtained, and reflow soldering is conducted. On the premise thatthe safety protection effect of the surge protector is not affected, qualified welding spots are obtained, the welding reject ratio is decreased, and the welding method and system are suitable for mass production of the surge protector with excellent and stable performance.

Owner:SHENZHEN HAIPENGXIN ELECTRONICS

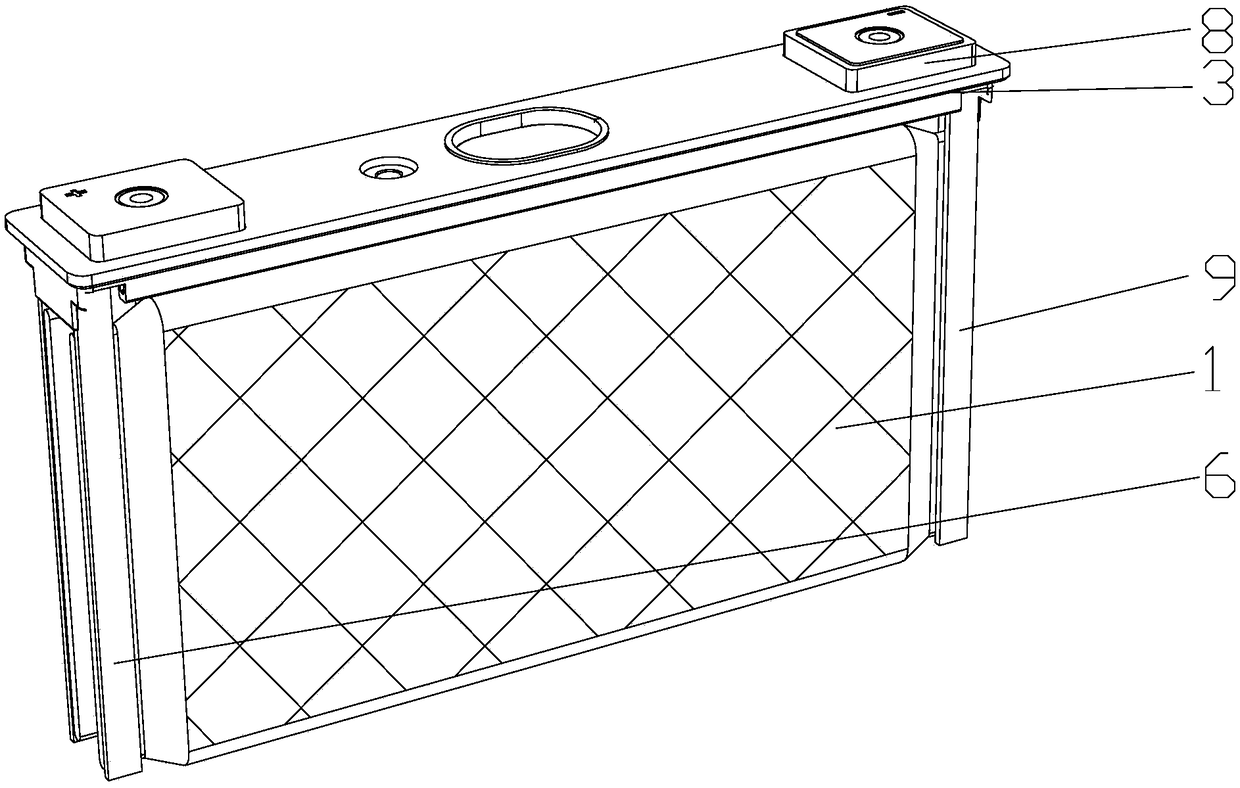

A battery cell and cover plate assembly structure and assembly method thereof

PendingCN109004259ASimplify the assembly processEasy to operateAssembling battery machinesFinal product manufactureEngineeringAssembly structure

The invention discloses a battery cell and cover plate assembly structure and assembly method thereof. The battery cell and cover plate assembly structure includes two bare cells and a cover plate structure, a positive electrode claw structure comprises a connecting piece and positive electrode claws, The positive electrode claw comprises a connecting piece and two positive electrode claws I arranged in parallel, a positive electrode claws I are arranged perpendicularly to a connecting piece I, a connecting part is connected to the connecting piece I, a negative electrode claw structure comprises a connecting piece II and negative electrode claws, the negative electrode claws comprises a connecting part II and two negative electrode claws I arranged in parallel, and the two bare cells arearranged side by side; The battery cell and cover plate assembly method comprises the following steps: 1) passing the positive electrode pillar through the positive electrode claw structure, lower plastic, and top cover in sequence and is connected with the positive electrode conductive block; 2) obtaining a battery cell and the cover plate preassembled structure; 3) bending the two positive electrode claws I and two negative electrode claws I respectively. The invention has the advantage that when the square battery is subjected to a squeezing test, a diaphragm is not scratched.

