Laser processing method of connecting parts based on binocular vision

A laser processing method and binocular vision technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem of not giving, optimize the solution of bubbles, etc., to solve difficult control, reduce welding defect rate, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

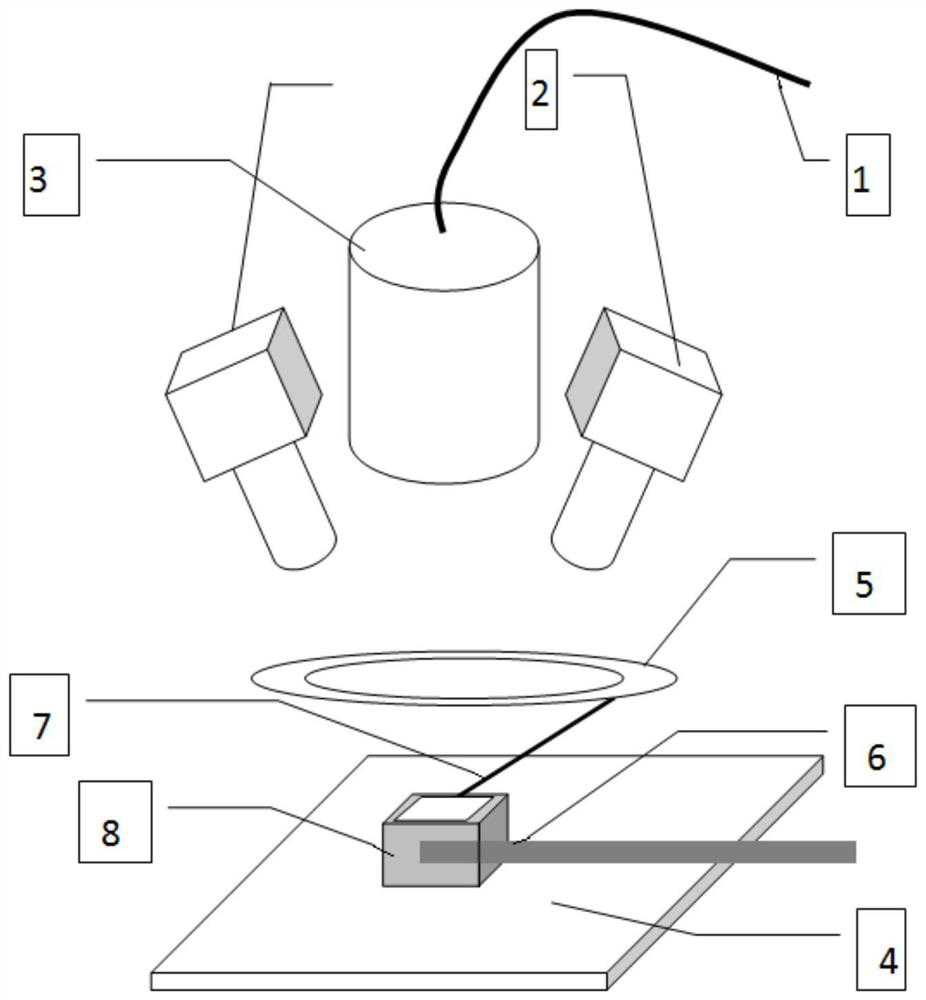

[0037] Such as figure 1 As shown, the hardware system required for the laser processing method of connectors based on binocular vision of the present invention includes an optical fiber 1, a binocular camera 2, a laser head 3, a two-dimensional workbench 4, a rotating mechanism 5, solder 7, welding The base 8 and the product 6 to be welded, the solder 7 of the present invention are fixed on the rotating mechanism 5 to precisely control the position of the solder 7 .

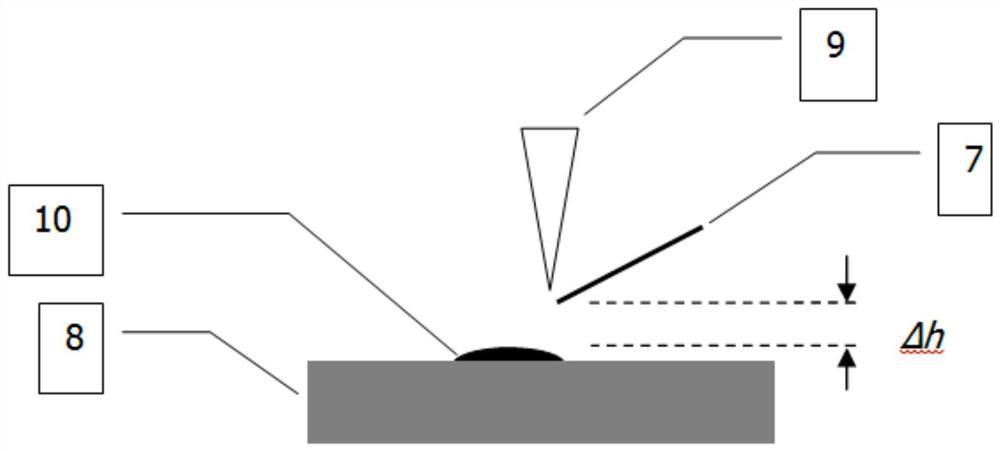

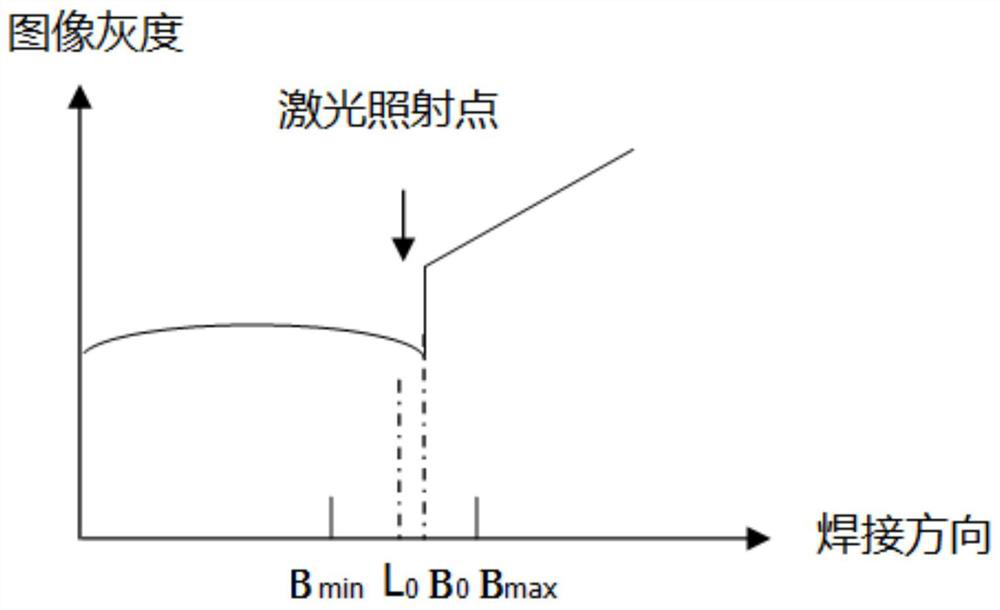

[0038] Such as figure 2 As shown, the laser processing method of connectors based on binocular vision of the present invention, the method obtains the real-time depth image of the welding filling area through binocular vision, uses the depth image to obtain the melting state and filling state of the solder 7, and according to the filling state The welding moving speed (that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com