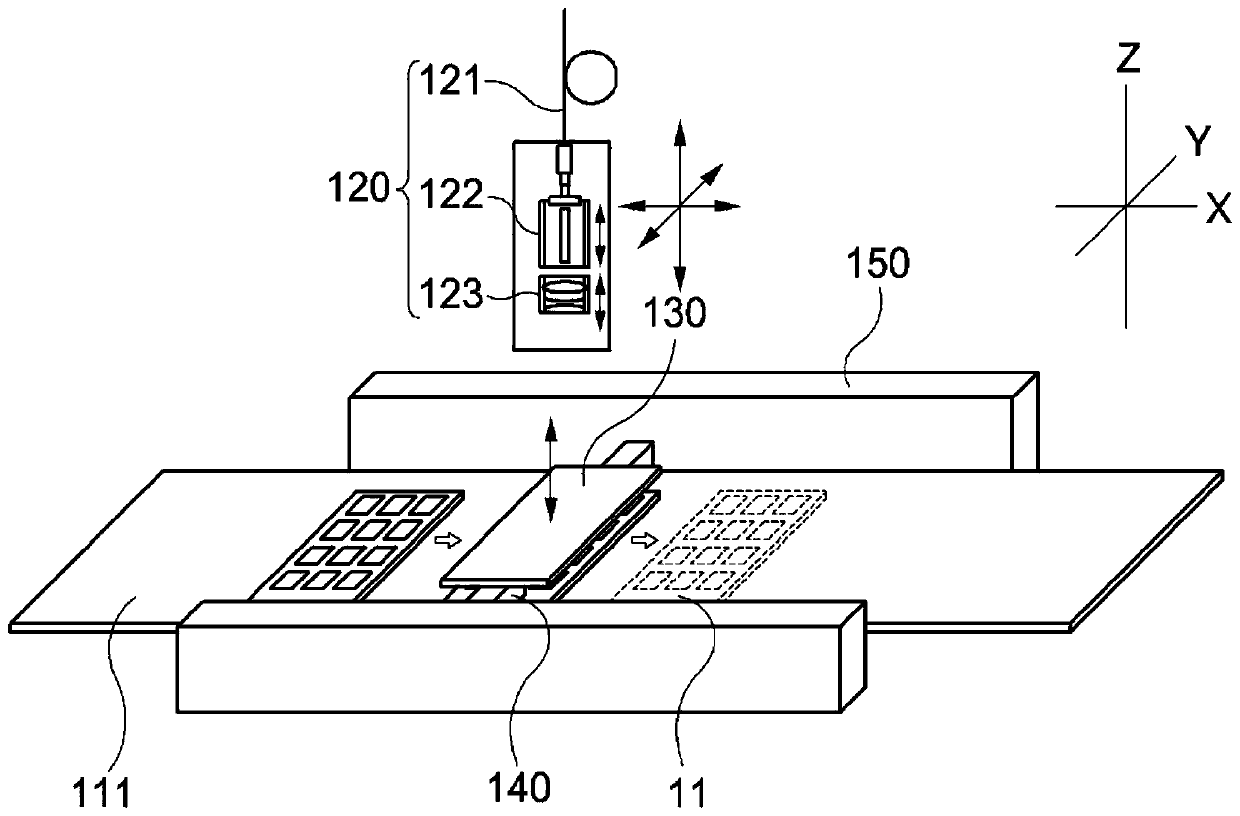

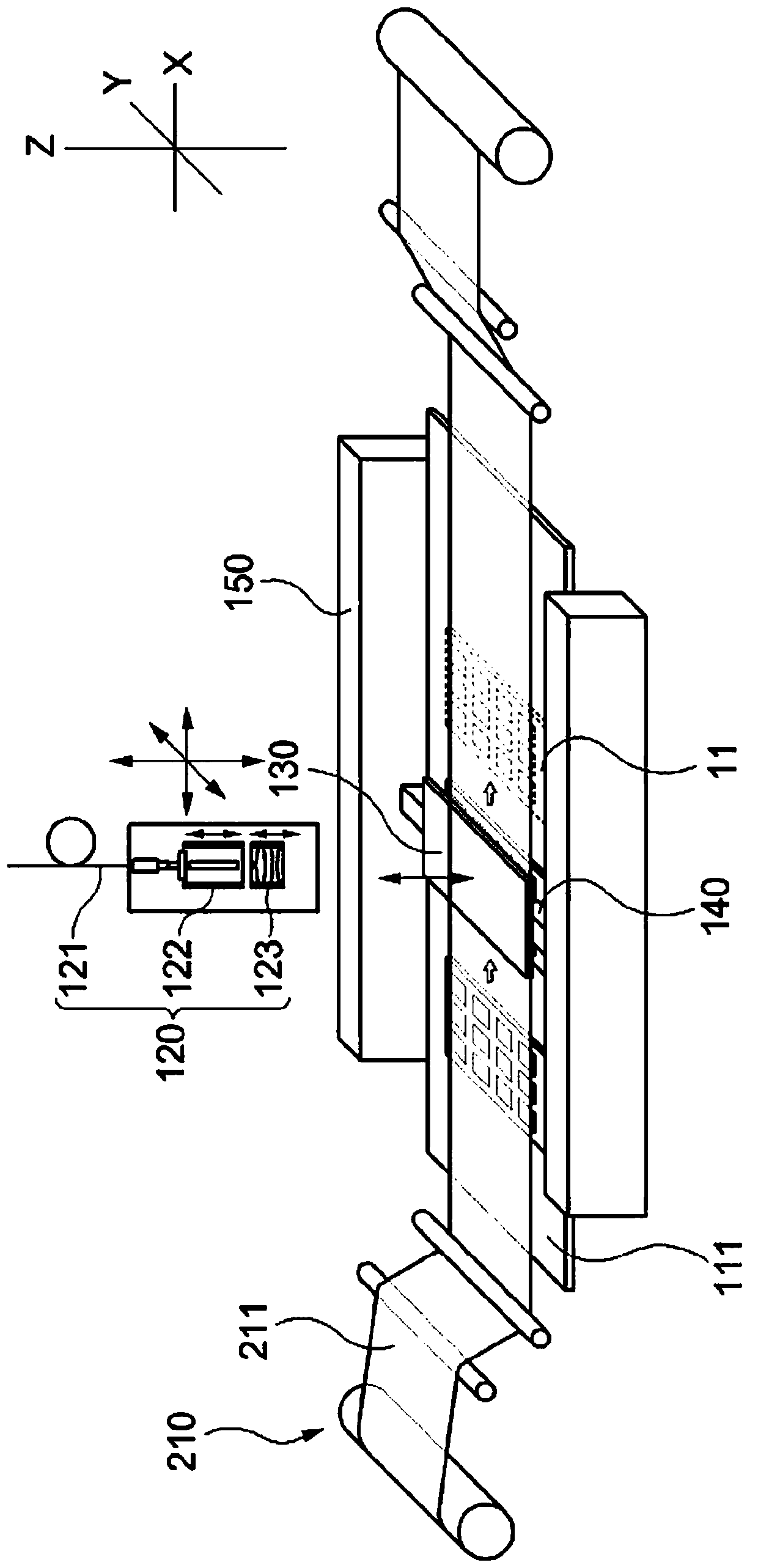

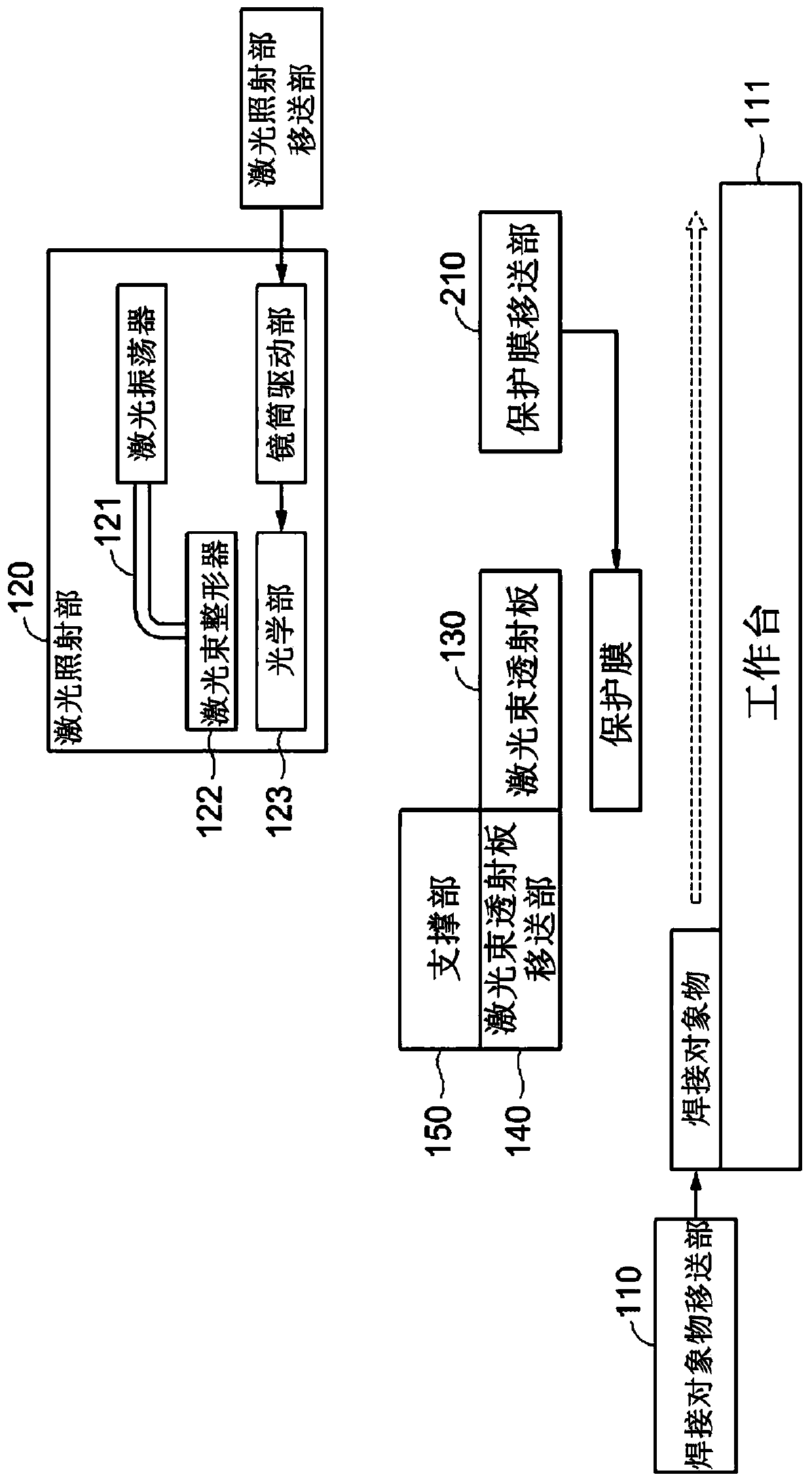

Laser reflow device

一种回流焊、激光的技术,应用在激光焊接设备、焊接设备、焊接设备等方向,能够解决激光照射部无法使用、长更换时间等问题,达到减少焊接作业等待时间、提高生产性、减少焊接不良率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The terms used in this specification are used to describe specific embodiments only, and are not used to limit the present invention. Expressions in the singular include expressions in the plural as long as the context does not clearly indicate otherwise. In this specification, terms such as "comprising" or "having" are used to designate the existence of features, numbers, steps, actions, structural elements, components or combinations thereof described in this specification, rather than to preclude one or more than one The existence or additional possibility of other features or numbers, steps, actions, structural elements, components or combinations thereof.

[0049] Unless otherwise defined, all terms used in this specification including technical or scientific terms have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. Terms defined by commonly used dictionaries have the same meanings as those in the contex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com