Owner:ETRUST POWER ETP GRP LTD

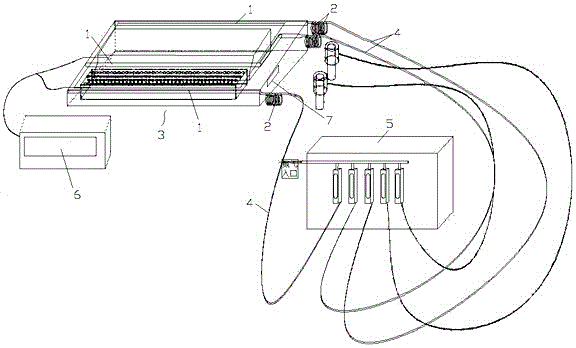

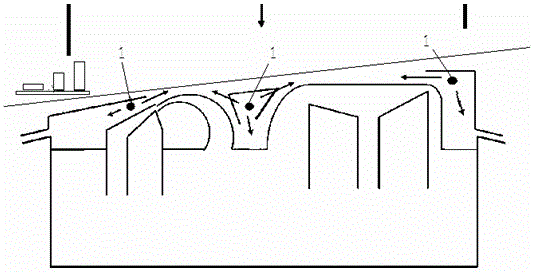

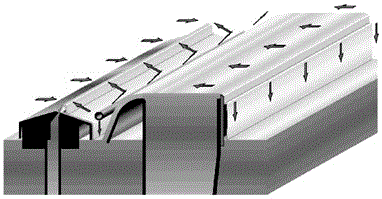

Wave-soldering nitrogen protection equipment

InactiveCN106513909AImprove anti-oxidation effectReduce nitrogen consumptionPrinted circuit assemblingSoldering auxillary devicesEngineeringNitrogen gas

The invention discloses wave-soldering nitrogen protection equipment applied to soldering equipment. The wave-soldering nitrogen protection equipment comprises a soldering wave main body and a microporous pipe for introducing nitrogen. The microporous pipe is connected with a gas flow control panel through a nitrogen input pipeline. The microporous pipe is arranged on the lower portion of a soldering wave. The oxidization prevention effect is improved; and the microporous pipe is provided with honeycomb-like interstitial holes, and the nitrogen consumption is effectively reduced.

Owner:深圳市凯丰实业发展有限公司

Laser processing method of connecting parts based on binocular vision

ActiveCN110842316BReduce defective welding rateImprove consistencyImage analysisHeating appliancesLaser processingMechanical engineering

The invention provides a connecting piece laser processing method based on binocular vision, and relates to the technical field of conductive connection. The method is characterized in that in the connecting process of a conductive piece, the laser power is fed back in real time according to a gray scale step point formed in a depth image by a fusion point when brazing filler metal is fused; in the filling process, the welding speed is optimized according to the gray scale of the depth image; and the speed optimization method is characterized in that the welding motion speed is determined according to the gray scale of the image, the gray scale average value is taken as a base point, the speed is slowed down when being less than the value, and the speed is increased when being larger thanthe value. According to the method, welding track and speed planning is optimized according to the depth image, and the connecting processing efficiency of the conductive piece is improved.

Owner:WUHAN BESKYS TECH CO LTD

An electric core shell and electric core

ActiveCN101150177AInhibition lossReduce defective welding ratePrimary cellsSecondary cellsEngineeringCore shell

This invention discloses a shell of electric core and a core using it, in which, the shell includes a drum, a top cover plate and a bottom cover plate, and the drum is a drum with a bottom with a through hole and an paerture at the top, a groove along the circle is set on the bottom plate and a groove along the circle is set on the drum of the shell. Since the heat conductivity of air is much lower than that of metal, it can stop losing of heat at the welding place when welding by laser effectively by grooves along the circle directin on the drum bottom and on the bottom plate so as to deepen the depth fusion under definite laser strength.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Processing technology for high-resolution digital interface

InactiveCN100502486COrderly rowsAvoid mutual interferenceTelevision system detailsColor television detailsDigital interfaceHigh definition

A manufacturing process of high definition digital interface includes assembling wire rubber plug, rubber plug in stab mode, medium rubber plug and automatic welding unit on said digital interface; pressing each core wire into grooves of wire rubber plug and rubber plug in stab mode, brushing tin solder on core wires and clamping them on automatic welder for carrying out automatic welding, shining light on core wire and terminal wiring end by welder to weld core wire on terminal wiring end by melting tin solder with heating for finalizing said welding at only one time.

Owner:许庆仁

Welding method and welding system for electrode sheet of surge protector

ActiveCN111375858BQualified solder jointsReduce defective welding rateSolder feeding devicesSoldering auxillary devicesWelding defectSolder paste

Owner:SHENZHEN HAIPENGXIN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com