An electric core shell and electric core

A battery cell and casing technology, which is applied in the field of battery cell components, can solve the problems of shallow welding penetration, high defect rate of laser welding, and easy loss of battery heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

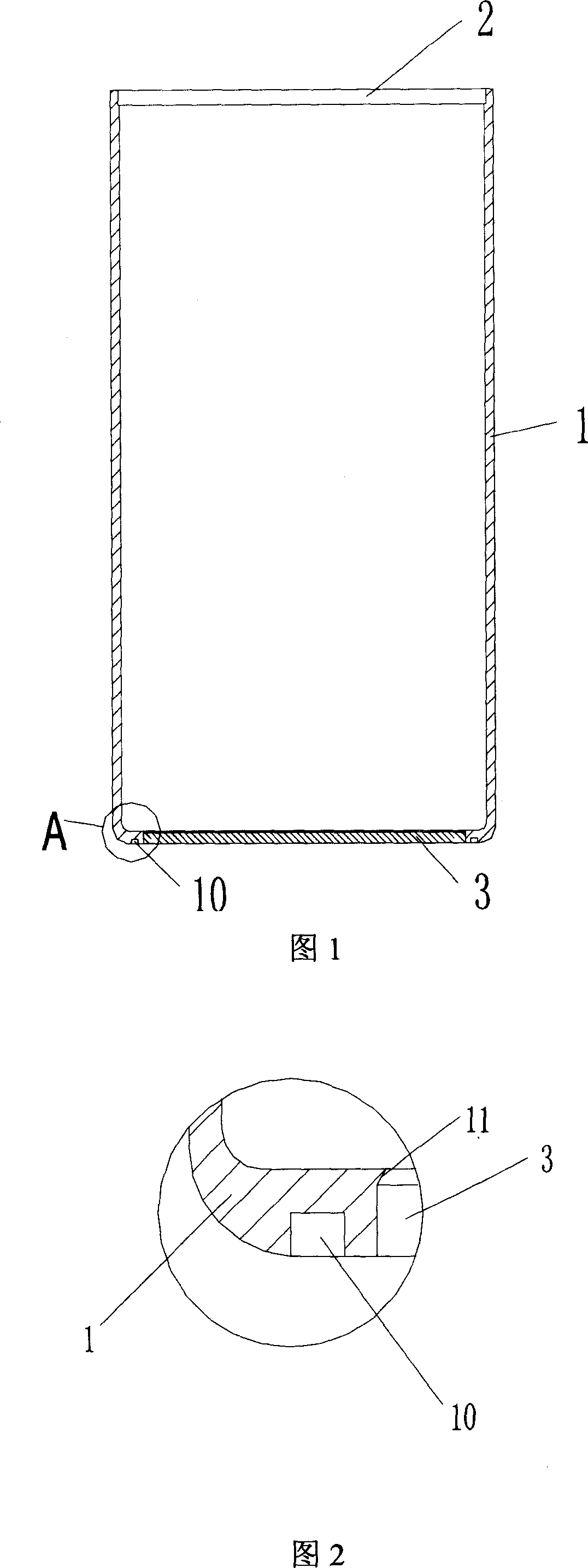

[0027] A kind of electric core housing, as shown in Figure 1, it comprises a cylindrical body 1, upper cover plate 2 and lower cover plate 3, the cylindrical body is the shape of a bottomed cylindrical body with an upper end opening, and a through hole is provided on the bottom of the cylinder , a groove 10 along the circumferential direction is arranged on the bottom of the cylinder. The periphery of the through hole is provided with a positioning step or a positioning slope 11 . This embodiment can be understood more clearly through FIG. 2 , which is an enlarged view at A in FIG. 1 . The wall thickness of the battery case is 0.3 mm, and the bottom thickness is 0.8 mm. In this embodiment, the distance between the groove and the circumference of the through hole is 0.3 mm, the groove width is 0.9 mm, and the depth is 0.2 mm.

Embodiment 2

[0029] The structure of this embodiment is basically the same as that of Embodiment 1, except that no groove is provided on the lower cover. In this embodiment, the distance between the groove and the circumference of the through hole is 0.9 mm, the width of the groove is 0.3 mm, and the depth is 0.4 mm.

Embodiment 3

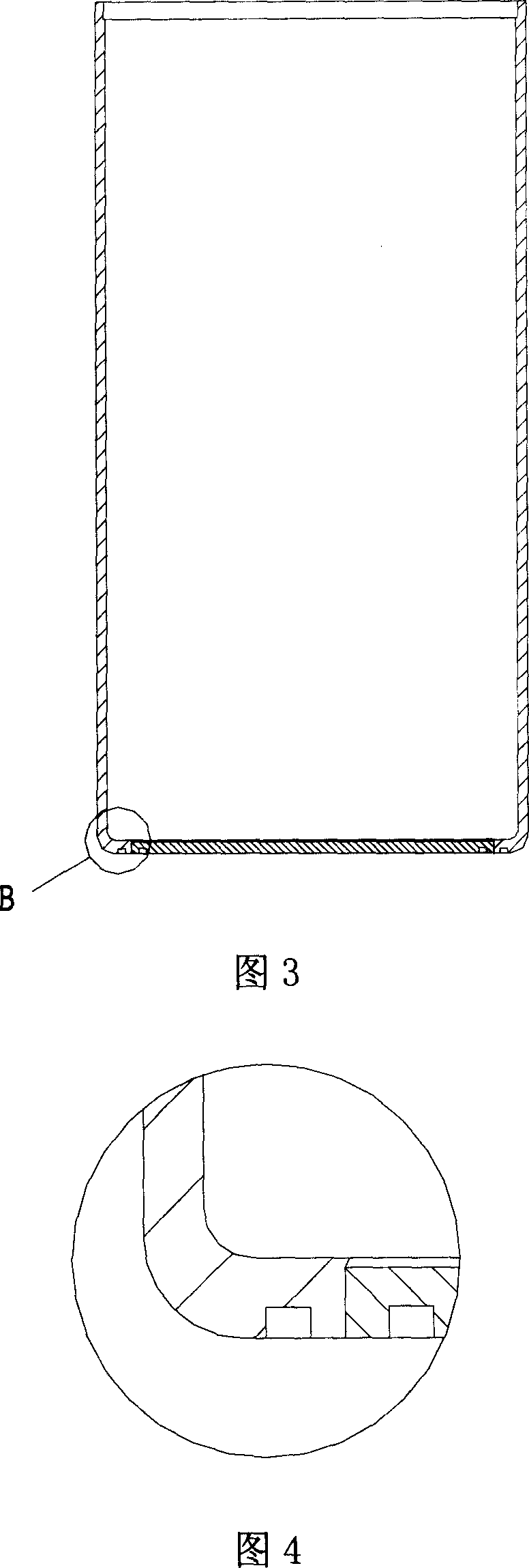

[0031] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that a groove along the circumferential direction is also provided on the lower cover of the battery case, as shown in FIG. 3 , through the enlarged view at A in FIG. 3 4 can clearly understand the present invention. In this embodiment, the distance between the cylinder bottom groove and the circumference of the through hole is 0.6mm, the width of the groove is 0.6mm, and the depth is 0.6mm; the distance between the groove of the lower cover plate and the circumference of the through hole is 0.6mm, and the width of the groove is 0.6mm, the depth is 0.35mm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com