Lead acid battery flux and preparation method and application thereof

A lead-acid battery and flux technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of lead-acid battery grid and busbar welding quality, poor compatibility of tabs, corrosion of welding points, etc. Achieving good busbar welding effect, low production cost and less residue after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

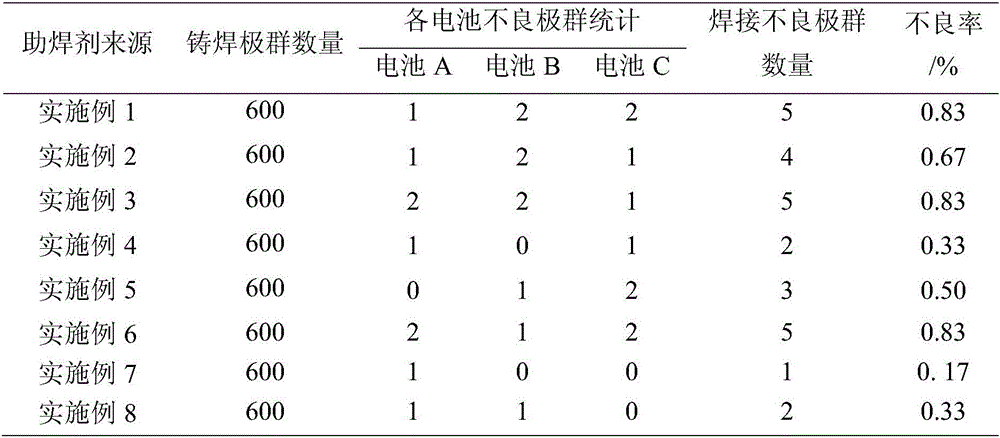

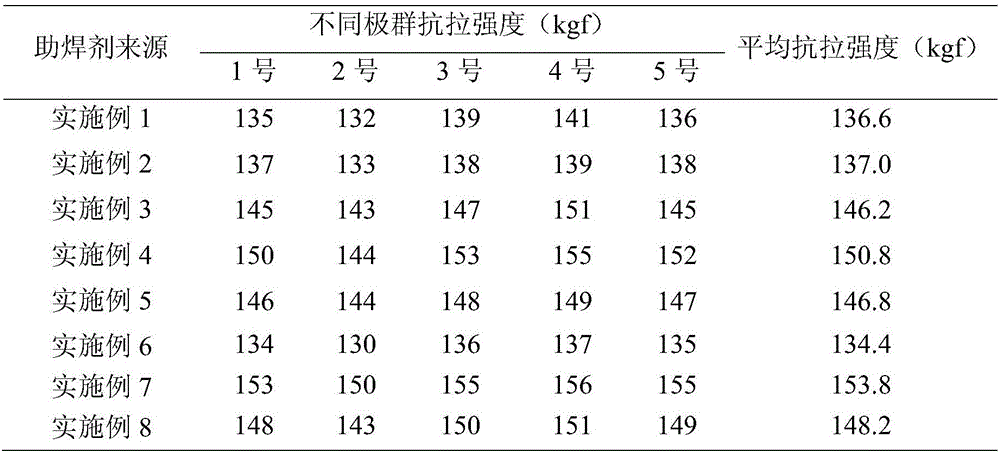

Examples

Embodiment 1

[0043] A kind of lead-acid storage battery soldering flux, the mass percent is composed of:

[0044] Alcohol 5%

[0045] Phosphoric acid 65%

[0046] The rest is water.

[0047] Take alcohol, phosphoric acid and water according to the mass ratio; mix the taken alcohol, phosphoric acid and water together, and stir at 100rpm for 30min.

Embodiment 2

[0049] A kind of lead-acid storage battery soldering flux, the mass percent is composed of:

[0050] Alcohol 8%

[0051] Phosphoric acid 55%

[0052] The rest is water.

[0053] Take alcohol, phosphoric acid and water according to the mass ratio; mix the taken alcohol, phosphoric acid and water together, and stir at 200rpm for 20min.

Embodiment 3

[0055] A kind of lead-acid storage battery soldering flux, the mass percent is composed of:

[0056] Alcohol 12%

[0057] Phosphoric acid 60%

[0058] The rest is water.

[0059] Take alcohol, phosphoric acid and water according to the mass ratio; mix the taken alcohol, phosphoric acid and water together, and stir at 300rpm for 15min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com