A miniature ultra-thin unidirectional rectifier bridge device and its processing technology

A rectifier bridge, ultra-thin technology, applied in the field of micro-ultra-thin unidirectional rectifier bridge devices and their processing technology, can solve the problems of increasing defect, reducing product reliability, reducing yield, etc., to reduce welding defect rate, improve Product reliability and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

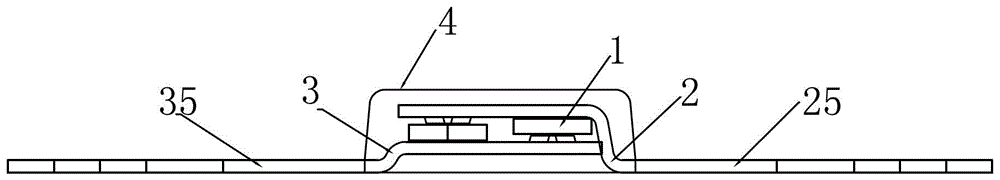

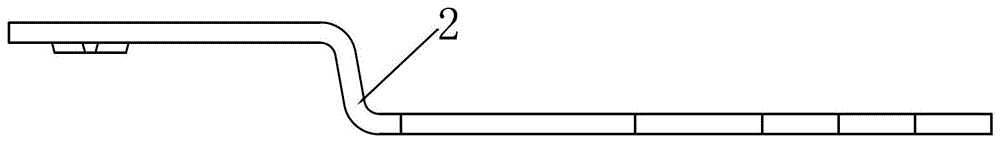

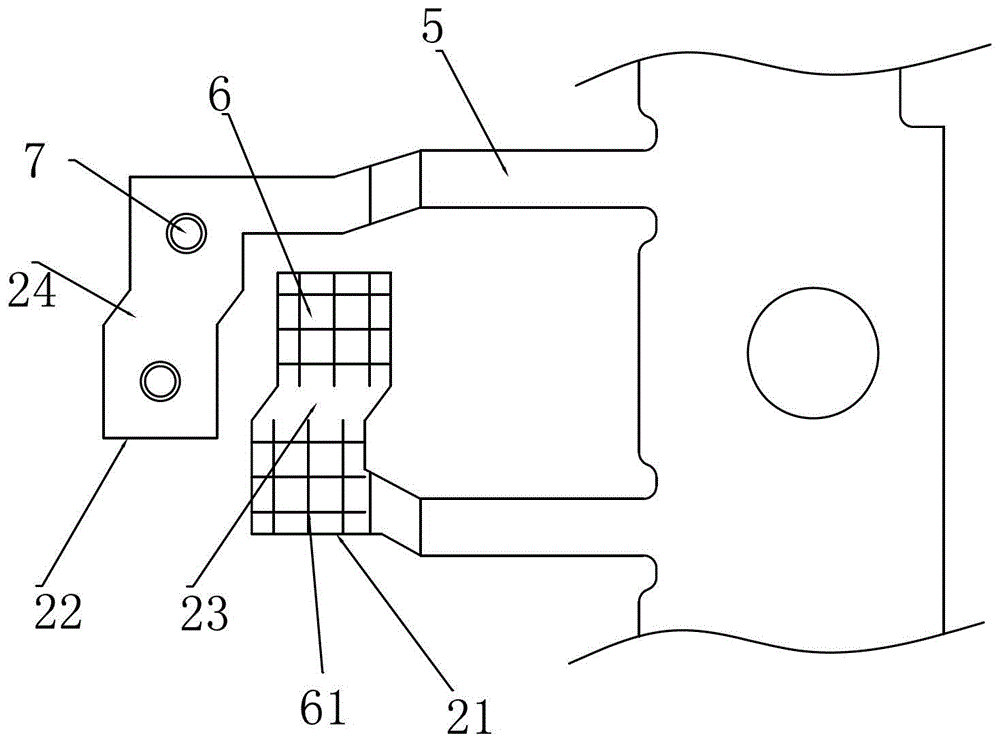

[0038] like Figure 1-8 As shown, a miniature ultra-thin unidirectional rectifier bridge device includes 4 rectifier chips 1 forming a rectifier bridge circuit, an upper material unit 2, a lower material unit 3 and a package body 4, and the rectifier chip 1 is arranged on the Between the above-mentioned upper material piece unit 2 and the described lower material piece unit 3, the described upper material piece unit 2 and the described lower material piece unit 3 are arranged oppositely, and the cross section is "Z" shape; the said upper material piece unit 2 and the lower material unit 3 both include two lead-out terminals 5, the lower surface of the lead-out terminal 5 is coplanar with the bottom surface of the package body 4; on the upper material unit 2 and the lower material unit 3 Both are provided with flat pads 6 and convex pads 7 with bumps. The upper material unit 2 protruding out of the package 4 forms an output terminal 25 , and the lower material unit 3 protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com