Combined lithium battery tab kneading method

A lithium battery and combined technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems affecting tab welding, false welding or over-welding, and potential safety hazards, so as to reduce welding defect rate and improve flatness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiment:

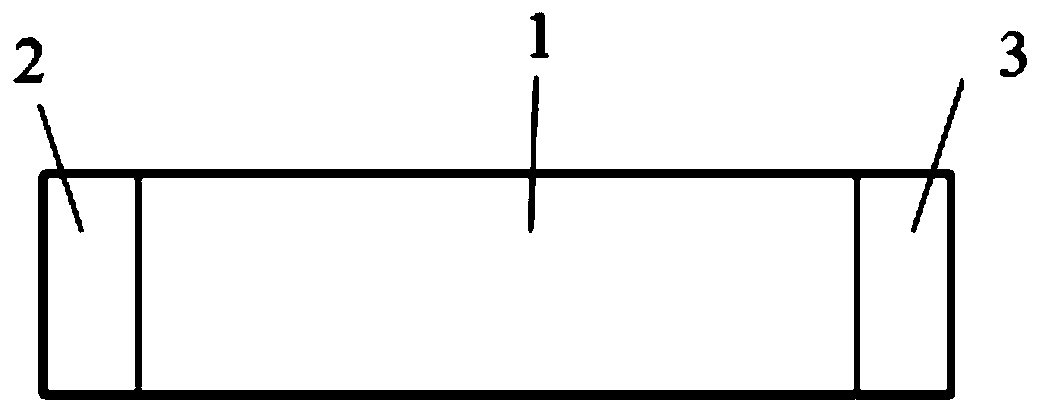

[0025] Such as figure 1 The lithium battery 1, the blank foil of the positive electrode sheet and the blank foil of the negative electrode sheet of the lithium battery 1 are respectively used as the positive electrode conductive tab 2 and the negative electrode conductive tab 3 of the lithium battery 1, and the two conductive tabs are respectively located in the lithium battery. 1 at both ends.

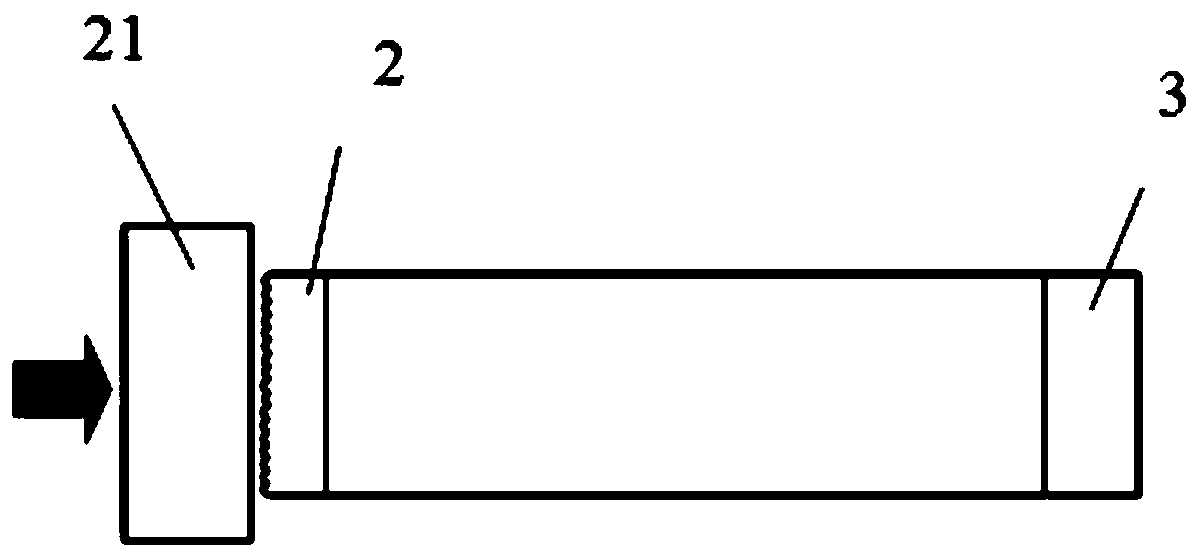

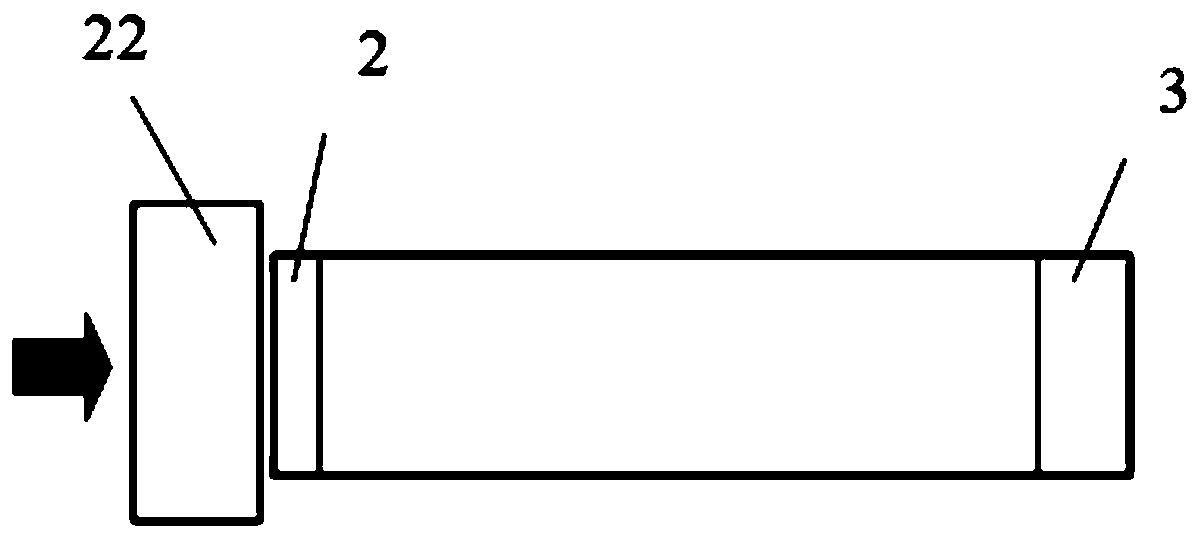

[0026] In this embodiment, the combined flattening method of firstly ultrasonically flattening and then mechanically flattening is adopted for the conductive ears of the two ends of the lithium battery 1. Knead the negative pole flat.

[0027] Specifically, kneading mainly includes the following steps:

[0028] First, if figure 2 As shown, the ultrasonic kneading head 21 moves closer to the positive end of the lithium battery 1, and ultrasonically kneads the positive electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com