Aluminum alloy for preparing battery shell

A battery shell and aluminum alloy technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of laser welding prone to trachoma, high air leakage quality defect rate, easy shell expansion, etc., to reduce shell The effect of reducing mouth and surface deformation, reducing the welding defect rate, and increasing the internal space of the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to examples, but these examples should not be construed in any way to limit the scope of the present invention.

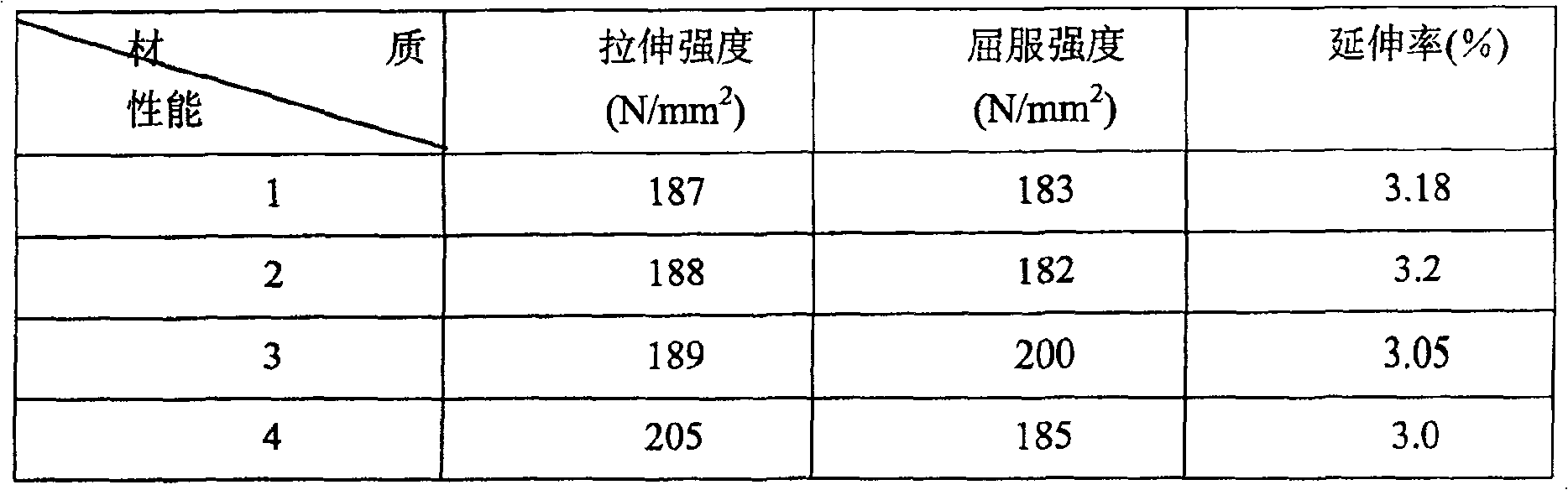

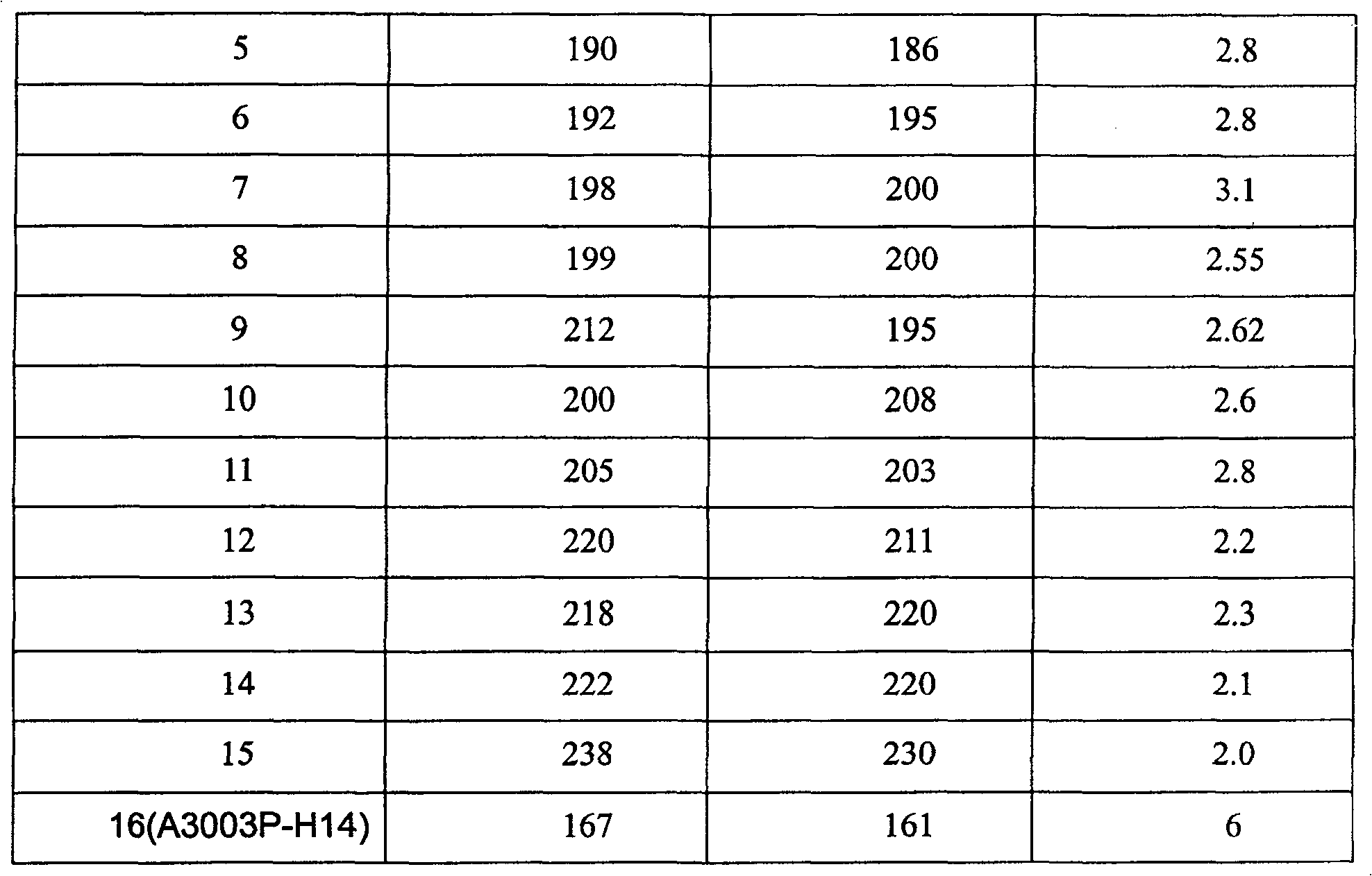

[0020] As shown in the following table 1, it is based on weight percentage, the aluminum alloy made of the alloy composition of the present invention is compared with A3003P-H14 in different examples, wherein the embodiments (1-15) are the material compositions of the present invention, and the comparative example ( 16) is the material composition of A3003P-H14.

[0021] Table 2 shows the mechanical properties of the aluminum alloy in Table 1. It can be seen from Table 2 that the tensile strength and yield strength of 1-15 are significantly better than A3003P-H14, and the elongation is more than 50% lower than that of A3003P-H14 aluminum alloy.

[0022] Table 1 is the chemical composition of the experimental aluminum alloy in weight percentage, and the balance is aluminum and impur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com